-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Materials and Chemistry

p-ISSN: 2166-5346 e-ISSN: 2166-5354

2013; 3(3): 45-50

doi:10.5923/j.ijmc.20130303.01

Some Mechanical Properties of SiC-Treated Recycled HDPE

Ibitoye S. A.1, Adeleke A. A.1, Aramide F. O.2, Olawale J. O.1, Tiamiyu A. O.1, Oluwasegun K. M.1, Abdul-Kareem T. O.1, Shittu M. D.1

1Department of Materials Science and Engineering Obafemi Awolowo University Ile-Ife, Nigeria

2Department of Metallurgical and Materials Engineering Federal Univesity of Technology Akure, Nigeria

Correspondence to: Olawale J. O., Department of Materials Science and Engineering Obafemi Awolowo University Ile-Ife, Nigeria.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

This paper reports the mechanical properties of recycled High Density Polyethylene (reHDPE) blended with silicon carbide (SiC). Composite of SiC-reHDPE were prepared by blending SiC powder with reHDPE in a laboratory-sized mixer (Brabender Plasticorder 350E). Blend ratio of SiC/reHDPE was varied from 0/100, 5/95, 10/90 and 15/85. After mixing, some of the samples were shaped in a compression mould for tensile test specimens while other were extruded to diameter 15 mm rods from which Izod impact test specimens were machined. The prepared samples were then tested for tensile and impact strength. Results obtained show that the addition of SiC to reHDPE gives rise to improved tensile and impact strength, greater modulus of elasticity and increased stiffness. The brittleness however increased and ductility reduced. It was concluded that addition of SiC in the proportion of 5% to 15% improved some mechanical properties of reHDPE.

Keywords: HDPE, Strain, Strength, Stress

Cite this paper: Ibitoye S. A., Adeleke A. A., Aramide F. O., Olawale J. O., Tiamiyu A. O., Oluwasegun K. M., Abdul-Kareem T. O., Shittu M. D., Some Mechanical Properties of SiC-Treated Recycled HDPE, International Journal of Materials and Chemistry, Vol. 3 No. 3, 2013, pp. 45-50. doi: 10.5923/j.ijmc.20130303.01.

Article Outline

1. Introduction

- Although many types of plastics may appear more expensive than some traditional materials, when the overall costs of production and accompanying properties are put into consideration, plastics are usually preferable. For these and other reasons, plastics are widely utilized and accepted among the basic engineering materials[1]. Plastics are generally strong, light, highly dielectric, workable, corrosion and chemical resistant, and durable. In addition, although the absolute mechanical property values of plastics are less than those for metals, the low density of plastics means that their specific properties compare very favourably with other materials[2]. Plastic and plastic-based composites are at the centre of the search for alternative decking materials. Plastics abundance, ease of processing, and ability to mix with a wide variety of fillers along with a reasonable price make it a well suited material to replace pressure treated materials. Also, plastic-based replacement products are claimed to withstand temperature and moisture changes, insects and fungi attacks, and not to crack or splinter[3-5]Polyethylene is made by the polymerization of ethene/ethylene (CH2 = CH2)[6]. The chemical notation for the polymerization of ethylene indicates a simple reaction:

| (1) |

2. Experimental Method

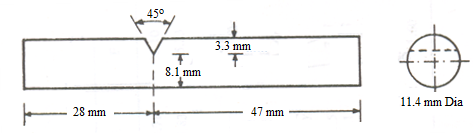

- Materials used were reHDPE granules obtained from post-consumer packaging materials with melt flow index 0.88 g/10 min, density 0.96 g/cm3 and thermal conductivity 0.505 W/m·K; and SiC powder with the maximum particle dimension of 100 μm. The composite of SiC-reHDPE were prepared by blending SiC powder with reHDPE in a laboratory-sized mixer (Brabender Plasticorder 350E). Blend ratio of SiC/reHDPE was varied from 0/100, 5/95, 10/90 and 15/85. The mixing conditions were set as follows: fill factor = 0.8, intial chamber temperature = 130˚C, rotor speed = 40 rpm and mixing time = 15 min. After mixing, some of the samples were shaped in a compression mould that has the shape of tensile test specimen shown in Figure 1 at 160˚C. The resulting composites were preheated in the mould for 4 min, then pressed for 5 min and finally cooled down. Necessary finishing was made and the samples were tested for tensile properties using Monsanto Tensometer machine.The remaining samples after mixing were extruded to diameter 15 mm rods from which impact test samples were machined. The impact test samples were prepared according to Izod specimen (Figure 2). The Izod specimen has a round cross-section with a V-shaped notch. The depth of the notch is 3.3 mm and included angle is 45˚.

| Figure 2. Notched Izod specimen |

3. Results and Discussion

3.1. Results

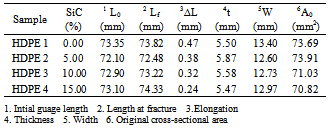

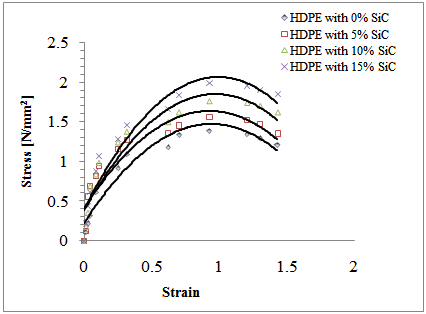

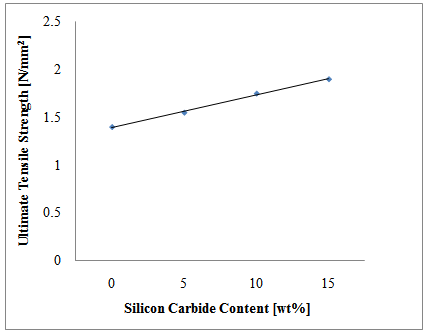

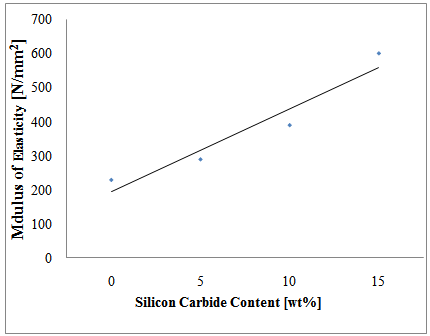

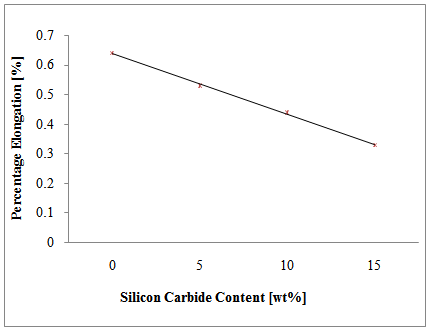

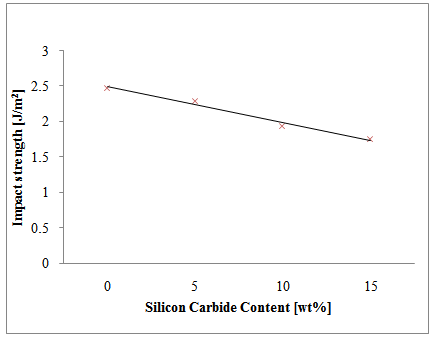

- The average of three readings for various parameters taken during the tensile tests for the prepared samples are presented in Table 1, the stress – strain relationships are presented in Figure 3. The changes in UTS and modulus of elasticity with changes in SiC content are presented in Figures 4 and 5 respectively while the percentage elongation and impact strength results are presented in Figures 6 and 7 respectively.

3.2. Discussion of Results

- Plastic is preferable in recycling process as it uses less energy and fewer resources. However, as earlier mentioned, recycling causes deterioration of polymer mechanical properties resulting into products of lower quality and less valuable[11]. This is also evident from the various tensile and ductility test obtained (Figures 3 – 7). In all cases the reHDPE to which nothing was added (with zero per cent SiC) shows inferior properties.

|

| Figure 3. Stress-strain curve for recycled HDPE containing different SiC content |

| Figure 4. Changes in ultimate tensile strength with increasing SiC content |

| Figure 5. Changes in modulus of elasticity of recycled HDPE wih increasing SiC content |

| Figure 6. Changes in percentage elongation with increase in the SiC content |

| Figure 7. Changes in Impact strength with increase in the SiC content |

4. Conclusions

- The addition of SiC to reHDPE at ambient temperature improves its tensile strength while its ductility and impact strength decreases. The increase in strength arises as the SiC content in the reHDPE increases. The ductility and energy absorption capacity of the material however decreases as the SiC content increases. The treated recycled HDPE are said to be strong and stiff plastics the extent of which depends on the quantity of SiC in the HDPE matrix. It can also be inferred that the prepared reHDPE reinforced with SiC is a suitable engineering material for application where high strength and stiffness are required.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML