Le Dai Vuong, Phan Dinh Gio, Truong Van Chuong, Dung Thi Hoai Trang, Duong Viet Hung, Nguyen Trung Du

Department of Physics, College of Sciences, Hue University, 77 Nguyen Hue street, Hue city, Vietnam

Correspondence to: Le Dai Vuong, Department of Physics, College of Sciences, Hue University, 77 Nguyen Hue street, Hue city, Vietnam.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Abstract

Low-temperature sintering of 0.8Pb(ZrxTi1-x)]O3 – 0.125Pb(Zn1/3Nb2/3)O3 – 0.075Pb(Mn1/3Nb2/3)O3 + 0.7 % wt Li2CO3 (PZT-PZN-PMnN) ceramics was prepared by using Li2CO3 as the sintering aid. Their structure and physical properties were investigated according to the Zr/Ti ratio content. From X-ray diffraction patterns showed that samples formed a phase perovskite structure without secondary phases. The electromechanical coupling factor (kp), the maximum dielectric constant (εmax), the piezoelectric constant (d31) and the mechanical quality factor (Qm) increased with the increase of Zr/Ti ratio content and reaches to the highest value at the ratio content of Zr/Ti = 48/52. At this ratio content, the ceramic has the optimal electromechanical properties: the εmax = 19500, the kp = 0.62, the d31 = 140 pC/N and the Qm = 1112.

Keywords:

Crystal Structure, Dielectrics, Piezoelectrics, Electromechanical Coupling Factor

Cite this paper: Le Dai Vuong, Phan Dinh Gio, Truong Van Chuong, Dung Thi Hoai Trang, Duong Viet Hung, Nguyen Trung Du, Effect of Zr/Ti Ratio Content on Some Physical Properties of Low Temperature Sintering PZT−PZN−PMnN Ceramics, International Journal of Materials and Chemistry, Vol. 3 No. 2, 2013, pp. 39-43. doi: 10.5923/j.ijmc.20130302.04.

1. Introduction

take extreme values when Zr/Ti ratio corresponds to the composition of the MPB which separates the tetragonal (T) and rhombohedral (R) phases towards Ti-rich and Zr-rich sides, respectively[3,4]. Rangson Muanghlua et al.[5]. studied the effect of Zr/Ti ratio on the structure and ferroelectric properties of0.07Pb(Mn1/3Nb2/3)O3-0.6Pb(Ni1/3Nb2/3)O3-0.87Pb(ZrxTi1-x)O3 ceramics. From XRD analysis and ferroelectric properties measurements indicated the existence of the MPB composition between x = 0.50. At this composition, the ceramics exhibits the highest ferroelectric properties. Yoo and Lee[6] also reported that the PZT-PNN-PMnN ceramics were strongly influence by the Zr/Ti ratio. They found that the electromechanical coupling factor kp, the piezoelectric constant d33 and the mechanical quality factor Qm increased with the increase of Zr/Ti ratio and then decreased after the ratio exceeded 50/50. Recently, Fares Kahoul et al.[7] studied the structure and electrical properties of Pb0.98Sm0.02[(Zrx,Ti1-x)0.98 (Fe1/2Nb1/2)0.02]O3 ceramics with the composition near the MPB. They found that the kp, d31 and Qm of the ceramics are enhanced with the increase of Zr/Ti ratio. At Zr/Ti ratio of 55/45, the ceramics has the optimal electromechanical properties, kp = 0.631, d31 = 120.10-12C/N, Qm = 462. The research results of the above authors clearly showed the significance of Zr/Ti ratio in controlling the electromechanical properties of the PZT-based ceramics. In this paper, we investigated the effect of Zr/Ti ratio content on some physical properties of the low temperature sintering PZT-PZN-PMnN ceramics.

2. Experimental Procedure

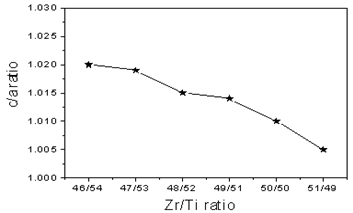

The general formula of the material was 0.8Pb(ZrxTi1-x)O3 – 0.125Pb(Zn1/3Nb2/3)O3 – 0.075Pb(Mn1/3Nb2/3)O3 + 0.7 wt% Li2CO3, where x is 0.46, 0.47, 0.48, 0.49, 0.50 and 0.51. They are denoted by M46, M47, M48, M49, M50 and M51, respectively. The raw materials including powders (purity of 99%) of ZrO2, TiO2, Nb2O5, ZnO and MnO2 for the given composition were weighted by mole ratio and the powders were mixed and milled (the PM 400/2 milling machine) for 8 h using ziconia balls and ethanol as the medium, then were calcined. Thereafter, PbO was added and milled again. Powders were calcined at 850oC for 2 h, then the sintering aid, Li2CO3 was added[8] and milled again for 16h. The ground materials were pressed into disk 12mm in diameter and 1.5mm in thickness under 100 MPa. The samples were sintered in a sealed alumina crucible with PbZrO3 coated powder at temperature 950oC for 2h.The crystalline phase was analyzed using an X-ray diffactometer (XRD, D8 ADVANCE). The microstructure of the samples was examined by using a scanning electron microscope (SEM). The density of samples was measured by Archimedes method. The samples were poled in a silicone oil bath at 120oC by applying 30 kVcm−1 for 20 min, then cooled at this electric field. They were aged for 24h prior to testing. The piezoelectric properties were determined by the resonance and antiresonance technique using an impedance analyzer (Agilent 4396B and RLC HIOKI 3532). The calculation equations are as follows:  where fs and fp are resonant and antiresonant frequencies (Hz), and Zmin and Cs are resonant impedance (ohms) and electrical capacitance (farads). The dielectric properties were measured by RLC HIOKI 3532.

where fs and fp are resonant and antiresonant frequencies (Hz), and Zmin and Cs are resonant impedance (ohms) and electrical capacitance (farads). The dielectric properties were measured by RLC HIOKI 3532.

3. Results and Discussion

3.1. Phase Analysis and Microstructure

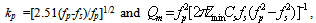

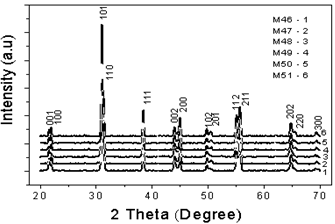

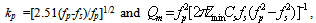

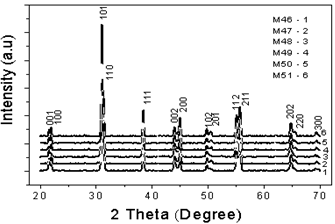

Figure. 1 shows X-ray diffraction patterns (XRD) of the PZT–PZN–PMnN ceramics with the variation of Zr/Ti ratio content. All the samples showed a tetragonal perovskite phase without any secondary phase. The lattice parameters for various compositions were calculated using the least square method from the double (002) and (200) peaks of tetragonal structure and results for the tetragonality c/a of perovskite phase are shown in Figure 2. The c/a ratio decreases with increasing Zr/Ti ratio content, indicating that the tetragonality of PZT-PZN-PMnN ceramics decreased when Zr increased. | Figure 1. X-ray diffraction patterns of the ceramics with different Zr/Ti ratio contents |

| Figure 2. The tetragonality c/a of the ceramics as a function of Zr/Ti ratio |

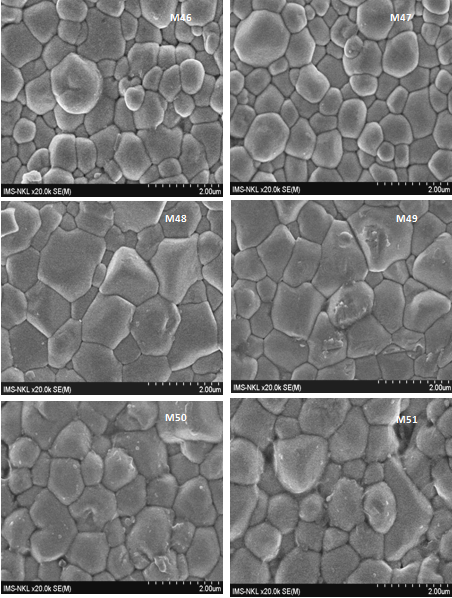

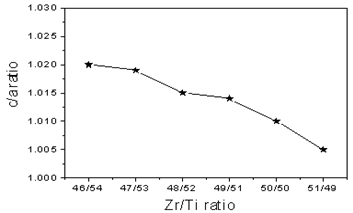

| Figure 3. Microstructures of samples with the different Zr/Ti ratio contents |

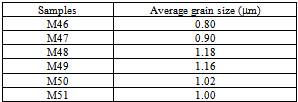

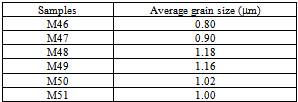

Figure 3 shows the SEM image of the fractured surface of PZT–PZN–PMnN ceramics at different Zr/Ti ratio contents. It is observed from the micrographs that the average grain size of samples are increased with the increasing amount of Zr/Ti ratio (Table 1). It is explained that the initial and intermediate stages of sintering, densification and grain growth occur through liquid-phase diffusion (Li2CO3)[8], and then the liquid phase at the intergranular boundaries gradually dissolves into the grains with grain growth[9,10]. However, figure 3 also shows that further increasing the Zr/Ti content to 51/49 gives rise to an abnormal grain boundary, and the average grain size is reduced.Table 1. The average grain size of ceramic samples

|

| |

|

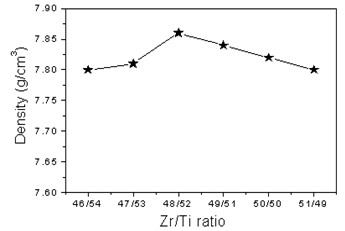

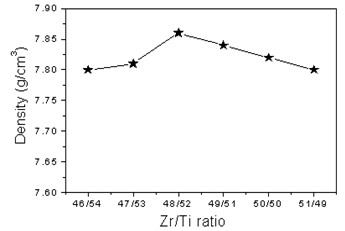

3.2. The Ceramic Density

The densities of the samples containing different amounts of Zr/Ti ratio were measured, and the results are shown in Figure 4. As seen, the densities of the ceramics are in the range from 7.80g/cm3 to 7.86g/cm3 (94-97 % theoretical density) and dependent on Zr/Ti ratio content. When Zr/Ti ratio content increases, the density of samples increases and achieves the highest value (7.86g/cm3) at the ratio of Zr/Ti = 48/52, and then decreases. This may be explained from microstructures of ceramic samples. When the amount of Zr/Ti ratio increased, the ceramic samples became more dense, and at Zr/Ti = 48/52, the ceramic sample was almost fully dense (fig. 3). When the further increasing the Zr/Ti ratio content to 49/51 and above, a large number of pores were present, giving rise to an abnormal grain boundary. Hence, the densities of the ceramics are decreased. The variation in density of the ceramic samples is in good accordance with the microstructure.  | Figure 4. The density of PZT-PZN-PMnN samples as a function of the Zr/Ti content |

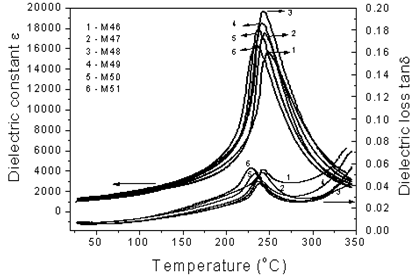

3.3. Dielectric Properties

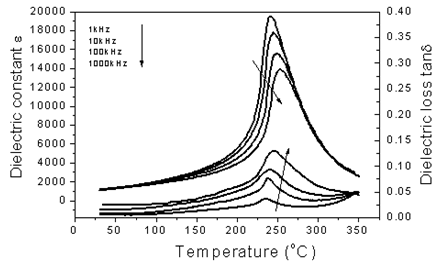

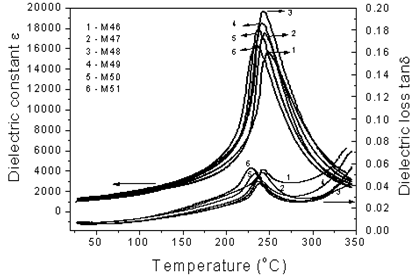

The change of Zr/Ti content also significantly affects the piezoelectric and dielectric properties of PZT–PZN–PMnN ceramics. Figure 5 shows the dependence of dielectric constant ε and dielectric loss tanδ of the ceramic on temperature at 1 kHz. As observed, the dielectric properties exhibited characteristics of a relaxor material in which the phase transition temperature occurs within a broad temperature range. This is one of the characteristics of ferroelectrics with disordered perovskite structure. The maximum dielectric constant εmax increases with increasing Zr/Ti ratio content, and at Zr/Ti = 48/52, the highest dielectric constant εmax of about 19500 and then sharply decreases beyond this point. This can be explained by the increase of grain size effect[10]. The dielectric loss tanδ shows the reversed trend, this appropriate to the characteristics of dielectrics[11].  | Figure 5. Temperature dependence of the dielectric constant and dielectric loss tanδ at 1 kHz of ceramic |

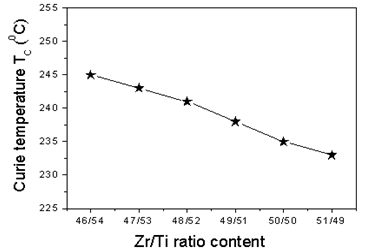

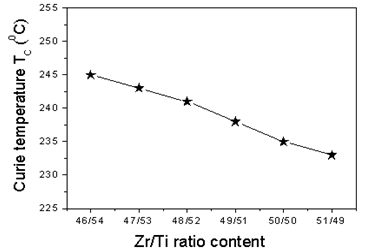

In Figure 6, the change of Curie temperature TC with the Zr/Ti ratio is shown. With the increase in Zr amount, the Curie temperature decreases because the Curie temperature of PbZrO3 is about 232oC and it is lower than that of PbTiO3, 490oC[11,12]. | Figure 6. The Curie temperature TC of PZT-PZN- PMnN ceramics with different amounts of Zr/Ti ratio |

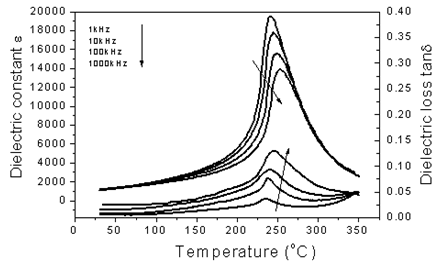

Figure 7 shows the temperature dependence of the dielectric constant ε and dielectric loss tanδ of the M48 sample measured at frequency of 1kHz, 10kHz, 100kHz and 1MHz, respectively. It show that the shape of the ε peaks was broad, which is typical of a case diffuse transition with frequency dispersion. When the measured frequency increased, the maximum of εmax was decreased and shifted to higher temperature while dielectric loss increased near the Curie point, which is typical of a relaxor material[13].  | Figure 7. Temperature dependence of relative dielectric constant ε and dielectric loss tanδ of M48 sample at different frequencies |

3.4. Piezoelectric Properties

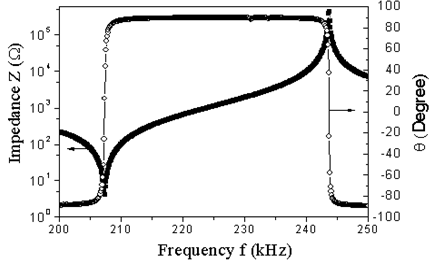

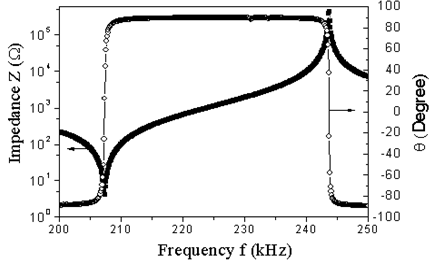

To determine piezoelectric property of ceramics, resonant vibration spectrum of samples were measured at room temperature in Figure 8. | Figure 8. Spectrum of radial resonance of M48 sample |

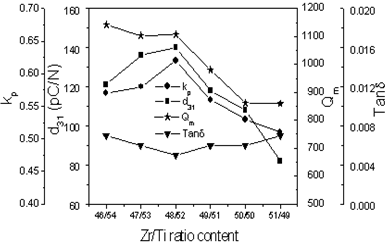

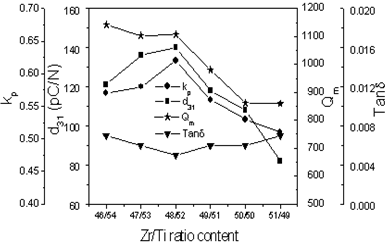

From these resonant spectra, electromechanical coefficients kp, piezoelectric coefficients d31, mechanical quality factor Qm and dielectric loss tanδ were determined. Figure 9 shows the changing in the electromechanical coupling factor (kp), the piezoelectric constant (d31), mechanical quality factor Qm and dielectric loss tanδ as a function of the amount of Zr/Ti ratio. As can be seen, both kp and d31 show a similar variation with increasing Zr/Ti ratio content. When the amount of Zr/Ti ratio is lower than 48/52, the kp and the d31 are rapidly increased with increasing Zr/Ti ratio content, while the mechanical quality factor Qm and the dielectric loss tanδ are desreased. The optimized values for kp of 0.62, d31 of 140.10-12C/N, Qm of 1112 and tanδ of 0.005 were obtained at Zr/Ti = 48/52. This is probably related to characteristics of the increasing grain size. As well known, the increased grain size makes domain reorientation easier and severely promotes domain wall motion, which could increase the piezoelectric properties[13]. However, the further increasing of Zr/Ti ratio content gives rise to an abnormal grain boundary and the average grain size is also reduced as shown in Fig. 3. Therefore, electrical properties of PZT-PZN-PMnN ceramics are reduced. | Figure 9. The values of kp, d31, Qm, and tanδ of the PZT-PZN-PMnN ceramic samples |

4. Conclusions

We have investigated some physical properties of the low temperature sintering 0.8Pb(ZrxTi1-x)O3 – 0.125Pb(Zn1/3Nb2/3)O3 – 0.075(Mn1/3Nb2/3)O3 + 0.7 wt% Li2CO3 ceramics. Results of this study are summarized as follows:- All the specimens displayed a tetragonal perovskite structure without secondary phase. With increasing the Zr/Ti ratio content, the tetragonality c/a was decreased. - At the Zr/Ti ratio content of 48/52 and sintering temperature (Ts) of 950oC, the density, the electromechanical coupling factor kp, the dielectric constant εmax, the piezoelectric constant d31, the dielectric loss tanδ and the mechanical quality factor Qm showed the optimum values of 7.86g/cm3, 0.62, 19500, 140 pC/N, 0.005 and 1112, respectively. Therefore, they are a promising candidate material used in high power piezoelectric devices.

References

| [1] | Smolenskii. G. A., V. A. Isupov and A. I. Agranovskaya New ferroelectrics of complex composition of the type A22+(BI3+,BII5+)O6 . I. Sov. Phys.Solid State, 1, 1959 150-151. |

| [2] | F. Gao., L. Cheng, Hong R., J. Liu, C. Wang and C. Tian, Crystal structure and piezoelectric properties of xPb(Mn1/3Nb2/3)O3–(0.2 − x)Pb(Zn1/3Nb2/3)O3–0.8Pb(Zr0.52Ti0.48)O3 ceramic, Ceramics International 35, 2009, 1719–1723. |

| [3] | H. Kang S., C. W. Ahn, H. J. Lee & I. W. Kim, E. C. Park & J. S. Lee, Dielectric and pyroelectric properties of Li2CO3 doped 0.2Pb(Mg1/3Nb2/3)O3 – 0.5Pb(Zr0.48Ti0.52)O3–0.3Pb(Fe1/3Nb2/3)O3 ceramics, J Electroceram 21, 2008, 855–858. |

| [4] | Yuhuan Xu, Ferroelctric Materials and Their Applications (North-Holland, Amsterdam- London- Newyork-Tokyo), 1991. |

| [5] | R. Muanghlua, S. Niemchareon, W. C. Vittayakorn and N. Vittayakorn, Effects of Zr/Ti Ratio on the Structure and Ferroelectric Properties in PZT-PZN-PMN Ceramics Near the Morphotropic Phase Boundary, Advanced Materials Research 55-57, 2008, 125-128. |

| [6] | J. Yoo and S. Lee, Piezoelectric and Dielectric Properties of Low Temperature Sintered Pb(Mn1/3Nb2/3)0.02 (Ni1/3Nb2/3)0.12 (ZrxTi1-x)0.86O3 System Ceramics Transactions on electrical and electronic materials 10, 2009, 121-125. |

| [7] | K. Fares, H. Louanes, A. Nora and B. Ahmed, Synthesis and Piezoelectric Properties of Pb0.98Sm0.02[(Zrx,Ti1-x)0.98 (Fe1/2Nb1/2)0.02]O3 ceramics, Materials Sciences and Applications 3, 2012, 50-58. |

| [8] | Hou Y. D., Chang L. M., Zhu M. K., Song X. M. and Yan H. 2007 Effect of Li2CO3 addition on the dielectric and piezoelectric responses in the low-temperature sintered 0.5PZN–0.5PZT systems Journal of applied physics 102, 084507. |

| [9] | X. Chao, Z. Yang, C. Kang, Y. Chang, Effects of BiFeO3 addition on electrical properties and temperature stability of low temperature sintered PZT–PFW–PMN ceramics, Sensors and Actuators A 141, 2008, 482–488. |

| [10] | Lee J. S., Choi M. S., Nguyen V. H. Kim Y. S, Kim I. W., Park E. C., Jeong S. J., Song J. S., Effects of high energy ball-milling on the sintering behavior and piezoelectric properties of PZT-based ceramics, Ceramics International 33, 2007, 1283–1286. |

| [11] | Phan Dinh Gio, Vo Duy Dan, Some dielectric, ferroelectric, piezoelectric properties of0.35Pb(Zn1/3Nb2/3)O3-0.65Pb(ZrxTi1-x)]O3 ceramics, Journal of Alloys and Compounds, vol. 449, 1-2, 24-27. |

| [12] | J. Yoo, Y. Lee, K. Yoon, S. Hwang, S. Suh, J. Kim and C. Yoo, Microstructural, Electrical Properties and Temperature Stability of Resonant Frequency inPb(Ni1/2W1/2)O3–Pb(Mn1/3Nb2/3)O3–Pb(Zr,Ti)O3 Ceramics for High-Power Piezoelectric Transformer, Jpn. J. Appl. Phys 40, 2001, 3256–3259. |

| [13] | C.H. Wang, S.J. Chang, P.C. Chang, Effect of sintering conditions on characteristics ofPbTiO3–PbZrO3–Pb(Mg1/3Nb2/3)O3–Pb(Zn1/3Nb2/3)O3, Materials Science and Engineering B 111, 2004, 124–130 |

| [14] | Y. D. Hou, M. K. Zhua, C. S. Tian, H. Yan, Structure and electrical properties of PMZN–PZT quaternary ceramics for piezoelectric transformers, Sensors and Actuators A 116, 2004, 455–460. |

where fs and fp are resonant and antiresonant frequencies (Hz), and Zmin and Cs are resonant impedance (ohms) and electrical capacitance (farads). The dielectric properties were measured by RLC HIOKI 3532.

where fs and fp are resonant and antiresonant frequencies (Hz), and Zmin and Cs are resonant impedance (ohms) and electrical capacitance (farads). The dielectric properties were measured by RLC HIOKI 3532.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML