-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Energy Engineering

p-ISSN: 2163-1891 e-ISSN: 2163-1905

2018; 8(3): 62-66

doi:10.5923/j.ijee.20180803.02

Optimization of Water Flow in Sustainable Buildings

Okon B. B., Okon V. E., Tom K. A.

Department of Mechanical Engineering, Sustainable Infrastructure Services Group, Akwa Ibom State University, Uyo, Nigeria

Correspondence to: Okon V. E., Department of Mechanical Engineering, Sustainable Infrastructure Services Group, Akwa Ibom State University, Uyo, Nigeria.

| Email: |  |

Copyright © 2018 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

In Nigeria, water mains connected from public supply are most dried up thus prompting the search for appropriate water source to serve the needs of the society. The process of acquiring water from a reliable source like borehole requires a pump, pipe fittings, control mechanism and storage facilities. In this study, a simple automatic water level controller (AWLC) for water storage facilities was designed, constructed and tested as a prototype. Many buildings in this country often experience water overflows from overhead tanks and other reservoirs habitually when the user is not at watch. This results in several issues such as pumps malfunctioning as a result of incessant suction, water spillage, corrosion on water facilities, possible collapse of stanchions, dark stains, discolourations and other microbial growths on the entire water structures. In the light of the above, this study addresses these issues through a control system (a portable water detector) with buzzer alarm and LED indicators for water levels which was developed using locally available resources for cost effectiveness. In this study, two sensor levels were maintained, that is, Point A (95%) maximum level or pump-off sensor and Point B (10%) minimum level or pump-on sensor. The on/off actions at the two positions were successfully confirmed through multiple iterations of test for the optimization of the water flow. Thus, sustainability of water in the tank was enhanced and the tendency of overflow was controlled during the analysis. This work also covers the fundamental principles underlying materials selection, construction, installation and testing the overall performance of the AWLC and the achievable results yielded value added knowledge and understanding in regulating water flow.

Keywords: Facilities, Pump, Sensor devices, Water level, Water management practice

Cite this paper: Okon B. B., Okon V. E., Tom K. A., Optimization of Water Flow in Sustainable Buildings, International Journal of Energy Engineering, Vol. 8 No. 3, 2018, pp. 62-66. doi: 10.5923/j.ijee.20180803.02.

Article Outline

1. Introduction

- Water is a universal solvent which plays important role in domestic activities, industrial processes, irrigation and other agricultural purposes. Although the world is experiencing water shortage which implies that water source should be adequately managed to minimize wastage [4, 8], control of water level should be an essential task for domestic and industrial operations. In this way, it would be possible to track the actual process of the initiatives with integration of various controlling actions so that water regulatory system will provide potential significance for both domestic and industrial applications.AWLC is a device designed to monitor the level of water in a storage system [6, 14]. It is a mechanism fitted in the water distribution system to regulate the supply of water to storage facilities. Other functions of the device include; system optimisation, energy and cost savings [1], as well as automatic workability. Moreover, water level control systems are widely used to monitor liquid levels in reservoirs, silos and dams. Usually, this type of system provides visual multi-levels as well as continuous points indications. Audio visual alarms at desired levels and automatic control of pumps based on user’s requirements are incorporated as water management system strategy. Proper monitoring is needed to ensure water sustainability is actually achieved with disbursement linked for sensing automation [1, 2].In some domestic and industrial buildings in Nigeria, borehole is one of the most reliable sources of water as supplies from the public mains are most dried up due to poor water management practices. This necessitates the use of overhead tank (OHT) or underground tank (UGT) as storage facilities for the water resource in many buildings. Water facility users generally switch on the pump once water tanks are short of supply and switch it off minutes the tank starts overflowing. The switch-on requires monitoring of the tank for peak storage. In some occasions, when the tank is placed on top of the building, over time the weight of the tank often affects the structure.Also, the overflow as a result of uncontrolled pumping can pose serious environmental issues to include corrosion, dark stains and microbial growths on the structure [13]. To avoid the aforementioned issues, there is need for integration of an AWLC in the system as a sustainability measure. It is in this quest that a portable water level detector is of utmost importance.The common method of water level control for home appliance is simply to start the feed pump when the water level is low and allow it run until a higher water level is attained in the reservoir [1-3]. The local methods of finding the level of water in the storage tank include sound detection, temperature variance and dig-stick measurement. While the sound detection method can be achieved by tapping down the side of the tank until the sound suddenly changes, the dig-stick measuring technique is accomplished by immersing the dig-stick through the cover of the tank [2]. Equally, the process of temperature variation is attainable by touching the reservoir with hand to feel the degree of heat.

2. Future of Water Resources

- One of the biggest concerns for our water-based resources in the future [17] is the sustainability of the current and even future water resource allocation. A sensor mechanism in the water storage tank is one of the sustainability approaches incorporated in water facility management. Inadequate and poor maintenance management culture without integration of sustainability agenda can lead to the depletion of resources, dearth, shut-down and sometimes malfunctioning of building services equipment generally [5, 18]. This ethos of maintenance management culture associated with sustainable buildings, is viewed in the context of achieving sustainable development goals [12]. The field of water resources management will continue to adapt to the current and future issues facing the allocation of water resource [8, 17].

2.1. Pump

- Pump is essential in water supply system and it is used for the lifting water resource to the storage tank by adding pressure to the delivery head. An average pumping machine is not in control of the amount of liquid (water) delivered to the reservoir. If the pump is left to run for a long time, its components tend to develop faults and become inefficient and after some time, it may completely break down. There is an urgent need to incorporate an AWLC with water level detector to check the overflow and overrun of water [2].

2.2. Level Sensors and Indicator Circuit Operation

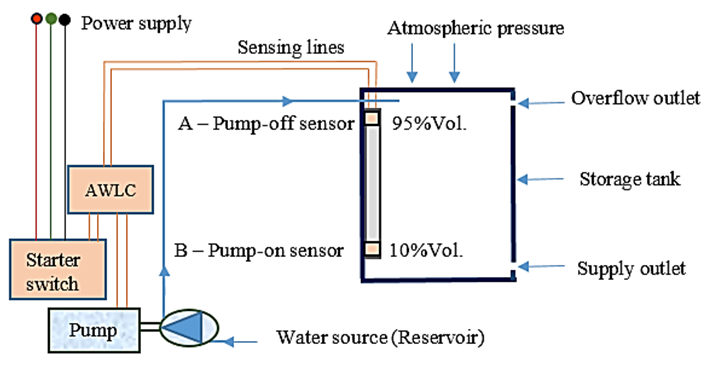

- Sensor or transducer is a device that receives energy from one system and transmit it to another, like physical variable into signal variable. Broadly defined, the sensor is a device which is capable of being actuated by energizing input from one or more transmission media and in turn generating related signals to one or more transmission systems. The automatic water pump controller also finds its application in agricultural farms, industries, offices, households and all places that water reservoir is needed. In view of the foregoing, due consideration was given in this study to the design and optimization of a highly efficient automatic water pump control with level sensing and overload protection to cut-off supply to the pump in case of an overload or short circuit faults occurrence. The water level control unit is an electrical device with contacts that opens and closed in response to liquid level sensed by the probe [6]. The probe is a sensor that extends downward from the fitting with the tip positioned precisely at the level where the control should be activated while the fitting houses the probe [3].In this study also, the simple water level indicator circuit operates by switching on the pump when the water level in the OHT goes low and switches it off as soon as the water level reaches a pre-determined level [9] as contained in Figure 1.

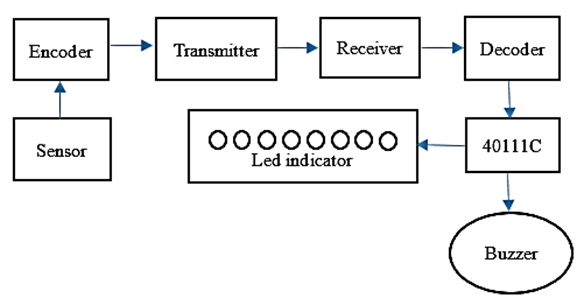

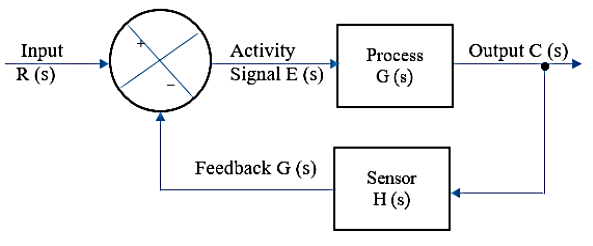

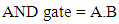

2.3. Conductive AC Signal Sensor

- The microcontroller in the AWLC depends on the input signals from the different sensor positions in the storage tank [7] to actuate the pump for the flow of water. This is based on the principle of conduction through water wherein 1.5V, 100Hz AC signal are processed to the water and further processed signal is being received through the level sensors set at desired levels [6, 9], Figure 1. In this type of sensor, the dirt in the water will not affect the performance [11, 14] and the signal transfer process and Feedback as shown in Figures 2 and 3.

| Figure 1. Schematic diagram of the water storage tank with sensor lines |

| Figure 2. Signal transfer process |

| Figure 3. Feedback (close loop) system |

3. Methodology

- This study adopted a two-stage methodology; literature search and field survey. Extant literature from other related studies WASas employed for this study was aimed at identifying the issues relating to water, energy and utilities management practices for sustainability success.

3.1. Components of the AWLC

- The following components were used for the construction of the AWLC: 400 Ohms, (single pole dual throw), 15V DC adapter (transformer), 32A relay, 555 and 4011 ICs as well as BC547 transistor.

3.2. Mathematical Model and Calculations

- In Figure 1, the total system head, HT is:

| (1) |

results in Equation 2, [10].

results in Equation 2, [10]. | (2) |

| (3) |

| (4) |

| (5) |

| (6) |

3.3. Pump Selection

- An inappropriate design of water systems will cause inadequate supply of water, thus, adequate sizing of water pump is needed for effective water flow and energy serving. In this study, a 0.5hp (0.37kW) centrifugal pump was employed for investigation and the performance was satisfactory.

4. Testing and Implementation

- This project was experimented through the application of a simple water distribution system which has a 0.5hp centrifugal water pump; 1500 and 1000 litre water containers which serve as a reservoir and a storage tank respectively were applied. In addition, polyvinyl chloride pipes (PVC) were connected from the reservoir already filled with water into the inlet of the pump and from the outlet of the pump to the storage container. The pump and starter switch were linked to the AWLC with three sensors (A, B and C), mounted inside the storage facility. Thereafter, the pump switch was connected to a 220 V power supply and switched on to fill the storage tank with water. Point A is the pump-off position at 95% and above. That is, the water level at which the circuit opens and the electric current instantaneously ceases to flow. At this point also, the pump motor is automatically turned off but sooner the water level drops, the process continues. Point B is the pump-on position at 10% water level. This indicates the water level at which the circuit closes and the current instantaneously starts to flow. At this point, the pump motor is automatically turned on but sooner the level increases to 95% volume, the process stops. Thus, sustainability of water in the tank is enhanced and the tendency of overflow remains constantly at zero. This explains the fact that at 95% level, water will automatically cease to flow into the storage tank. Consequently, water wastage is prevented against the current trend in water management and guarantees the longevity of the centrifugal pump. The contribution of this work further sensitise the public and academic community on the need to employ the AWLC for sustainable water management ethics and energy conservation as lack of awareness aids unsustainable water management practices.

5. Conclusions and Recommendations

- The AWLC was designed, constructed and tested in the Department of Mechanical Engineering laboratory, Akwa Ibom State University, Nigeria. This device can monitor water levels and regulate pump in order to impede failure and maximize water storage without overflow and wastage. The performance evaluation of the AWLC has shown the capability of the system to control water level at the tested stages. The analysis was to ascertain three levels of sensor positions thus, the pump needed to turn off when the storage container was near full (95%) volume and turns on when water is at the minimum sensor position (10%) volume. The performance at the three positions were satisfactory and confirmed through multiple iterations of test. This study has been able to accomplish its aim and corroborates the related literature and assessment information [2, 3, 7, 10] which also provided suitable platform for logical conclusions in the achievable results. In this article also, the design parameters were limited to standard mathematical models obtained from engineering textbooks as well as journals and this factor presents value added knowledge and understanding in the field of water and energy management as best practices.The integration of AWLC will prevent water spillage, flood, wastage and further maintain the pump efficiency with increase lifespan. However, the simple demonstration of this system requires a DC motor to be used directly at the output of 555 IC instead of a relay. Practical implementation requires a relay with a motor chosen according to variable load of water head. A 32 amperes relay is best suited for domestic applications [2, 5] as revealed from this study and AWLC is recommended for use as a sustainable device to water management success.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML