-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Materials Engineering

p-ISSN: 2166-5389 e-ISSN: 2166-5400

2012; 2(2): 6-9

doi: 10.5923/j.ijme.20120202.02

Investigation of Crushing Type of Concrete s on Mechanical Properties of Concrete

Ali Uğur Öztürk , R. Tugrul Erdem , Celal Kozanoglu

Celal Bayar University Engineering Faculty Department of Civil Engineering, Manisa, 45140, Turkey

Correspondence to: Ali Uğur Öztürk , Celal Bayar University Engineering Faculty Department of Civil Engineering, Manisa, 45140, Turkey.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

In this study, determination of the effects of concrete aggregates on mechanical properties of concrete due to crushing type was investigated. For this purpose, mechanical properties of concrete mixtures such as strength and flow are determined by using aggregates crushed by two different types of crusher. Different types of concrete mixtures are prepared by using aggregates developed by vertically shafted (VS) and impact crushers (IC). Properties of concrete compounds such as water, cement are kept constant for each crushing type to determine the aggregate effect for concrete sets having different mixture rates. Four different types of concrete sets with two different aggregate types have been produced to prevent the predominant influences of concrete compounds except aggregate on mechanical properties. Thus, there was no mineral and chemical admixture used in the mix to obtain the nominative effect of aggregates produced with different crushing types, on strength and flow. Strength values for 7 and 28 days are obtained and comparisons have been made according to crushing type.

Keywords: Aggregate, Crushing Type, Mechanical Properties

Article Outline

1. Introduction

- In today’s construction technology, aggregates having huge and different rates of grain sizes are being used in concrete that is the most common used building material. Aggregates play an essential role in mechanical and durability properties of concrete against aggressive environmental media during service life. The most effective properties of aggregate utilization in concrete are reducing the volume change in concrete, improving the concrete properties against environmental effects and against static and dynamic loads on concrete by its own capacity[1]. Concrete aggregates improve the strength of cement mortar and hinder the crack development against shrinkage and creep in process of time.Properties such as strength, grain shape, surface roughness, size distribution, the maximum grain size, elasticity module, mineral structure, porosity, water permeability, coefficient of expansion, fine material ratio and purity of the aggregate in concrete effects the mechanical properties, durability and service quality of the concrete. On the other hand, workability property of concrete directly changes with the aggregate properties. On the account of such reasons, aggregate can be named as the most important component of the concrete structural members.Furthermore, concrete is a heterogenic material and made up of aggregate, cement paste, and interface of these two components. If strength of aggregate is lower than strength of mortar, cracking occurs in the aggregate in the first place. For this reason, load bearing capacity of the concrete is considerably effected by aggregate properties. In other words, aggregates form the carrier system of regular concrete[2].Nonetheless, achievement of aggregates on strength and durability could occur with the good relationship between aggregate and cement paste. Properties of contact surface between aggregate and cement paste also names as interfacial transition zone (ITZ) have a significant place in terms of strength and durability characteristics. Factors occurring in interfacial transition zone and affecting the adherence between aggregate and cement paste may cause decline in mechanical and durability properties. Therefore, aggregate surfaces shall not be covered adherence reducing materials such as silt and clay. Furthermore, aggregate and surface geometries shall not allow spaces arised from strike of cement particles and restitution of them. This situation is defined as “wall effect”[3]. Geometrical characteristics of aggregates depend on the mineralogy of the host-rock, cracking operation and method. Shape, angularity and surface texture terms are widely used geometric properties which are used while characterizing aggregates. These properties are effective on the performance of materials in which aggregates are used. Determining aggregate properties accurately and performing the desired characteristics are inevitable in terms of strength and durability to produce high performance concrete. These properties effect workability, pumpability, placement, bleeding and segregation of fresh concrete. In hardened concrete, strength, density, permeability, pore amount, shrinkage and creep are affected by these properties of aggregate. Besides, all these properties determine the durability of concrete and one can encounter durability problems due to inappropriate aggregate selection[4,5].Shape of the aggregate and surface texture is vital characteristics in the view of mechanical bonding effect and bond strength in concrete design[6]. Fineness module of the aggregate, specific weight and are taken into consideration in mixture density. In addition to this, although two fine aggregate samples have the same fineness module, they may have various size distributions and surface properties. Properties such as shape, surface texture, granulometry and fine material rate of crushed aggregates are more complicated than natural aggregates. Therefore, aggregate selection is important. Cracking method and crushing type selection according to rock type are significant to obtain fast and reliable results for cubic shape properties.Researches show that, natural aggregates are tended to be round shaped under the erosion effects of nature. In spite of this, crushed aggregates are angular but every crushed aggregate does not have the same angularity[7-11].Shape of the aggregates effects the workability of fresh concrete and water requirement of concrete accordingly[12]. Concrete produced by using natural aggregates is easy to process. Crushed aggregates reduce the workability of fresh concrete due to their irregular surfaces and friction effect. Round shaped aggregates require less water and cement usage for a specific workability and strength in normal strength concrete. On the other hand, angular and rough shaped aggregates shall be used in high strength concrete due to their superior internal friction and bonding provision.Aggregates may provide better adherence by cracking process. Effective properties of aggregates improve when they are processed by cracking natural rocks. Crushed aggregates are angular and they have rough surfaces. Crushed aggregates present good adherence with cement paste due to their surface and geometry properties when they are exposed to proper granulometry [13].

2. Materials and Experimental Study

2.1. Materials

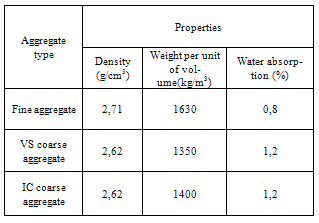

- In the scope of this study, effect of crushing type of aggregate on concrete compressive strength was investigated. For this purpose, change in slump and compressive strength values of different concrete samples are taken into consideration. Two different aggregate types as impact crushers (IC) and vertically shafted (VS) are used and mechanical properties of produced concrete samples which are aimed for different strength values are investigated. CEM I 42.5 cement type having 3,15 kg/dm3density value was used while producing concrete and material properties of the used aggregates are given in Table 1.While aggregate type is taken as variable for each concrete set, other mixing components are taken constant.

|

2.2. Experimental Study

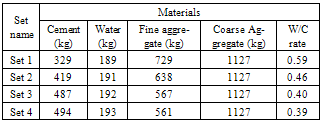

- Concrete is a material whose tensile strength is lower than compressive strength. Because concrete tensile strength is usually ignored, compressive strength is the most important characteristic of concrete. In this study, aggregates produced by impact and vertically shafted crushers were used in concrete design. 4 different concrete sets each of which contain 12 samples are produced for each aggregate type.Experimental analyses of the specimens are performed by using a computer aided press machine. Loading speed is constant in all tests. Computer aided full automatic test press machine has high mechanical strength to provide minimum deformation and it is appropriate for usage consistently. Loading speed of the machine is entered automatically and the system calculates the section areas of the concrete specimens. So, it selects the loading speed. Unit of the applied force is N/mm2/sec and can be followed easily.In this way, concrete compressive strength tests are performed in laboratory conditions at 20±2ºC temperature and 80% relative humidity rate for 96 samples according to each crushing type. While half of the 12 samples are used for 7 days strength values, the rest is evaluated for 28 days strength values for each set. Materials that are used for 1m3concrete design and mixture properties are given in Table 2.

|

3. Conclusions and Suggestions

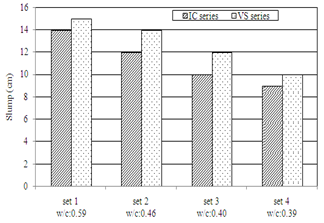

- In this paper, effects of two crushing types for concrete aggregates on compressive strength are investigated. For this purpose, factors effecting concrete compressive strength as water and cement are kept constant and concrete mixtures have been prepared by using two types of aggregates. 4 different sets have been produced for each crusher type and 12 concrete samples were cast for each set. Mineral and chemical admixtures have not been used in concrete mixtures.Slump values were determined for each set and these values are presented in Figure 1. Concrete slump values for VS aggregate type are higher than the values for IC aggregate type. Increase in slump values has been observed according to w/c ratio and difference between slump values for VS and IC sets are observed between 1 and 2cm.

| Figure 1. Slump values for IC and VS sets |

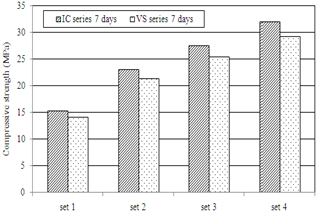

| Figure 2a. 7 days compressive strength values for IC and VS sets |

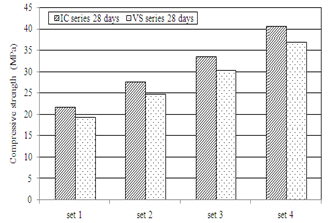

| Figure 2b. 28 days compressive strength values for IC and VS sets |

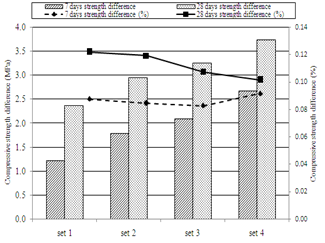

| Figure 3. 7 and 28 days compressive strength differences between IC and VS sets |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML