-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Energy Engineering

p-ISSN: 2163-1891 e-ISSN: 2163-1905

2019; 9(1): 7-11

doi:10.5923/j.ijee.20190901.02

To What Extent Could Methanol, Toluene and Gas Condensate Effect on Heavy Crude Oil Viscosity, Sheikhan Oil Field, Kurdistan, Iraq

Hawbash Mahmood1, Ahmed AlBajalan2

1Head of Petroleum Lab, Ministry of Natural Resources, Erbil, Iraq

2Petroleum Technology, Erbil Technical Institute, Erbil Polytechnic University, Erbil

Correspondence to: Ahmed AlBajalan, Petroleum Technology, Erbil Technical Institute, Erbil Polytechnic University, Erbil.

| Email: |  |

Copyright © 2019 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Sheikhan crude oil faces obstacles during transportation from production wellsite to processing facilities due to high viscosity. To enhance the flowability, reducing the sheikhan crude oil viscosity is a promising approach. For this purpose, a heavy crude oil sample from Sheikhan oilfield was blended with various rate of industrial polar solvents such as (Toluene, methanol) and gas condensate at different temperatures. This experimental study shows that mixing sheikhan heavy crude oil with toluene have a good reduction in the crude oil viscosity since this polar tends to interface between asphaltene sheets and dissociation of asphaltene aggregates. However, the impact of methanol on viscosity is less where this solvent tends to forming hydrogen bond between asphaltene sheets and methanol molecules. Finally, the gas condensate reduced the crude oil viscosity but its impact reduced at higher temperature.

Keywords: Heavy Crude Oil, Viscous Crude Oil, Crude Oil Recovery, Chemical Solvents

Cite this paper: Hawbash Mahmood, Ahmed AlBajalan, To What Extent Could Methanol, Toluene and Gas Condensate Effect on Heavy Crude Oil Viscosity, Sheikhan Oil Field, Kurdistan, Iraq, International Journal of Energy Engineering, Vol. 9 No. 1, 2019, pp. 7-11. doi: 10.5923/j.ijee.20190901.02.

Article Outline

1. Introduction

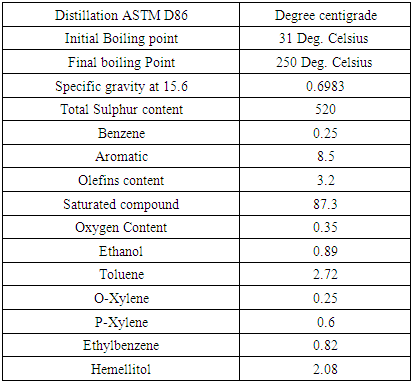

- Heavy crude oil is a complex fluid with a viscosity and density higher than the conventional oil. Where the viscosity of this type of crude oil is greater than 100 c.p and the specific gravity is less than 20 API degree [10]. These two physical factors affect negatively on the crude oil mobility in both in-situ and surface conditions [2]. According to the Iraqi ministry of oil, heavy crude oil forms 55% of the total of oil in place (OIP) and most of which are on developing stages. The figure 1. The existence of viscous heavy crude oil in high amount in Sheikhan oil field attract the petroleum companies to extract and produce it. exhibit the heavy crude oil distribution in the north part of Iraq.

| Figure 1. Heavy crude oil distribution according to the ministry of oil [1] |

2. Crude Oil Viscosity Dilution Techniques

- Several techniques have been utilized and examined to reduce the viscosity factor of heavy crude oil. However, dilution is one of the most common and widely used method. Since it allows increase the mobility of heavy and extra - heavy crude oil from a production site to processing units (P. Gateau, 2004). These techniques are: a) Viscosity dilution by adding light hydrocarbon or alcohols b) Crude oil viscosity reduction by applying heatc) Chemical viscosity reduction additives.

2.1. Dilution with Light Liquid Hydrocarbons and Alcohol

- This technique considers one of the effective and preferred option to reduce viscosity and increase the flow rate of heavy crude oil. Dilution with light liquid hydrocarbons fractions is widely used to facilitate pathway in the pipeline, and it involves adding light crude oil or condensate natural gas to heavy crude oil [5]. Although, the availability of transporting light hydrocarbon fractions or condensate from natural gas production, the large investment for pumping and pipeline are needed. The reason is increasing the volume of heavy crude oil carried and the need to separate the chemical solvents from the heavy crude oil at the same place [4]. This technique may face some challenges where any adjustment in the constitute of the crude oil impact on the required proportion of crude oil and solvents ratio [12].It is also important to predetermine the viscosity and compatibility of crude oil solution. In addition, diluting the heavy crude oil with light fractions can change the stability of the asphaltene and cause them to flocculate and patriciate which in turn block pipelines [6].

2.2. Viscosity Dilution by Applying Source of Heat

- The method is widely utilized to reduce the viscosity of heavy crude oil. The main principle of this technique lies in the fact that the viscosity factor decreases by increasing heat. The applied heat making the crude oil easier to be pumped through pipeline from the produced well to the production facilities. Therefore, it is necessary to maintain the temperature high at which the crude oil is extracted by isolated pipe [16]. Furthermore, an additional heat is required to be applied to the pipe which transports the crude oil due to the loss of the heat. This loss occurs as a result of a slow flow of crude oil through the pipeline. Therefore, the crude oil needs to be re-heating at the pump station [7].However, the main limitation of this operation is the high operational cost especially for a long distance. Secondly, it is difficult to stable the temperature of the heavy crude oil in the pipeline when it transported underwater [15].

2.3. Viscosity Dilution by Chemical Substances

- A series of studies have examined the chemical additives as a viscosity reducer in crude oil applications. However, these additives are extremely selective which means that some additives lack effectiveness for a specific type of crude oil [16]. In order to select the suitable chemical additives, it is essential to know rate of asphaltene in the crude oil whether it is low or high, the level of paraffin and the quantities of sulfur, nickel in the crude oil [13,17].Based on the investigation performed by (Xie, et al., 2001) the oil based or the water based chemical additives are two important factors for crude oil viscosity dilution. The study shows that the oil-based additives a good crude oil viscosity reducer for low and medium crude oil. However, the water-based additives were excellent reducer for high viscosity. According to (Junaki, et al., 2012) mixing the heavy crude oil with chemical ionic additives, dilute the viscosity of heavy crude oil sample up to 65%.

3. Methodology

3.1. Material and Apparatus

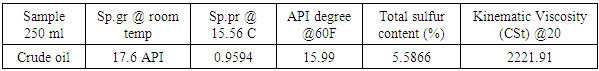

- A sample of heavy crude oil from sheikhan oil field/ Kurdistan / Iraq reservoir was collected in order to carry out this experimental study. The density of the sheikhan heavy oil sample is equal to 0.9594 gm/cc at the standard condition and the viscosity is 2221. 91C.st at the atmospheric pressure and temperature of T = 20°C. The table. 1 below summarizes the physical properties of the crude oil.

|

|

|

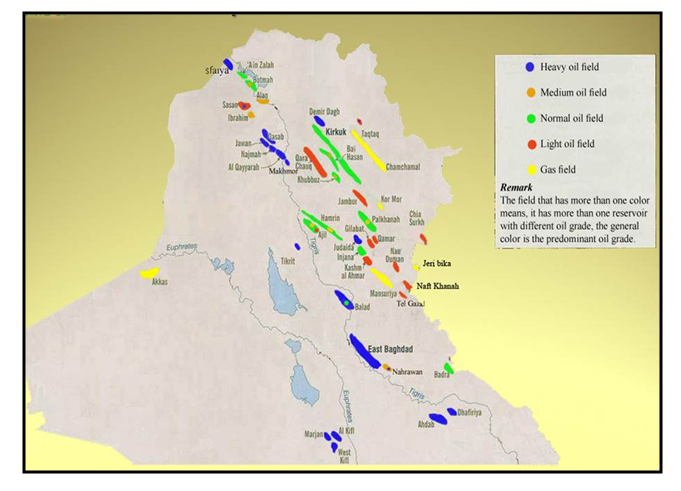

| Figure 2. Canon Fenske Viscometer |

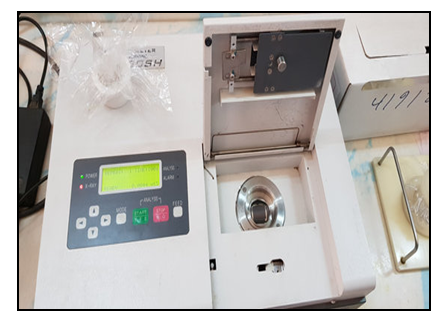

| Figure 3. X -Ray sulfur meter |

3.2. Crude Oil Sample Preparation

- The detailed experimental procedures for preparing the heavy crude oil sample for viscosity reduction are illustrated below. Firstly, the density and the specific gravity of the crude oil sample were measured by ASTM D1298 method (Hydrometer glass) at room temperature. Then the kinematic viscosity and sulfur content for the heavy crude oil sample were measured at room temperature. Secondly, 250 ml of heavy crude oil sample was mixed with methanol toluene and gas condensate of known concentrations (5, 10, 15, and 20 vol.%) in a closed beaker by stirrer device via magnet rotation. After appropriate mixing, Canon Fenske Opaque viscometer was utilized to measure kinematic viscosity at different temperatures (20, 35, 40 and 50 degree Celsius) and different solvents concentration.Finally, the total sulfur content of heavy crude oil was measured by X - ray sulfur meter with the same condition above.

4. Result and Discussion

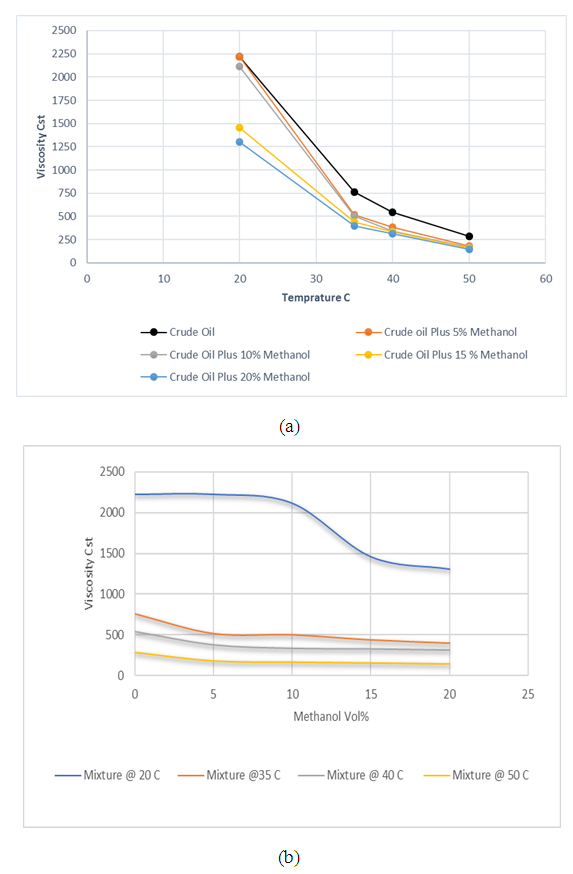

- The two significant factors which reduce the viscosity of heavy crude oil are temperature and polar chemical solvents. In this study, the heavy crude oil sample with different solvents concentration at different temperature was examined to measure the effect of these factors on heavy crude oil. The figures 4 (a &b) show that heavy crude oil viscosity reduction by using methanol solvent at different rate didn’t contribute that much on viscosity reduction, or there is slight decrease in the viscosity of heavy crude oil.

| Figure 4. (a, b) Viscosity of heavy crude oil with different Methanol concentration at different temperature |

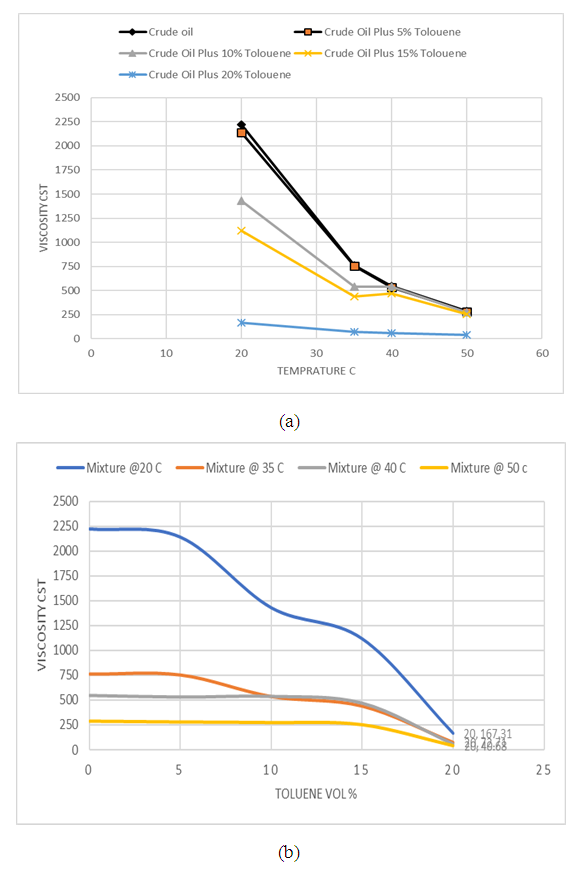

| Figure 5. (a, b) Viscosity of heavy crude oil diluted by Toluene solvent at different rates and temperatures |

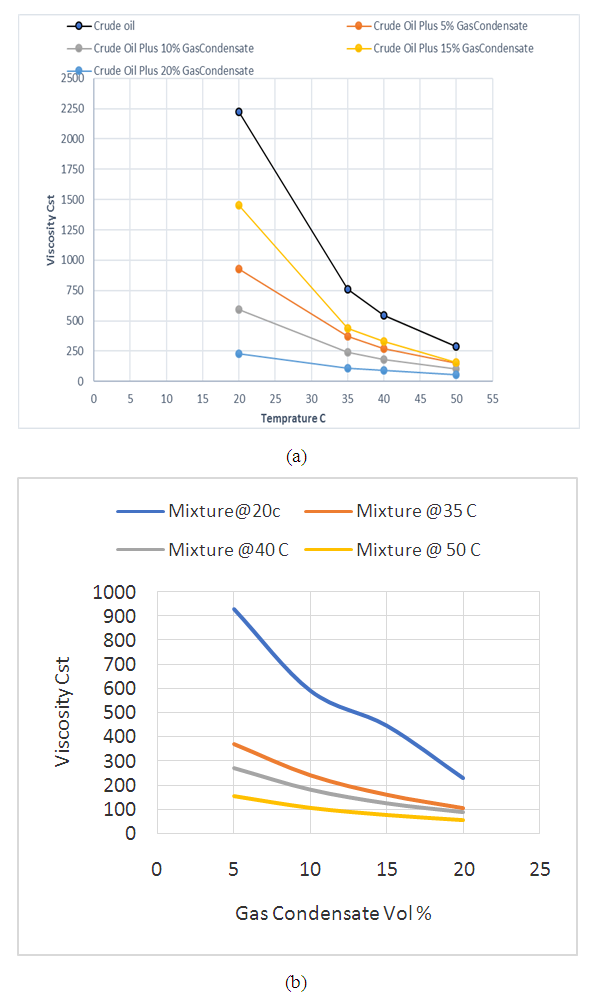

| Figure 6. (a, b) Viscosity reduction by gas condensate at different concentration and temperatures |

5. Conclusions

- Based on the experimental results which obtained from this research it can be concluded that, treating the sheikhan heavy crude oil sample with toluene solvent exhibits a high reduction in the crude oil viscosity. This is due to, the aromatic characteristic in this polar solvent. Where the aromatic molecules of toluene tend to settle between asphaltene molecules and increasing the breaking down of asphaltene agglomerates. We also concluded that, the influence of methanol on heavy crude oil viscosity was less comparing with other polar solvents. Where methanol solvent creating hydrogen bond between methanol molecules and asphaltene. Although the gas condensate diluted the viscosity of heavy crude oil, the situation was complex and it depends on the type of heavy crude oil. Since the gas condensate at high API showed lower viscosity reduction compared with, the lower one.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML