| [1] | S. Thomas, R. Stephen, “Rubber Nanocomposites Preparation, Properties and Applications”, Wiley, Singapore, 2010 |

| [2] | P. M. Ajayan, “Single-walled carbon nanotube-polymer composites: Strength and weakness”, Advanced Materials, Vol. 12, No.10, pp. 750–753, 2000 |

| [3] | E. T. Thostenson, “Advances in the science and technology of carbon nanotubes and their composites: a review”, Composites Science and Technology, Vol. 61, No. 13, pp. 1899–1912, 2001 |

| [4] | A. Krueger, “Carbon Materials and Nanotechnology”, Wiley-VCH, Verlag GmbH& Co. KGaA, 2010 |

| [5] | K. S. Novoselov, “Electric Field Effect in Atomically Thin Carbon Films", Science, Vol. 306, No 5696, pp. 666-669, 2004 |

| [6] | H. J. Salavagione, G. Martínez , G. Ellis, “Graphene-Based Polymer Nanocomposites” in Sergey Mikhailov , Ed., Physics and Applications of Graphene – Experiments, InTech, pp. 169-192, 2011 |

| [7] | M. J. Allen, V. C. Tung and R. B. Kaner, “Honeycomb carbon: A Review of Graphene”, Chem. Rev., Vol. 110, No. 1, pp. 132–145, 2010 |

| [8] | Y. Zhu, S. Murali, W. Cai, X. Li, J. W. Suk, J. R. Potts, R. S. Ruoff, “Graphene and Graphene Oxide: Synthesis, Properties, and Applications”, Adv. Mater., Vol. 22, No. 35, pp. 1–19, 2010 |

| [9] | O. C. Compton, S. T. Nguyen, “Graphene Oxide, Highly Reduced Graphene Oxide, and Graphene: Versatile Building Blocks for Carbon-Based Materials”, Small, Vol. 6, No. 6, pp. 711–723, 2010 |

| [10] | P. Mukhopadhyay, R. K. Gupta, “Trend and Frontiers in Graphene-Based Polymer Nanocomposites”, Plastics Engineering, pp.32-42, 2011, www.4spe.org |

| [11] | R. K. Prud’Homme, B. Ozbas, I. Aksay, R. Register, D. Adamson – U.S. Patent 7,745,528 June 29, 2010 |

| [12] | S. Pacchini, T. Idda, D. Dubuc, E. Flahaut, K. Grenier, “Carbon nanotube-based polymer composites for microwave applications”, Microwave Symposium Digest, IEEE MTT-S International, Conference Publications, pp. 101 – 104, 2008 |

| [13] | D. Micheli, R. Pastore, C. Apollo, M. Marchetti, G. Gradoni, F. Moglie, V.M. Primiani, “Carbon based nanomaterial composites in RAM and microwave shielding applications”, Nanotechnology, IEEE-NANO 2009. 9th IEEE Conference on, Conference Publications, pp.226-235, 2009 |

| [14] | A. Saib, L. Bednarz, R. Daussin, C. Bailly, Xudong Lou, J.-M. Thomassin, C. Pagnoulle, C. Detrembleur, R. Jerome, I. Huynen, “Carbon nanotube composites for broadband microwave absorbing materials”, Microwave Theory and Techniques, IEEE Transactions on, Vol. 54, No. 6, pp. 2745 – 2754, 2006 |

| [15] | Y. Zhai, Y. Zhang, W. Ren, “Electromagnetic characteristic and microwave absorbing performance of different carbon-based hydrogenated acrylonitrile – butadiene rubber composites”, Materials Chemistry and Physics, Vol. 133, No. 1, pp. 176–181, 2012 |

| [16] | Z. Liu, G. Bai, Yi Huang, F. Li, Y. Ma, T. Guo, X. He, X. Lin, H. Gao, and Y. Chen, “Microwave Absorption of Single-Walled Carbon Nanotubes/Soluble Cross-Linked Polyurethane Composites”, J. Phys. Chem. C, Vol. 111, 13696-13700, 2007 |

| [17] | Y. Xu, D. Zhang, J. Cai, L. Yuan and W. Zhang, “Effects of Multi-walled Carbon Nanotubes on the Electromagnetic Absorbing Characteristics of Composites Filled with Carbonyl Iron Particles”, J. Mater. Sci. Technol., Vol. 28, No. 1, pp. 34-40, 2012 |

| [18] | H. Li , J. Wang, Y. Huang, X. Yan, J. Qi, J. Liu, Y. Zhang, “Microwave absorption properties of carbon nanotubes and tetrapod-shaped ZnO nanostructures composites”, Materials Science and Engineering B Vol.175, pp. 81–85, 2010 |

| [19] | L. Liu, L. B. Kong, W. Y. Yin, Y. Chen and S. Matitsine, “Microwave Dielectric Properties of Carbon Nanotube Composites”, in J.M.Marulanda, Ed., Carbon Nanotubes, InTech, pp. 93-108, 2010 |

| [20] | H.Y. Zhang, G.X. Zeng, Y. Ge, T.L. Chen and L.C.Hu: “Electromagnetic characteristic and microwave absorption properties of carbon nanotubes/epoxy composites in the frequency range from 2 to 6 GHz” J. Appl. Phys., Vol. 105, No. 5, 054314, 2009 |

| [21] | Z.F. Liu, G. Bai, Y. Huang, Y.F. Ma, F. Du, F.F. Li, T.Y. Guo and Y.S. Chen, “Reflection and absorption contributions to the electromagnetic interference shielding of single-walled carbon nanotube/polyurethane composites”, Carbon, Vol. 45, No. 4, pp. 821-827, 2007 |

| [22] | S. Gunasekaran, R.K. Natarajan, A. Kala and R. Jagannathan, “Dielectric studies of some rubber materials at microwave frequencies”, Indian Journal of Pure&Applied Physics, Vol. 46, pp. 733-737, 2008 |

| [23] | A.M. Shanmugharaj, J.H. Bae, Kwang Yong Lee, Woo Hyun Noh, Se Hyoung Lee, Sung Hun Ryu, “Physical and chemical characteristics of multiwalled carbon nanotubes functionalized with aminosilane and its influence on the properties of natural rubber composites”, Composites Science and Technology, Vol. 67, pp. 1813–1822, 2007 |

| [24] | G. Sui, W. Zhong, X. Yang, and S. Zhao, “Processing and material characteristics of a carbon-nanotube-reinforced natural rubber”, Macromolecular Materials and Engineering, Vol. 292, No.9, pp.1020–1026, 2007 |

| [25] | M. Kolodziej, L. Bokobza, and J.L. Bruneel, “Investigations on natural rubber filled with multiwall carbon nanotubes”, Composite Interfaces, Vol.14, No.3, pp. 215–228, 2007 |

| [26] | J. Liang, Y. Huang, Y. Ma, Z. Liu, J. Cai, Ch. Zhang, H. Gao, Y. Chen, “Electromagnetic interference shielding of graphene/epoxy composites”, Carbon, Vol. 47, No. 3, pp. 922–925, 2009 |

| [27] | I. M. De Rosa, F. Sarasini, M. S. Sarto, A. Tamburrano, “EMC impact of advanced carbon fiber/carbon nanotube reinforced composites for next generation aerospace applications”, IEEE Trans. on EMC, Special Issue “EMC in Aerospace”, Vol. 50, No. 3, pp. 556-563, 2008 |

| [28] | I. M. De Rosa, R. Mancinelli, F. Sarasini, M. S. Sarto, A. Tamburrano, “ Electromagnetic Design and Realization of Innovative Fiber-Reinforced Broad-Band Absorbing Screens”, IEEE Trans. on Electromagnetic Compatibility, Vol. 51, No. 3, pp. 700 – 707, 2009 |

| [29] | I. M. De Rosa, A. Dinescu, F. Sarasini, M. S. Sarto, A. Tamburrano, “Effect of short carbon fibers and MWCNTs on microwave absorbing properties of polyester composites containing nickel-coated carbon fibers”, Composites Science and Technology, Vol. 70, No. 1, pp. 102-109, 2010 |

| [30] | G. De Bellis, I. M. De Rosa, A. Dinescu, M. S. Sarto, A. Tamburrano, “Electromagnetic Absorbing Nanocomposites Including Carbon Fibers, Nanotubes and Graphene Nanoplatelets”, Proceedings of the 2010 IEEE International Symposium on Electromagnetic Compatibility, pp. 202-207, 2010 |

| [31] | C.R. Paul, “Introduction to Electromagnetic Compatibility”, John Wiley & Sons, New York, 1992 |

| [32] | B. Meng, J. Booske, and R. Cooper, “Extended cavity perturbation technique to determine the complex permittivity of the dielectric materials”, IEEE T. Microw. Theory Tech., Vol. 43, pp. 2633–2636, 1995 |

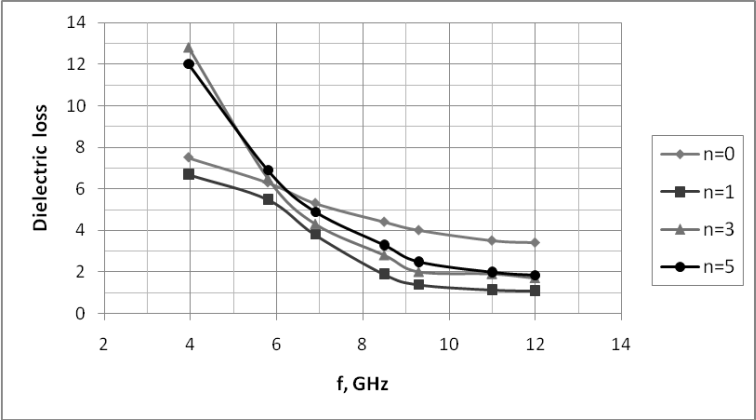

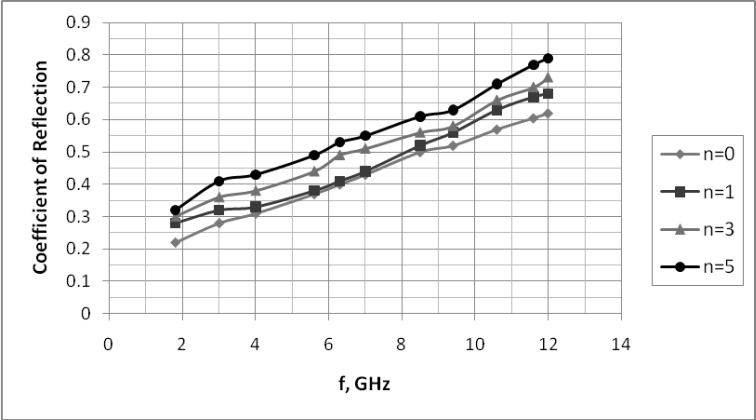

| [33] | O. A. Al-Hartomy, A. Al-Ghamdi, N. Dishovsky, R. Shtarkova, V. Iliev, I. Mutlay, F. El-Tantawy, ”Dielectric and Microwave Properties of Natural Rubber Based Nanocomposites Containing Graphene”, Materials Sciences and Applications, Vol. 3, 2012, Published Online July 2012 (http://www.SciRP.org/journal/msa) |

| [34] | Y. Li, J. Zhu, S. Wei, J. Ryu, Q. Wang, L. Sun and Z. Guo, “Poly(propylene) Nanocomposites Containing Various Carbon Nanostructures”, Macromol. Chem.Phys., Vol. 212, No. 22, pp. 2429-2438, 2011 |

| [35] | I. Balberg , “A comprehensive picture of the electrical phenomena in carbon black–polymer composites”, Carbon , Vol. 40, No. 2, pp.139-143, 2002 |

| [36] | N. Dishovsky, “Rubber Based Composites with active Behaviour to Microwaves” (Review),Journal of the University of Chemical Technology and Metallurgy, Vol. 44, No. 2, pp.115- 122, 2009 |

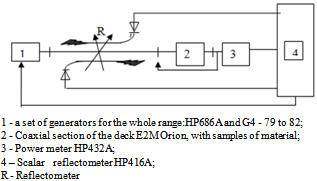

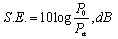

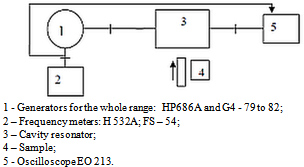

. The internal diameter depended on the relative dielectric permittivity of the material.The sample reflected a part of the incident electromagnetic wave with power Pin. The rest of the wave with power Pp penetrated the material, so that the attenuation L depended on the coefficient of reflection |Г|. Its module was determined by a reflect meter. Thus the attenuation was determined by

. The internal diameter depended on the relative dielectric permittivity of the material.The sample reflected a part of the incident electromagnetic wave with power Pin. The rest of the wave with power Pp penetrated the material, so that the attenuation L depended on the coefficient of reflection |Г|. Its module was determined by a reflect meter. Thus the attenuation was determined by

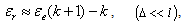

and l is the distance from the disc to the top of the resonator.

and l is the distance from the disc to the top of the resonator.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML