-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Materials and Chemistry

p-ISSN: 2166-5346 e-ISSN: 2166-5354

2025; 15(5): 89-95

doi:10.5923/j.ijmc.20251505.01

Received: Nov. 26, 2025; Accepted: Dec. 23, 2025; Published: Dec. 26, 2025

Application of Oleogel Based on Sesame Seed in Oil Emulsion Products

Shakhnozakhon Gaipova1, Akbarali Ruzibayev1, Octavio Calvo Gomez2, Shakhnozakhon Salijonova1

1Tashkent institute of Chemical-Technology, Tashkent, Uzbekistan

2Institute of Fundamental and Apllied Research, Tashkent Institute of Irrigation and Agricultural Mechanization Engineers-National Research University, Tashkent, Uzbekistan

Correspondence to: Shakhnozakhon Gaipova, Tashkent institute of Chemical-Technology, Tashkent, Uzbekistan.

| Email: |  |

Copyright © 2025 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

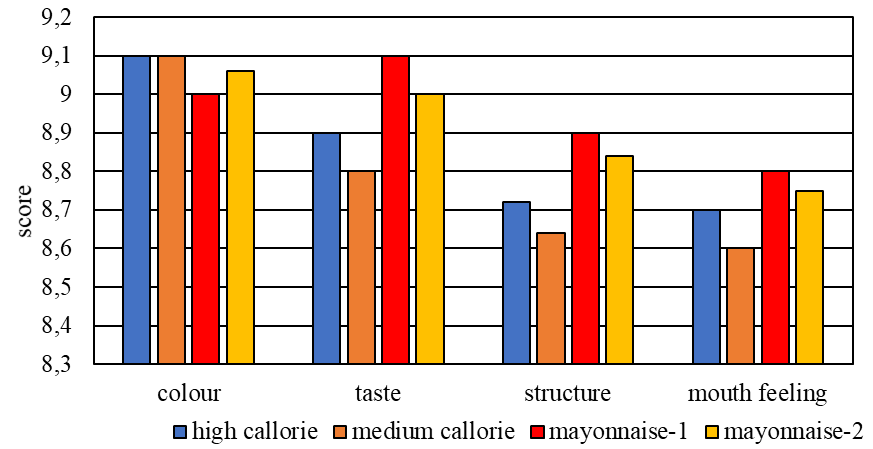

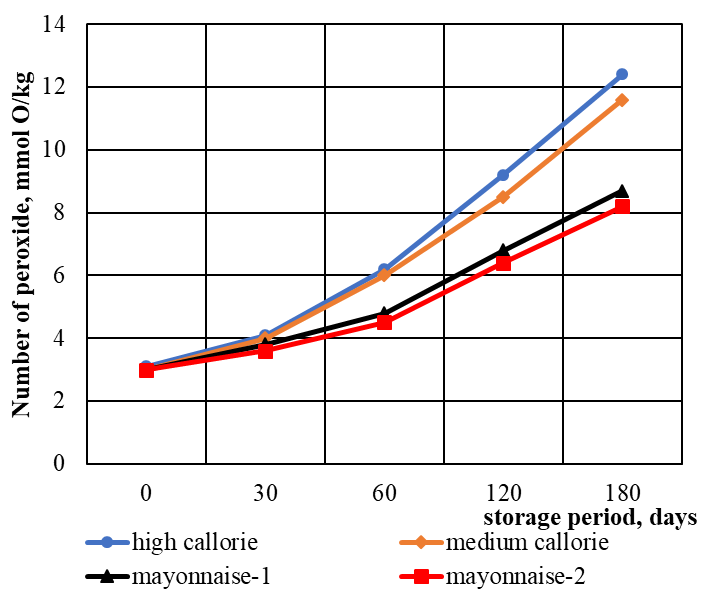

This study investigates the use of sesame-seed-based oleogel as a partial replacement for sunflower oil in mayonnaise formulations and evaluates its effects on the nutritional value, physicochemical properties, oxidative stability, and sensory characteristics of the final product. Oleogel was prepared from sesame seeds through homogenization, centrifugation, and protein lipid encapsulation, and incorporated into mayonnaise samples at different concentrations. Replacing sunflower oil with oleogel resulted in a marked reduction in fat content and energy value, while significantly increasing the protein content and improving the nutritional and biological value of the mayonnaise. During 180 days of storage, mayonnaise samples containing oleogel demonstrated substantially lower peroxide and p-anisidine values compared to the control, indicating enhanced resistance to primary and secondary lipid oxidation. The improved stability is attributed to the encapsulating properties of proteins and phospholipids in the oleogel, which reduce direct contact between lipids and oxygen. Sensory analysis showed that oleogel positively influenced taste, texture, and mouthfeel, although slight reductions in color intensity were observed. Emulsion stability tests revealed that increasing oleogel concentration significantly enhanced the structural stability of the mayonnaise. Overall, the incorporation of sesame-based oleogel offers a promising approach for developing healthier, more stable mayonnaise products with extended shelf life. Further research is required to determine the optimal oleogel concentration and assess its effects on viscosity, microbiological safety, and economic feasibility.

Keywords: Mayonnaise, Oleogel, Sesame seed, Sesame cake, Emulsion products

Cite this paper: Shakhnozakhon Gaipova, Akbarali Ruzibayev, Octavio Calvo Gomez, Shakhnozakhon Salijonova, Application of Oleogel Based on Sesame Seed in Oil Emulsion Products, International Journal of Materials and Chemistry, Vol. 15 No. 5, 2025, pp. 89-95. doi: 10.5923/j.ijmc.20251505.01.

1. Introduction

- In the contemporary food industry, a paradigm shift is occurring from simple caloric reduction toward the holistic optimization of nutritional profiles. Considerable attention is currently directed toward improving food product quality, reducing production costs, and enhancing functional properties [1–3]. Specifically, the demand for reduced-calorie food products designed to mitigate the risk of chronic non-communicable diseases such as obesity, cardiovascular disease, and metabolic syndrome, is steadily escalating [3,4]. Fats, with their high energy density, are significant contributors to the caloric content of many processed foods. Thus, modern food reformulation research increasingly focuses on reducing saturated fat content or enriching food matrices with functional potentially healthier oils to address public health concerns. This reformulation presents complex challenges: maintaining desirable sensory attributes and structural properties while reducing fats that contribute to texture, mouthfeel, and satiety [5–7]. The food industry must balance nutritional improvement with consumer expectations for product quality, taste, and the growing demand for minimally processed, "clean label" formulations [5,7,8]. To address these challenges, numerous studies have explored ways to reduce fat content by incorporating fat substitutes, mimetics, and structurally similar compounds. Significant scientific results have been achieved in identifying novel carbohydrate-, protein-, and lipid-based fat mimetics [5,7,9]. Researchers have rigorously investigated the physicochemical and rheological properties of these fat replacers to determine their technological applicability in various food systems [5]. These fat replacement strategies have been successfully applied across multiple food categories, including dairy products, baked goods, meat products, and cheese analogues [5,10].For instance, carbohydrate-based fat mimetics such as gels derived from inulin, cellulose, maltodextrin, or starch function by binding water to create a lubricious, cream-like texture [5,9,11]. Protein-based mimetics, including microparticulated proteins from plant or animal sources, can simulate the "rolling" sensation of fat globules on the tongue through a ball-bearing mechanism, whereby small spherical protein particles reduce friction between oral surfaces [12,13]. Modern structuring technologies, including encapsulation and controlled-release systems, have enabled the incorporation of bioactive compounds, proteins, vitamins, and minerals into reformulated food matrices while maintaining structural and sensory integrity [3]. Of particular interest are locally available raw materials, such as Jerusalem artichoke (Helianthus tuberosus) and sesame (Sesamum indicum), which provide functional additives rich in inulin or dietary fiber. These substances have been successfully used to reduce fat content in emulsion-based products like margarine, spreads, and mayonnaise [14–17].Technological methods for introducing gels into product formulations have been significantly improved. Gels are defined as viscoelastic materials that exhibit structural and sensory properties similar to solid fats. Based on the continuous phase, these systems are classified into two distinct categories: hydrogels, which are water-continuous systems structured by biopolymers (e.g., starch or protein) and are effective at bulking, though their hydrophilic nature limits their affinity for hydrophobic flavor compounds; and oleogels, which are oil-continuous systems where liquid oil is entrapped within a thermo-reversible network of structurants such as waxes, ethylcellulose, or monoglycerides [18,19]. Oleogels are promising alternatives for replacing trans-fats and solid fats with healthier unsaturated oils. While many natural gelators (e.g., plant waxes, monoglycerides) align with clean-label trends, some synthetic structurants such as ethylcellulose raise consumer perception challenges despite their regulatory approval [18,20].Despite these innovations, fats perform unique and irreplaceable functions in food systems that cannot be entirely substituted with proteins, carbohydrates, or gel-based replacers. Fats are not merely fillers; they contribute to spreadability, elasticity, plasticity, and the stabilization of air cells (aeration) in pastry production. For instance, in margarine and confectionery fats, the solid fat content (SFC) determines the product's ability to layer and flake—properties that remain challenging to fully replicate with current fat replacers [21,22]. Furthermore, essential fatty acids (omega-3 and omega-6) found in edible oils are vital nutrients that reside in the lipid phase; neither proteins nor carbohydrates can perform these biological roles [23,24]. Consequently, in formulations like mayonnaise and fatty sauces, fats can only be partially substituted to maintain nutritional density and thermodynamic stability [14,25,26].Recently, a distinct class of fat substitute has gained recognition that differs fundamentally from conventional engineered oleogels (oil gelled by gellants -waxes, ethyl cellulose, monoglycerides, lecithin-) [18] and hydrogels: oleosomes, also known as oil bodies or plant-derived oil bodies (POBs), which are natural organelles with phospholipid monolayer plus proteins [27,28]. Found in protein-rich oilseeds such as soybeans, sesame, and rapeseed, oleosomes are natural, pre-emulsified organelles used by plants to store energy. Unlike artificial emulsions, which require high-energy homogenization and synthetic surfactants to remain stable, oleosomes are naturally stabilized by a unique monolayer of phospholipids embedded with specific structural proteins known as oleosins, caleosins, and steroleosins [27]. This protein coat provides steric hindrance, preventing the oil droplets from coalescing even under environmental stress; oxidative stability, with the membrane acting as a physical barrier against oxygen and transition metals to preserve the quality of the polyunsaturated fatty acids inside [29]; and a submicron to micron-scale structure, with diameters typically between 0.2 and 2.5 µm, offering a smooth, creamy mouthfeel desirable in mayonnaise and spreads [29,30].Soybean (Glycine max) and sesame (Sesamum indicum) are among the most commonly studied oilseeds for oleosome extraction due to their widespread availability and distinct compositional profiles [27,31]. Soybean oleosomes contain diverse proteins including glycinin and β-conglycinin, which can interact with other food components and have been explored for applications in emulsion-based products [31]. Sesame seeds are notable for their high antioxidant content, particularly lignans such as sesamin and sesamolin, which contribute to enhanced oxidative stability of sesame oil [32,33]. However, widespread commercial application of oleosomes has been limited by the complexity of aqueous extraction processes required to maintain membrane integrity while achieving acceptable yields [29,34,35].In this research paper, we present results on the use of oleosomes extracted from soybean and sesame seeds in margarine and mayonnaise formulations, as well as their influence on the quality and sensorial properties of the final products.

2. Materials and Methods

- Preparation of oleosomesCleaned soybean and sesame seeds were soaked in water. Then they were mixed with water at a 1:10 ratio and ground using a homogenizer. After that, the mixture was filtered to separate the solid mass. The remaining suspension was centrifuged to isolate the oleosomes. Proteins were extracted from the remaining residue. Oleogel was obtained by mixing oleosomes, sunflower oil, and protein. To improve the stability of the gel, a small amount of phospholipid concentrate was added. The obtained oleogel was stored in a cool place.Preparation of MayonnaiseExperiments on preparing mayonnaise paste were carried out in the laboratory. A SHM-1 type homogenizer was used as a mixer, and an electric oven was used as a heating device. Water-phase ingredients were added into a 0.5 L beaker according to the formulation. Then oils were added. The mixture was heated to around 40–45°C. While mixing at 150–200 rpm, the process was continued until a homogeneous emulsion was obtained. At the final stage, acetic acid was added, mixed briefly, and the product was cooled and placed in a refrigerator for settling.Evaluation of Organoleptic PropertiesOrganoleptic evaluation of the mayonnaise samples was performed after the samples had been kept at room temperature for one day. The evaluation panel consisted of ten specially trained assessors selected based on their interest and sensory abilities. They assessed the organoleptic characteristics of mayonnaise and margarine samples, including appearance, color, smell, texture, taste, and overall acceptability.Organoleptic properties were evaluated using a 10-point hedonic scale, where 1 = lowest or "dislike extremely" and 10 = highest or "like extremely". All mayonnaise and margarine samples were coded randomly and presented to the assessors on white plates at room temperature.Determination of Emulsion StabilityThe quality and shelf life of mayonnaise largely depend on the stability of the emulsion achieved during production. Emulsion stability is determined as the percentage of the emulsion that remains intact after mechanical and thermal treatment.To determine this parameter, a 10 mL centrifuge tube was filled with the mayonnaise sample and centrifuged at 1500 rpm for 5 minutes. Then the tube was placed in a boiling water bath for 3 minutes, followed by another centrifugation at the same speed for 5 minutes. After this treatment, the remaining amount of stable emulsion was recorded. Multiplying this value by 10 gives the percentage of oil separated from the mayonnaise as a result of emulsion breakdown.According to GOST 30004.1-93, the emulsion stability should be at least:98% for high-calorie and medium-calorie mayonnaise,97% for low-calorie mayonnaise.

3. Results and Discussion

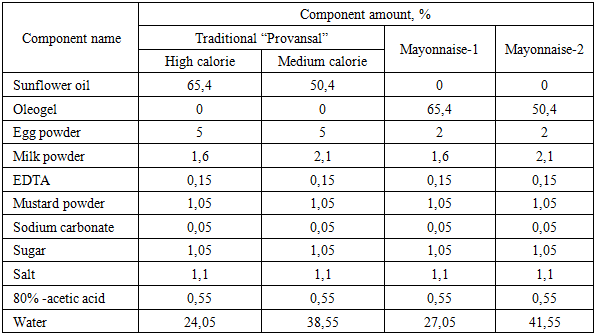

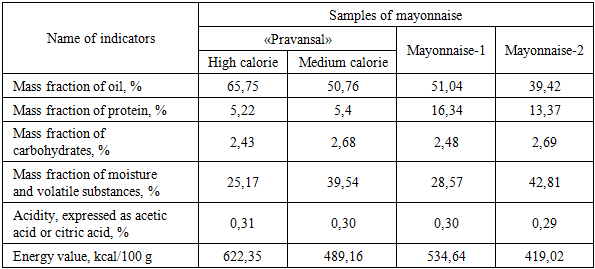

- Initially, experiments were conducted on the preparation of mayonnaise. In this study, commercial “Provensal” mayonnaise was used as the control sample. In the recipe of “Provensal” mayonnaise, sunflower oil was replaced with oleogel extracted from sesame seeds as the fat component. As an emulsifier, phospholipids isolated from vegetable oils were used instead of egg powder. In addition, citric acid was added to increase oxidative stability, and sodium alginate was incorporated to improve emulsion stability. The formulations of the prepared mayonnaise samples are presented in Table 1.

|

|

| Figure 1. Organoleptic evaluation results of the formulated mayonnaise samples |

| Figure 2. Changes in the number of peroxide number during the 180-day storage period of mayonnaise |

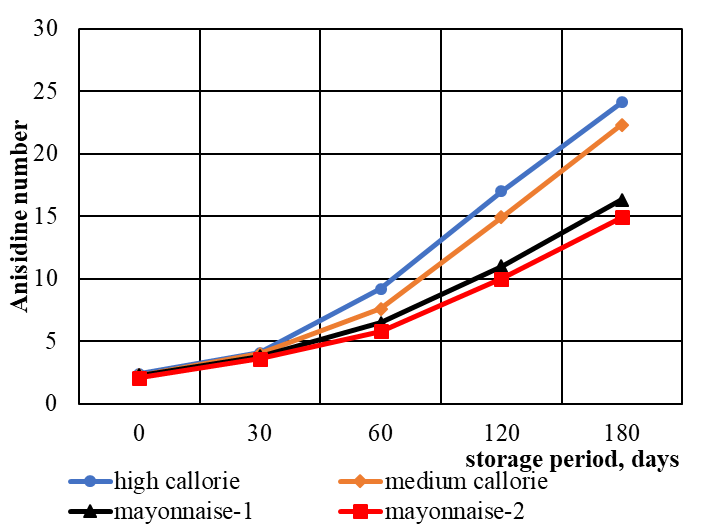

| Figure 3. Changes in the number of anisidine number during the 180-day storage period of mayonnaise |

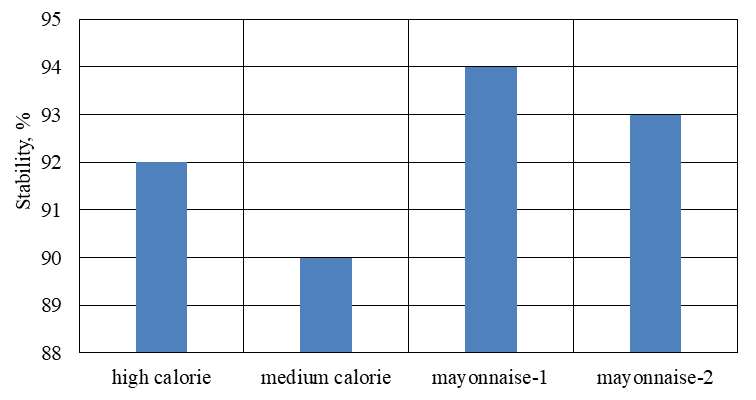

| Figure 4. Effect of fat base on the stability of mayonnaise emulsion |

4. Conclusions

- Thus, the conducted studies have shown that replacing sunflower oil in mayonnaise formulations with sesame-based oleogel significantly increases the nutritional and biological value of the product and improves its stability. At the same time, the energy value decreases and the shelf life is extended. However, this research is not yet complete. Further studies are needed to determine the optimal amount of oleogel, as well as its effects on emulsion viscosity, microbiological properties, and the economic efficiency of the final product.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML