-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Materials and Chemistry

p-ISSN: 2166-5346 e-ISSN: 2166-5354

2015; 5(5): 117-122

doi:10.5923/j.ijmc.20150505.03

Recent Trends and Modifications in Glass Fibre Composites – A Review

Muqsit Minhaj Pirzada

Department of Fibres and Textile Processing Technology, Institute of Chemical Technology, India (Affiliate of the Royal Society of Chemistry)

Correspondence to: Muqsit Minhaj Pirzada, Department of Fibres and Textile Processing Technology, Institute of Chemical Technology, India (Affiliate of the Royal Society of Chemistry).

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Glass fibre composites have found a host of applications in the automobile, industrial, marine engineering sectors as well as others mainly due to the inexpensive and light weight properties of glass fibre. Recent studies further diversify the scope of application of these glass fibre composites by changes in the chemical composition of classical silica glass, physical modifications to impart self-healing properties, using the composites as reinforcements for construction purposes amongst many others. Glass fibre composites are also developing as ideal fillers for orthopedic posts. Use of glass fibres as reinforcements is not only limited to polymer matrices but also to ceramic matrix composites. Chemical modifications of glass fibre reinforced plastics have helped achieve enhanced mechanical properties in matrix rich regions also. Nanoclay-Glass fibre hybrid composites are the latest development in elevated erosion resistant materials.

Keywords: Glass fibre, Composites, Chalcogenide, Self-Healing, Concrete, Endodontic, Ceramic, Carbon Nanotube, Nanoclay, Hybrid Fibres

Cite this paper: Muqsit Minhaj Pirzada, Recent Trends and Modifications in Glass Fibre Composites – A Review, International Journal of Materials and Chemistry, Vol. 5 No. 5, 2015, pp. 117-122. doi: 10.5923/j.ijmc.20150505.03.

Article Outline

1. Introduction

- Glass fibres are excellent at handling high tensile stress but are however, weak in terms of enduring compression owing to their brittle nature. Plastics, on the contrary, can handle compression loading very well but cannot endure high tension. By combining the two materials, Glass fibre reinforced plastics (GFRP) becomes a material that resists both compressive and tensile forces well [1]. Hence, GRPs find extensive uses in thermal insulation, electrical insulation, sound insulation, aerospace applications [2], building of boats and ships, automotive sectors, sports equipments, bulk moulding compound [3], sheet moulding compound [4], glass fibre reinforced concrete [5, 6, 7], etc. The primary objective of this review paper is to investigate modern trends and developments in glass fibre composites and to explore various avenues and study the effects of these modifications on the structure and properties of the composite. The paper also focuses on the scope of these developments for various applications such as orthodontic and construction purposes.

2. Chalcogenide Glass in Place of Silica Glass

2.1. Properties of Chalcogenide Glass

- Chalcogenide glasses can possibly replace silica glass in night vision devices because of higher transparency in the two atmospheric windows (3-5μm and 8-12μm). Chalcogenide glasses tend to replace, at least partially, the expensive monocrystalline Ge or polycrystalline ZnSe for infrared (IR) lenses [8]. Chalcogenide fibres are potentially excellent hosts for applications at higher wavelength beyond 1550nm as compared to silica glass as chalcogenides have particularly low phonon frequencies and can be used for laser transitions belonging to near Infrared to Middle Infrared regions [9]. Also, conventional glass fibres are reasonably anticipated to be a human carcinogen [10] owing to the presence of SiO2 also present in Asbestos which is a known carcinogen. Also, readily available silica fibres aren’t suitable for fibre evanescent wave spectroscopy (FEWS), an important tool to examine the core of a structurally critical composite panel and thereby fail to build in a system to check for absorption of contaminants or chemical degradation indicative of degradation in matrix properties [11]. Thus, chalcogenide glasses are at the centre of active and passive applications such as night vision [12], generation of new infrared sources [13], electronic devices [14], chemical and biological sensors to detect CO2 or tumours respectively [15], etc. They are also promising materials for energy applications, such as solid electrolyte [16] or thermoelectric materials [17].

2.2. Scope as a Substitute for Conventional Glass

- Chalcogenide glass-ceramics transparent in the range 8-12 µm showed a glass-ceramic modulus of rupture increased to as much as twice that of base glass and the Vickers hardness increased by 30% [18]. First chalco-halide glass-ceramics, transparent in the far infrared (10 µm) was obtained in 2003 within the system GeS2-Ga2Se3-CsCl in the “Glass and Ceramic” laboratory in Rennes (France) [19]. The simultaneous presence of ionic and covalent compounds prevent from the rapid and uncontrollable crystallization. Three years later, glass-ceramics transparent until 14µm, covering the second and third atmospheric windows entirely, were synthesized in the system GeS2-Ga2Se3-CsCl [20]. Hence, they are used in electronic appliances for their wide range of dielectric constants and are chosen instead of glasses for their lower dielectric losses [21]. They are also corrosion resistant against weathering and a wide range of chemicals as well as have appreciable Young’s modulus [22].

3. Self-Healing Composites

- The use of functional repair components stored inside hollow reinforcing fibres is being considered as a self-repair system for future composite structures. The incorporation of a self-healing capability within a variety of materials, including fibre reinforced polymers (FRPs), has been investigated [23]. According to the ways of healing, self-healing polymers and polymer composites can be classified into two categories: (i) intrinsic ones that are able to heal cracks by the polymers themselves, and (ii) extrinsic in which healing agent has to be preembedded [24].

3.1. Intrinsic Healing

- Intrinsic self-healing based on physical interactions- Healing process goes through five phases: (i) surface rearrangement, which affects initial diffusion function and topological feature; (ii) surface approach, related to healing patterns; (iii) wetting, (iv) diffusion, the main factor that controls recovery of mechanical properties, and (v) randomization, ensuring disappearance of cracking interface [25]. Thermoplastic/thermosetting semi-interpenetrating network is factually a material associated with repeatable self-healing ability. Upon heating a fractured resin system, the thermoplastic material like poly (bisphenol-A-co- epichlorohydrin), would mobilize and diffuse through the thermosetting matrix e.g. diglycidyl ether of bisphenol-A based resin, with some chains bridging closed cracks and thereby facilitating healing. When this healable resin was compounded with crossply glass fibre, effective healing of composites transverse cracks and delamination has been demonstrated [24].

3.2. Extrinsic Healing

3.2.1. Self-Healing in Terms of Healant Loaded Glass Fibre Pipelines

- The core issue of this technique lies in filling the brittle-walled vessels with polymerizable medium, which should be fluid at least at the healing temperature. Subsequent polymerization of the chemicals flowing to the damage area plays the role of crack elimination. Bioinspired self-healing using hollow fibres embedded within a structure has been investigated at different length-scales in several materials by various authors, e.g. bulk concrete [26, 27], bulk polymers and polymer composites [28]. The latter has seen exciting developments in recent years [23, 29] using the inspiration of biological self-healing applied with broadly traditional engineering approaches.Complete filling of healing agent into the tiny tubes is achieved by vacuum assisted capillary action filling technique. Accordingly, three types of healing system can be developed [26, 27, 28]. (i) Single-part adhesive. All hollow pipettes contained only one kind of resin like epoxy particles (that can be flowable upon heating and then cured by the residual hardener) or cyanoacrylate (that can be consolidated under the induction of air). (ii) Two-part adhesive. In general, epoxy and its curing agent were used in this case. They were filled into neighbouring hollow tubes, respectively. (iii) Two-part adhesive. One component was incorporated into hollow tubes and the other in microcapsules.

3.2.2. Self-Healing In Terms of Healant Loaded Micro-Capsules

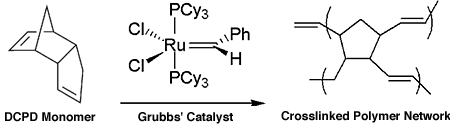

- The principle of this approach resembles the aforesaid pipelines but the containers for storing healing agent are replaced by fragile microcapsules [24]. An intelligent material system using 40% volume fraction unmodified epoxy particles to repair microcracks and delamination damage in a glass/epoxy composite laminate can be made [30]. A two component healant consisting of epoxy-loaded microcapsules as the polymerizable part and 2-methylimidazole/CuBr2 complex (CuBr2(2-MeIm)4) as the latent hardener, which was pre-dispersed in composites’ matrix to fabricate self-healing composites is able to take effect in woven glass fabric/epoxy composite laminates Delamination damage in woven glass/epoxy composites was found to be repaired by the healing agent containing microencapsulated dicyclopentadiene (DCPD) to be released into the crack plane where it comes in contact and mixes with the pre-embedded Grubbs' catalyst [29].

| Figure 1. Ring opening metathesis polymerization of DCPD in healant loaded microcapsules |

4. Glass Fibre Reinforced Concrete

- Glass fibre reinforced concrete consists of high strength glass fibre embedded in a cementitious matrix [31]. It is lighter than natural stone and solid concrete. Modern architecture is increasingly determined by the trend towards organically shape building facades in high quality. This continuously increases the requirements on the construction materials and technologies. The application of non-metallic high performance materials offers the opportunity of lightweight, thin, single- and double-curved elements [32]. The innovative material made of two-dimensional bi-directional warp-knit alkali resistant glass fibre reinforced concrete allows new degrees of freedom in design by increasing the strength as well as improving durability [33]. At present, textile reinforced concrete reaches a tensile strength of up to 45 MPa [34]. A significant amount of research work has been executed to investigate various aspects of the application of fibre reinforcement polymer (FRP) bars with concrete [35]. New hybrid materials containing glass fibre reinforced concrete with aluminoborosilicate glass (E-glass) reinforced polyester resin composite bars have been found to have a bulk density of 1.65 g/cm³ and a tensile strength of 165 MPa [32]. Hence, glass fibre composites have been found to have superior thermal insulation and seismic shear strength [36] thus making them an essential ingredient in modern building materials.

5. Glass Fibre Reinforced Composites in Endodontic Posts

- The fundamental requirements of endodontic posts include high tensile strength, high fatigue resistance to occlusal and shear loading and stress-free distribution of forces affecting the tooth root. Excellent fitting accuracy, biocompatibility and innocuous electrochemical activity are also essential [37]. Unnecessarily weakening the tooth root through increased substance loss should be avoided by selecting a suitable post form [38]. Resin glass fibre post has best properties in elasticity, translucency, adaptability, tenaciousness, and resistance to traction and to impact. Along with ease of application, fibre can be used as an alternative to traditionally used materials in the management of early childhood caries [39]. The quality of Glass Fibre Reinforced Composite endodontic posts varies greatly and the highest quality provides the most even distribution of the fibre in the organic matrix possible with the packing of fibres as dense as possible, a good combination of fibre with the matrix, a high degree of polymerization of the organic components and a homogeneous post structure without blisters or inclusions [40]. Endodontic posts fabricated from glass fibre reinforced composite have favourable biomechanical properties. These posts show lower incidences of root fracture because the fibre reinforced posts has a similar elastic modulus to dentin. However, a major drawback observed was failure due to debonding of the post [41]. The microtensile bond strength (MTBS) of modern dentin bonding systems for intra-coronal cavities has now been shown to reach as high as 40—50 MPa before cohesive fractures in dentin occurred [42]. However, failures of adhesion at the interface between the dentin and adhesives or between the adhesives and the post in the range of 10—15 MPa [43] have been noted. The use of adhesive materials which have similar bond strength to the root canal dentin and to the FRP may offer a possible solution to reduce the contraction gaps and thereby reduce chances of debonding.Prolonging the photo-irradiation time for light-cured dentin bonding systems was found to be effective to improve the bonding strength to root canal dentin. Using chemically cured adhesive materials, where the progress of curing is relatively slow and the slower process of polymerization shrinkage produces less stress, may have an advantage in root canal adhesion, where extremely high stress is generated in the post-space. Dual-cured adhesive materials have been also recommended for use in bonding in root canals. Total-etch resin cement show greater bonding potential than a self-etch or a self-adhesive resin cement when luting the FRP to radicular dentin [44]. Bond strength can also be enhanced by silane coupling agents[45], a combination of silane coupling agents and two-step self etch adhesive[45], sand-blasting and use of a combination of H2O2 etching and silanization.

6. Glass – Ceramic Composites

- Fibre reinforced composites are ideal materials which are used in fuselage, wings, fairings, luggage racks, doors, bulkheads and other secondary structures [46]. Fibre- reinforced glass and glass- ceramic composites constitute a class of materials suitable for applications requiring a combination of lightweight, strength, and toughness at intermediate to elevated temperatures [47]. The mechanical properties of ceramics can be significantly improved in terms of toughness, shock resistance and reliability through the use of fibre reinforcement concept which has led to new class of composite materials referred to as ceramic matrix composites (CMC). The development of glass fibre reinforced ceramic matrix composites is a promising means of achieving light-weight, structural materials combining high temperature strength with improved fracture toughness, damage tolerance and thermal shock resistance [48]. Hence extensive research has been performed in this field and aluminosilicate glass fibres and borosilicate glass fibres have been found as good potential reinforcements for CMC. The processing can be done by simple slurry infiltration for loosely packed fibre weaves [48], Chemical Vapour Infiltration when cost is not a decisive parameter or the more recent and novel Electrophoretic Vapour Deposition (EPD) which is relatively inexpensive and suitable to tightly woven fibre preforms. Some of the ceramic composite forms made by EPD technique [48] include whisker reinforced composites, laminated composites [140], composite coatings, composites with porous layers, functionally graded materials often consisting of nonconductive aluminosilicate glass woven fibre cloth reinforcements in which case EPD is also referred as Electrophoretic Filtration Deposition(EFD) [49].

7. Multi-Wall Carbon Nano Tube (MWCNT) in glass fibre composites

- While composite materials have remarkable properties along the fibre directions, a common shortcoming of FRPs is failure in matrix-rich interlaminar regions where stress transfer between load-bearing fibres is less efficient and neat polymer properties dominate [50]. Even though composites often incorporate approximately 60 volume percent fibres, local matrix-rich regions persist and are of critical concern in commercial applications where failure can cause catastrophic damage [51]. Hybrid composites, which differ from traditional FRPs by the incorporation of nanofillers into the matrix phase, exhibit multi-scale reinforcement leading to increased stiffness, strength and toughness and are often imbued with multifunctionality in the form of enhanced electrical and thermal conductivity or barrier properties depending on the choice of nanoparticle reinforcement. Multi-scale composites can be classified into two types of systems, one system entails independent dispersion of the nanofillers throughout the polymer matrix, resulting in a ‘‘mixed inclusion’’ system through the incorporation of various types of nanoparticles, rubber particles or elastomeric block copolymers [52] or combinations of the above into the matrix. Alternatively, nanofillers can be chemically linked to the fibres, often by growing carbon nanotubes (CNTs) or carbon nanofibres (CNFs) from the fibre surface by chemical vapor deposition prior to infiltration by the polymer matrix, resulting in a hybrid-fibre composite system [53] or catalyzing fibre surfaces and directly attaching loose CNTs on CNFs to the outer surface of parent fibres can achieve the same hybrid fibre effect. The region of CNTs or CNFs on hybrid fibers has been referred to as the ‘‘forest’’ region due to the dense packing, preferential alignment, and similar lengths of the nanoparticles. Upon infiltration and curing of a polymer resin to form a hybrid-fiber composite system, the forest region can act as an anchor to further strengthen the fiber–matrix interface and more efficiently transfer stress, as determined by single-fiber pullout experiments [54] thus overcoming the short comings of traditional glass fibre composite systems.

8. Nanoclay-Glass Fibre Hybrid Composites

- When the influence of nano clay on epoxy/glass fibre hybrid composites was studied, it was observed that a small amount of nanoclay (1%) enhances the tensile strength by 14.8%, flexural strength by 9% and interlaminar shear strength by 25% as nanoclay acts as an interface material between fibre and matrix [55]. The influence of MMT in the matrix of unidirectional glass fibre/epoxy composites has also been recently studied [56]. It was noted that the mechanical and impact properties of such epoxy/glass fibre composites containing nanoclay were improved through hybridization techniques when compared with the neat epoxy matrix composites. Much of the work in this area however has focused on montmorillonite and silica. Now there has been an increased research on organic modified kaolin as a filler to reinforce the mechanical properties and reduce the cost. Fibre-matrix adhesion and dispersion of fibres and thermal stability of Polypropylene-short glass fibre composites can be increased by the addition of organomodified Kaolin [57]. Nanoclay dispersed polymer composites possess high specific stiffness and strength measured in-plane. Such composites can withstand out-of plane low-energy impacts, wear, abrasion and erosion. Glass fibre reinforced composites are used in marine, automotive, aerospace and other structural applications in an erosive environment. For all such applications, nanoclay dispersed glass fibre nanocomposites have developed as a new class of functional composites as incorporation of hard particles in polymer system can provide improved wear resistance [58]. Layered silicate nano fillers have been observed to trigger tremendous mechanical properties.

9. Conclusions

- Glass Fibres have developed as essential reinforcement materials for a host of composite materials and recent developments suggest high potential for varied uses as enhanced erosion resistance, higher tensile strength, impact resistance and other superior mechanical properties can now be imparted in the composites. These composites are suitable for orthopaedic uses and glass fibre composites can be used as smart materials for self-healing properties.

ACKNOWLEDGEMENTS

- The author is grateful to Prof. Dr. Usha Sayed from the Institute of Chemical Technology, Mumbai for the guidance and advice on the subject.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML