-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Hydraulic Engineering

p-ISSN: 2169-9771 e-ISSN: 2169-9801

2019; 8(1): 7-10

doi:10.5923/j.ijhe.20190801.02

Influence of Wingwall Configuration on Outlet Scour at Bottomless Box Culverts

Michael Horst

Associate Professor, Department of Civil Engineering, The College of New Jersey, Ewing, NJ, USA

Correspondence to: Michael Horst, Associate Professor, Department of Civil Engineering, The College of New Jersey, Ewing, NJ, USA.

| Email: |  |

Copyright © 2019 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The purpose of this study was to determine what influence the inclusion of wingwalls, of various types, located on the downstream side of a bottom box culvert, have on the magnitude of the resulting scour hole depths. Seven laboratory experiments were conducted with constant hydraulic conditions, each one with a different outlet configuration, and the resulting scour hole depths were measured. The results of the experiments showed the deepest scour holes occurred when there were either no wingwalls or when wingwall configurations were either at 45 degree angles or had a truncated circular beveled configuration. Conversely, the shallowest scour holes occurred when there was either a smooth wingwall placed on an 8 degree angle or a streamlined beveled wingwall configuration. Boundary roughness of the wingwall was also shown to influence the resulting scour hole depth.

Keywords: Culvert, Scour, Experimentation

Cite this paper: Michael Horst, Influence of Wingwall Configuration on Outlet Scour at Bottomless Box Culverts, International Journal of Hydraulic Engineering, Vol. 8 No. 1, 2019, pp. 7-10. doi: 10.5923/j.ijhe.20190801.02.

Article Outline

1. Introduction

- Scouring of bed material at hydraulic structures is of concern to design engineers. Should enough bed material erode in the vicinity of a supporting element (pier, abutment, foundation) such that the element becomes undermined, there is an increased likelihood that the structure will fail. Scouring phenomenon around bridges has been well-studied and a concise overview of some of the major studies/results is presented in Hydraulic Engineering Circular No. 18 - Evaluating Scour at Bridges (USDOT-FHWA 2012). Comparatively, previous analysis of scouring phenomenon at culvert outlets is sparse. Bohen (1970) completed the most inclusive study of scour at culvert outlets. He correlated the scour hole dimensions with various hydraulic parameters such as tailwater conditions, culvert diameter, flow rate, and Froude number. Abt et al (1987) investigated the influence that culvert shape had on the resulting scour hole at the outlet of a culvert. Their results showed that culvert shape has a direct influence on the overall magnitude of depth of the resulting scour hole. Abida and Townsend (1991) analyzed the influence of various hydraulic parameters, such as flow rate, depth, and culvert width, amongst others, on the resulting scour holes in a sand bottom. Their results showed that the location of the deepest part of the scour hole with respect to the immediate exit of the culvert is not constant but is influenced by hydraulic conditions. The purpose of this study was to determine what influence the wingwall configuration at the exit of a bottomless box culvert has on the magnitude of the resulting scour hole depth.

2. Scour Hole Experiments

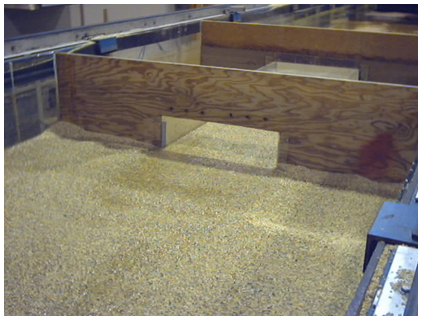

- A total of 7 experiments were performed, each one with constant hydraulic conditions (depth and velocity), but with differing outlet configurations. The seven different configurations at the outlet to the culvert consisted of the following: no wingwalls, wingwalls at an 8-degree angle with a “rough” (wood) finish, wingwalls at an 8-degree angle with a “smooth” (plexiglass) finish, wingwalls at a 45 degree angle with a “rough” (wood) finish, wingwalls with a “smooth” (plexiglass) truncated circular beveled shape, wingwalls with a “smooth” (plexiglass) short streamlined beveled shape, and wingwalls with a “smooth” (plexiglass) long streamlined beveled shape. Figures 1-7 show each of the outlet configurations.The experiments were conducted in a 21.34 meter (m) by 1.83 m rectangular flume with a 2.4 m by 1.83 m recessed section to allow for the scour hole formation. The walls of the flume were made of smooth glass. The flume was set at a constant slope of 0.04 percent, and the depth of flow was controlled with an adjustable tailgate located at the downstream end of the flume. Flow was supplied by a 0.3 cubic meter per second (m3/s) pumping system. The discharge was measured with an electromagnetic flow meter. The bottomless box culvert had a width of 0.60 m and a height of 0.15 m. Steady flow experiments were conducted for an approach flow depth of 0.12 m and an approach velocity of 0.15 m/s, leading to a flowrate of 0.033 m3/s. The particle size (D50) was kept constant at 2.0 mm. At the completion of each experiment, the water was slowly drained from the flume and an automated electronic distance meter was used to map the scour hole characteristics.

| Figure 1. Culvert outlet, no wingwalls |

| Figure 2. Culvert outlet, 8 degree rough (wood) finish wingwalls |

| Figure 3. Culvert outlet, 8 degree smooth (plexiglass) finish wingwalls |

| Figure 4. Culvert outlet, 45 degree rough (wood) finish wingwalls |

| Figure 5. Culvert outlet, truncated circular beveled shaped (plexiglass) wingwalls |

| Figure 6. Culvert outlet, short streamlined beveled shaped (plexiglass) wingwalls |

| Figure 7. Culvert outlet, long streamlined beveled shaped (plexiglass) wingwalls |

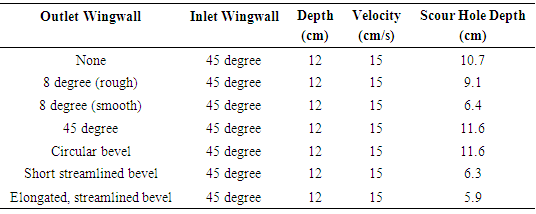

3. Experimental Results and Discussion – Outlet Scour

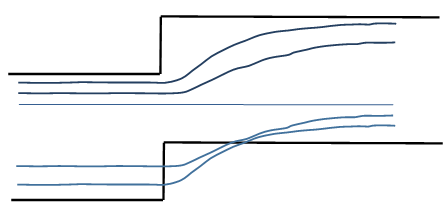

- Table 1 shows the results of the 7 trials. The resulting scour holes varied in depth between 5.9 cm and 11.6 cm. These results show a wide variation in resulting scour holes and verify that something other than flow conditions contribute to the overall scour hole dimensions. The deepest scour holes occurred with either no wingwalls (10.7 cm), wingwalls on a 45 degree angle (11.6 cm) or wingwalls with a truncated circular beveled wingwall (11.6 cm). It is very interesting to note that the inclusion of either the 45 degree wingwall or the truncated circular bevel wingwall actually led to the development of a greater scour hole depth as opposed to when no wingwall was included in the outlet configuration. Given that wingwalls placed on a 45 degree angle are commonly found in engineering designs, it is recommended that this configuration be tested in greater detail over a wider range of flow conditions to verify if the results remains consistent. The author surmises the reason that both the 45 degree and the truncated circular bevel configurations had high scour depths is due to the geometry of the wingwall expanding more rapidly than the streamlines of the flow exiting from the culvert, thereby leading the wingwalls to have no impact on the corresponding flow field.The shallowest scour holes resulted when a streamlined (elongated (5.9 cm), short (6.3cm)) or 8 degree smooth wingwall (6.4cm) was used. In both streamlined wingwall configurations, the geometry of the wingwall was designed to more approximately coincide with streamlines that result when flow transitions through a “sudden expansion” as generally depicted in Figure 8. The 8 degree wingwall configurations were tested to determine if the orientation of a linearly shaped wingwall could reduce the scour hole depth. The results of these three wingwall configurations indicate that the use wingwalls which either mimic natural stream line expansion when flow exits from a contracted section, or gradually expands the flow at a predetermined angle can have a significant impact on the resulting scour hole depth. The reason for this is that when flow exits suddenly from a contracted section, a separation vortex (vortex shedding) occurs which increases shear stresses felt on the channel bottom. The increase in shear stress will directly impact the resulting scour hole depth since sediment transport has been shown to be a function of both shear stress and grain size diameter (Shields, 1936). While the use of streamlined wingwalls may not be practical for design purposes, orientating linear wingwalls at angles less than the standard 45 degree may have a drastic impact on reducing scour depths at the outlet of box culverts. Additionally, a comparison of results between the 8 degree rough (wood) wingwall (9.1 cm) and the 8 degree smooth (plexiglass) wingwall (6.4 cm) shows that boundary roughness of the wingwall itself can have an impact on the overall scour depth and should be taken into consideration when trying to develop optimal designs with the purpose of reducing scour hole depths.

|

| Figure 8. Generalized streamlines as flow transitions through a sudden expansion |

4. Conclusions

- The outlet scour experimental results showed the effects of using different wingwall configurations at the outlet. Changing the angle and/or shape of the wingwalls affects the overall scour depth. The outlet experiments clearly demonstrate that outlet scour can be substantially reduced by using outlet wingwalls with a streamlined shape. The elongated streamlined bevel wingwall was best at reducing scour. The reason for this is because with the streamlined bevel there is less flow separation and hence an overall reduction in vortex shedding therefor leading to less turbulence and associated shear stresses felt along the channel bottom. Conversely, without the gradual flow expansion associated with the wingwalls, such as what occurs from a square (ie – no wingwalls) or abrupt exits (ie – 45 degree wingwalls), vortex shedding is induced and leads to increased scour depths. Finally, for design purposes, consideration should also be given to the roughness of the associated wingwall as “smoother” surfaces of the wingwall itself were shown to lead to shallower scour hole depths.

ACKNOWLEDGEMENTS

- The work presented in this paper was completed at the Federal Highway Administrations Turner-Fairbanks research facilities. These findings were discovered as part of a thorough analysis of scour occurring at both the inlet and outlet of various culvert shapes. The complete findings of the study can be found as part of Publication No. FHWA-HRT-07-026 (USDOT-FHWA 2007).

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML