-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Materials and Chemistry

p-ISSN: 2166-5346 e-ISSN: 2166-5354

2023; 13(2): 28-33

doi:10.5923/j.ijmc.20231302.03

Received: Sep. 11, 2023; Accepted: Sep. 27, 2023; Published: Oct. 13, 2023

Industrial Tests of Drying of Mineral Fertilizers in a Rotary Drum Dryer

Adil Axunbaev

Candidate of Technical Sciences, Docent, Department of Technological Machines and Equipment, Fergana Polytechnic Institute, Fergana, Republic of Uzbekistan

Correspondence to: Adil Axunbaev, Candidate of Technical Sciences, Docent, Department of Technological Machines and Equipment, Fergana Polytechnic Institute, Fergana, Republic of Uzbekistan.

| Email: |  |

Copyright © 2023 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

In the article, the process of drying superphosphate mineral fertilizers, the problems associated with them and the design of the used equipment were analysed. The study presents the findings of the industrial tests of two types of flights at the workshops of FARG‘ONAAZOT JSC. Based on the study, recommended flight shapes and sizes are proposed according to the properties of the material used in drying superphosphate fertilizer.

Keywords: Rotary drum dryer, Superphosphate, Material humidity, Coolant temperature, Dispersed composition

Cite this paper: Adil Axunbaev, Industrial Tests of Drying of Mineral Fertilizers in a Rotary Drum Dryer, International Journal of Materials and Chemistry, Vol. 13 No. 2, 2023, pp. 28-33. doi: 10.5923/j.ijmc.20231302.03.

Article Outline

1. Introduction

- Drying is a process consisting of the removal of water by evaporation from a solid, semi-solid or liquid state, and is often used as a final production step before the dried product is sold or packaged. Despite their importance, in many cases, the design and operation of dryers are subject to empiricism based on previous experience [1].Rotary drum drying is one of the many drying methods that are widely used in various industries. The most commonly used rotary drum dryers in the industry are direct convective type, based on the method of heat transfer between hot air and solid particles [2,3,4]. The widespread use of rotary drum dryers is due to their ability to process a wide range of solids such as fertilizers, pharmaceuticals, mineral concentrates, cement, sugar, soybean meal, corn meal, plastics and many others. The dried material, cascading out of the flights, is actively in contact with the gas phase and is located in the active zone of the dryer. The material located in the flights and at the bottom of the drum represents a dense phase and is localized in the passive zone of the device [5,6,7].The performance of rotary drum dryers depends primarily on the efficiency of contact between the cascading particles and the drying gas along the length of the drum. High operational efficiency can be achieved by optimally loading the drum, increasing the residence time of the material in the apparatus, as well as maximizing the presence of the material in the active zone, where drying occurs to a greater extent [8,9].To create conditions conducive to good operation of the rotary drum dryer, the shape of the flight is influenced. The geometry of the flight determines the cascading of particles [8,10], the amount of material in the active and passive zones [4,11] and the distribution of material across the cross-section of the apparatus [5,8].Various types of attachments are used to process bulk materials in rotating drums. Flight geometry is directly related to the characteristics of solid bodies [4,12]. For bulk materials, semi-circular, angular and rectangular flights are used [13,14,15].Two-section rectangular flights provide maximum particle loading, ensuring large quantities of solids enter the gas stream. Three-section flights contribute to good mixing of still wet material and lead to uniform distribution of material across the cross-section of the drum [15,16].Other forms of flights have been studied in the literature and studies have been conducted to examine the influence of design variables on the drying process in rotating drum apparatus. Researchers have evaluated different flight types [8,10,15], optimal number of flights [17], and section sizes [4,12] to determine appropriate flight geometry. However, there is still not enough research related to the influence of changing the angles between sections [10,14] on the behaviour of particles in the core, which determines the efficiency of the drying process. We were faced with the task of industrial testing of the shape and size of the flight, which we had previously chosen as optimal for drying mineral superphosphate fertilizer under the conditions of FARG’ONAAZOT JSC to obtain a finished product that meets the requirements of the technological regulations.The final results of drying, therefore, the presentation of the product depends on the initial parameters of the material and coolant, the nature of the movement of the material through the apparatus, depending on the design of the drying drum. Therefore, it is necessary to select the optimal design options, first of all, the shape of the drum flight ensures intensive contact between the dried fertilizer and the hot coolant. The grain size, quality and export properties of fertilizers depend on the drying process.

2. Materials and Methods

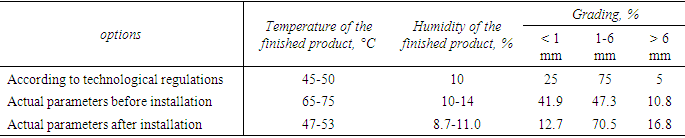

- The drying process of the superphosphate mineral fertilizer we are studying is carried out at FARG’ONAAZOT JSC. The chemical complex of FARG’ONAAZOT JSC is a large chemical complex of the Republic of Uzbekistan, including the production of several products such as ammonia, nitric acid, ammonium nitrate, urea and superphosphate fertilizer. The production of superphosphate fertilizer is established in the AS-72M workshop. It is known that the production process of superphosphate fertilizers in this enterprise includes: mixing phosphorite fines with sulphuric acid in a reaction medium, granulating the mixture with spraying ammonium sulphate, granulating, drying granulated fertilizers, separating into granulometric components according to regulations and packaging the finished product [4-10]. Drying of the finished bulk product is carried out using a parallel rotary drum dryer, following the granulator drum. This technological scheme is considered energy efficient compared to existing classical lines of this type. However, initial results from the shop showed that the temperature of the fertilizer entering the drum granulator was 100°C and its moisture content was 28%. The temperature at the outlet of the rotary drum dryer was 70°C, and the humidity was 14%. The results obtained show that the fertilizer produced does not meet the requirements of the regulations established for the production line. In addition, fertilizers smaller than 3 mm must be processed during the production process, and fertilizers larger than 5 mm must be crushed and sorted. This, in turn, increases the amount of time and energy spent on this process. However, analysis of the granulometric composition and thermophysical properties of the finished superphosphate fertilizer do not fully comply with the technical regulations. Table 1 presents the requirements of technical regulations and the actual parameters of the dried product.Based on the above, the existing problems in the production process of superphosphate mineral fertilizers in the AS-72M workshop were analysed. In a horizontal mixing reactor, ammonium sulphate is sprayed into particles, and the resulting mass is fed for drying and granulation. This process occurs in two successively coaxially located drum apparatuses. The first drum granulator has a size of Ø1.6×11.6 m, and the second rotary drum dryer has a size of Ø2.2×10 m. The drums simultaneously rotate at a speed of 3 rpm and are slightly inclined (2.5%) to the horizontal. The choice of drum rotation speed is because the dryers are installed in the workshop of FARG’ONAAZOT JSC and have parameters following the technological regulations. Therefore, we were unable to change the dryer speed during testing and conduct research at other drum speeds. The granules pass through the cylinders by rotation, thrust and tilting effects and are discharged from the other end onto a conveyor belt. The rotary drum dryer is equipped with flights inside to lift and drop the granules into a stream of hot air and baffles to increase the efficiency of material distribution and reduce the formation of dust as it passes through the drum. Air is sucked from the atmosphere through a filter using a fan and then heated by an air heater. Because the pellets are very heat sensitive and must be thoroughly dried, hot air and pellets are introduced simultaneously to ensure rapid cooling of the hot air during the initial evaporation of surface moisture. The solids then enter a second rotary drum dryer for final drying. Dust captured by the exhaust air stream is captured in a washing column (scrubber), where it is dissolved with water, and the resulting solution is sent back to the neutralizer.In the first stage, the granulometric composition of the produced mineral fertilizer was determined and the temperature and humidity of the finished material were measured. Recommended standard techniques were used in conducting the experiments. This is presented in Table 1. The results obtained show that the fertilizer production line does not meet the requirements specified by the regulations. In addition, when fertilizers are smaller than 1 mm in size, they require repeated granulation to enlarge the granules, and for fertilizers larger than 6 mm, they need to be crushed. This in turn increases the amount of time and energy consumed in the process. The occurrence of this condition is associated with heat exchange processes in the dryer, which is caused by the transition of granular fertilizer into the dryer and the lack of sufficient contact with the thermal agent there. The body of the rotary drum dryer during the manufacturing process is equipped with a standard L-shaped flight; this type of design is poorly adapted to distribution, and its selection did not take into account the physical properties of the fertilizer produced.

|

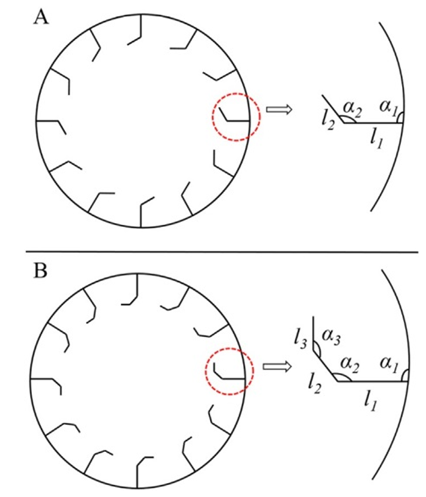

| Figure 1. Diagram of dryer flights. A - two-section flight, B - three-section flight |

3. Results and Discussion

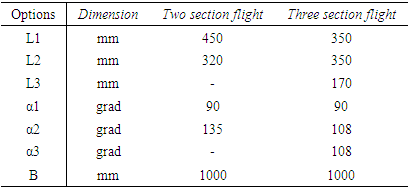

- Experience in the operation of drum devices shows that changing the angle of inclination along the drum axis of standard flights on a drying drum does not provide a significant increase in the area covered by the spilt material. If the flight is installed along the line of the drum, the strip area will be maximum, but it will not be sufficient. Open zones are formed to the right and left of the drum surface. Along with other technical measures designed to expand the area covered by the spilling material, a checkerboard arrangement of flights and a ridge edge of the flight are used. However, the drum cross-section remains open on 30-40% of the surface. The optimal solution for reducing the open area in the dryer is to select a flight suitable for the drying process of a specific mineral fertilizer, taking into account the physical and chemical properties of the specific material. In order to select the optimal flight shape suitable for superphosphate fertilizer, we experimentally studied several flight designs [18].The experimental setup was a rotary drum dryer segment with a diameter of 1.2 meters and a width of 0.5 meters. Studies were conducted with 7 different types of two- and three-section flights to determine the optimal material distribution and design of drum flights. In the experiments, the distribution functions of superphosphate fertilizer over the cross-section of the drum were obtained. The actual dimensions of the sections and the angles between them are shown in Table 2.

|

| Figure 2. Processes of pouring out mineral fertilizers from the flight. A - two sectional 1, B - three sectional 1, B - three sectional 4 |

|

| Figure 3. Installation diagrams for two (A) and three (B) sectional flights |

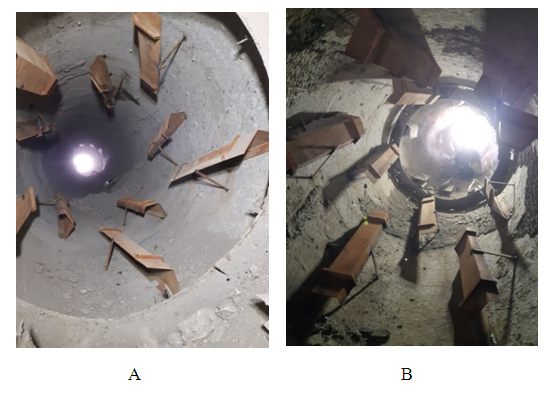

| Figure 4. Photo of the installation of two (A) and three (B) sectional flights on the drum |

4. Sequence of Industrial Tests

- 1. Visual assessment of the influence of the flight on the distribution of the product over the cross-sectional surface of the drum;2. Experimental determination of the influence of the flight on the heat transfer process;3. Experimental determination of the influence of the flight on the granulometric composition of the fertilizer.In order to study the distribution of the product over the cross-sectional surface of the drum and the state of open and closed zones, two-stage experimental studies were carried out.In the first stage, using the MATLAB program, based on the technical parameters of the existing dryer, the flights were placed in a checkerboard pattern along the cross-sectional surface of the drum in 2 rows (Fig. 3). The semi-industrial version of the flights consists of 2 zones located in a checkerboard pattern. Two-section flights are installed in the first zone, and three-section flights are installed in the second zone. A diagram of the visual state of the process has been developed and the values of open and closed zones for the first row have been approximately determined. According to the diagrams, the closed area was 1.30 m2, and the open area was 0.71 m2. For three section flights in the second row, the closed area was 1.36 m2, and the open area was 0.65 m2, respectively.In the second stage, the working condition of the proposed flight was studied. Based on the technical parameters of the existing dryer, the flights were arranged in 2 rows along the cross-sectional surface of the drum in a checkerboard pattern. Photographs of the work process were taken and the values of the open and closed zones for the first row were determined. According to photographs, the closed area was 1.39 m2, and the open area was 0.62 m2. For the three-part flight in the second row, the closed area was 1.44 m2 and the open area was 0.57 m2, respectively.The mineral fertilizer obtained in the installed state of the proposed flight was divided into granulometric composition. Standard methods were used to carry out the experiments. In accordance with it, the manufactured fertilizer was subjected to 3-stage sorting for 10 minutes on a laboratory model of the SMC-25 sieve apparatus. sieve with mesh sizes 1mm and 6mm. The obtained data are presented in Table 1.

5. Conclusions

- 1. Installation of two and three-section flights allowed the cross-section of the drum to be more completely covered with a curtain of material and will reduce the open areas along the cross-section of the drum not covered with material. This made it possible to increase the contact of the material curtain with the hot coolant and intensify the heat exchange process, which is reflected by a decrease in the final moisture content of the mineral fertilizer from the initial 10-14% to 8.7-11% after installing the proposed flights.2. Intensification of the heat exchange process made it possible to reduce the consumption of gas coolant. This resulted in a decrease in the final temperature of the mineral fertilizer from the initial 65-75°C to 47-53°C after installing the proposed flights. Due to the installation of the flight, the heat exchange process has increased by 1.7 times compared to the current situation, and the energy spent on the process is 1.24 times less.3. Reducing the consumption of coolant gas made it possible to create a “softer” drying mode due to less thermal energy spent on the process. In our opinion, this reduced the cracking of mineral fertilizer grains and made it possible to reduce the amount of fraction to less than 1 mm. Which reduced the amount of fractions less than 1 mm from 41.9% to 12.7%.

ACKNOWLEDGEMENTS

- We would like to express our sincere gratitude to all the individuals and organizations who have contributed to the publication of this research paper. We are also grateful to the management of FARG'ONAAZOT JSC for providing us with the resources and support we needed to complete this project. We would also like to thank our colleagues at Fergana Polytechnic Institute for their feedback and support throughout the research process. Finally, we would like to thank all the participants in this study for their time and willingness to share their experiences. Their contributions have been invaluable in helping us to understand the topic and draw meaningful conclusions. We would also like to express our appreciation to the International Journal of Materials and Chemistry for considering our work and providing the opportunity to publish our findings.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML