R. R. Udawant1, A. M. Pathak1, N. K. Mohite2, S. R. Jadkar1, M. G. Takwale3, K. C. Mohite4

1School of Energy Studies, Department of Physics, Savitribai Phule Pune University, Pune, India

2AISSMS College of Engineering, Pune, India

3Department of Electronics Science, Savitribai Phule Pune University, Pune, India

4C.T. Bora College, Shirur, Pune, India

Correspondence to: K. C. Mohite, C.T. Bora College, Shirur, Pune, India.

| Email: |  |

Copyright © 2022 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

This paper presents evaluation of a thermal performance of linear Fresnel Lens Solar Concentrator (FLSC) system for generation of low pressure steam for cooking and industrial process heat applications. Linear refracting type Fresnel lens was used to concentrate solar radiation on a receiver which is placed at the focal line. The Experimental investigations were carried out to determine the thermal performance of FLSC system. A Fresnel lens having aperture area 2.84 m2 was used to develop thermosyphon based concentrator system. The solar radiation, fluid temperature, ambient temperature, steam temperature and pressure were recorded. Thermal efficiency and rate of heat delivery were evaluated from the experimental data. The performance of FLSC system has been studied on horizontal surface (β = 0) and tilted surface (β = 18.52°, latitude of Pune) to achieve the maximum yield in order to maximize the system performance. The overall efficiency has been improved due to the tilt from 43% at β = 0 to 53% at β = 18.52°. FLSC system generates steam required for the industry. The thermal performance of FLSC system has been compared with other solar concentrator systems available in India. The results obtained from FLSC system reveals that Fresnel lens Solar Concentrator system has a very good potential for generation of low pressure steam and other industrial applications.

Keywords:

Concentrating Solar Thermal, Steam Generation, Steam cooking, Process heating application

Cite this paper: R. R. Udawant, A. M. Pathak, N. K. Mohite, S. R. Jadkar, M. G. Takwale, K. C. Mohite, Thermal Performance of a Line Focus Fresnel Lens Solar Concentrator System for Generation of Low Pressure Steam, International Journal of Energy Engineering, Vol. 12 No. 1, 2022, pp. 15-22. doi: 10.5923/j.ijee.20221201.02.

1. Introduction

Solar Thermal Technologies developed during last twenty years are being used for many domestic as well as commercial uses. However, most of the applications are confined to the temperature range up to 80 ~ 100°C. Flat Plate and Evacuated Tube Solar Collectors provide thermal energy in the temperature range below 100°C and are cost effective, hence popularly used in the domestic sector and industries where temperature requirement is below 100°C. To generate thermal energy using solar radiation and needs operating temperature above 100°C, solar radiation is concentrated on absorber using some optical system. The optimum temperature generated by a solar concentrator depends on the Concentration Ratio. Solar Concentrators of various optical shapes, concentration ratio ranging from 3 to 500 have been developed during recent times and their use demonstrated for generating thermal energy in the temperature range 100 - 500°C or above. [1-6]. However, they are yet to become cost-effective. The major Solar Concentrator Technologies developed in recent times are; Compound Parabolic Collectors (CPC), Parabolic Trough Collectors (PTC), Parabolic Dish Concentrators (PDC), Fresnel Reflector Concentrators (FRC) and Central Receiver Systems or Power Tower [1,7]. These technologies have been developed mainly for electricity generation and have high capital investment. Besides, the deterioration of reflecting mirrors is a major problem [8,9,10].Fresnel lenses made of glass and plastics are extensively used in railway signals and as image magnifiers. However, these lenses are point focus and of small size. In recent years, point focus as well as linear focus Fresnel lenses made of acrylic material and of large size are developed for solar applications, mainly for Concentrated PV power systems [11]. However, very little work has been done on solar thermal applications of refraction type linear focus Fresnel lens solar concentrators.Recently Belgian company Solarmundo has been operating a 2500 m2 prototype Linear Fresnel lens collector system for steam generation at Liege, Belgium. However, in this system, reflecting mirrors are used for concentrating solar radiation on stationary receiver, hence system becomes bulky and costly. In some systems, point focus refracting Fresnel Lens made of acrylic with two axis tracking mechanism are used as a concentrating collectors for the application of power generation mainly for PV systems [4]. There are two types of Fresnel Lenses viz; “Reflective Lens” and “Refractive Lens”. Reflective Fresnel lens use mirrors to focus solar radiation on an absorber with the help of tracking system. Tracking may be one axis tracking or two axis tracking depending on the optical system. Refractive Fresnel Lens use plastic or glass lenses to focus solar radiation on the absorber. Both point focus and line focus lenses are used in the Fresnel solar concentrators. Fresnel lenses are more flexible as far as optical designs are considered and can produce uniform flux density on the absorber. For solar thermal applications, Linear Fresnel Reflectors have proved to be promising technology for medium temperature solar thermal applications. However, these systems are costly and bulky. Moreover, the detoration of reflecting surface due to atmospheric condition is a major problem. The major advantages of plastic/ acrylic Fresnel lens are; light weight, cheaper that mirrors and suitable for mass production. Fresnel lens is essentially a chain of prisms arranged in such way that solar radiation after passing through the prism is brought to focus at a point or on line. Each prism has different prism angle depending on the focal length and its location from the centre of the lens. The optical properties of Fresnel lens depend on many parameters such as pitch of the prism, prism angle of each prism, focal length etc. [28]Linear focus refracting type Fresnel Lens Solar Concentrator (FLSC) has been developed for thermal applications in the temperature range 100° to 200°C [12,13,14]. The studies presented in these papers demonstrate use of linear focus FLSC system for generation of low pressure steam using thermosyphon principle. In the present work long term thermal performance of FLSC system has been studied. The results have been compared with other solar concentrator systems.

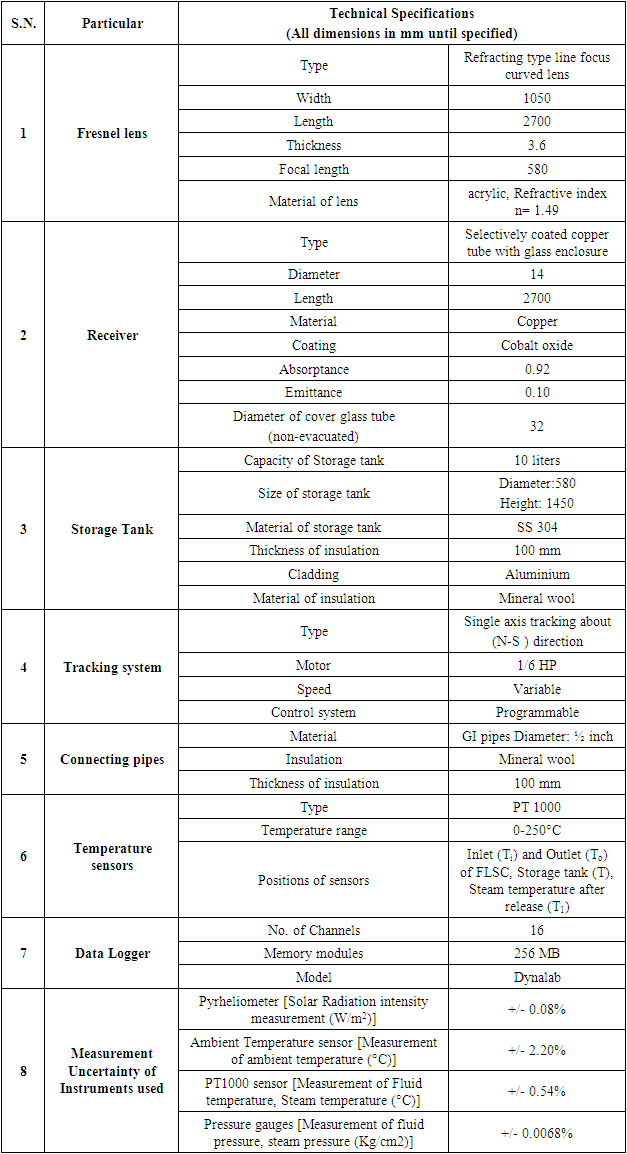

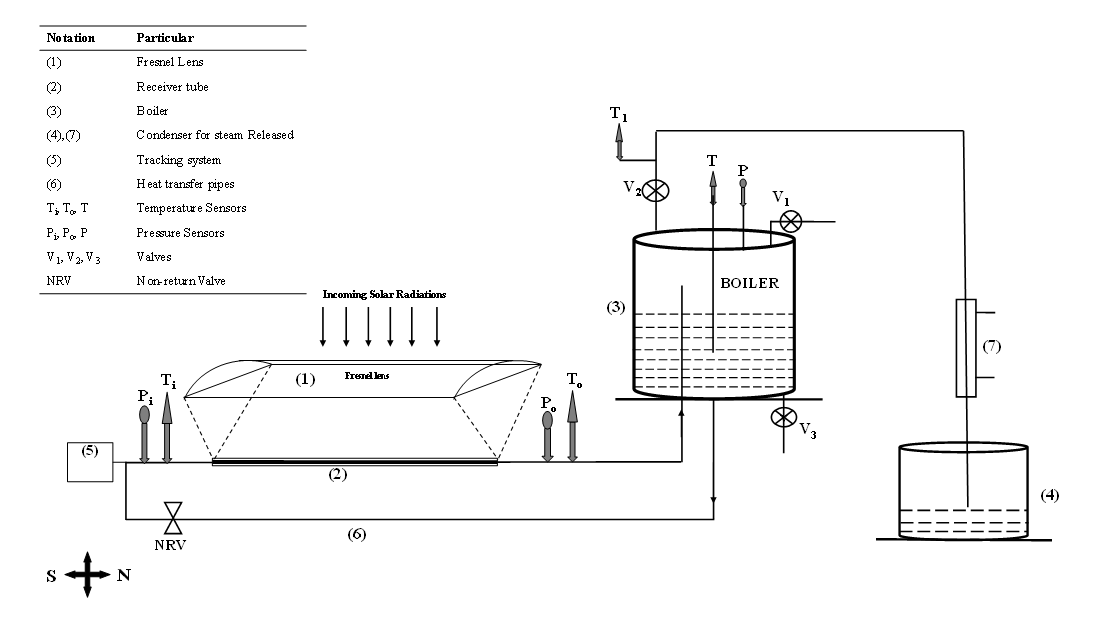

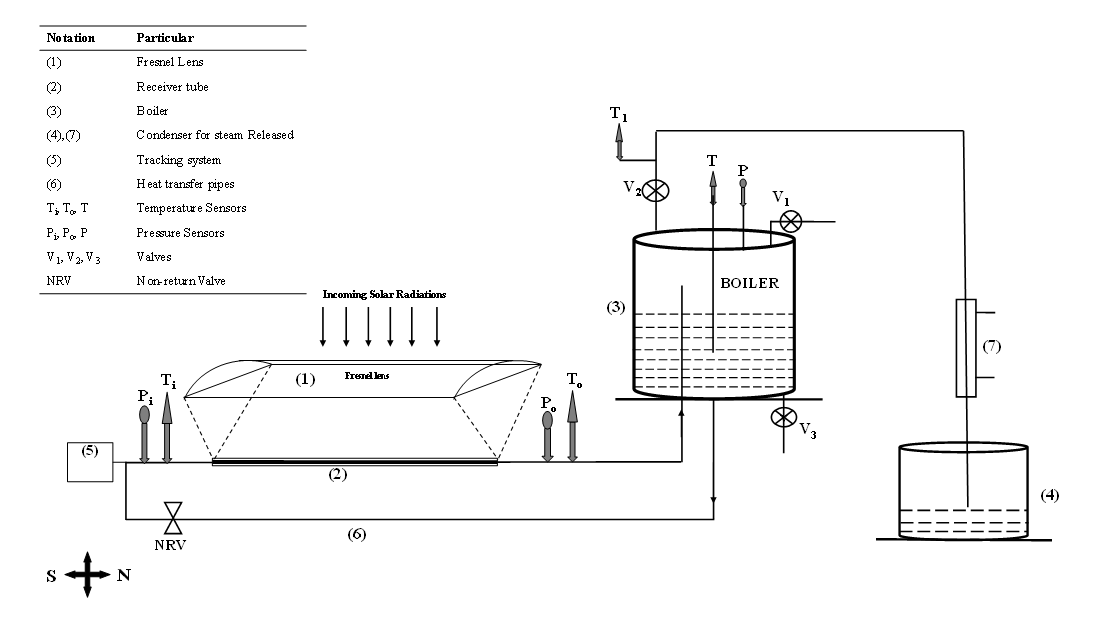

2. Experimental

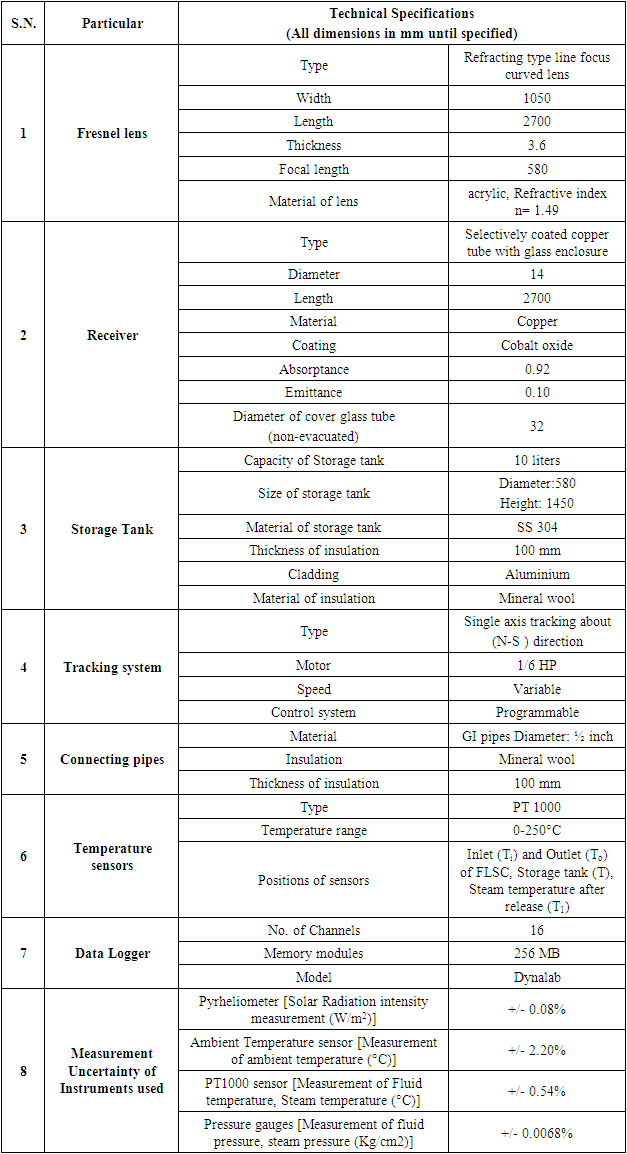

The linear focus FLSC System used for generating steam is basically closed loop system based on thermosyphon principle. The experimental set-up consists of a linear focus Fresnel Lens of size 1050 mm x 2700 mm and having focal length of 580 mm. The receiver is made of Cu-tube of 14 mm diameter and 3000 mm length coated with Cobalt Oxide selective coating. (α = 0.92, ε = 0.10 at 1000 C) The receiver is enclosed in a non-evacuated glass tube of diameter 32 mm and length 3000 mm and is placed along the focal line. The receiver is stationary and Fresnel Lens mounted on a frame rotates about the receiver tube using single axis tracking system. The boiler consists of a storage tank made of stainless steel of 10.0 litter capacity and insulated with mineral glass. The schematic view and photograph of the system are shown in the Figure (1a and 1b). The other specifications of the system are given in the Table (1). The experimental set-up used for studying the thermal performance of the system is as shown in the figure (1a). The system is placed on horizontal plane such that focal line of Fresnel Lens is along the North-South direction. The boiler is placed above the Fresnel Lens as shown in the figure (1a) and connected to FLSC using 15 mm pipe which is well insulated by mineral wool. The condenser system is attached to the exhaust of steam release valve to condense the steam and collect condensate in the container. The temperature and pressure sensors are placed at various points as shown in figure (1a). Table (1). The technical specifications of the FLSC System

|

| |

|

| Figure (1a). Schematic diagram of Fresnel Lens Solar Concentrating system |

| Figure (1b). Photograph of Fresnel lens solar concentrating system |

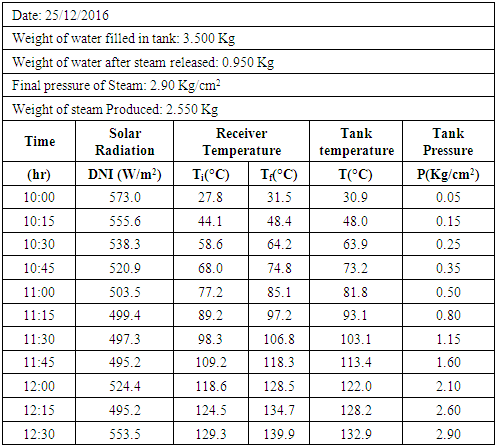

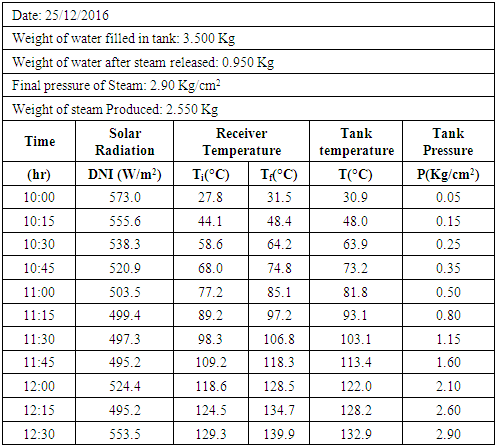

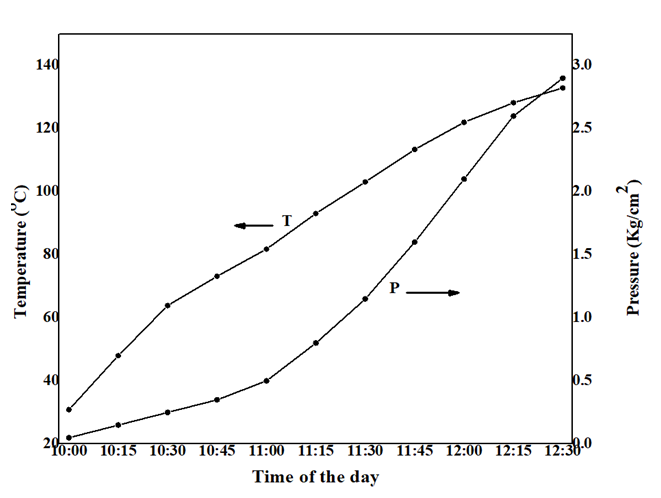

When solar radiation falling on the Fresnel Lens is concentrated on the receiver tube, water in the receiver tube gets heated; the heated water then is pushed to the boiler due to convection current. The equal amount of cold water from inlet side of the boiler is pushed to the receiver tube. Thus thermosyphon generates convective flow which keeps on circulating the water through the receiver. The continuous flow thus transfers heat received by the receiver to the boiler and temperature of water in the boiler increases. To study the thermal performance of the system, experiments were carried on clear sunny days. Initially cold water of known amount (3500 gram) is filled in the boiler such that enough space is left to accommodate the steam generated by heating water. On a clear sunny day, at about 10:30 am, Fresnel lens is adjusted so as to focus solar radiation on the receiver tube. Then the tracking system is started to track the sun. As soon as solar radiation is focused on the receiver tube, water in the receiver starts heating, the convective current starts and heat is transferred to the boiler. When water is heated at atmospheric pressure, the steam is generated when temperature reaches the boiling point. This “phase change” required large amount of additional heat input to convert water into vapour. In a closed loop system as steam is generated, the boiling point of water also increases, hence process required additional heat input besides Latent heat of vaporization. In FLSC system heat collected by the absorber is transferred to the boiler due to convection currents produced by thermosyphon. The “Latent heat of vaporization” demonstrates why steam is able to carry large amount of heat. [27].After about three hours, Fresnel Lens is defocused, the final temperature and the pressure of the steam measured and steam is released through the pressure relief valve and condensed in a condenser. Following parameters were measured during the period of experiments,1. Inlet (Ti) and outlet (Tf) temperatures of water passing through the receiver, 2. Temperature (T) of water in the tank,3. Pressure (P) of steam in the tank,4. Temperature of steam when released from boiler (T1),5. Direct Normal Irradiance (DNI),6. Ambient Temperature (Ta) and relative humidity (RH),7. Wind Velocity, 8. Weight of water filled in the boiler,9. Weight of water remained in the boiler after steam is released,10. Weight of water condensed. Experimental data were collected on clear sunny days during the period August (2016) to May (2017), the observations on a particular day are shown in the Table (2) and Figure (2). Experimental data were collected during the period August to May on clear sunny days to evaluate variation of efficiency with time. The months June and July were excluded from the data because during this period Pune receives monsoon rains and most of the time sky is covered with dense clouds. The rainfall during this period is almost 190mm of precipitation [26]. From these data the average monthly efficiency of FLSC system was evaluated, the results are shown in Table (3).Table (2). Experimental Data

|

| |

|

Table (3). Variation of thermal efficiency with time

|

| |

|

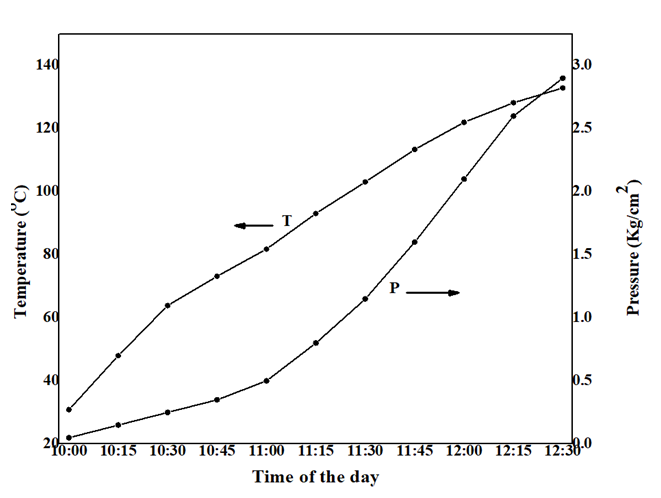

| Figure 2. Variation of temperature, pressure of the boiler water with time |

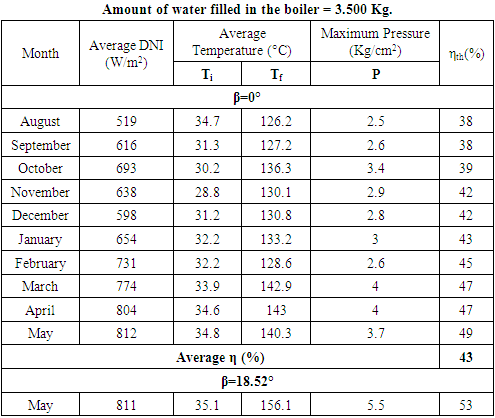

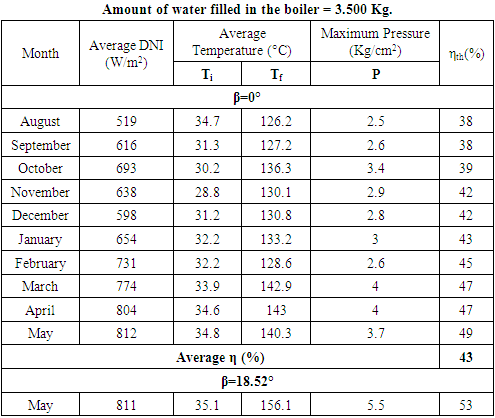

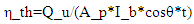

The system was set in the horizontal position (β = 0.00). In order to see the effect of inclination on the thermal performance of FLSC system, the system was tilted (β = 18.52°) and experiments were repeated in month of the May. Thermal Efficiency of the FLSC system: Thermal efficiency of the FLSC system is evaluated using following equation, | (1) |

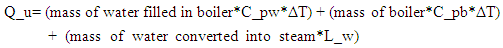

where Qu is the heat gain from the receiver during the interval of time (t), Ap is the aperture area of Fresnel Lens, Ib is the intensity of Direct Normal Irradiance (DNI), cosθ is the geometrical factor in which θ is the angle of incidence of solar radiation. The useful heat gain Qu in the experiment is heat received by the boiler from FLSC during the period of observation i.e. time t. Therefore, Qu is given by, | (2) |

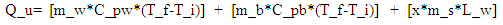

| (3) |

where mw is mass of water filled in the boiler, Cpw is specific heat of water, Ti initial temperature of water in the boiler, Tf is temperature of steam at the end of the time interval (t), Cpb is specific heat of boiler material, mb is the mass of the boiler material, ms mass of steam which is equal to the difference of mass of water filled in the boiler and mass of water remaining in the boiler after steam is released, Lw latent heat of vaporization of water at pressure P and x is dryness fraction which is assumed to be 1.0.

3. Results and Discussion

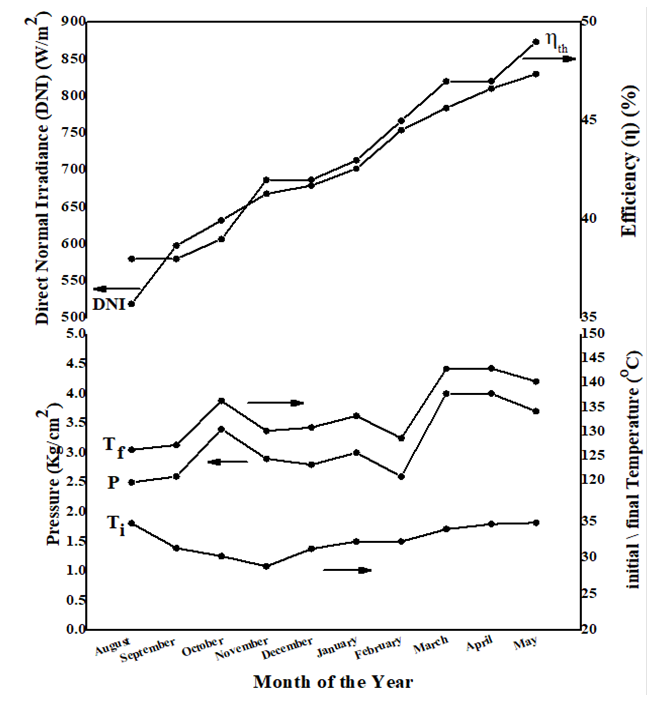

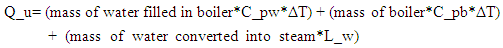

The thermal performance of a linear FLSC system depends on many parameters such as optical properties of the concentrator, absorptance and emittance of the receiver, tracking mode, intensity of solar radiation, heat extraction method, etc. In our studies equations (1) - (3) were used to evaluate the thermal efficiency ηth of the system. Figure (2) shows the variation of temperature and pressure of steam in the boiler, inlet and outlet temperatures of receiver, solar irradiance (DNI) with time of the day. Initially the pressure increases slowly till the boiling point of water is reached. Once the boiling point is reached, pressure increases fast. After a period of 2.5 hours, the temperature of the steam and pressure are 132.9°C and 2.90 Kg/cm2. The variation of average efficiency of the system, temperature and pressure of steam in the boiler and DNI with the months of the year 2016-17 is shown in the Figure (3) when the system was on the horizontal plane (β = 0.00). As can be seen from the figure that the efficiency of FLSC system increases with the intensity of the Direct Normal Irradiance (DNI), the average annual efficiency being 43%. | Figure 3. Variation of Efficiency, DNI, Initial temperature, Final Temperature and Pressure reached with months |

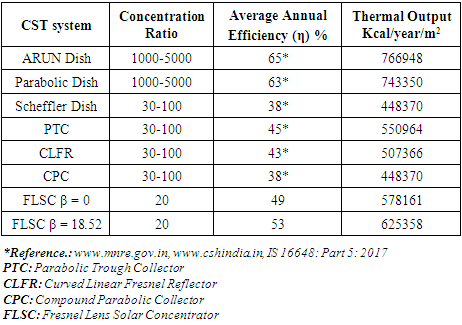

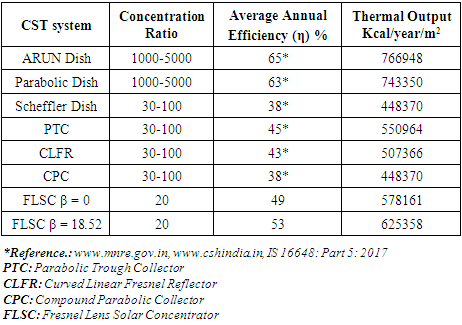

The FLSC is rotated about a horizontal N-S axis and adjusted continuously so that solar beam makes minimum angle of incidence with the aperture plane of Fresnel Lens. The angle of incidence varies from day to day which influences performance of the solar concentrator system [15-17]. When aperture plane is inclined at a fixed angle equal to the latitude of the place, the effect of the angle of incident can be reduced. Therefore, the FLSC system was tilted to the angle of latitude β = 18.52° and the thermal performance of the FLSC system was studied. The tilt angle β of the concentrator is defined as the angle between aperture plane of the concentrator and horizontal plane. When beam of solar radiation passes through the Fresnel lens and gets focused on the receiver, some part of focal line falls beyond receiver since focal line shifts according the angle of incidence which affects the performance of the concentrator [18-20]. It has been observed that the overall efficiency is increased to 53% and maximum temperature and pressure of the steam in the boiler were 162.5°C and 6.2 Kg/cm2 respectively. When aperture plane is tilted with horizontal plane, the Buoyancy force increases on up-coming vapour in the absorber and gravity force increases on down coming liquid from the boiler to lower end of the absorber. The process increases the convection current and more heat is transferred to boiler, hence efficiency increases. In the month of May, Solar radiation is almost perpendicular to the horizontal plane, hence intensity of solar radiation on the inclined plane is slightly less than intensity of solar radiation on horizontal surface. Hence increase in efficiency of the system when aperture plane is inclined to horizontal plane is due to buoyancy force.In a single axis tracking system, the incident solar radiation always makes some angle with the normal of the aperture plane. Due to this, the focal line goes out of end of the absorber tube, hence part of some radiation is lost which affects the efficiency of the system. To avoid this, we have made an arrangement to move Fresnel lens along line of focus, so that by moving Fresnel lens end losses can be avoided.The thermal performance of different solar concentrator systems has been studied by number of authors [21-25]. In these studies, the average thermal efficiency of various types of systems is in the range 35% - 50%. We have compared thermal efficiency of our system with solar concentrator systems available in India. In India, six types of solar concentrator systems are available in the market. The thermal performance of these systems is summarised in Table (4). It is clear from Table (4) that the average efficiency and thermal output of Arun and Parabolic dish are about 64% and 755149 Kcal/year/m2 respectively since these concentrators are point focus and have higher concentration ratios. Scheffler dish, PTC, CLFR and CPC have lower efficiencies (~ 38 - 45%) and thermal output (~ 448370 - 550964 Kcal/year/m2) since these are non-imaging solar concentrators having lower concentration ratios. FLSC system which we have developed have thermal efficiency (~ 49%) and heat output (~ 578161 Kcal/year/m2) for horizontal mounting which is higher compared with non-imaging solar concentrator systems developed in India. Further, the efficiency and thermal output can be enhanced by inclining aperture plane of the concentrator by an angle equal to latitude of the place.Table (4). Thermal performance of various types of Solar concentrator systems in INDIA

|

| |

|

The expected thermal output from our FLSC system is found to be 1641920 Kcal/year at tilt angle β = 0° and 1776016 Kcal/year at tilt angle β = 18.520. Thus FLSC system gives more thermal output compared with other non-imaging solar concentrator systems and has tremendous potential in the process heat applications.

4. Conclusions

The analysis of thermal performance of linear FLSC system has shown that,1. The overall efficiency of linear FLSC is about 43% at β = 0 and 53% at β = 18.52° and can generate process steam required in the industry. The expected heat delivery from the FLSC system is found to be 16, 41,920 Kcals/year at β =0 and 17, 76,016 Kcals/year at β = 18.52°.2. The performance of FLSC system has been improved by tilting the system at the angle equal to latitude of the place. Because of the tilt, buoyancy force increases on up going vapour which gives enhanced thermal performance.3. Refracting type Fresnel Lens Solar Concentrators can be used for generating heat in the temperature range of 1000 to 2000 C. Fresnel lens solar concentrator system has advantage that lens has life more than 5 years which is very important for cost effective application, whereas for reflecting type solar concentrator, mirrors have to be changed every three to four years because of the deterioration of mirrors.

ACKNOWLEDGEMENTS

The authors are thankful to Prof. S. R. Jadkar, Director, School of Energy Studies and Prof. S. V. Ghaisas, former Director School of Energy Studies, SavitribaiPhule Pune University, Pune 411 007 India for providing laboratory facilities for this work.

References

| [1] | Firdaus Muhammad-Sukki, Roberto Ramirez-Iniguez, Scott G, Mc Meekin, Brian G. Stewart, Barri Clive: “Solar Concentrator”, International Journal of Applied Science Vol.1 (2010) p.1. |

| [2] | R. Pitz Paal: “High temperature solar concentrators”, Solar energy conversion and photenergy Systems, EOLSS publication (2009) Vol.1, p.199. |

| [3] | S. Madala, R.F. Boehm: “A review of non-imaging solar concentrators for stationary and passive tracking applications”, Renewable and Sustainable Energy Review (2017). |

| [4] | L. wang, Z. Yuan, Y. Zhao: “Review on development of small point - focusing Solar concentrators”, Journal of Thermal Sciences (2049) Vol.28, p.929. |

| [5] | Nayab Bushra, Timo Hartmann: “A review of state of art reflective two stage solar concentrators” Technology categorization and research trends, Renewable and sustainable energy review (2019) Vol.114, P.109307. |

| [6] | R. Leutz, A Suzuki: “Non-imaging Fresnel Lenses design and performance of Solar Concentrator” Springer Publication (2001). |

| [7] | John A. Duffie and William A. Beckman: “Solar Engineering of Thermal Processes”, Third Edition (2006). |

| [8] | S. P. Sukhatme and J. K. Nayak: “Solar Energy, Principles of Thermal Collection and Storage” Tata McGraw-Hill Publication (2013). |

| [9] | H. P. Gerg and J. Prakash: “Solar energy fundamentals and applications”, Tata McGraw-Hill Publishing Company Limited, New Delhi (1997). |

| [10] | A newsletter of Industrial Research and Consultancy Centre; “Solar Concentrator for Industrial Process Heat, Update” IIT Bombay, Issue-1, (2006). |

| [11] | Ralf Leutz, Akio Suzuki, Atsishi Akisawa and Takao Kashiwagi: “Design of a Non imaging Fresnel lens for solar concentrators”, Solar Energy 65, 6, 379-387, (1999). |

| [12] | A. M. Pathak: “Development and study of Fresnel lens based solar concentrator”, Ph. D Thesis, University of Pune (2009). |

| [13] | R. R. Udawant, “study of performance of line focusing Fresnel lens solar concentrator” M. Phil. thesis, S.P. Pune university, (July 2013). |

| [14] | Udawant Rahul, Mohite Kakasaheb, Takwale Murlidhar: “Study of Performance of fresnel lens solar concentrator”, International Journal of Energy Engineering. (2016) 14-22. 10.5923/s.ijee.201601.03. |

| [15] | Gadhia Deepak: “Successful use of Solar Concentrators for various applications from cooking to process needs for rural development: Indian Experience”, www.gadhiasolar.net. |

| [16] | M.J. Brooks, I. Mills, T.M. Harms: “Performance of a parabolic trough solar collector, Journal of energy in southern Africa” (2006) Vol.17 P. 307. |

| [17] | Abdulkadir Kocer, Ismet Faruk Yaka, Gozde Tugce Sardogan and Afsin Gungor: “Effect of tilt angle on Flat Plate Solar Thermal collector systems”, British Journal of applied Science and Technology (2015), Vol. 1, P.17. |

| [18] | Development and Optimization of a Parabolic Trough Collector System for Generation of Industrial Process Heat, www.fabrikderzukunft.at. |

| [19] | The 2nd European Solar Thermal Energy Conference: “PTC 1000 - Modular parabolic trough collector”, Freiburg, (21-22 June 2005). |

| [20] | P. Selvakumar, Dr. P. Somasundaram: “Effect of Inclination Angle on Temperature Characteristics of Water in-Glass Evacuated Tubes of Domestic Solar Water Heater” International Journal of Engineering and Innovative Technology (IJEIT) Volume 1, Issue 4, (April 2012). |

| [21] | Vishal R. Sardeshpande, Ajay G. Chandak and Indu R. Pillai: “Procedure for thermal performance evaluation of steam generating point-focus solar concentrators”, Solar Energy 85, 1390-1398 (2011). |

| [22] | Liang Zhang, Wujun Wang, Zitao Yu, Liwu Fan, Yacai Hu, Yu Ni, Jianren Fan and Kefa Cen: “An experimental investigation of a natural circulation heat pipe system applied to a parabolic trough solar collector steam generation system”, Solar Energy, 86, Issue 3, 911-919, (March 2012). |

| [23] | Tao Tao, Zheng Hongfee, Hey Kaiyan, Xue Xiaode, Xie Guo: “Performance comparison and experimental study on seven kind of congregation type solar concentrator”, International journal of low-carbon technologies (2009) Vol.4, p.246. |

| [24] | A. Nene, S. Suyambazhan, S. Ramchandra: “Comparative analysis of performance of two Scheffler Solar Concentrator having different concentration ratios”, International journal of Engineering and technology (2017) Vol.9, p.704. |

| [25] | G.N. Tiwari, D. Atheaya, A/ Tiwari: “Review on Solar Thermal Power Concentrators” MOJ Solar and Photo energy systems (2017), Vol.1, p.71. |

| [26] | www.weather-atlas.com |

| [27] | www.cleanboiler.org |

| [28] | Gang Wang, Zeshao Chen, Peng Hu, Xiaofang Cheng, "Design and optical analysis of band focus Fresnel Lens Solar Concentrator" Applied Thermal Engineering, vol. 102, (2016) p. 695-700. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML