-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Energy Engineering

p-ISSN: 2163-1891 e-ISSN: 2163-1905

2020; 10(3): 90-94

doi:10.5923/j.ijee.20201003.03

Comparative Study of Coal Mixing Using Chevron Stockpile and Windrow Stockpile Methods in PT. Anugerah Bara Kaltim Kecamatan Loa Janan District Kutai Kartanegara Provinsi Kalimantan Timur, Indonesien

Sakdillah, Windhu Nugroho

Mining Engineering Faculty of Engineering, Mulawarman University, Jl. Sambaliung No.9, Sempaja Selatan, Samarinda City, East Kalimantan, Indonesien

Correspondence to: Sakdillah, Mining Engineering Faculty of Engineering, Mulawarman University, Jl. Sambaliung No.9, Sempaja Selatan, Samarinda City, East Kalimantan, Indonesien.

| Email: |  |

Copyright © 2020 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

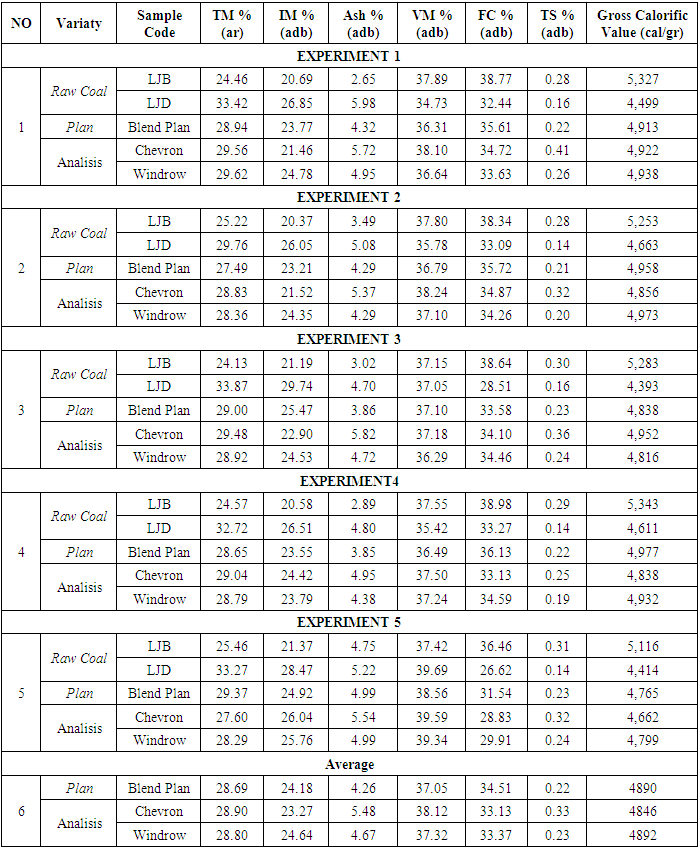

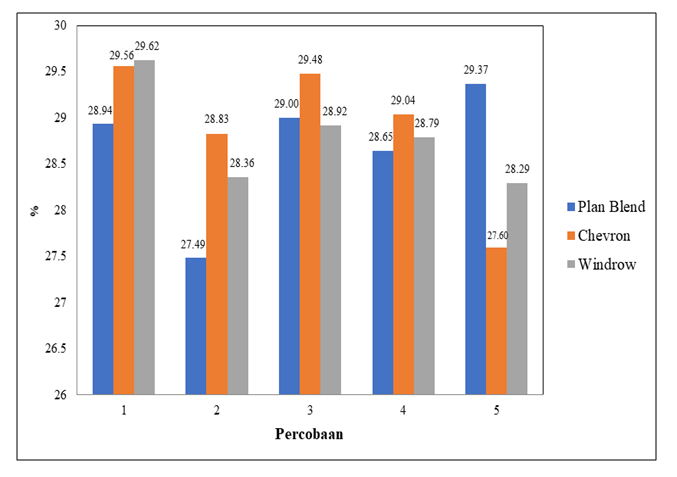

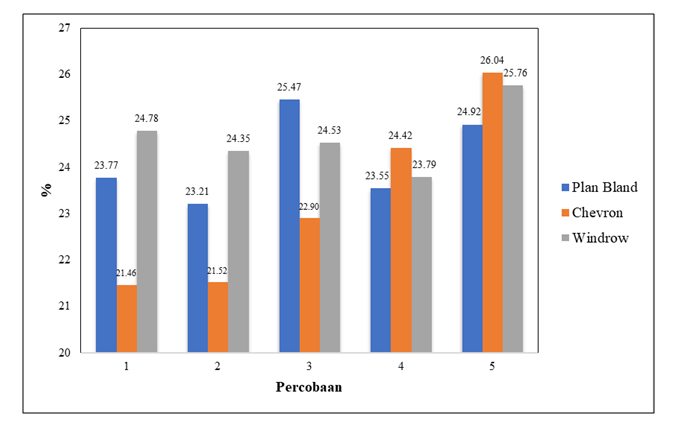

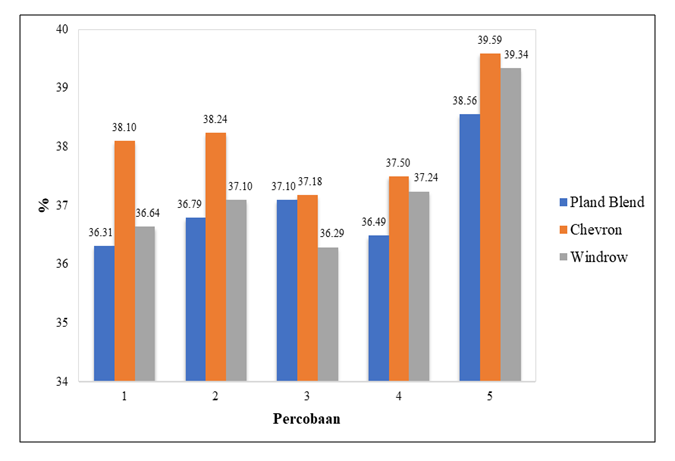

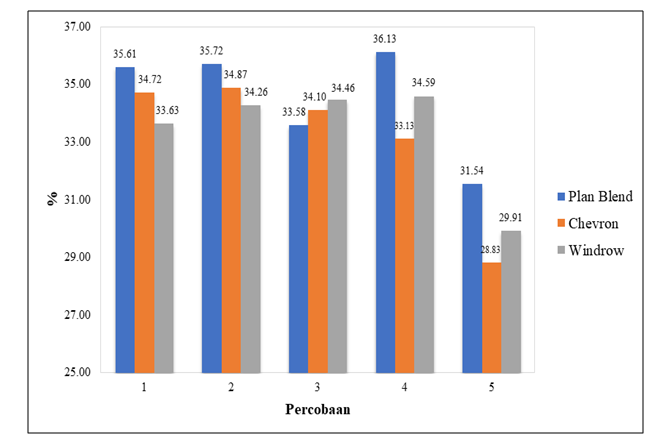

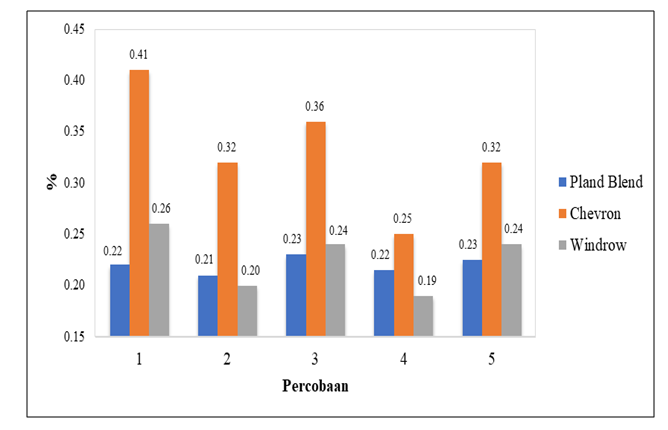

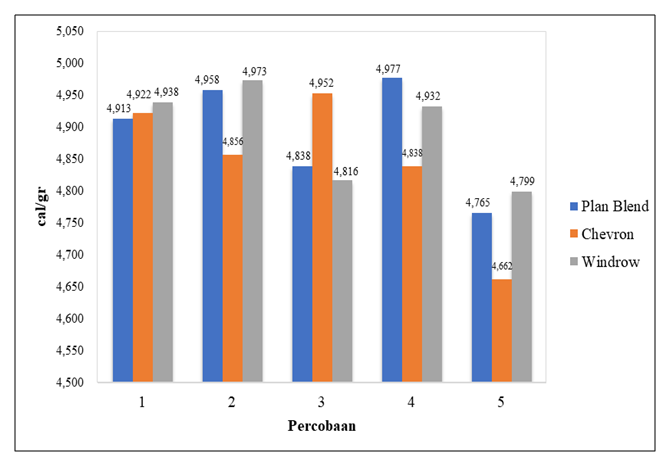

Coal is still used in various industries with certain specifications, such as caloric value, ash content, sulfur content (Total Sulfur), flying substances (Volatile Matter) and water content (Total Moisture). Because the availability of coal with a variety of qualities is certainly not possible to meet the specification criteria that can be used by industry. Therefore we need a coal mixing system that can provide the quality desired by the industry or Market. In mixing coal there are several methods which are carried out and have different homogeneity. Coal blending using the chevron stockpile method and the windrow stockpile method were tested 5 times. Then the preparation of process was carried out using method of proximate analysis was carried out on the coal. The analysis results were then processed using the exel application. In the chevron stockpile method, the fluctuation value of coal quality analysis was as follows: total moisture had a range of 10.90, inherent moisture had a range of 14.58, ash content had a range of 39.76, votalite matter had a range of 4.71, fixed carbon had a range of 10.14, total sulfur had a range of 72.72 and calorie value had a range of 5.15. In the windrow stockpile method, coal quality fluctuation values were as follows: total moisture had a range of 6.84, inherent moisture had a range of 8.6, ash content had a range of 22.28, votalite matter had a range of 4.24, fixed carbon had a range of 8.18, total sulfur had a range of 31.82 and calorie value had a range of 1.61.

Keywords: Coal mixing, Chevron stockpile method, Windrow stockpile method, Coal preparation, Coal analysis, Coal quality

Cite this paper: Sakdillah, Windhu Nugroho, Comparative Study of Coal Mixing Using Chevron Stockpile and Windrow Stockpile Methods in PT. Anugerah Bara Kaltim Kecamatan Loa Janan District Kutai Kartanegara Provinsi Kalimantan Timur, Indonesien, International Journal of Energy Engineering, Vol. 10 No. 3, 2020, pp. 90-94. doi: 10.5923/j.ijee.20201003.03.

Article Outline

1. Background

- Coal is a very complex mixture of organic chemicals that contain carbon, oxygen and hydrogen in a carbon chain. Coal comes from plants that have died and are buried in a basin filled with water for a very long time, around millions of years to thousands of years. Coal is also one of the types and fuels for energy generation and is one alternative energy source that is currently increasing rapidly in the world market as an abundant and economical source of energy.The increasing demand for coal in the world, makes Indonesia exploit this fuel on a large scale. Its greater availability and lower price compared to petroleum makes coal more economical when used in industry.In its development, coal has now become one of the largest regional revenue contributors for the East Kalimantan region, one of which is a company that has contributed to the revenue, namely PT. Anugerah Bara Kaltim. Coal is still used in various industries with certain specifications, such as caloric value, ash content, sulfur content (Total Sulfur), flying substances (Volatile Matter) and water content (Total Moisture).Because the availability of coal with a variety of qualities is certainly not possible to meet the specification criteria that can be used by industry. Therefore we need a coal mixing system that can provide the quality desired by the industry.In mixing coal there are several methods of accumulation which are carried out and have different homogeneity. Therefore this research was conducted in order to find out the comparison of the level of homogeneity between methods.

2. Research Methodology

- Data Collection Techniques.This research was conducted in the area of the Coal Handling Facility (CHF) at PT. Anugerah Bara Kaltim. Some things that become a reference in taking data in this thesis include:1. Taking Coal for Mixing CoalSampling is taking a small portion of material from a large pile of material to represent the overall quality of the large material. Sampling is done in ROM Stockpile.2. Coal BlendingThe method for mixing various kinds of coal and the mixing method used in this study were the chevron stockpile method and the windrow stockpile method.3. Sampling for AnalysisThis sample is taken after mixing the mixed coal and this sampling is done randomly.4. Coal Sample PreparationPreparation is a process of working the sample before it is analyzed by making the size and condition of the sample ready for analysis, the stages of which include drying if the coal is wet, reducing the size of the sample, mixing and reducing the weight of the sample by dividing it into two parts.

|

| Figure 1. Total Moisture |

| Figure 2. Ash Content Graph |

| Figure 3. Volatile Matter Graph |

| Figure 4. Fixed Carbon Graph |

| Figure 5. Total Sulfur Graph |

| Figure 6. Calorific Value Graph |

3. Error Factors in Research

- Based on my research, there were factors that cause imperfections in this research, namely the treatment of sampling that will be used in analyzing my research. In this study I conducted vertical sampling using a shovel and should had taken horizontal sampling using a pipe to match the rules of taking at the stockpile using a drill tool. Due to the limited use of sampling tools in the company, this study uses a shovel tool that did not use pipes and horizontal sampling was more difficult to use a shovel than a pipe.

4. Conclusions

- 1. The process of coal mixing is done by 2 methods, namely the chevron stockpile method and the windrow stockpile method.a. In the chevron stockpile method the coal piling process is in the first stage with LJB quality with a weight of ± 30 kg, then in the second stage LJD quality coal weighing ± 30 kg is stacked on top of the first pile, after that it is piled back with LJB quality with a weight of ± 30 kg kg for the third and fourth stages are stacked on top of the third stack with LJD quality with a weight of ± 30 kg to form a pyramid.b. In the windrow stockpile method, the process of coal stacking in the first stage is by stacking 3 adjacent piles of coal with a quality of LJB weighing ± 10 kg, then the second stage between the LJB stacks is stacked with coal quality LJD weighing ± 20 kg, after that the third stage is stacked back at on the LJD pile, LJB quality coal weighing ± 10 kg, and in the fourth stage there is a stacking of LJB piles with LJD quality coal pile of ± 20 kg, and the last stage is the LJB quality coal stacking ± 10 kg as much as above the LJD pile thus forming a pyramid.2. Differences in the quality of mixing coal with the chevron stockpile method and the windrow stockpile method in 5 trials include:a. Chevron Stockpile Methodi. Total moisture has a range of 10.90ii. Inherent moisture has a range of 14.58iii. Ash content has a range of 39.76iv. Votalite matter has a range of 4.71v. Fixed carbon has a range of 10.14vi. Total sulfur has a range of 72.72vii. Calorie value has a range of 5.15b. Windrow stockpile methodi. Total moisture has a range of 6.84ii. Inherent moisture has a range of 8.6iii. Ash content has a range of 22.28iv. Votalite matter has a range of 4.24v. Fixed carbon has a range of 8.18vi. Total sulfur has a range of 31.82vii. Calorie value has a range of 1.613. Based on my research, there are factors that cause imperfections in this research, namely in the treatment of sampling that will be used in analyzing my research. In this study I conducted vertical sampling using a shovel and should have taken horizontal sampling using a pipe to match the rules of taking at the stockpile using a drill tool. Due to the limited use of sampling tools in the company, this study uses a shovel tool that does not use pipes and horizontal sampling is more difficult to use a shovel than a pipe.

5. Suggestion

- It is better to do the combustion wire installation more carefully to avoid miss fire and the installation of a bomb calorimeter must be tight and be careful because there can be an explosion when the analysis process is going on.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML