-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Materials and Chemistry

p-ISSN: 2166-5346 e-ISSN: 2166-5354

2016; 6(1): 6-11

doi:10.5923/j.ijmc.20160601.02

Electromagnetic Interference Shielding of Polyaniline/Poloxalene/Carbon Black Composite

Ayesha Kausar

Nanosciences Division, National Centre For Physics, Quaid-i-Azam University Campus, Islamabad, Pakistan

Correspondence to: Ayesha Kausar, Nanosciences Division, National Centre For Physics, Quaid-i-Azam University Campus, Islamabad, Pakistan.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Novel polyaniline (PANI), poloxalene (POX), and carbon black (CB) composites and PANI/POX blend have been successfully fabricated. The electromagnetic interference (EMI) shielding effectiveness measurement indicated that the PANI/POX/CB composites acted as effective lightweight shielding materials. The EMI shielding mechanism and relationship between the shielding effectiveness and electrical conductivity were also studied. CB nanofiller was used to improve the electrical conductivity of the composite. Morphology of PANI/POX blend consisted of two phases while PANI/POX/CB showed homogeneous diminutive granular morphology. Acid fucntionalization of CB improved its dispersion in PANI/POX matrix and created good adhesion between the PANI/POX blend and nanofiller. It is demonstrated that the inclusion of CB particle led to higher electrical conductivity and EMI shielding efficiency. Only 10 wt.% CB addition into the blend matrix revealed EMI shielding effectiveness of ~20 dB i.e. desired for significant commercial applications.

Keywords: Polyaniline, Carbon black, Electrical conductivity, EMI shielding

Cite this paper: Ayesha Kausar, Electromagnetic Interference Shielding of Polyaniline/Poloxalene/Carbon Black Composite, International Journal of Materials and Chemistry, Vol. 6 No. 1, 2016, pp. 6-11. doi: 10.5923/j.ijmc.20160601.02.

Article Outline

1. Introduction

- The growing interest in the use of electronic devices has also enhanced the electromagnetic pollution [1, 2]. The pollution is caused by recent interference impacts induced by magnetic and electric fields from electrical circuitry in close proximity [3, 4]. The interference between processing equipment, business machines, consumer products and other instruments can reduce the potential and even direct to complete failure [5, 6]. Hence, EMI has been synchronized for several years by organizations and governments around the world [7]. The EMI shielding effectiveness (SE) of a material can be defined as the ratio between the incoming power (Pi) and outgoing power (Po) of an electromagnetic wave. In general, SE is expressed in decibels (dB). By employing conductive metal powders and flakes, (carbon nanotube (CNT), carbon black (CB), and carbon fiber (CF)) conductive composites for EMI shielding have been studied [8, 9]. Carbon black, with its low cost and chemical stability, is one of the most widespread fillers for improving the electrical conductivity [10]. It was shown by many reports that at lower CB content, for the achievement of desired conductivity, the improvement of a perfect conductive network in single-component polymer matrix is necessary. The percolation threshold was considerably decreased to 1 vol.% CB in the electric field of 500 V/mm. In the past, metals were utilized for EMI shielding since they could conduct or reflect free electrons. Moreover, metals had a number of disadvantages such as susceptibility to corrosion, high density, rigidity and complex, and costly processing. Metals do not enhance mechanical features and can act as catalysts for oxidative degradation of polymer matrix. So as an alternative, carbon materials have been demonstrated for this application because of their low weight, high conductivity, EMI adsorption properties, flexibility, and environmental and thermal stability [11]. Especially, nano-scaled carbon materials have been studied due to the high efficiency of EMI shielding efficiency. In spite of these significances, poor integration of carbon in a matrix creates poor adhesion within the matrix frustrating the retreat of EMI shielding efficiency and electrical properties. Conductive polymers have been used as actuators and sensors, antistatic coatings, electrically conducting adhesives, and electromagnetic interference shielding materials for electronic devices [12, 13]. The polyaniline (PANI) is frequent conducting polymer. High molecular weight polyaniline is developed as one of the most capable conducting polymers. Preparation of high molecular weight polyaniline is a problem throughout the diverse literature. Polyaniline has been commonly classified as an inflexible material. Melt-processing of PANI is not possible, since the decomposition of polymer occurred at temperature i.e. below a melting or softening point. PANI has been explored because of its distinctive chemical, electrochemical, and physical properties in addition to environmental stability and electrical conductivity [14]. Moreover, PANI has considerable tunable chemical structure [15, 16]. PANI also has difficulty of poor lasting thermal stability [17]. Among several conducting polymers, PANI has been effectively employed to produce polymer/carbon filler composites due to environmental stability, good processability, and conductivity through charge-transfer and doping protonation [18]. The mixture of PANI and carbon filler might produce excellent composite material for electronic devices with morphological modification or electronic interaction between the two components [19]. In this study, polyaniline (PANI) and poloxalene (POX)-based blend and composites with carbon black were prepared. The PANI/POX blend was used as a matrix for shielding EMI and CB was embedded due to its high conductivity and low cost. The electromagnetic interference (EMI) shielding effectiveness measurement indicated the formation of cost-effective and lightweight shielding materials. The correlation between the shielding effectiveness and electrical conductivity and the EMI shielding mechanism of PANI/POX/CB composite were also discussed. The main objective of this study was to develop novel polyaniline-based composite system in which conducting particles are uniformly distributed to form conductive network. Such type of system can better interact with the electromagnetic waves and contribute to the EMI shielding effectiveness. Thus development of low cost conducting composite with fine EMI shielding effectiveness was an important objective of the research.

2. Experimental

2.1. Chemicals

- Poloxalene (POX, poly (ethylene glycol)-block-poly (propylene glycol)-block-poly(ethylene glycol), polyaniline (PANI, emeraldine salt, average Mw >15,000, 3-100 μm particle size), 1-Methyl-2-pyrrolidinone (NMP, 99%), and carbon nanopowder (<100 nm particle size) were purchased from Aldrich.

2.2. Instrumentation

- Field Emission Scanning Electron Microscopy (FE-SEM) of fractured samples was performed using Scanning Electron Microscope S-4700 (Japan Hitachi Co. Ltd.). The samples were fractured under liquid nitrogen, and then vacuum-coated with thin gold layer before analysis. For the electrical conductivity, dielectric and EMI SE characterization, rectangular samples (5 cm2) were prepared by compression molding using Carver hot press at 200°C under 5 T pressure for 10 min. The DC electrical resistivity Loresta GP (MCP-T610 model, Mitsubishi Chemical Co. Japan) electrical resistivity meter connected to a four-pin probe (MCP-TP08P model, Mitsubishi Chemical Co. Japan) was used. For the EMI SE characterization in the X-band (8.2-12.4 GHz) frequency, ENA series network analyzer (Model E5071C) connected with a WR-90 rectangular waveguide was used.

2.3. Functionalization of Carbon Black

- I g CB was refluxed in 50 mL HNO3 (1M aqueous solution) for 4 h. The product was isolated through centrifugation and washed several times with deionized water to attain neutral pH. Finally black powder was vacuum-dried at 80°C [20].

2.4. PANI/POX Blend Preparation

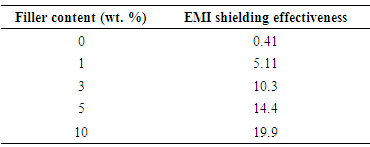

- 0.9 g of PANI and 0.1 g POX were refluxed at 90°C in 20 mL of NMP for 6 h. The blend film was cast in Petri dish. The film was prepared by evaporating solvent at 80°C for 6 h (Fig. 1).

| Figure 1. PANI/POX blend preparation |

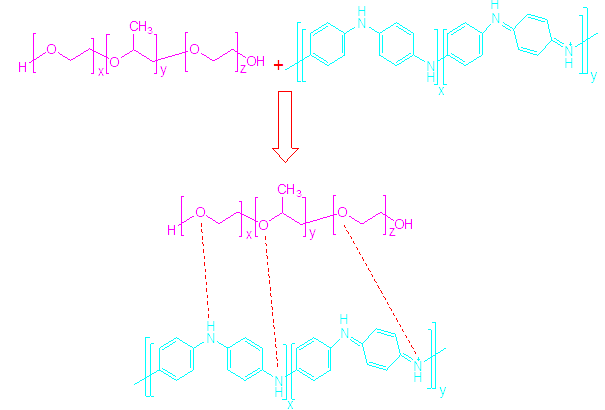

2.5. PANI/POX/CB Preparation

- At first the PANI/POX blend was prepared by refluxing 0.9 g of PANI and 0.1 g POX in 20 mL of NMP for 6 h. The desired CB content (1, 3, 5, and 10 wt.%) was dispersed in 5mL of NMP by sonication of 3h. Afterwards CB dispersion was added to the blend solution prepared. The mixture was further refluxed at 90 °C for 2 h. The mixture was sonicated for 10 min before film casting. The mixture was cast on glass Petri dishes and left at 80 °C for 6 h to evaporate the solvent. Then the samples were placed in a vacuum oven for 6h at 80 °C to remove the remaining traces of solvent (Fig. 2).

| Figure 2. Interaction in PANI/POX/CB composite |

3. Results and Discussion

3.1. Morphology of PANI/POX/CB Composite

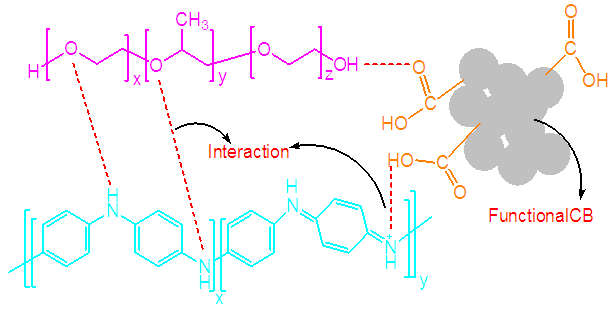

- Fig. 3 shows the representative SEM images of the cross section of PANI/POX blend and PANI/POX/CB 1, PANI/POX/CB 5, and PANI/POX/CB 10 composite. In the blend, two phase morphology was observed (Fig. 3A).

| Figure 3. FESEM images of (A) PANI/POX blend; (B) PANI/POX/CB 1; (C) PANI/POX/CB 5; and (D) PANI/POX/CB 10 |

- Conventional polymer blends generally consist of two phases dispersed among one another. The PANI/POX composite was composed of two solid phases, the PANI matrix and the POX phase. The granules of POX were dispersed among the PANI particles. Moreover the dispersion of two phases seems to be homogeneous. The PANI/POX/CB 1 composite with 1 wt.% CB showed very fine dispersion of polymer covered CB particles through out the PANI/POX blend matrix (Fig. 3B). The homogenous dispersion indicated the physical and chemical interaction among the blend components and functional filler. With the increase in nanofiller loading, the dispersion of PANI/POX/CB 5 (Fig. 3C) and PANI/POX/CB 10 (Fig. 3D) became more uniform. One can clearly see that the functional carbon black nanoparticlas were dispersed and embedded throughout the PANI matrix and an interconnected CB and blend network has formed. This conductive nanotube network may establish electrical conduction pathways throughout the system, which was responsible for the conductivity and EMI shielding characteristics.

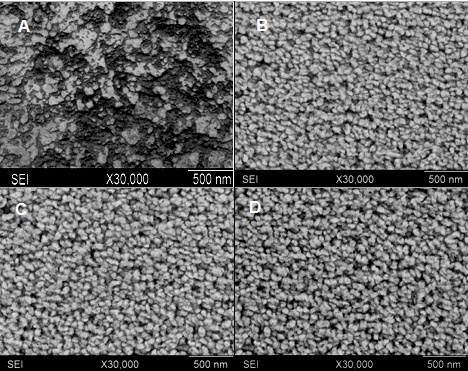

3.2. EMI Shielding Effectiveness of PANI/POX/CB Composite

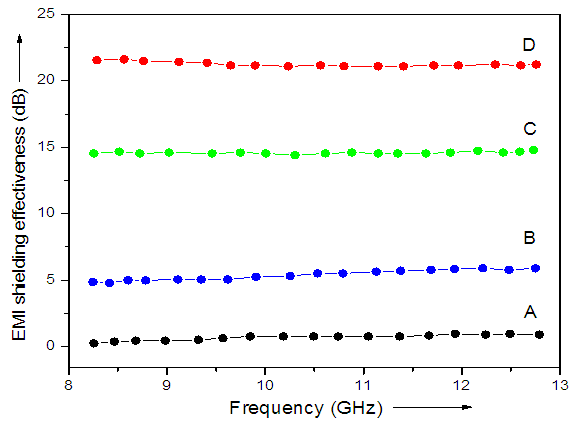

- In this study, the EMI shielding effectiveness of PANI/POX/CB composites was measured. An electromagnetic wave was injected directly into the composite using a waveguide setup. The frequency was scanned from 8.2 to 12.4 GHz (X band). Total 200 data points were taken within this frequency range. Fig. 4 shows the variation of the EMI shielding effectiveness over the frequency range of 8.2-12.4 GHz for PANI/POX blend and PANI/POX/CB composite with 1, 5 and 10 wt.% CB loading. The shielding effectiveness of each composite was independent of the frequency in the measured frequency region. The results also showed that the EMI shielding effectiveness was increased with increasing CB content in the composite. The shielding effectiveness of the foam composite containing 10 wt % CB was measured to be 19.2-19.9 dB over a frequency range of 8.2-12.4 GHz. This increment of the EMI shielding effectiveness was attributed mainly to the formation of conducting interconnected blend-CB networks. The augment in filler loading increased the number of interconnected blend-CB network that interacted with the incident radiation and led to the higher shielding effectiveness.

| Figure 4. EMI shielding effectiveness as a function of frequency measured in the 8.2-12.4 GHz range (A) PANI/POX; (B) PANI/POX/CB 1; (C) PANI/POX/CB 5; and (D) PANI/POX/CB 10 |

3.3. Relationship between Electrical Conductivity and EMI Shielding Effectiveness

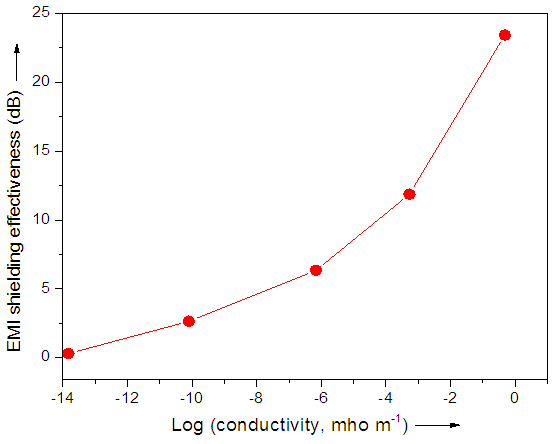

- Fig. 5 describes the correlation between the shielding effectiveness and electrical conductivity of PANI/POX/CB composites. Initially a slight increase in the shielding effectiveness occurred with the variation of conductivity from -14 to -3.1. However the system became more proficient in shielding and the shielding effectiveness was increased dramatically at higher conductivity (log conductivity > -3). This variation in the shielding effectiveness against conductivity was correlated with the change in conductivity of PANI/POX/CB. At first, change in the conductivity remained trivial up to the percolation threshold. With the further addition of CB content in PANI/POX matrix, there was large increase in conductivity. The results imply that the insulating PANI/POX blend matrix became conductive at higher CB content. The reason might be the formation of conductive CB-blend network at higher filler content. This is a typical percolation threshold for carbon nanostructure-filled polymer composites as reported in the literature [21-23]. The uniformly distributed conductive network in blend matrix actually interacted with the electromagnetic waves and contributed to the EMI shielding effectiveness.

| Figure 5. EMI shielding effectiveness at 10 GHz as a function of electrical conductivity of PANI/POX/CB composite |

|

4. Conclusions

- In summary, PANI/POX/CB composites were productively developed for EMI shielding applications. The EMI shielding effectiveness provided by the PANI/POX blend and CB at 10 wt.% loading was around 20 dB. The results entail that the novel composite can be commercially utilized as a shielding material against electromagnetic radiation. The PANI/POX/CB 10 composite was found to be more effective in providing EMI shielding compared to the other composites and blend. The major EMI shielding mechanism was attributed to the reflection of electromagnetic radiation.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML