-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Materials and Chemistry

p-ISSN: 2166-5346 e-ISSN: 2166-5354

2017; 7(2): 21-24

doi:10.5923/j.ijmc.20170702.01

The Production of Biogas Using Cow Dung and Food Waste

Ukpabi Chibueze1, Ndukwe Okorie2, Okoro Oriaku3, John Isu4, Eti Peters5

1Department of Biochemistry, Abia State Polytechnic, Aba, Nigeria

2Department of Biology, Abia State Polytechnic, Aba, Nigeria

3Department of Chemistry, Abia State Polytechnic, Aba, Nigeria

4Department of Physics, Abia State Polytechnic, Aba, Nigeria

5Department of Mechanical Engineering, Abia State Polytechnic, Aba, Nigeria

Correspondence to: Ukpabi Chibueze, Department of Biochemistry, Abia State Polytechnic, Aba, Nigeria.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

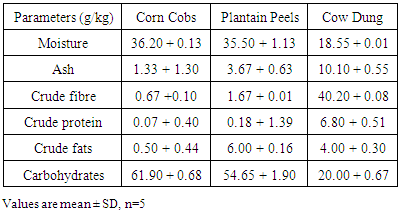

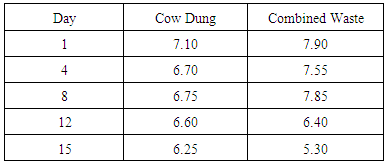

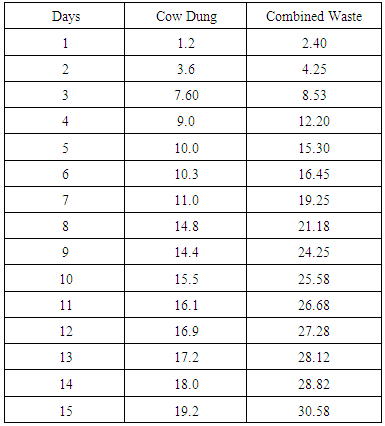

In Nigeria, the scarcity of petroleum supply particularly kerosene has become a national concern. Biogas technology has gained national interest. This research was to generate biogas using cow dung and food wastes. Food wastes (corn cobs and plantain peels at the ratio of 1;1) were collected from the Abia State Polytechnic canteen and cow dung from Aba North LGA slaughter house as feedstock for the anaerobic digestion system to produce biogas energy. This design was to combined feedstock with high caloric content and anaerobic microbes. The proximate composition revealed that the two feedstock contained energy yielding nutrients but at varying concentrations. The study revealed that the pH decreased possibly as the bacteria produce acids in the digester. The decrease was more observed in the cow slurry experiment as it recorded acidic at the 4th day than the combined waste slurry which recorded acidic at 12th days. The data showed the volume of biogas production in respect of number of days under the various slurry. It can be deduced from the data that gas production increased in the earlier days of the experiments and then started decreasing as acid concentration increases as indicated by the decrease in pH. This observation was more pronounced in combined waste slurry than the cow dung slurry. The result supported the observation that acid concentration greatly affects the biogas production. Thus the combined waste slurry produces more gas (30.58ml) than cow dung slurry (19.20ml) as food wastes contain more nutrients than the dung. It has been demonstrated by this study that by using combine feedstock (cow dung and food wastes) the efficiency of biogas generation can be increased.

Keywords: Biogas technology, Cow dung, Food waste

Cite this paper: Ukpabi Chibueze, Ndukwe Okorie, Okoro Oriaku, John Isu, Eti Peters, The Production of Biogas Using Cow Dung and Food Waste, International Journal of Materials and Chemistry, Vol. 7 No. 2, 2017, pp. 21-24. doi: 10.5923/j.ijmc.20170702.01.

Article Outline

1. Introduction

- Biological degradation of organic material under aerobic and anaerobic conditions is a key process within the natural metabolism of ecosystem [1]. This term is often used in relation to energy, waste management and is now commonly associated with the anaerobic generation of methane. Anaerobic process could either occur naturally or in a controlled environment such as a biogas plant. Organic waste such as livestock manure and food waste are put on an airtight container called digester [2]. Livestock manure has been established as major source of microbes while food waste have high caloric and nutritive values for growth and sustainability of microbes [2-4]. Biogas technology is distinct because of its potentials of using organic material to generate energy and at the same time producing superior nutrient compost or digestate as fertilizer. This process produces gases principally methane (CH4) and carbon (iv) oxide (CO2) and has positive environmental impact due to the reduction of CO2 and CH4-the cause of global warming [3]. Generally, anaerobic digestion of animal manure solves three problems, unpleasant odour management, creation of new source of bioenergy and the reduction of green house gases emission [5, 6]. Anaerobic decomposition involves three stages (hydrolysis, acidification and methanogenesis) of biochemical processes with release of energy rich biogas [7]. The organic matter is catabolized externally by extra cellular enzymes, in the first stage. The acid producing bacteria converts the intermediate to low molecular weight compounds thereby creating anaerobic condition which is essential for the methane producing micro organisms [7]. Methane producing bacteria which are involved in the third stage decompose compounds having low molecular weight to form CH4 and CO2 [8]. These gases can be measured by counting anaerobic microbes and/or the amount of CH4 that are produced [7-9].In Nigeria, the scarcity of petroleum supply particularly kerosene has become a national concern. Biogas technology has gained national interest. It does not have any geographical limitations or requires advanced technology for producing energy, nor is it complex or monopolistic. However, due to instabilities in set-up and operation, a large number of factors affect biogas production efficiency including pH, type and quality of feedstock. In this study attempt was made to evaluate the biogas production efficiency from animal dung and its combination with food waste.

2. Materials and Methods

2.1. Raw Materials

- The wastes used in this study were corn cobs, plantain peels and the cow dung. Fresh food wastes (corn cobs and plantain peels at the ratio of 1:1) and the cow dung were collected from the Abia State Polytechnic canteen and the Aba North LGA slaughter house Aba respectively. This design was to combined feedstock with high caloric content and anaerobic microbes. The food wastes were crushed with mixer grinder while the fresh cow dung was mixed with water thoroughly by hand. The cow dung served also as inoculums as it contained the required microorganisms for anaerobic digestion. The waste samples were weighed and poured into the digester based on the experimental design. After that digester was kept for that day and gas production was checked the next day.

2.2. Experimental Procedures

- In this study, biogas production was done in batch system, in which the slurry was added once in the digester for the whole duration of the process. In the combined waste experiment, the digester was fed with 75 g of cow dung and 75 g of food wastes mixed with water at a ratio of 1:1 respectively. In the single dung experiment 150g of the cow dung was introduced into the digester at the same ratio. The digester was provided with suitable arrangements for feeding, gas collection and draining residues. The digester was connected to a calibrated measuring cylinder with paraffin oil displacement arrangement to measure the volume of biogas produced. The slurry was allowed to ferment anaerobically for 15days under mesophilic temperature of 26-35°C.

2.3. Digester Description

- A biogas chamber of 20kg slurry capacity was constructed and used for this experiment. The diameter and height of the digester are 0.34m and 0.38m respectively. The biogas digester was built to maintain the anaerobic condition. The gas production was measured via the connection of a calibrated measuring cylinder with paraffin oil displacement arrangement. The digester was fed by opening the cover of the dome and remnant was evacuated through the outlet device at the bottom of the dome.

| Figure 1. Diagram of the Constructed Digester |

2.4. Proximate Analysis and pH Determination

- Proximate composition of the dung was carried out according to the method of AOAC [10] as described in Ukpabi et al [11]. The slurry pH were determined electrometrically using glass electrode pH meter at 1st, 4th, 8th, 12th and 15th days. The pH was measured at the ratio of 2:1 dung/ water suspension.

3. Result and Discussion

- Recent studies have shown that production of biogas is partly dependent on pH and the volume of the slurry in the digester [12, 13]. Thus, in the course of the experiment, attention was given to the pH within the digester, with the avoidance of much volume of the slurry in the digester. Gas production were recorded on daily basis via the connection of calibrated measuring cylinder with paraffin oil displacement arrangement while the pH values were measured from small slurry taken from the outlet device of the digester.

|

|

|

4. Conclusions

- This study investigated biogas production of animal dung and food waste using locally made anaerobic digester. The result shows that locally fabricated anaerobic digester could serve as alternative to foreign commercial products. Similarly, high caloric feedstock with high carbohydrates content such as food waste combined with animal dung could yield more biogas than dung alone. The result also shows that acid concentration greatly affected the biogas production. This observation was more pronounced in the feedstock with high protein content.

5. Recommendations

- Although, biogas can be used as a fuel, for cooking or other purposes and the solid residue can be used as organic compost, there is need for comparative analyses of the biogas produced from various feedstock.

ACKNOWLEGEMENTS

- The authors are grateful to the management of Abia State polytechnic, Aba and Tertiary Education Trust Fund (TETFUND), Nigeria for sponsoring this research.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML