-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Internet of Things

2017; 6(3): 106-148

doi:10.5923/j.ijit.20170603.03

IoT Applications in Future Foreseen Guided by Engineered Nanomaterials and Printed Intelligence Technologies a Technology Review

G. K. Moinudeen1, F. Ahmad2, D. Kumar3, Y. Al-Douri4, 5, S. Ahmad3

1CII, Gurgaon, Haryana, India

2IRIS Worldwide Integrated Marketing, Gurgaon, Haryana, India

3YMCA University of Science and Technology, Faridabad, Haryana, India

4Nanotechnology and Catalysis Research Centre (NANOCAT), University of Malaya, Kuala Lumpur, Malaysia

5Physics Department, Faculty of Science, University of Sidi-Bel-Abbes, Algeria

Correspondence to: S. Ahmad, YMCA University of Science and Technology, Faridabad, Haryana, India.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The impact of ‘engineered-nanomaterials’ in cost effective fabrication of micro/nanosensors, and on site energy harvesting devices using ‘printing technology’ for Internet of things (IoT) applications has been assessed in this technology review after analyzing the ongoing progresses reflected in market research forecasts and the anticipated future projections.Being actively involved in the study of ‘engineered nanomaterials’ using inorganic, organic, and biomolecular building-blocks for improving the characteristics of microelectronic/microsystems (MEMS/NEMS) based sensors/actuators, theoretical/experimental studies of 1, 2, and 3D nanomaterials along with the developments of low-cost printing technology for fabricating the electronic/optoelectronic devices and circuits on plastics, paper, and textiles, an attempt has been made in this review to examine the impact of these novel nanomaterials and their printing technology to enhance the capabilities of the related enabling technologies of IoT applications. Novel designs of supra molecular nano-building-blocks to realize hierarchically organized molecular complexes responding to single/multi stimuli with additional electronic intelligence realized by low-cost printing of sensors and actuators along with the wireless connectivity on flexible substrates in the background, possible answer for meeting the gigantic requirement of trillion devices by 2020 has been searched in this study. Combining the cost effective printing of active devices using polymeric molecules with known electronic/optoelectronic transport properties and 2D-layered materials like graphene and other graphene like materials, is found promising to pursue by addressing to the problems of compatible patterning for devices/circuits fabrications. A number of practical issues are discussed in which the basic concept of ‘materials by design’ is foreseen to play a major role in the coming times. Biomimetically produced supra molecular-complexes deserve special attentions for realizing printed sensors/actuators/devices and interfaces to generate big-data for cloud based decisions initiating local control actions better in IoT proliferations in future.

Keywords: Internet of Things (IoT), Sensors, Nanomaterials by design, Printed intelligence, Biomimetic Material synthesis

Cite this paper: G. K. Moinudeen, F. Ahmad, D. Kumar, Y. Al-Douri, S. Ahmad, IoT Applications in Future Foreseen Guided by Engineered Nanomaterials and Printed Intelligence Technologies a Technology Review, International Journal of Internet of Things, Vol. 6 No. 3, 2017, pp. 106-148. doi: 10.5923/j.ijit.20170603.03.

Article Outline

1. Introduction

- The syntheses of nanomaterials using novel paradigm of ‘materials by design’ involving inorganic, organic/polymeric, and biomolecular building blocks that are chemically conjugated through strong and weak interactions have already started showing ‘smart’ and ‘intelligent’ functionalities in form of proof of concept [1, 2]. Further extensions of the capabilities of these nano building blocks are anticipated in preparing supramolecular hierarchical architectures appropriate for a number of applications. Adding molecular recognition based self-assembly initiated conjugation properties resulting in topology dependent self-organizing behavior are found to mimic the Nature by acquiring the desired physico-chemico-biological features. These developments would certainly introduce more novel applications in near future meeting intelligent material requirements [3, 4]. A variety of self-correcting features, autonomously applied to the undesirable changes caused by externally influences, are getting introduced in new materials possessing self-healing, self-cleaning, and many more features that have already started appearing on the horizon of R&D to mature for industrial applications [5-7]. These kinds of nanomaterials with programmable physico-chemico-biological properties are expected to influence the huge demand of generating, mining, and analyzing the ‘big-data’ arising from the Internet of things (IoT) applications [8]. It is quite likely that the fast-growing developments of smart and intelligent materials might ultimately enable sharing part of the cloud computing based decision making loads of the IoT by distributing the decision-making and action-taking activities locally among the sensors and actuators interconnected throughout. This would enable more efficient use of the cloud resources in organizing other related activities of integrating the large number of smart objects predicted to reach a trillion in number by 2020 [9]. While employing a large variety of engineered hybrid nanomaterials for meeting application-specific responses in abundance, it is quite possible to minimize or eliminate the toxic effects arising from using these synthetic materials in all-pervasive IoT applications involving human beings by employing biomolecular species derived from natural sources like plants. It is further becoming more pertinent to evolve greener methods of synthesizing these nano building blocks from natural materials of plant origin comprising of almost unlimited varieties of phytochemicals that are evolved through millions of years in Nature for minimizing their cytotoxicity [10]. Employing biomimetically motivated green material syntheses and developing hybrid nanomaterials by conjugating nano particulate inorganic, organic and biomolecular species would enable minimizing the inorganic part required for some specific purpose in addition to increasing the biomolecular part with the appropriate combinations of polymeric components of organic origin. This would allow incorporating the features of soft materials with added advantages of green smart/intelligent compositions possessing minimum toxic properties. Ideally, once this strategy of optimizing the material composition is mastered using computer aided designs involving quantitative structure activity relation data (QSAR), already compiled for a very large number of materials at atomic and molecular levels, mimicking some features of the living organism, would not remain a far-fetched dream [11-14]. What Nature took so long might be possible to mimic with the help of supercomputers based designs in a relatively much shorter duration while synthesizing newer compositions that would be smart/intelligent as well as green in nature. This would especially turn the entire ecology smart and intelligent resulting in better living conditions. Addition of these materials in realizing components, devices, and systems for their uses in the all-pervasive applications of IoT is indeed expected to make a number of significant changes in near future as a whole [15]. The ever-increasing demand put on cloud hub of IoT applications would certainly necessitate providing matching kind of ‘electronic intelligence’ using the existing foundries of very large-scale integrated circuits (VLSICs) and micro-electromechanical systems or microsystems technologies (MEMS/MSTs). Taking into account all these fast growing designs of future nanomaterials and their applications in responding to external stimuli, it would make the whole IoT applications more flexible while organizing their roles in addition to distributing the tasks of the sensors and actuators with the help of built-in material intelligence already suggested. Possibly, adopting the ‘More than Moor’s’ approach with addition of ‘clever’ integrations of functionalities might offer a better solution over and above the existing scaling down of the device dimensions of VLICs. This might involve shifting to vertical integration of devices and functionalities along with deploying parallel processing based implementations to move ahead in future. And all these changes must be made at affordable cost by deploying functional materials as ink for printing devices and circuits on polymeric flexible substrates including papers and textiles as well. In this context, the concept of 0, 1 and 2-dimensional nanomaterials will not only help in reducing costs but also incorporate functionalities with more flexibilities in varying the fundamental properties of electrons and holes as charge carriers. Currently, these possibilities are being demonstrated well in a number of 2D materials including graphene along with an ever-growing family of other layered/non layered materials that are currently being studied as they appear better suited to convert them into active material inks for printing metal, semiconductor and insulator components. It would, thus, be easier to realize low-cost flexible electronics to provide electronic intelligence somewhat similar to living organisms aided by the existing VLSI systems already in vogue [16-20].Development of functional nanomaterials for preparing hierarchical molecular complexes responding to multiple stimuli would partly compensate for further extensions of VLICs and MEMS/MST activities up to certain extent. Moreover, this ongoing development of ultraminiaturized devices and circuits is currently reaching its theoretical limits. Further developments do need complementary supports from other areas of innovation. Large scale and large area printed intelligent systems and displays using smart and intelligent nano inks will be possible without cost intensive investing in mask making and patterning facility [20, 21].Another important aspect in connection with the success of IoT applications lies in taking care of the energy consumptions of the sensors that are remotely located and difficult to interface with existing power lines. No respite is currently foreseen to meet the projected energy demands growing enormously with continuously increasing population of interconnected information-gathering devices that are expected to reach to ‘trillion’ by 2020. Only viable solution, foreseen feasible in this context, is to improve the conversion efficiency of solar photovoltaic (SPV) devices and their ruggedness such that they are deployed locally to generate sufficient energy to meet the requirements adequately. In this context, the emerging ~21% efficient perovskite solar cells appear to offer better option. Of course, the stability and useable life of these devices are certainly expected to settle down in near future as it happened in the case of silicon and other materials in the last six decades. Addition of 2D-perovskites and lamellar mono crystalline materials having enhanced photosensitivity, reasonable carrier lifetimes and higher charge carrier mobility are the future hopes on which currently made efforts are hinging to improve the efficiency closer to or if possible exceeding its theoretical limits. The alternate approach of tandem configuration of PVSCs along with spectral splitting for optimal PV conversion by a combination of suitable materials instead of only one is practically being aimed at for ~50% efficient conversion of solar radiation into electrical energy for developing mini-panels with affordable investments [7, 22, 23].The main objective of this review is to examine the extent to which these anticipated advantages are possible to achieve in future IoT applications as evidenced in currently emerging system performances reported or published. Single/multi stimuli responsive engineered nanomaterials possessing smart and intelligent features would collect environmental data without external power sources for monitoring themselves autonomously with wireless connectivity. Numerous IoT applications are being translated into the businesses as noted by M/S Allied Market Research (AMR) in their report projecting market to grow @ 15% annually in revenue generation of ~ US$70 billion by 2022. Smart material applications in ‘Market Research Projects’ include sensors, actuators, motors, structural materials, and several types of novel coatings to name a few. Driven by the potential end-users, the market could further be segmented into industrial, consumer electronics, healthcare, retail, automotive, and many more like that. The observations made by ‘eSafety Forum’ are worth mentioning in this context. They concluded from the data available that on average one third of the serious road accidents are generally caused by driver’s fatigue. A ‘Harken Project’ was initiated for improving driver’s safety by developing embedded non-intrusive sensors for assessing cardiac and respiratory functions. Integrating sensing materials into safety belts and seat covers of the cars could thus detect the heartbeats and the respiratory conditions of the driver by eliminating the noise due to moving vehicle generated vibrations, and the body movements. The ‘Harken’ system monitors the fatigue-related physiological activity of the driver by identifying the changes in breathing and heart rates to anticipate and prevent car accidents related to fatigue by timely alerting the driver. Another European supported ‘Graphene Flagship’ program succeeded in developing graphene ink for fabricating sensors for measuring the parameters like temperature, humidity, pressure, and light by printing an electronic circuit onto an RFID tag. The low energy consumption and the ability to support high data speeds achievable from these sensors would certainly make the graphene a more useful material for new communication technologies like 5G for IoT applications [24].Applying graphene ink onto cotton to produce a conductive textile is foreseen in contrast to the existing wearable sensors relying on the rigid electronics mounted on apparel textiles. This new ink-impregnated cotton fabric being interactive is also breathable, comfortable to wear, and washable while retaining textile electronics. These smart clothes have potentials in sports and health related products replacing wrist wearable devices like ‘fitness tracker’ and ‘heart rate monitor’. Similarly, ‘Hexoskin smart shirts’, for example, are capable of monitoring heart and breathing rates, steps and pace, acceleration, the intensity of the sporting activities and also the sleeping positions. The fabric is machine-washable, breathable, and odor-free besides providing UV-protection. Hexoskin connected Health Platform and data analysis software for health research are currently in use in clinical development, sports, and fitness projects [25].Bristol University reported developing a self-healing compound for airplane wings and fuselage. This self-healing carbon skin is coated with a thin layer of nano sensors that measure pressure and temperature, which, in case of getting damaged due to stone chips or bird strikes, sends a signal to activate uncured material within the nano crystalline structures to start curing the damaged area like an adhesive heals a crack. These materials would be usable in bike helmets, golf clubs, tennis racquets, fishing rods, and even nail polish and cracked mobile phone screens [26]. Such smart garments are already available in the market although most smart material technologies are still at R&D stage. Small and medium enterprises currently lack the adoption of smart materials due to their higher costs, according to the AMR study. But the researchers estimate that with several governmental initiatives and programs as well as the increasing demand for smart materials from industries like construction, manufacturing, and automotive would be driving the market in the coming years [27].

2. Engineered Nanomaterials for Intelligent Sensors and Actuators

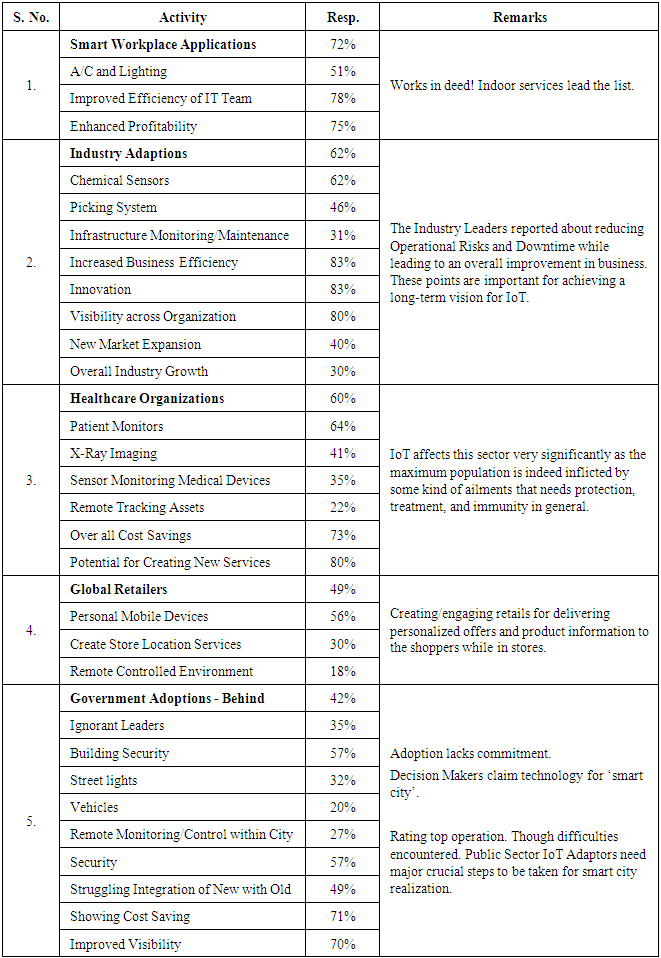

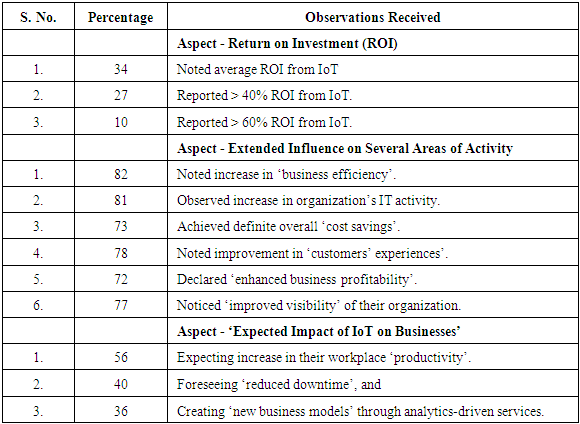

- Although, the IoT term came into existence about two decades ago, however, a common acceptable definition is not yet settled among the businesses adopting it. Almost 98% of the respondents (e.g. claiming to understand IoT) offered widely varying descriptions. For instance, 67% of the respondents considered IoT to add ‘Internet Connectivity’ to everyday objects. This may perhaps be the leading definition of IoT from research angle, but it certainly differs from the one proposed by Kevin Ashton, who coined the term ‘Internet of Things’ in 1999 [28]. Others claim that IoT includes a network connecting multiple objects, for instance, devices and sensors (65%); a platform to connect industrial components (55%); automating building services (52%), and using wearable technology (46%). Whereas, Ashton made it explicit that the IoT means sensors connected to the Internet that behave in an Internet-like way by making open ad-hoc connections, sharing data freely, and allowing novel applications, so computers could understand the world around and become humanity’s nervous system. IoT has already started showing its advantages and applications accordingly right from its start. In order to have a glimpse of how various socio-economic groups are responding to IoT adoptions in their areas of activities, a very useful survey was conducted recently and the responses received are compiled in Table 1 [29].

|

|

2.1. IoT - Making Everything Intelligent

- Growing impact of information and communication technologies (ICTs) combined with low-cost production of smart/intelligent subsystems/systems has started improving the performance of various enterprises. This is also affecting even day-to-day activities particularly in relation to overall improvement in the quality of life by introducing functionalities aided by the recent developments. Engaging a large number of computers in this context is primarily based on standard and inter-operable communication protocols that are not only capable of identifying the physical as well as virtual objects but also involved in integrating their attributes into the information network. Dynamically self-configuring global IoT network has started penetrating deep into the surrounding environment along with consumer goods as the ‘things’ comprising of electronic devices endowed with the capabilities like localized recognition, computing, and communication providing object-level tracking. Accordingly, subsequent to the past two major developments in the field of computers followed by the introduction of ‘Internet’ in the recent past; the IoT is certainly emerging as the next revolutionary force driving the development of ICT much ahead. It is not difficult to foresee the stronger impacts of IoT by counting the current level of usage of nearly 1.5 billion personal computers (PCs) and over 1 billion cell-phones connected to the Internet along with the anticipated number of devices to go well beyond 100 billion by 2020. All these features, put together collectively, are bound to influence the emerging markets generating over 40 times bigger impact as a whole compared to that produced by ‘Internet Technology’ as assessed [30-32].

2.2. The Enabling Technologies

- The fast-growing interest in IoT applications comes from full access to a number of constituent enabling technologies that are being developed under different disciplines at their own pace and are put to use in IoT, where the electronic functionalities have been playing crucial roles. These basic enabling technologies are described below to highlight their impacts on IoT covered in more detail in the references cited [33-44].

2.2.1. The Wireless Communications

- Short/long-range wireless communication channels covering ranges from a few centimeters to a few meters (e.g. in personal area network); and to hundreds/thousands of meters in local and global area networks, respectively, are playing dominant roles in ongoing IoT development. Wi-Fi is the common term used in wireless local area networking of devices employing IEEE 802.11 standards. Wi-Fi devices used in Wi-Fi (2.4/5GHz Radio Band WLAN network) include a variety of personal computers, laptops, video-game consoles, smartphones, digital cameras, tablets, digital audio players, and modern printers, besides many others in offing. These devices are Internet connected having a wireless access within the range of ~ 20 meters indoors but even greater than in outdoors. The technologies including Wi-Fi, Bluetooth, and IR, are certainly the backbones of data transfer among smart devices deployed as nodes at different levels.A distributed arrangement of sensor and actuators in a wireless sensor actuator network (WSAN) has been gathering data about the physical environment for sending the same to the controllers/actuators through single/multi-hop communication system, wherein, the controllers/actuators act in changing the behavior of the environment or physical systems within certain limits [45]. It has thus become possible to remotely control the distributed interactions taking place within the physical world. Depending upon the nature of the target application, the WSAN nodes are either stationary or mobile. Sensor nodes are generally stationary, whereas the actuators are mobile such as in robots and unmanned aerial vehicles (UAVs). Sensor nodes are usually low-cost and low power consuming miniature devices with limited sensing, data processing, and communication capabilities, whereas the actuator nodes possess stronger computation and communication features with higher energy consumption and thus always put more constraints. WSANs are different from the wireless sensor networks (WSNs) involving new generations of sensor networks though there are quite a few common features including the reliability, connectivity, scalability and energy efficiency. Coexistence of sensors and actuators in WSANs makes the major difference between these two networks. WSANs have the ability to change the physical world, but not the WSNs. In WSNs, the power consumption is of primary concern. However, this may be for meeting the real-time, reliable communication requirements in WSANs. There are situations where only WSNs are required, e.g. environment and product quality monitoring. The number of applications is continuously growing requiring actuators along with sensors wherein the network interacts with the physical system or the environment. WSAN applications include disaster relief operations, intelligent buildings, smart homes, smart spaces, and pervasive computing systems [46-58]. WSANs employ the feedback control systems comprising of sensors and actuators. This is the reason that WSANs are forming the backbone of many applications providing an excellent distributed control system in contrast to wired solutions. For instance, WSANs allow more flexible installation and maintenance, fully mobile operations, and monitoring and control of equipment in hazardous and difficult-to-access environments at relatively affordable costs [49, 51, 59-61]. Generic design of platform independent WSAN was reported promising results for its implementations [54].

2.2.2. The Sensors and Actuators

- Sensors provide information related to the environmental parameters around a monitoring unit along with their variations with the help of appropriate transducers. The measured parameter variations are transferred to data collection for further analytics and applications. Some important features of IoT sensors are discussed here briefly.The current theme of examining the influence of engineered nanomaterials and printed intelligence becomes more pertinent in case of sensors and actuators that form the backbone of IoT data collection applications. In this context, a number of features of these devices are seen to depend on various features mentioned in the following.MEMS/NEMS fabricated using micro/nano mechanical components by modified CMOS IC technology and anisotropic etching of silicon, respond to a number of physical, chemical and biological measurands resulting in a new class of sensors and actuators with unprecedented precision, sensitivity and resolution. Particularly, Si based MEMS/NEMS platforms (also called micro system technology (MST) and micro machines in Europe and Japan, respectively, [62-68] are well suited for integration of CMOS signal conditioning and processing circuits along with. Syntheses of nano particulate inorganic, organic, polymeric, and biological species conjugated to prepare hybrid nano materials with size and shape specific physico-chemico-biological properties possessing stimulus responsive behavior are expected to improve the capabilities of these devices further. In addition, biomimetic synthesis of materials in combination with MEMS/NEMS based sensor platforms are expected to result in intelligent features derived from molecular recognition based self-regulated processes and configurations of nano species providing large-scale green processing suitable for production. Moreover, low cost printing using engineered nano inks would produce sensors, actuators, and electronic circuits on rigid, flexible or uneven surfaces including low cost substrates like plastic sheets, paper, and textiles. Finally, intelligent packaging of sensors, actuators and signal conditioning/processing circuits would enhance the usage of sensor/actuator technology resulting in material savings due to timely consumptions prior to their degradations because of external environmental conditions. The precision, accuracy and sensitivity of the current nanosensors have been enhanced significantly in areas involving MEMS/NEMS components. Further, introducing engineered nano materials has the potentials to add another new dimension to the whole sensor technology, where hybrid nanomaterials in 1, 2 and 3D are offering unprecedented sensitivity, selectivity, and resolution via their topology specific physico-chemico-biological interactions resulting in single/multiple stimulus responsive molecular complexes. Nanoparticulate forms of inorganic, organic, polymeric, and biomolecular species combined with MEMS/NEMS device structures are opening numerous novel possibilities not foreseen earlier. Addition of 2D materials (i.e. graphene and graphene like many others) is another area, which is getting explored fast, adding still more potentials to these engineered nano materials for their sensor/actuator applications in particular [69].Processes used for introducing engineered hybrid nanomaterials in MEMS/NEMS are, in general, carried out in solution form, which is bound to reduce the costs once the involved technologies mature. Out of several options, printed nano sensors with intelligence are making revolutionary changes in this context as foreseen in future IoT applications.Going by the conventional way of environmental parameters assessments using commonly available sensors, it may be quite expensive with many physical limitations including constrained modifications involving lengthy procedures. However, with the recent advances made in engineered nano materials, a large number of alternatives are emerging fast that are expected to overcome these constraints by changing the sensor modality. Because of flexibility provided by a large variety of nano sensors available today, a given sensor meant for measuring a particular parameter could instead be used for a different purpose, while answering the same end-question via a low cost route. This was demonstrated by employing a temperature sensor to replace flow meters in pipes and mechanical switches in refrigerator doors, thus changing the modality of the temperature sensor from measuring the room temperature to measuring other physical parameters [70]. Current market research has been linking the growth of the MEMS/NEMS market to the increasing demands arising out of monitoring/control requirements of the environment and in developing better equipment and instruments. With increasing number of sensors deployed in cars, industrial equipment, installations, and ambient intelligence, it is certainly going to demand higher production of sensor and actuators consequently. Keeping in view their uses as well as overall reliability, such sensors must be self-sustaining while using wireless communication in their system networking [71]. A wireless local-area network (LAN) uses RF energy in contrast to the wired network for connecting devices like laptops, printers, and similar others to the Internet, and business networks. The simplest wired networks use ‘Ethernet’ ports on the network router and the computer/other devices. Although wired networks, at some point of time in past, were considered faster and more secure than wireless networks, but of late, the situation has reversed with improved wireless networking standards and technologies resulting in speed and security in the intervening period. There are reasons to replace wired network with wireless network, for instance, to incorporate added mobility to network resources from any locations within the coverage area ultimately affecting productivity besides ease in operation and expansion. Even robust security is available at lower cost because of no additional investment in cable laying for interconnections as in the wired networks [71]. The ever-increasing number of future devices required is currently the driving force behind introducing further overall miniaturization in the devices to reduce power consumptions, and provide effective communication networks besides convenient packaging along with their system integrations. Instead of sourcing a number of sensors from a large capacity power supply, it is preferred to provide for local energy harvesting modules along with their associated wireless communication networks individually [72,73]. MEMS/NEMS sensor applications are proliferating more in human health care sector with the growing population of the elderly citizens requiring medical care through medical infrastructures globally. For cost-effective healthcare accessible to more number of people at affordable costs, the hospitals/healthcare facilities must be established at reduced costs by improving the overall efficiency without sacrificing the quality. Hospitals are being motivated to find innovative ways to meet this objective. Consequently, a centralized medication distribution system has been emerging as a standard model, but more facilities are also switching over to a hybrid or decentralized distribution model. There is also a growing trend in transferring general medical test facilities from a fully equipped central laboratory to smaller units, which are closer to the patients needing them. This leads to growing demands of small and affordable diagnostic devices, especially for point of care type of applications using ‘laboratory on a chip’ type facility [74]. In addition, the rising concern for National Security is another factor needing serious attention for combatting the terrorist threats and outbreaks of infectious human or animal diseases. This would facilitate developing portable multi-parameter measuring instruments to test atmospheric contaminations including air, water, and foodstuffs as well as human blood for microbial attacks in case of emergency [75, 76]. Another reason for exploring MEMS/NEMS technology is for adding a ‘clever factor’ in mitigating the limitation due to imminent terminus of the Moore’s law. The IC industry is bound to look for other ways to improve the performance of their circuits and systems. The emerging ‘More than Moore’ concept is expected to add new technologies to 2D-landscape of the current microelectronic devices and circuits to incorporate additional functionalities via vertical integration using die stacking [77]. Besides, more flexible and more affordable production technologies are also emerging driven by the possibility of producing lower cost, and larger surface area devices like solar cells, displays, wearable electronics and disposable diagnostics devices [78]. Modified printing technology is one alternative besides using low cost substrates like plastics, paper, and textiles in printing intelligence at lower cost. This is to complement the existing VLSIC capabilities better. Eventually, a large number of nano-enabled products will emerge from future R&D investments [79]. The current market trend is progressively relying upon merging of functionalities in products like cameras, music systems, computers, mobile phones, and portable consumer electronics as well as the merger of MEMS/NEMS technologies with VLSICs. In this context, there are examples of MEMS/NEMS being introduced into portable electronic products comprising of silicon-based microphones and liquid lenses for autofocus and zoom options [80, 81]. Similar pressures are being felt from ever-increasing demand of large memories of higher capacities with embedded or stand-alone types [82, 83]. It is significantly important to note that the increasing use of sensors and other miniaturized electronic devices is gradually shaping the environment available for intelligent interactions through IoT. For this to happen, stronger needs are emerging for low cost miniaturized devices and subsystems, which are energy efficient and self-sustaining as well as able to communicate wirelessly with other electronic devices and subsystems used as ‘smart dust’. These smart dusts comprise of large number of MEMS/NEMS/MST based sensors, robots, or similar other devices, that can detect light, temperature, vibration, magnetic field, and chemicals to name a few, and are operated through computer network while distributed over certain specific area for sensing through RF network [84]. The wireless sensor networks are exploring to incorporate sensors even in previously inaccessible locations. It is also becoming feasible to use a large numbers of sensors because there is no longer the need for their regular replacement or recharging their power sources [85]. MEMS/NEMS offer special advantages in contrast to commonly used counterparts available commercially. Adding few special etching, bonding and assembly techniques to common CMOS IC fabrication, it has been possible to produce them without much of alterations in process lines. Although MEMS/NEMS have grown extensively in the past decade, many challenges are still there in terms of their fabrication, packaging, and applications and upcoming solutions of these challenges will determine the commercial success of these devices both in technical and economic terms [86]. In a typical MEMS based human health care system, a clear shift from the clinical to point of care diagnostics is noted with a slow but significant changeover from medical diagnostics to more lifestyle oriented tests of allergy, drugs, cholesterol, alcohol, and sport injuries. These additional application areas put together make the MEMS market more consumer-oriented. Perhaps the fastest growing market for MEMS/NEMS with many interesting applications especially includes ‘Point of Care’ monitoring in which glucose level monitoring could be cited as one of the largest single segment. But there are also many niche areas like: retinal implants, robotic surgical devices and diagnostic pills [87]. The introduction of nucleic acid amplification into molecular biology has made the laboratory detection of pathogens simpler. The process of diagnosing and treating a disease facilitated by identification and characterization of causative agents in conventional form is very time-consuming, besides requiring skilled personnel and laboratory. On the other hand, DNA chip offers multiplex detection including printed double-stranded DNA and oligonucleotide arrays, in situ-synthesized arrays, high-density bead arrays, electronic microarrays, and suspension bead arrays, to name a few. DNA chips have impacted medical diagnostic including the detection and identification of pathogens, antimicrobial resistance, epidemiological strain typing, and determination of viruses [88]. DNA microarray (i.e. ‘lab-on-a-chip’) is further getting extended to implantable “pharmacy-on-a-chip” with proper modifications for precise drug release in body timely without injections. The delivery of insulin is one such example besides delivery of hormones, chemotherapy drugs and painkillers. The first, second, and third generation of devices release their medications upon receiving signals from an outside source, wired through the skin; are wireless interconnected to interact with MEMS sensors embedded to respond to body's internal signals [89]. Microfluidic devices are also being used in analytical equipment like mass spectrometry and chromatography. A microfluidic platform integrating sample definition, injection, detection and diagnostics leads to a faster and easy analysis via remotely operated handheld devices. These devices are not only used in home defense, but also in environmental measurements and industrial process controls as seen emerging in chemical industry. In continuous processing, using microfluidics is easier, while the duration of analytes staying in the reactor is much better controlled along with easy scaling. Microfluidic up scaling is not so much related to changing from a small reactor to a big one; it is a matter of increasing the number of reactors, without changing the process. Furthermore, it can increase the catalytic efficiency due to its inherent larger exposed surfaces. Consequently, compared to traditional installations, microfluidic ones are more energy efficient, safer with higher yields, and easy to expand [90, 91]. In case of using MEMS micro cantilevers, a coating of application-specific thin layer is applied before immersing them in the test fluid. During this process, a molecule/microbe attached to a cantilever coating causes change in its resonance frequency. Employing molecular recognition specific cantilever coating the device can be used for detecting a number of specific materials. For detecting E. coli, for instance, the cantilever should be coated in antibodies specific to E. coli cells. A cantilever array with different coating on each should detect a number of different molecules/microorganisms simultaneously. IBM is already deploying these micro/nano sensors to detect DNA, bacteria and even parts of bacteria, making the sensors ideal for quality testing of water and food samples [92, 93]. One of the major concerns of using polymeric materials for fabricating such devices involves considering their temperature stability, performance shift over time, tolerance of higher electric field, and chemical/environment stability [94]. Many polymers exhibit electric charging and low dielectric breakdown fields. For example, polymer based electrostatic actuators show hysteresis because of charging. For sensor applications, crosstalk may become another serious issue to take care of. For example, resistors made of nano composite elastomers may change its resistance in the presence of varying stress/strain, temperature, humidity, and chemical environment. The thermal, mechanical, and chemical properties of the polymers to be used should be understood properly in fabricating poly MEMS before taking them to commercial applications. These technologies in great demand include large area processing (e.g., roll to roll), heterogeneous polymer-semiconductor integration, and appropriate packaging. Instead of making every component from polymer, a heterogeneous integration of organic and inorganic materials is often necessary and desirable. It is always advantageous to integrate signal conditioning and signal processing electronics directly with polymeric sensors. By doing so, the signal to noise ratio is improved with better sensitivity. For large area sensor skin, for instance, integrating electronics and sensors becomes indispensable to manage interconnect complexity. Many polymeric materials could, thus, find applications in future MEMS including conducting polymers, electro active polymers like polypyrrole, photo pattern able gelatin, shrinkable polystyrene film, shape memory polymers, and piezoelectric polymers such as polyvinylidene fluoride (PVDF) [95-105].

2.2.3. Radio Frequency Identification (RFID) Technology

- Recognizing an object using reflected electromagnetic radiation was although explored during World War II, but its details were worked out later in 1948 by using modulated signal that laid down the foundation of the modern RFIDs. The first generation of commercial RFIDs started getting deployed in 1960s containing 1-bit information to check particularly the thefts in shops. This was followed by rapid growth of RFIDs in 1970s due to the availability of CMOS ICs that not only reduced their sizes with improved functionalities, but also cut their costs down. Deployment of PCs in collecting and analyzing data gathered from the RFIDs opened up still better and newer applications in the fields of personal access, industrial productions, business management and public transportation in 1980’s. International Standards Organization (ISO) started coordinating the RFID regulations, after noting their growing popularity, to integrate the different practices evolved in different countries and regions by offering international standard protocols [106]. There are three basic components of a RFID system consisting of tags, a reader and a computer. The low cost tags are deployed in large numbers, while the reader, relatively being more involved functionally and expensive, is connected to the computer for storing and processing data collected from the tags. In actual operation, the reader transmits interrogating signals containing power, data and clock information, which upon entering the detection zone make the tags respond to the interrogating signals to activate the internal circuits decoding the received signal by the tag circuit and modulated before transmitting it back to the reader. The reader recognizes the ID codes encrypted in the given tags from received signals [106]. RFIDs are of three types namely - passive, active, and semi-passive ones. Passive tags neither have any internal source of power nor are any radio transmitter and the internal circuits are driven by the rectified energy from the signal received. In contrast, semi-passive tags employ a local battery to operate the internal circuits, but the energy for sending out the data is derived again from the interrogating signals transmitted by the reader. Active RFID tags have both the internal power sources and transmitters to send the interrogating signals. Semi-passive and active tags offer longer operating ranges; higher data rates and larger memories than passive ones in contrast to the passive tags being maintenance free serving for much longer durations. Consequently majority of the prevailing RFID tags in the global market are passive ones with the frequency of operation in low (LF), high (HF), ultra-high- (UHF) frequencies and microwaves. For instance, cards operating @ 125 kHz and 13.56 MHz cover a distance up to 1m (with inductively coupled antenna) and are robust. Being less prone to the effect of metal/liquid-contained environments, these tags are quite often used in the high-security area, in particular for transportation as access-control cards. UHF RFID tags operating in 866-868 MHz in European (EU) countries and 902-928 MHz in North America with a range of 10m, providing faster data communications. The performance of UHF tags is susceptible to the existing environment as the radiation used is incapable of penetrating materials like metals, liquids, dusts and frogs. RFIDs employ inductive or capacitive coupling of the antenna in LF/HF, and UHF/Microwave regions, respectively. The performances of LF/HF RFIDs are relatively compromised against those of UHF/Microwave RFIDs because of antenna size [106, 107].Chipless RFIDs possess the capability of automatic tracking through long-range communication and non-line of sight data access. The major reason of RFID tags not replacing commonly used barcodes is their higher costs including the cost of chips, batteries, antennas, and assembly processes [108, 109]. Still currently the RFID market is flooded with passive tags without batteries at low cost [110-112]. With the evolution of microelectronics processing technology, the prices of the IC chips have also been cut down, translating into considerable reductions in the cost of a single tag. Further reduction in conventional passive RFID tag’s cost is currently being considered as a challenge primarily due to two basic constraints. One is the extraordinarily high cost of investment in setting up of an advanced foundry for manufacturing the IC chips with finer features resulting in higher integration density at affordable costs. The other is the higher cost of the assembly line to attach these chips to the package with antennas. In absence of a standard integration procedure, the production efficiency is severely reduced. In addition, the assembly is becoming tougher due to the continuously shrinking size of the chips and the flexibility of the substrates. The cost per silicon IC-based passive tag is, for instance, approximately US$0.05 with the deployment of modern chips which is still higher than the targeted cost of ≤ US$0.02 for meeting the massive requirement of low-cost item-level tags anticipated to cost a fraction of a cent [106, 113-116]. Alternately, chipless RFIDs are attracting more attentions due to their low manufacturing cost while eliminating the use of IC chips offering more competitive prices. Besides, chipless tags possess longer communication range since they do not deploy active devices that require some minimum power to energize [117]. These tags are successfully commercialized as surface acoustic wave (SAW) tags compatible with the present RFID band regulations (@2.45 GHz) offering 96 bit large coding capacity. The cost of such a tag, however, is still comparable to that of the silicon-based counterparts since they involve sophisticated sub-micron lithographic process and expensive piezoelectric substrates [118-122]. Developing printable chipless RFID tags is quite attractive given the fact that printing is a high throughput process like inkjet printing, which is fully additive depositing material on the required positions of the substrate, offering significant saving in using costly electronic materials for fabrication. Besides, printing process is quite compatible with cheap flexible substrates including plastic, paper, and textile sheets, offering better options of reducing the tag costs further [123, 124]. A number of research results on printable chipless RFID tags have already been reported [113, 125, 126]. One of the most promising families of the chipless tags was reported using electromagnetic properties of printable metallic structures. According to the adopted encoding principles, these tags are basically put into two categories namely – time and frequency domain signature based RFID tags [127-131]. The time domain tags employ a transmission line (TL) along with a capacitor terminated microwave circulators to introduce reflections for storing binary ID codes and is compatible with various RFID frequency regulations [117, 128, 129, 132]. In frequency domain tags, spectrum signatures is encoded by placing inductors nearby a micro strip line, or by assembling an array of metallic microwave resonators with different resonant frequencies such as micro strip dipoles, split ring/four-square resonators and other resonators [119, 125, 126, 133-136]. Observing the presence of either resonances, or the shift in the resonance frequency helps in recognizing the code during tag reading [121, 133, 137]. Practically every form of printing technologies comprising of screen, gravure, flexographic, offset, and inkjet printings [138-140], have been used in printing the electronic circuits and devices. However, out of these processes, inkjet printing is the most frequently used one due to its digital nature and ease of operation in small-scale fabrication of electronic products. Inkjet printer patterns are readily modified by software on site, which is different from semiconductor manufacturing process where numerous masks are to be prepared in advance and thus it leads to significantly shorter turnaround time with cost effective layout modifications, compared to time consuming and expensive equivalents in silicon processing. Moreover the additive nature of pattern printing saves considerable amount of materials due to location specific material deposition by minimizing the use of ink consumption and material wastage. While printing, the nozzles for ink jetting stay away from the substrate, which is not only beneficial for preserving the surfaces of the printed materials, but also facilitates ink depositing with higher spatial accuracy.Inkjet printing is carried out on a rigid or flexible substrate allowing for low temperature curing (typically < 200 °C), involving polymer and paper based substrates that have great potential to be employed in RFID applications. The inkjet printing of electronic circuits is extended to R2R printing where the print heads containing various functional materials deposit materials on required positions on the substrate in the form of web. A fast curing process is applied to solidify the deposited layer following the first print head has finished depositing specific type of solution materials. Subsequently, the reel moves the patterned substrate to directly under the second print head for taking the next material and so on to manufacture multilayer-structured components in a cost effective and time saving manner.Conducting inks containing metal NPs encapsulated by dispersion solvents added to isolate them by preventing from sedimentation are deposited onto the substrates. Subsequently, applying heat to the substrate with patterns makes the solvents evaporate, and sinter the metallic NPs forming the conductive lines. For instance, it is easy to fabricate a simple electronic circuit based on metal-oxide semiconductor (MOS) transistors using only a few steps in a printing process while it involves over three hundred steps in silicon CMOS IC processing. Further, the process being subtractive, large amount of raw materials go waste. On the other hand, commercially available printers modified for electronics fabrication only cost much less compared to the investment involved in building up of a modern silicon foundry (e.g. costing billions of dollars) besides spending huge amount of money and time in the maintenance of the ultra-clean rooms. Few drawbacks of inkjet printing are also there to examine. For instance, it produces inferior features with reduced performances due to limitations of the printing processes. The printed RFID technology may, therefore, hardly match with conventional chip based tags in terms of the available advanced functionalities, but they provide a disruptive technology for realizing the ultra-low-cost RFID tags for item-level tracking and identification applications towards IoT vision, where low cost is of prime concern [106]. It is understood that printed RFID tags would cost a fraction of a cent. Currently, there are two types of the printed RFID tags being explored as ultra-low-cost RFID solutions. One is a plastic chip with printed thin film transistor circuits (TFTCs), in which the components and circuits are similar to those of silicon. This could be a disruptive way to develop RFIDs with considerable complexity if the carrier motilities of TFT materials are improved sufficiently to meet the demand of operating at 13.56 MHz. The other more revolutionary approach is known as all-printed chipless RFIDs offering advantage of much lower fabrication cost over chip-based ones owing to the absence of IC chips. Coupled with fast printing techniques, it is expected that future chipless tags would be fabricated at sub-one cent or even lower cost, especially in large volumes [106, 115, 123]. RFIDs restarted attracting attention as a part of IoT, though, its popularity in recent past went into oblivion in object-level tracking due to its higher cost. Using RFIDs in common retails is found redundant with additional investment in case there is no serious problem. However, with the developments in manufacturing costly products, it becomes necessary to track the items like apparel, jewelry and medical equipment. The maximum impetus of deploying RFIDs comes from apparel retails as clarified by ‘Impinj’. Similarly, higher cost of the pharmaceutical items combined with the cause of eliminating the counterfeits became the motivation for their RFID-tracking as they moved from manufacturer to the pharmacy via distributors [141]. In this context, the passive UHF RFID tags and near field communication (NFC) were the two standards chosen by the IBM in examining the future of RFIDs in IoT by considering them as one of the inputs of many data channels. RFIDs are currently being used for connecting the physical and digital worlds and supplying data that identify a particular object at exact location and time by interrogating it that responds with unique identification code according to Zebra Technologies [142]. This kind of RFID’s revival in IoT made a number of manufacturers forming a consortium by combining their resources and capabilities with cloud service providers, chipmakers and others to make UHF RFID as a significant requirement in the future. For example, Google, Impinj, Intel and SMARTRAC, along with the Radio Identification Industry Association AIM Global, formed the RAIN (RAdio-frequency IdentificatioN) Alliance, in 2014, for promoting awareness, education to accelerate the growth of UHF RFIDs in business and consumer applications Worldwide. Adding reading capability into the smartphones is another example to cite for having access to the details of the apparels, book and food products while shopping them from the stores, which is still inventory management combined with the powerful Internet as a complex mix of identification, sensor and cloud computing that promise to make such services more useful, ubiquitous and less expensive in future [142]. The tag reader wirelessly acquires unique information embedded in RFID tags that are attached to the objects for tracking their location as well as movement. Currently, these RFIDs are somewhat limited, in which, all the tagged items are necessary to enter a “gateway” where readers are positioned to pick up each tag’s signal during its passage. In the logistics industry, RFID tags are traditionally attached to shipping containers so that when the trucks carrying these containers enter or exit the port, where RFID readers are positioned at the gate, are tracked for their arrival or departure. In manufacturing sector, tags may be attached to components, such as car parts in an automotive plant, which can then be tracked as they move along the production conveyer belt. While this kind of RFID applications is broad, they still depend on tags passing through a gateway of readers. More developments are discussed later to take care of some of these limitations [143].

2.2.4. Energy Harvesting

- It will be a better option to derive energy from the environment to energize the smart devices due to various reasons. For instance, energy harvesting devices integrated with functional devices/circuits would form a part to replace bulky and maintenance-intensive batteries. The captured energy stored in capacitors could be generated from solar radiation, temperature variations, radio signals, or even wind.The concept of interfacing ‘anything and everything’ of real or virtual World to a global network of Internet is emerging fast. Their participations in a number of smart systems configured to handle numerous kinds of day-to-day activities in smart and intelligent manner is steadily growing. With the help of big data analytics, taking optimal decisions is eventually expected to put a variety of demands on various resources. For example, every piece of sensors and actuators involved in collecting the relevant data for implementing the logical decisions resulting in actions for smart functioning thereof would certainly require some finite amount of energy. The total requirement of energy collectively would turn out to be an extremely large especially in case of ‘trillion’ devices projected to be in use by 2020. For meeting such requirements of energy besides that already met from the conventional electric supply lines, a number of methods would be required to generate energy locally in which case photovoltaic solar energy harvesting comes on top priority.While, examining different forms of solar PV energy harvesting technologies already developed, the one based on printed organic materials seems better as it is simple to manufacture at low cost. Particularly in this context of energy harvesting by organic PV devices, one can see from the recent developments that 21% efficient perovskite solar cells are already realized on small substrates, of course, still, struggling with shorter life span besides lead toxicity. A number of research teams are, therefore, steadily striving for sorting out these problems. In order to get familiarity with the progress made in this context, some recent experimental and theoretical results are given below. For making use of full solar spectrum to extract maximum energy, it is common to join a number of cells in tandem for combining their contributions using different band gap materials as one of the approaches of enhancing efficiency. In case of perovskite based tandem solar cells, some significant results were reported with 14.8% efficient perovskite solar cells employing low band gap material, the teams from Stanford and Oxford could produce a novel all-perovskite based tandem solar cell with 20.3% efficiency outlining a roadmap for solar cells delivering over 30% PEC in near future. This strategy was put to use after sorting out the problems of synthesizing the right kind of smaller gap perovskite comprising of tin, lead, cesium, and iodine based devices with better efficiency than the best tandem solar cells, made so far with other low-cost materials like organic small molecules and microcrystalline silicon. Further optimization of the related materials to generate even higher currents by absorbing solar radiation better will certainly transform the solar PV industry once manufacturability and stability issues are taken care of appropriately [144]. Similarly, making large area perovskite solar cells with higher efficiency is another alternative to collect more solar radiation as reported by University of New South Wales, to fabricate 12.1% efficient 16cm2 cells duly confirmed by the international testing center. These cells are particularly 10 times larger in size than the currently certified high-efficiency perovskite solar cells (i.e. with 18% efficiency) measured on 1.2 cm2 single perovskite cell. The UNSW team reached to the top position in producing state-of-the-art high-performance perovskite solar cells, which is certainly expected to reach 24% within a year [145]. Although, perovskite solar cells hold much promise for cost-effective solar energy harvesting, they are still sensitive to temperature fluctuations and moisture, making them last only for a few months without protection. However, it seems quite feasible to derive similar advantages in perovskite cells as noted in other PVSCs in past. Nevertheless, there are still numerous applications, where even disposable low-cost, high-efficiency solar cells could be deployed in disaster response systems, device charging, and lighting in electricity deprived regions. Perovskite cells possess the highest power to weight ratio amongst the viable photovoltaic energy harvesting technologies [145]. Linköping University came quite close to finalize the process of material homogenization over the entire surface of the printed organic solar cells comprising of an active layer placed between two transparent electrodes generating electron-hole pairs when irradiated by solar radiation. This was the outcome of more than two and a half decade of R&D in printed solar cell technology demonstrating a record PCE (11%) in organic solar cells as compared to 18% of silicon solar cells [146]. Swanson's Law describes the observed trend in overall price reduction of solar cells (i.e. similar to Moore’s of Si) by observing that the cost of solar cells has been on average reducing to almost half within every passing decade. The flexible organic solar cells, in this context, rely mostly on the polymeric/small organic molecules, offering two major advantages by using smaller quantity of material to convert photons into electrons, besides being amenable to mass production using R2R printing. There are, however, still some challenges in terms of low cost transparent electrodes replacing ITO, and the barrier layers. The projected goals of the EU-funded program called "TREASORES" are related to find solutions to these problems. Recent review of this project already demonstrated an ultra-thin transparent silver electrode being superior as well as more cost effective than ITO resulting in 7% efficient perovskite cells with commercially acceptable device lifetimes. Spray-coating of silver nanowires (AgNWs) onto vacuum-processed small molecule organic solar cells, organic light emitting diodes (OLEDs) and organic light emitting thin film transistors (OLETs) were reported by dispersing these NWs with a per-fluorinated methacrylate in a highly fluorinated solvent. The optimized AgNW dispersion spray-coated @ 30 °C could produce high performance electrodes with low sheet resistance (i.e. 10Ω/square) at 87.4% transparency (80.0% with substrate). This kind of multi-institutional development was found successful in demonstrating the suitability of the R2R processes in producing flexible cells and organic LEDs that would invariably drive the technology price even lower with improvements made in the related processes [147, 148]. The UNSW's Australian Centre for Advanced Photo voltaics demonstrated a 28-cm2 four-junction 34.5% efficient mini-module embedded integrated with a prism. A new World record was set for unfocused sunlight reaching closer to the theoretical limits. By splitting the incoming solar radiation into four bands and using four-junctions to extract electrical energy from each beam it became almost 44% better than the previous record - made by Alta Devices, USA, which reported 24% efficiency, but over a larger area of 800 cm2. This novel approach of converting solar radiation into electrical energy is ultimately expected to make PV conversion more affordable by lowering the investment and making the payback faster. This new result, however, was achieved using normal sunlight with no concentrators as compared to the previous one. Consequent upon this kind of success, Germany's ‘Agora Energiewende Think Tank’ expected to have 35% efficient modules by 2050 using normal sunlight in standard homes. These triple-junction cells responded to the incoming sunlight, using a combination of three layers of indium-gallium-phosphide, indium-gallium-arsenide, and germanium. Thus, each junction extracted maximum PV energy at its most efficient wavelength allowing for the unused part of the light to pass through the next layer. The IR part of incoming sunlight, unused by the triple-junction cells, was filtered out and bounced onto the silicon cell so that practically entire energy was extracted from each beam hitting this mini-module. The performance of 34.5% efficient 28-cm2 mini-module already being World record seems well within reach to scale it up to a still larger area of 800 cm2 leaping beyond Alta Devices' 24%. This result of PEC from UNSW has already reached two-thirds of the way to the theoretical limit of 53% for such a four-junction device [149]. The UNSW’s team is trying to reduce the manufacturing complexity besides preparing cheaper multi-junction cells so that these mini modules find their ways onto the rooftops of homes and offices soon. This approach is, however, ideal for solar towers, like those being developed by Australia's RayGen Resources, which deploy mirrors to concentrate sunlight that is then converted directly into the electrical energy [150]. The energy requirement of ‘trillion’ smart objects expected to be used in IoT application via global network by 2020 would be involved in future smart homes for taking care of the health of the inhabitants along with the organization of the numerous day-to-day activities of the house. Even after leaving aside those cases, where the energy supply is available from nearby electric supply line, those located remotely for generating the required information pertaining to a particular set of requirements may not be that easy to meet. In such cases, the access to locally situated low cost organic solar panels would be better in powering sensors. These OPVs unlike silicon SCs are fabricated from synthetic organic materials deposited onto low cost PET substrates. It is interesting to note that ROI of these OPVs is met in one day in contrast to that of couple of years in case of silicon cells. OPVSCs are molded for roof tiling or even clothing besides being quite effective in diffuse or slanting lights. For IoT applications, however, these improvements are significant as these cells will produce energy throughout the day, even indoors or when attached to the clothes [151]. The overall demands of sensor’s energy requirement deployed in future are growing exponentially. For instance, assuming an average power of 5mW per sensor required in measuring once every minute (lasting a minute each time), 1 trillion sensors would need an energy of 4.38.1013 KWh annually – putting an incredible demand on the power grid, in addition to running the corresponding data centers involved in handling Big data. Thus, deployment of low-power electronics seems to be imminent in keeping the energy demands of sensors in the realizable limits. Batteries are not viable for long-term operations due to their finite energy capacity. Therefore, developing smart sensors harvesting their own energy from the local environment seem to be a viable solution where the organic solar technology would find its niche [151]. The organic solar cells (OSCs) belonging to the third-generation solar technology, following the previous two generations of mono crystalline silicon and thin-film cells are put into two sub-categories namely-polymer-based (large molecules) and oligomer-based (small molecules). OSCs being lightweight, flexible, nontoxic, and semi-transparent hold great promise of low-cost manufacturing, but efficiencies are comparatively low (i.e. until now, at least) with poor long-term reliability [152]. The commercial interest, thus, has been in exploring vacuum deposition of very homogenous layers of oligomers at low temperatures with no solvents that separates them from the competitors while using just 1g of organic material per square meter in its R2R process while getting closer to commercially viable production process with the claim of product lifetime of 20 years extrapolated from the accelerated aging tests [152]. The emerging trend in solar cell development is noted in form of wearable solar cells, which are lighter in weight and cheaper in cost as projected by Georgia Institute of Technology while targeting for not only using doped layer based solar cells but also cutting its cost by PVD [153]. For doping the organic films, the samples were dipped in a solution of polyoxometalate (PMA and PTA) in nitromethane at room temperature for a few minutes resulting in p-type doping with a doping depth of just 10–20 nm, which has a high work function along with improved protection from oxidation against the organic PV cell that is important for both manufacturing and increased product life. While these OPVSCs are approximately 13% efficient compared to 20% efficient standard silicon solar cells, the current trend indicates that the efficiency will continue to increase in organic-based devices. But organic devices require less power to produce and are easier to recycle, making them better from environmental point of view. The process of room temperature immersion doping has the potentials to impact the printed electronics manufacturing. According to a recent report, around 15% of the PVSC market is based on thin-film PVSCs, as these are cheaper with a shorter energy payback time than crystalline silicon cells, which represent the other 85 per cent of the market. A rapidly developing competitor to thin-film PVSCs is a technology based on organic-inorganic perovskite-structured semi-conductors as noted by CSIRO, Australia. Adding a non-electro active or insulating polymer could regulate the problematic rapid crystallization in the coating process [154]. Kapton® (DuPont) polyimide film, currently under development for use as a flexible superstrate for CdTe thin film photovoltaic modules, has shown a new world record of 13.8% efficient cells by deploying a new colorless film, exceeding their own previous record of 12.6% and nearing that of the glass substrate [153]. Kapton® films are over 100 times thinner and 200 times lighter than glass substrates. There are advantages in switching over to deploying these flexible film-based processing against glass based CdTe systems. High-speed and low-cost R2R deposition technologies could be applied for high-throughput manufacturing of flexible cells on polymer film as substrates. The new polyimide film potentially enables significantly thinner and lighter-weight flexible modules that would certainly be easy to handle and less expensive to install, making them ideal for applications including building-integrated photo voltaics [155]. EMPA is developing high-efficiency thin film solar cells using novel concepts of enhancing their performance, simplifying the fabrication processes, and advancing device structures for next generation of more efficient and lower-cost devices. This involves optimized deposition by a low temperature process (below 450oC) for high-efficiency CdTe solar cells on glass (e.g. with 15.6% efficiency) and polymer film (12.6% efficiency), the highest value before the recent improvement to 13.8%. Only sometime back, a new World record in energy efficiency (i.e.18.7%) was set up using another type of flexible solar cells based on copper indium gallium (di)-selenide (also called CIGS).Though, finding a film that could both be transparent and withstand high processing temperatures is a challenge as such, but the new Kapton® colorless polyimide film has both the features for high temperature processing, and better light transparency allowing it to exceed the previous World record in conversion efficiency of flexible CdTe solar cells. Of course, further developments are needed for addressing to cost reductions and stability problems [155]. A green method was also reported using CuOX as an anode buffer layer for OSCs prepared by spin-coating a copper acetylacetonate precursor based aqueous solution onto an ITO substrate at room temperature in ambient air. Hydrogen peroxide (H2O2) is used to modify the precursor aqueous solution to enhance the work function of the CuOX film to improve the hole-collection efficiency and the charge-transport efficiency. UV-ozone post-treatment of the CuOX film produced fully oxidized state of copper oxide, which significantly improved the performance of OSCs. Through H2O2 modification and UV-ozone post-treatment on the CuOX anode buffer layer, the highest PCE of the OSCs based on PTB7: PC71BM blends reached up to 8.68%, which was 10% higher than that of the standard PEDOT: PSS anode buffer layer based OSCs. In addition, the devices with the CuOX buffer layer showed much better air stability than those with PEDOT: PSS. This indicated that CuOX with low cost and green solvent is promising anode buffer layer materials for efficient and stable OSCs [156]. A simple method for enhancing performance and stability of perovskite solar cells was reported recently by incorporating solution-processed cetyltrimethylammonium bromide (CTAB)-doped zirconium oxide (ZrOx) as cathode buffer layer (CBL) [157] with several advantages including ease of fabrication without the need for thermal annealing; reasonable conductivity (2.9×10–5 S/cm); good ambient stability; effective work function modulation of Ag electrode; relative weak thickness-dependent performance property; and wide applicability in a variety of active layers. Compared with ZrOx CBL without CTAB, CTAB-doped layers could significantly improve PCE from 0.57% to 2.48% in organic solar cells based on diketopyrrolopyrrole-thiophene-bezothiadazole low-band gap polymer (PDPP-TBT): [6,6]-phenyl-C71-butyric acid methyl ester (PC71BM) blend. With this n-doped ZrOx CBL, cells deploying polythieno(3,4-b)-thiophene-alt -benzodithiophene (PTB7): PC71BM blend could deliver a record high PCE of 9.3%. The effectiveness of this novel CBL was also extended to perovskite solar cells resulting in high PCE up to 15.9%, which was superior to those of the devices with undoped ZrOx and state-of-the-art CBL zinc oxide NP film. Moreover, the long-term stability of the devices could be secured without encapsulation [157]. An effective cathode interfacial layer for perovskite solar cells was reported from N, N-dimethyl-N-octadecyl (3-aminopropyl) trimethoxysilyl chloride silane (DMOAP)-doped [6,6]-phenyl-C61-butyric acid methyl ester (PC61BM). The hydrolysable alkoxysilane groups on DMOAP moisture cross-linked through siloxane bonds ensured uniform coverage of PC61BM on the perovskite layer and prevented the undesirable reaction between the mobile halide ions and Ag electrode. The quaternary ammonium cations on DMOAP formed dipoles, allowing the Ag layer to act as cathode. Thus, chloride anions on DMOAP efficiently provided n-doping of PC61BM via anion-induced electron transfer, increasing the conductivity of PC61BM film by more than 2 orders of magnitude producing 18.06% efficient cells, which is better than the un doped PC61BM film (PCE = 4.34%) and a state-of-the-art ZnO NPs interfacial layer (PCE = 10.40%). Combining this with an encapsulation layer, the devices exhibited long-term ambient stability, with negligible (<5%) loss in PCE after more than 5000 h of aging [158]. A fullerene derivative (α-bis-PCBM) was reported as a good template for solution processing of perovskite films producing α-bis-PCBM-containing perovskite solar cells with better stability, efficiency, and reproducibility against analogous cells containing PCBM alone. This occurred due to vacancy and grain boundaries filling by α-bis-PCBM of the perovskite film enhancing the perovskites crystallization. It resists the moisture ingression while passivating voids/pinholes generated in the hole-transporting layer resulting in 20.8% cells against 19.9% ones by PCBM, along with an excellent stability under heat and simulated sunlight. The PCE of unsealed devices dropped by less than 10% in ambient air (40% RH) after 44d at 65°C, and by 4% after 600h under continuous full-sun illumination @ maximum power point tracking, respectively [159]. Perovskite NCs were used in fabricating LEDs based on FA(1−x) CsxPbBr3 (FA = CH (NH2)2). These compounds with optimized composition (FA0.8Cs0.2PbBr3) exhibited the highest luminance of 55005 cd/m2 @ a current efficiency of 10.09 cd/A setting a new milestone in the development of bright and efficient perovskite LEDs [160]. With rapid growth of efficiency from 3.8% to 22.1% in recent years, perovskite solar cells (PVSCs) have drawn significant attentions from all using them. To develop high-efficiency and stable devices as well as environmentally benign perovskites is still critical because of the problems in PVSC development. In a recent review article, improved stability was reported introducing lead-free perovskite solar cells for further advances resulting in efficient and stable solar-to-electricity conversion technologies [161, 162]. Engineered interfaces between the photosensitive layer and the electrodes are promising for enhancing PCE of hybrid perovskite solar cells. A novel approach was reported by inserting hexamethonium bromide (HMB)-doped [6,6]-phenyl-C61-butyric acid methyl ester (PC61BM) film between the active layer and the Ag cathode. This interfacial layer delivered several useful features including solution processing, better electrical conductivity, and finer tuning of work function of the Ag electrode. Consequently, planar-hetero junction perovskite solar cells fabricated using such compositions could produce 18% cells with approximately 5.6-fold enhancement compared to the control devices (un doped PC61BM layer). A family of 15.58% cells was prepared even with larger thickness of PC61BM layer (120 nm). This appeared as the highest performance ever reported for perovskite SCs with a PC61BM thickness more than 100 nm. Large-area cells (active area = 1.2 cm2) via the doctor-blade coating exhibited 15.23% PCE with good long-term stability under an inert atmosphere. These results confirmed the utility of the interfacial layer in perovskite SCs being quite compatible with high throughput R2R manufacturing processes [163]. Lead-free perovskite solar cells with Sn were prepared except having the tendency of leakage from p-type defect states (Sn4+/Sn vacancies) resulting in poor reproducibility. A reduced pressure atmosphere during the fabrication of Sn perovskite solar cells was found useful with absorbers like MASnI3, CsSnI3, and CsSnBr3 enabling cells with PCEs of 3.89%, 1.83%, and 3.04%, respectively. The reduced pressure atmosphere during processing produced >20% reduction of Sn4+/Sn2+ ratios causing suppressed carrier recombination comparable to their Pb-based counterparts [164]. For taking care of two major problems of lead toxicity and stability of lead perovskite cells in field applications, employing low-toxic metal halide perovskites was suggested with other unexplored applications besides indicating towards further research directions in a recent review [165].

2.2.5. Location Detection