-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Materials and Chemistry

p-ISSN: 2166-5346 e-ISSN: 2166-5354

2025; 15(1): 5-8

doi:10.5923/j.ijmc.20251501.02

Received: Feb. 27, 2025; Accepted: Mar. 13, 2025; Published: Mar. 15, 2025

Processing of Wastewater Treatment in Gas Industry Enterprises Using Flocculant Composition

Matluba Mukhtarovna Amonova

Doctor of Philosophy (PhD) in Chemical Sciences, Associate Professor, Bukhara University of Innovative Education and Medicine, Bukhara, Uzbekistan

Correspondence to: Matluba Mukhtarovna Amonova, Doctor of Philosophy (PhD) in Chemical Sciences, Associate Professor, Bukhara University of Innovative Education and Medicine, Bukhara, Uzbekistan.

Copyright © 2025 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

One of the most important methods for treating wastewater from soluble organic impurities is chemical water treatment, in which synthetic water–soluble organic polymers are used as flocculants. It is known that flocculants chemically interact with various impurities in wastewater, forming insoluble compounds. Effective polymers of this type include substances containing anionic and cationic surfactants, humic and fulvic acids, various dyes, high–molecular–weight acids, as well as mineral acids and their salts. These substances are present in the wastewater of gas processing enterprises. This article presents the results of a study on the potential application of new compositions of synthetic water–soluble and highly absorbent polymeric flocculants in wastewater treatment processes at gas processing enterprises.

Keywords: Wastewater treatment, Flocculants, Synthetic water–soluble polymers, Chemical oxygen demand (COD), Coagulants, Sorption and desorption processes

Cite this paper: Matluba Mukhtarovna Amonova, Processing of Wastewater Treatment in Gas Industry Enterprises Using Flocculant Composition, International Journal of Materials and Chemistry, Vol. 15 No. 1, 2025, pp. 5-8. doi: 10.5923/j.ijmc.20251501.02.

1. Introduction

- Experimental and analytical methods have been used to study their effect on the removal of various pollutants from wastewater. The research is aimed at ensuring an innovative approach to solving environmental problems.Since synthetic water–soluble polymers have an organic nature, their macromolecules facilitate the accelerated settling of coagulated impurities in wastewater, thereby increasing the efficiency of removing various substances and fine–dispersed mechanical impurities. The removal of these impurities using traditional mechanical methods such as sedimentation, flotation, and filtration is not feasible [1, p. 47; 2, p. 50–53].This study examines the effect of new compositions of synthetic water–soluble and highly absorbent polymeric flocculants on the wastewater treatment of gas processing enterprises.The composition of flocculant mixtures, including sodium carboxymethyl cellulose (Na–CMC), polyacrylamide (PAA), and hydrolyzed polyacrylonitrile (HPAN) in a mass ratio of 1.0:0.5:0.5, demonstrated high efficiency. During the experiments, various flocculant concentrations in the range of 0.15–0.30 mg/L were studied. The resulting suspension was allowed to settle for 10–15 minutes until complete sedimentation of the formed flocs, ensuring water clarity.A comprehensive study was conducted on the relationship between the reduction in flocculant dosage and treatment efficiency. The experimental results help determine the optimal flocculant dose to ensure both economic and environmental safety [3, p. 3026].An experimental analysis of the relationship between the compositional characteristics of various pollutants and the effect of flocculants on their removal was also evaluated, which has practical significance for improving wastewater treatment technologies [4, p. 757; 5, p. 892].

2. Materials and Methods

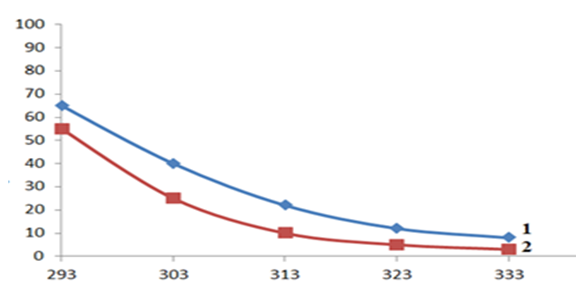

- Wastewater samples were characterized based on key parameters: turbidity, suspended solids content, and chemical oxygen demand (COD). The flocculant composition was prepared by sequentially adding synthetic water–soluble polymers (sodium carboxymethyl cellulose (Na–CMC), polyacrylamide (PAA), and hydrolyzed polyacrylonitrile (HPAN)) in a specific proportion. The composition optimization was carried out experimentally. The resulting suspension was allowed to settle for 10–15 minutes until complete sedimentation of the formed flocs.Wastewater samples were treated with the prepared flocculant composition under varying pH levels and temperatures. The mixture was stirred to ensure the interaction of reagents with contaminants. After treatment, sedimentation was performed to separate the sludge.The treatment efficiency was evaluated based on the reduction in turbidity, suspended solids concentration, and COD levels. Analyses were conducted using spectrophotometry and titrimetric methods.A flocculant in the form of water–soluble polymers Na–CMC, PAA and HPAN in a weight ratio of 1.0:0.5:0.5, prepared in advance, demonstrates its high efficiency. During the experiments, various amounts of flocculants were studied at a total concentration of 0.15–0.30 mg/l. In this process, the resulting suspension was maintained for 10–15 minutes until the flocculated sediment was completely deposited, i.e. until the water became transparent. Depending on the nature of the curve of the dependence of dispersed turbidity on temperature, all the studied flocculants can be divided into three groups (Figure 1).

3. Results and Discussion

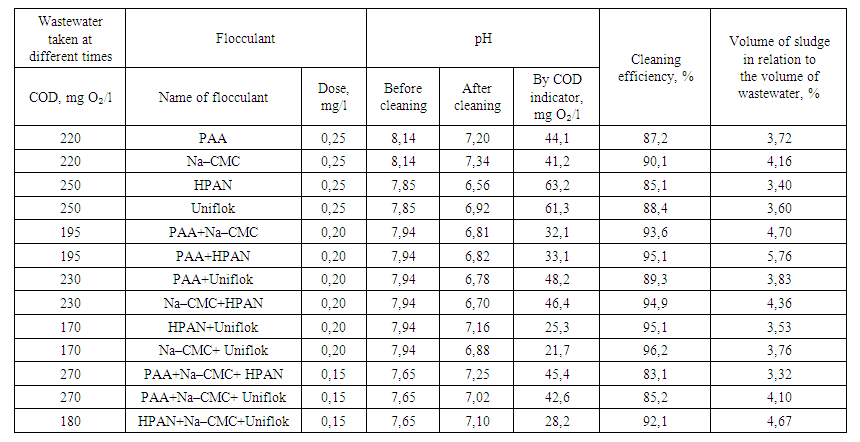

- The ratio of flocculants Na–CMC, PAA and HPAN 1.0:0.5:0.5 provided a transparency level of 95–97%. The total concentration of polymers was 0.15–0.20 mg/l. To achieve consistent interaction of reagents (coagulant and flocculant) with purified water, the dispersion level of coagulant particles should be within 0.006–0.016 μm–1, flocculant–0.003 μm–1, sorbent–0.02–0.05 μm–1.Considering the dependence of the rate of sorption and desorption processes on the concentration of substances on the adsorbent surface and in the solution, various coagulant dosages were studied to reduce the chemical oxygen demand (COD) of wastewater. Table 1 presents the changes in COD values depending on the flocculant dosage.

| Table 1. Change in the efficiency of wastewater treatment at the Mubarek gas processing plant from various pollutants depending on the dosage of flocculants |

4. Conclusions

- Thus, as a result of the conducted research, an innovative composition of reagents for highly effective wastewater treatment was developed. This composition includes powdered coagulants, such as aluminum sulfate and iron chloride, which provide primary sedimentation of pollutants. In addition, it contains water–soluble polymer flocculants (PAA, HPAN, Na–CMC), which have high adsorption capacity and promote the aggregation of dispersed particles, which significantly increases the degree of purification.The developed reagent composition provides improved efficiency of coagulation and flocculation processes, which is confirmed by experimental data. The use of this composition allows not only to minimize the concentration of residual pollutants in purified water, but also reduces the volume of sediment formed, which is an important factor for optimizing the operation of treatment facilities. Moreover, the use of these reagents helps to reduce the corrosive effect on equipment, which increases its service life and reduces operating costs. These results demonstrate the practical importance of using the proposed reagent composition in industrial wastewater treatment, especially at gas processing plants, where effective removal of complex organic and mineral contaminants is required.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML