Giyanto1, Hardiansyah Sinaga2

1Department of Plantation Product Processing Technology, STIPER Agrobisnis Perkebunan (STIP-AP), Medan, Indonesia

2Department of Plantation Agriculture, STIPER Agrobisnis Perkebunan (STIP-AP), Medan, Indonesia

Correspondence to: Giyanto, Department of Plantation Product Processing Technology, STIPER Agrobisnis Perkebunan (STIP-AP), Medan, Indonesia.

| Email: |  |

Copyright © 2019 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

Palm oil industry waste has the potential to be used as a raw material for alternative energy sources as a substitute for fossil fuels. This research aim was to determine the characteristics and quality of charcoal bio-briquettes produced from oil palm empty fruit bunches and oil palm fronds with starch as the adhesives. This research used a non-factorial completely randomized design with three replications. The results showed that differences in the composition of ingredients significantly affected the calorific value, water content, density and ash content of charcoal bio-briquette. Calorific value is positively correlated with water content and particle density but negatively correlates with bio-briquette ash content.

Keywords:

Bio-briquette, Energy, Waste

Cite this paper: Giyanto, Hardiansyah Sinaga, The Making and Quality Testing of Bio-Briquette from Oil Palm Waste Raw Materials as an Alternative Energy, International Journal of Energy Engineering, Vol. 9 No. 1, 2019, pp. 1-6. doi: 10.5923/j.ijee.20190901.01.

1. Introduction

Energy is one of the basic human needs, consumption of energy in Indonesia is increasing year by year. Data from the Ministry of Energy and Human Resources [1] recorded Indonesia's energy consumption in 2017 reached 1.23 billion Barrels Oil Equivalent (BOE), raise 9% from the previous year. However, reserves of conventional non-renewable fuel are depleting. Many efforts to diversify energy sources have been carried out, one of which is the use of agricultural, plantation and forestry wastes [2]. Oil palm empty fruit bunches is one of the wastes produced in the processing of fresh fruit bunches into crude palm oil, the waste volume is large because in processing 1 ton of FFB produces 20-23% of oil palm empty fruit bunches [3]. Other wastes produced are fronds derived from oil palm pruning in the field. Generally, both wastes are used as mulch, but this waste is difficult to decompose because of the high content of lignin, cellulose and lignocellulose [4]. The decomposition process of oil palm empty fruit bunches and oil palm fronds takes 12 to 18 months [5], during the decomposition process there is a loss of nutrients due to evaporation and leaching [6]. Fronds stack between oil palm trees interfere with the application of oil palm agricultural mechanization tools [7] and can be a place to nest / host for pests and diseases [8] hence their use is considered to be less effective. Other uses of oil palm empty fruit bunches and oil palm fronds need to be developed to make them more useful and economic value. In this research, bio-briquette from oil palm empty fruit bunches and oil palm fronds raw material was made. Bio-briquettes are artificial solid fuels which are considered strategic to replace oil fuels. Briquettes produced from oil palm empty fruit bunches and oil palm fronds are relatively more environmentally friendly because they do not produce toxic gas emissions [9]. Briquetting was aiming to obtain a quality fuel that can be used for all sectors as an alternative energy source [10]. Research on the effect of stem, midrib and leaf composition variation of palm oil plants on the quality of bio-briquette charcoal was obtained the highest calorific value in variations of 0% stem, 100% midrib and 0% leaves with a caloric value of 5419.53 cal/gr and the lowest obtained in the composition of 50% stems, 10% midribs and 40% leaves with a calorific value of 4931.13 cal/gr [11]. Another research, making briquettes from shells and oil palm empty fruit bunches showed the largest calories in the treatment of shell composition, empty bunches and adhesives with a ratio of 2: 1: 0 resulting 5.196 cal/g [12]. In this research, charcoal bio-briquette was made by utilizing empty bunches and oil palm fronds in order to determine the characteristics and quality of the bio-briquettes produced.

2. Materials and Methods

2.1. The Experiment

This research used a non-factorial completely randomized design. The treatment was done by mixing the types of briquette-making materials, namely oil palm empty fruit bunches and oil palm fronds with certain compositions which aim to observe the effect of the ingredients composition combination on the quality produced. The basis for choosing this composition refers to the research [11] which stated that the best bio-briquette is obtained in the treatment with a composition of 0% stems, 100% midribs and 0% leaves of oil palm. Furthermore, in this research midribs/fronds were combined with oil palm empty fruit bunches. The selection of oil palm empty fruit bunches was due to the large volume of empty bunches obtained from the processing of oil palm fresh fruit bunches [3]. The mixing of both briquette material composition was assumed to have the same mass i.e. 1000 grams per treatment.The making of briquettes was divided into 7 ingredients combinations, namely: C1:100% oil palm empty fruit bunches; C2:80% oil palm empty fruit bunches, 20% oil palm fronds; C3:60% oil palm empty fruit bunches, 40% oil palm fronds; C4:50% oil palm empty fruit bunches, 50% oil palm fronds; C5:40% oil palm empty fruit bunches, 60% oil palm fronds; C6:20% oil palm empty fruit bunches, 80% oil palm fronds and C7:100% oil palm fronds. Each treatment was carried out 3 replications. The collected data were analyzed and tested the parameters compiled on the variance list, the significant results were followed by the Duncan's Multiple Range Test (DMRT). DMRT involves the computation of numerical boundaries that allow for the classification of the difference between any two treatment means as significant or non-significant [13].

2.2. Procedure for Making Bio-briquettes

Oil palm empty fruit bunches and oil palm fronds were cleaned of dirt, then dried under the sun. The dried material was put in the carbonization kiln, after becoming charcoal then mashed and sifted to obtain a uniform material size. The material size of charcoal was 20 mesh.Next, print charcoal flour into briquettes. The adhesive used was starch which was dissolved in water with a ratio of 1:10, then heated.The mixture of starch that has become adhesive, mixed with charcoal flour from the results of sifting, then stir the mixture hence all ingredients were evenly mixed. The results of the briquette dough were put into the press type briquette mold, ovened at a temperature of 105°C for about 12 hours, the resulting briquettes were tested for the characteristics of calorific value, water content, particle density and ash content.

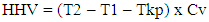

2.3. Observation Parameters

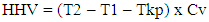

The quality of the calorific value was measured using a bomb calorimeter (cal/gr) tool.Ÿ Calculated calorific value with the formula: Description:HHV = Higher Heating Value (calg-1) T1 = temperature before bombing (°C)T2 = temperature after bombing (°C)1 Joule = 0.239 kalCv= heat type of bomb calorimeter (73,529.6 joulekg-1°C)Tkp = the increase of the ignition wire temperature (0,05°C)Ÿ Water ContentWater content can be obtained using equations:

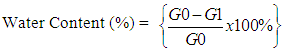

Description:HHV = Higher Heating Value (calg-1) T1 = temperature before bombing (°C)T2 = temperature after bombing (°C)1 Joule = 0.239 kalCv= heat type of bomb calorimeter (73,529.6 joulekg-1°C)Tkp = the increase of the ignition wire temperature (0,05°C)Ÿ Water ContentWater content can be obtained using equations: Description:G0 = sample weight before drying (g) G1 = sample weight after drying (g) Ÿ Density (particle density) Briquette density can be calculated using the equation:

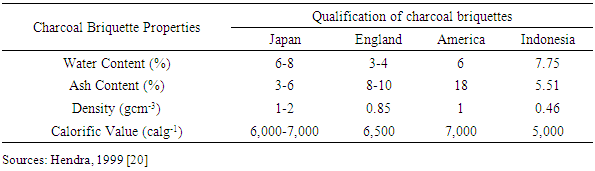

Description:G0 = sample weight before drying (g) G1 = sample weight after drying (g) Ÿ Density (particle density) Briquette density can be calculated using the equation: Description:K: Density (gr cm-3)G: Briquette weight (gr) V: Volume (cm3)Ÿ Ash ContentThe amount of ash was calculated by the formula:

Description:K: Density (gr cm-3)G: Briquette weight (gr) V: Volume (cm3)Ÿ Ash ContentThe amount of ash was calculated by the formula:

3. Results and Discussions

The production of briquettes made from a mixture of empty bunches and palm oil fronds with an adhesive of starch as much as 10% and the size of cylindrical 20 mesh briquettes have been made. Visually the bio-briquettes produced can be seen in Figure 1. | Figure 1. Bio-briquette from empty bunches and oil palm fronds raw materials |

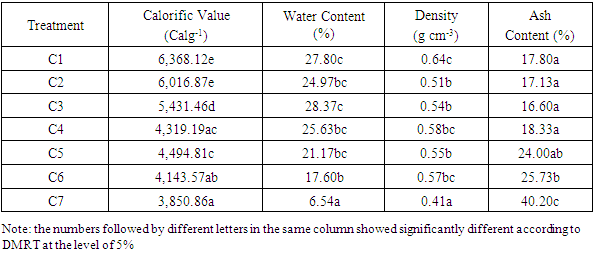

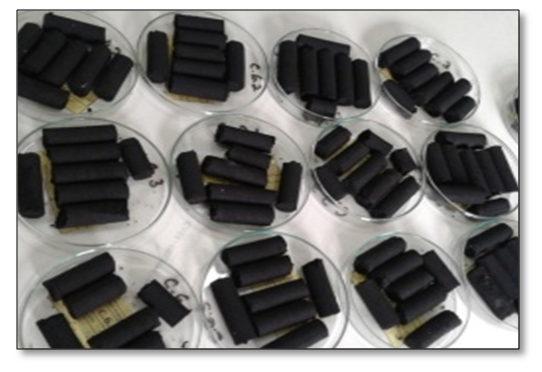

Based on statistical tests, differences in the composition of empty bunches and oil palm fronds significantly affect the calorific value, water content, density and ash content of the bio-briquettes produced. The average calorific value, water content, bio-briquette density and ash content also the Duncan test results were presented in Table 1.Table 1. The average of calorific value, water content, density and bio-briquette ash content

|

| |

|

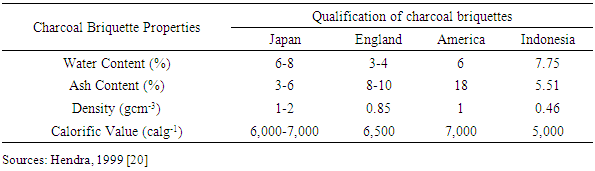

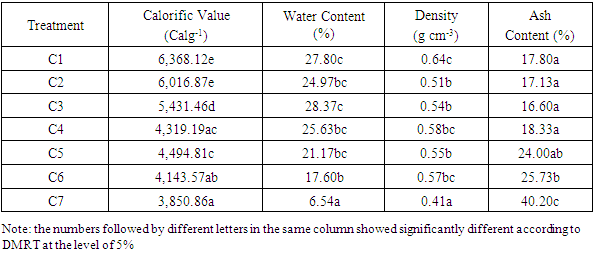

Table 2. Quality standards for Japan, England, America and Indonesia charcoal briquettes

|

| |

|

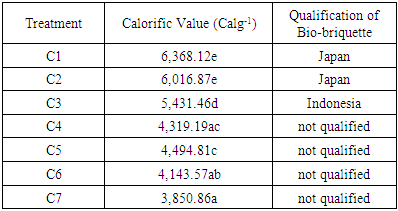

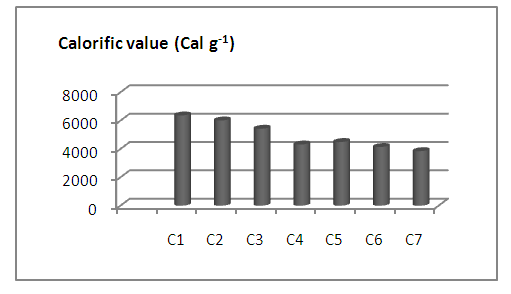

3.1. Calorific Value

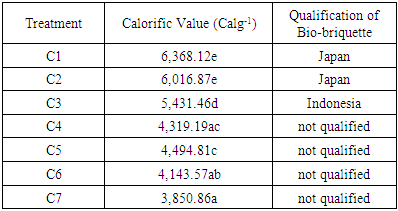

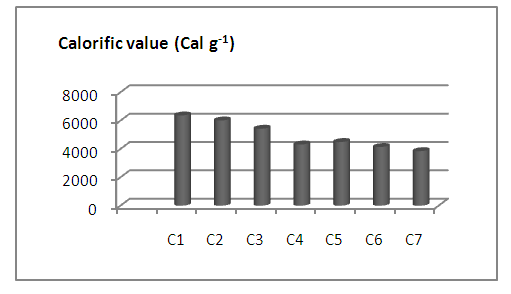

Based on statistical tests, the difference in the composition of empty bunches and oil palm fronds on the making of charcoal bio-briquettes had a significant effect on the calorific value produced.Table 3. The average of calorific value and qualification of Bio-briquette

|

| |

|

The lowest calorific value was found in the C7 treatment, which was 3,850.86 calg-1, while the highest calorific value in treatment C1 was 6,368.12 calg-1. In the research of making biochar briquettes from shells and oil palm empty fruit bunches produced bio-briquettes with calorific values between 3,537.00 calg-1 up to 5,196.00 cal g-1, lower than the calorific value produced in this research. The calorific value determines the quality of briquettes [12]. The higher the calorific value, the better the quality of the briquettes produced. One of the factors that affect the quality of briquettes is raw materials. The drier the material used, then the water content contained in the briquette will be small hence it will be able to provide a high calorific value [2]. | Figure 2. Calorific value of charcoal bio-briquette |

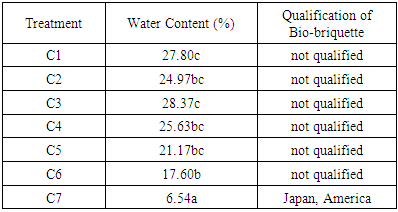

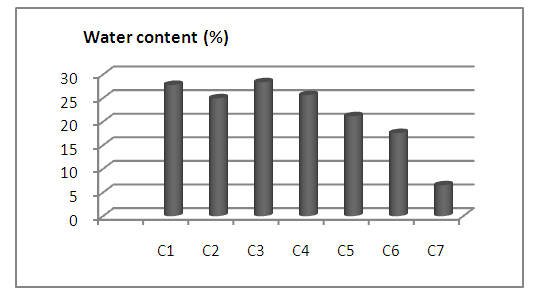

3.2. Water Content

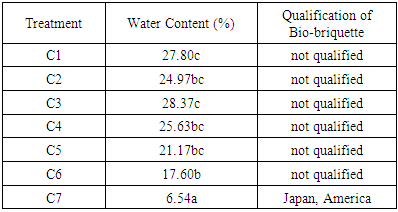

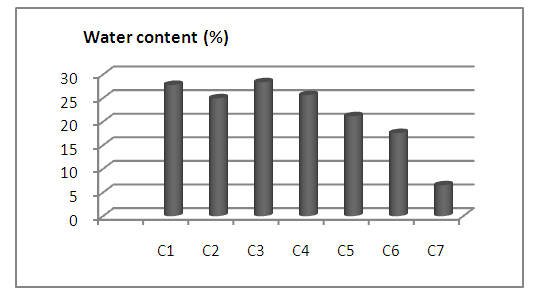

The difference in the composition of empty bunches and oil palm fronds significantly affected the water content of bio-briquettes. Table 4. The average of water content and qualification of Bio-briquette

|

| |

|

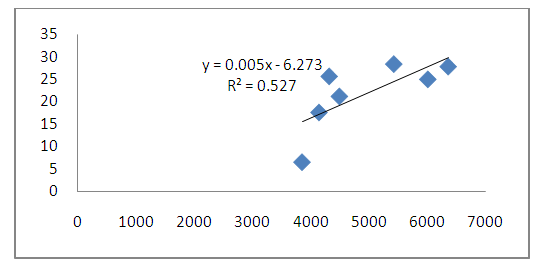

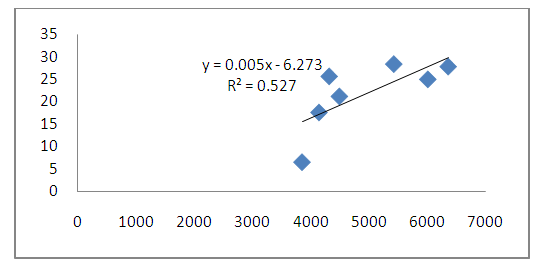

The percentage of water content of bio-briquettes produced in this research was quite high, above the standard percentage and only in the treatment of C7 (100% oil palm fronds) that meets Japan and Americanstandards. In the research on the effect of oil palm empty fruit bunches application to the quality of briquettes made from cassava peel waste conducted by [14], the highest water content was found in briquettes with the largest empty bunches composition. Water content has a large effect on the heat produced. Briquettes that still contain high water content will make it difficult to ignite, cause smoke and cause the heat produced to decrease [15]. The high water content is caused by one of the charcoal briquettes properties which are hygroscopic hence when making briquettes there is still bound water from outside, charcoal has the ability to absorb large amounts of water from the surrounding air which is influenced by surface area and charcoal pores. In this research can be seen the relationship between the composition of briquettes raw materials, the calorific value and water content. In general, the higher the empty bunch composition compared to the fronds composition, the higher the calorific value produced and the water content of the bio-briquette. Linear regression equation of calorific value and moisture content; y = 0.005x - 6.273, R² = 0.527 and correlation coefficient (r) = 0.72 strong category [16]. Thus it can be stated that the calorific value produced correlates strongly with the bio-briquette moisture content. | Figure 3. Water content of charcoal bio-briquette |

| Figure 4. Linear regression of calorific value with bio-briquette water content on different raw material compositions |

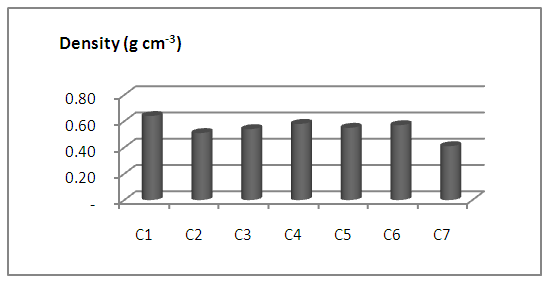

3.3. Density

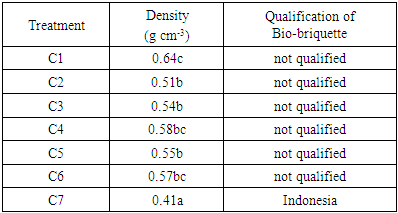

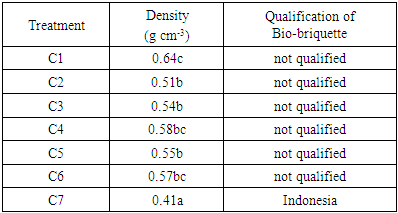

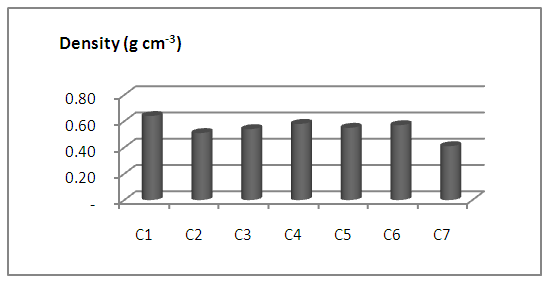

The density showed the ratio between the weight and volume of the briquette. Table 5. The average of density and qualification of Bio-briquette

|

| |

|

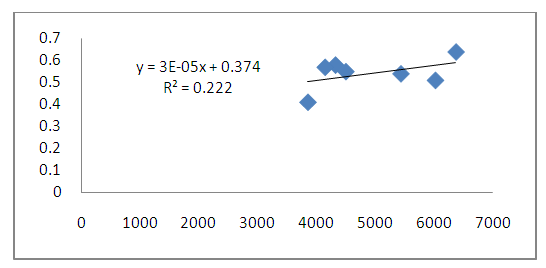

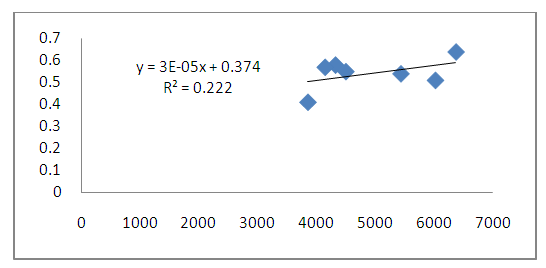

The density value produced in this research varied between 0.41g cm-3 to 0.64 g cm-3. The lowest density value of 0.41 g cm-³ was obtained in the treatment of C7 (100% oil palm fronds) and the highest average density value was obtained in treatment C1 (100% oil palm empty fruit bunches) of 0.64 g cm-³. The results of the charcoal bio-briquette analysis in this research showed that empty bunches without fronds charcoal mixture produced the highest density, while in bio-briquettes with fronds charcoal raw materials showed the lowest density. In contrast to the research of [14], the greater the empty bunch composition in briquette making, causing the density value to decrease. The density affects the quality of charcoal briquettes because with high density can increase the calorific value of charcoal briquettes. The size of density is influenced by the size and homogeneity of the charcoal making up the briquette. According to [17], the higher the uniformity of the charcoal powder size will produce charcoal briquettes with higher density and firmness. The finer the size of the charcoal powder, the bond between the powder is stronger hence it can increase the density of charcoal briquettes. The density will affect the packaging, storage and transportation of briquettes, if the greater the density, the volume or space needed will be smaller for the same weight of briquettes [18]. The relationship between the calorific value and particle density was expressed in the regression equation, y = 3E-05x + 0.374, R2 = 0.222 and the correlation coefficient (r) = 0.47. Thus it can be stated that the bio-briquette calorific value produced was moderately correlated. | Figure 5. Charcoal bio-briquette density |

| Figure 6. Linear regression of calorific value with the density of bio- briquette on different raw material compositions |

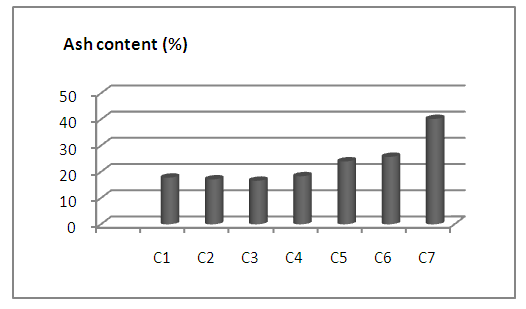

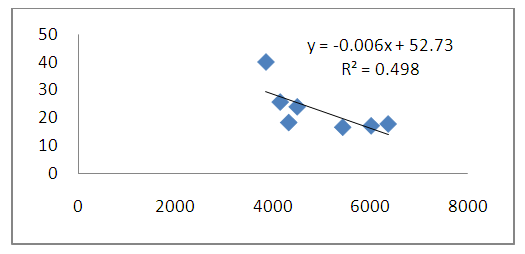

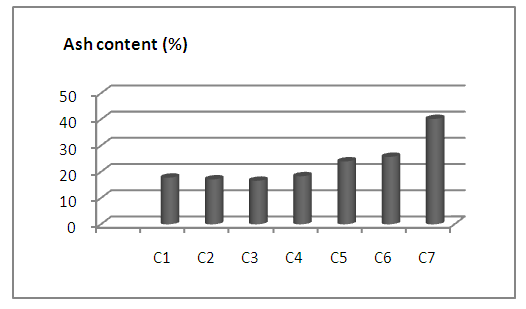

3.4. Ash Content

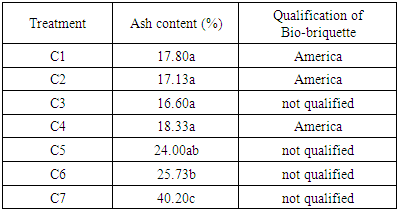

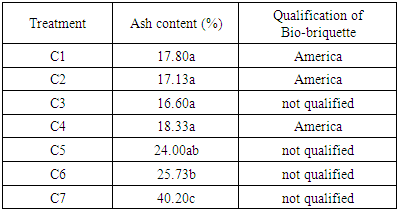

Determination of ash content was intended to find out the unburned part which has no more carbon elements after the briquettes were burned. Table 6. The average of ash content and qualification of Bio-briquette

|

| |

|

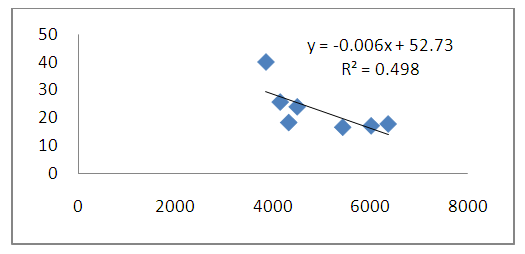

In this research, the lowest ash content was 16.60%, obtained in C3 treatment (60% oil palm empty fruit bunches, 40% oil palm fronds), while the highest ash content was 40.20%, produced in the C7 treatment (100% oil palm fronds). The ash content produced in this research was far above the standard, in contrast to the bio-briquette ash content produced from research on the utilization of the potential wealth of palm frond waste into alternative energy charcoal briquettes with variations in the type of adhesive between 6.8 - 7.4% [19]. High levels of ash can be caused due to poor processing and still need to be improved. The relationship between the calorific value and bio-briquette ash content was expressed in the equation; y = -0.006x + 52.73 with the value of R2 = 0.498 and the correlation coefficient (r) = 0.70. Calorific value was negatively correlated with ash content, the higher the calorific value the lower the ash content in bio-briquette. | Figure 7. Charcoal bio-briquette ash content |

| Figure 8. Linear regression of calorific value with bio-briquette ash content on different raw material compositions |

4. Conclusions

Charcoal bio-briquette from empty bunches and oil palm fronds raw material can be used as an alternative energy source, the calorific value produced was 3,850.86 cal g-1 to 6,368.12 cal g-1. Judging from the calorific value produced, the best composition was 100% oil palm empty fruit bunches. The bio-briquettes quality produced was closely related to water content, ash content and the density of bio-briquette particles. Calorific values were positively correlated with water content and particle density with the correlation coefficient values of 0.72 and 0.47, but negatively correlated with ash content with a correlation coefficient of 0.70.

ACKNOWLEDGEMENTS

This research was funded by the Ministry of Research, Technology and Higher Education, in the beginner lecturer research scheme. We thank the Ministry of Research, Technology and Higher Education and STIPER Agrobisnis Perkebunan (STIP-AP) for the opportunity and support for us during the conduct of this research.

References

| [1] | https://databoks.katadata.co.id/datapublish/2018/10/10/berapa-konsumsi-energi-nasional. |

| [2] | Sulistyanto, A. 2006. Mixedbiobriquette characteristics of coal and coconut coir. Machine Media. 7 (2): 77-84. |

| [3] | Singh, G., Manoharan, S danToh, T. S. 1989. United Plantation’s approach to palm oil mill by product management and utilisation. Proccedings of 1989 International Palm Oil Develpoment Conference. Palm Oil Research Institute of Malaysia, Kuala Lumpur. Pp 225-234. |

| [4] | Dewanti, D., 2018. Cellulose potential of empty fruit bunches waste as the raw material of bioplastics environmentally friendly. Journal of Environmental Technology. 19 (1): 81-88. |

| [5] | Khalid, H. Zin. Z. Z. and J. M. Anderson. 2000. Decomposition processes and release pattern of oil palm residues. Journal of Oil Palm Research 20 (1): 46-63. PORIM Malaysia. |

| [6] | Moralia, https://www.borneonews.co.id/berita/78495. 01 November 2017. |

| [7] | Bulan, R., Mandang, T., Hermawan, W and Desrial, 2016. Development of mechanization systems for utilizing oil palm fronds for mulch and compost. Dissertation, IPB University. http://repository.ipb.ac.id/handle/123456789/83521. |

| [8] | Risza, S. The future of Indonesian oil palm plantations. Kanisius, Yogyakarta, 2010. |

| [9] | Arganda, M. 2007. Utilization of palm oil empty bunch and shell as Charcoal Briquettes. Thesis. Master of chemistry. University of Sumatera Utara. |

| [10] | Brades, A.C dan Tobing, F.S. 2007. Making charcoal briquettes from Eichorniacrassipes Solm with sago for binding. Chemical Engineering Department. UNSRI. Inderalaya. |

| [11] | Sarwono, E., M.B. Adinegoro and B.N Widarti, 2018. Effect of variations in the composition of stem, midrib and palm leaves on the quality of bioarang briquettes. Journal of Environment technology. 2 (01): 11-22. |

| [12] | Susanto, A and Yanto, T. 2013. Bioarang briquette makings from shells and palm oil empty bunch. Journal of Agricultural Product Technology, 6 (2): 68-81. |

| [13] | Parsad, R. http://www.iasri.res.in/ebook/EBADAT/. |

| [14] | Abdullah, K., Zulfa and M. D. Jyoti. 2016. Effect of palm oil empty fruit bunch (POEFB) on the quality of briquettes from cassava skin waste. Journal of Dynamics of Industrial Research. 27 (1): 49-58. |

| [15] | Sriharti and Salim, T., 2011. Effect of material composition on briquettes characterization of jatropha seed waste (Jatrophacurcas Linn), Journal of Indonesian Technology, 34: 40-48. DOI: http://dx.doi.org/10.14203/jti.v34iKhusus.38. |

| [16] | Sugiyono, Combination Research Method. Jakarta. 2014. |

| [17] | Nurhayati. Properties of Charcoal, Charcoal Briquettes and Alcohol made from Wood Industry Waste: Forest Products Research Institute, Bogor. 1983. |

| [18] | Hendra, D dan S. Darmawan, 2000. Manufacture of charcoal briquettes in wood sawdust with coconut shell addition. Bogor Forest Product Research Bulletin. 18 (1): 1-9. |

| [19] | Rika, F. Arsi and E. Taer, 2016. Utilization of potential of oil palm waste to energy alternative of charcoal briquette with adhesive variations. National Seminar on Environmental Science and Technology. 2: 101-104. |

| [20] | Hendra, D. Raw materials for making charcoal and charcoal briquettes. Research and Forest Product Development Agency. Bogor. 1999. |

Description:HHV = Higher Heating Value (calg-1) T1 = temperature before bombing (°C)T2 = temperature after bombing (°C)1 Joule = 0.239 kalCv= heat type of bomb calorimeter (73,529.6 joulekg-1°C)Tkp = the increase of the ignition wire temperature (0,05°C)Ÿ Water ContentWater content can be obtained using equations:

Description:HHV = Higher Heating Value (calg-1) T1 = temperature before bombing (°C)T2 = temperature after bombing (°C)1 Joule = 0.239 kalCv= heat type of bomb calorimeter (73,529.6 joulekg-1°C)Tkp = the increase of the ignition wire temperature (0,05°C)Ÿ Water ContentWater content can be obtained using equations: Description:G0 = sample weight before drying (g) G1 = sample weight after drying (g) Ÿ Density (particle density) Briquette density can be calculated using the equation:

Description:G0 = sample weight before drying (g) G1 = sample weight after drying (g) Ÿ Density (particle density) Briquette density can be calculated using the equation: Description:K: Density (gr cm-3)G: Briquette weight (gr) V: Volume (cm3)Ÿ Ash ContentThe amount of ash was calculated by the formula:

Description:K: Density (gr cm-3)G: Briquette weight (gr) V: Volume (cm3)Ÿ Ash ContentThe amount of ash was calculated by the formula:

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML