-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Energy Engineering

p-ISSN: 2163-1891 e-ISSN: 2163-1905

2018; 8(1): 19-24

doi:10.5923/j.ijee.20180801.03

Exhaust Emissions Characterization of a Single Cylinder Diesel Engine Fueled with Biodiesel-Ethanol-Diesel Blends

I. Yahuza1, H. Dandakouta1, R. I. Ejilah2, D. Y. Dasin3, S. S. Farinwata4

1Department of Automobile Engineering, Abubakar Tafawa Balewa University, Bauchi, Nigeria

2Department of Mechanical/Production Engineering, Abubakar Tafawa Balewa University, Bauchi, Nigeria

3Department of Mechanical Engineering, Modibbo Adama University of Technology, Yola, Nigeria

4Department of Mechatronics and Systems Engineering, Abubakar Tafawa Balewa University, Nigeria

Correspondence to: D. Y. Dasin, Department of Mechanical Engineering, Modibbo Adama University of Technology, Yola, Nigeria.

| Email: |  |

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Due to exponential growth in industrialization, the demand for conventional automotive fuels increases sharply which adversely affects not only the economy but the environment. This necessitates the quest for an alternative fuel. In this research, the blends of ethanol and biodiesel with diesel in varying proportions were carried out to access the emission levels of the blends. The emission levels of carbon dioxide (CO2), carbon monoxide (CO), hydrocarbon (HC), oxides of nitrogen (NOx), oxides of sulfur (SOx) and exhaust gas temperature were investigated under various operating conditions. The tests were carried out on a horizontal single-cylinder, 4-stroke, air-cooled, 3.68 kW engine. The engine was coupled to a manometer and DG eddy current dynamometer with rated power of 3.68 kW at 2600 rpm and was operated at a constant load of 1000 g. The results showed that BED30 fuel gave the best exhaust emission, and a considerable increase in exhaust temperature of the blends compared to diesel was noticed with the exception of BED30 which appeared to be similar to that of diesel at all speed conditions. The results also indicate that the blends gave less CO when compared to diesel. The minimum and maximum reductions of CO of the blends compared to diesel were 9.5% and 49.1% respectively. The emissions of NOx, SOx and CO2 increased with increase in ethanol in the blends. All the findings are in agreement with the results of other researchers.

Keywords: Energy, Emission, Engine, Industrialization, Environment, Biodiesel

Cite this paper: I. Yahuza, H. Dandakouta, R. I. Ejilah, D. Y. Dasin, S. S. Farinwata, Exhaust Emissions Characterization of a Single Cylinder Diesel Engine Fueled with Biodiesel-Ethanol-Diesel Blends, International Journal of Energy Engineering, Vol. 8 No. 1, 2018, pp. 19-24. doi: 10.5923/j.ijee.20180801.03.

Article Outline

1. Introduction

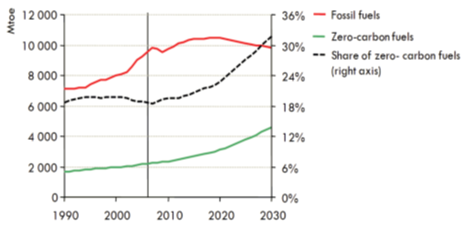

- The increasing demand for energy in the world increases the consumption of fuels. As a result, access to the conventional fossil fuels is becoming more and more difficult and an increasing trend for the price of oil would be a disaster for the economic recovery. The peaks in oil price are generally related to the countries’ concern for energy availability. Apart from economic aspects, the main problem is that fossil fuels are non-renewable. The global interest in “alternative energy” or “renewable energy” sources is due to the mentioned problems in addition to the environmental issues of fossil fuels. Alternative energy is basically a type of energy produced from a source other than conventional fossil fuels, such as, oil, natural gas, and coal.According to the International Energy Agency’s (IEA) world energy outlook, the total energy consumption in the world will increase by a rate of 1.5% per year until 2030. Figure 2 shows the share of different types of energy resources in this scenario [1]. Fossil fuels such as coal, oil and gas produce huge amounts of CO2, the major greenhouse gas, when they are used in transportation, electricity or heat production processes. The best alternative energy resources to replace the fossil fuels are renewable energy carriers such as zero-carbon fuels. When renewable energy sources are used to produce energy for transportation, heat and power they produce little or no carbon dioxide. For this reason, they are often referred to as being 'zero carbon'.Figure 1 demonstrates that in the IEA scenario, the demand for fossil fuels peaks by 2020, and zero-carbon fuels make up a third of the world's primary sources of energy by 2030. Biomass, which already has a large percentage of the total renewable energy sources, is expected to have a strong growth in the coming decades within three key sectors: heat and power generation, transportation biofuels, and other bio-products. The term “bioenergy” is generally used for the energy extracted from biomass resources for the industrial or residential applications, or the extracted liquid fuel, biofuel, to be used in the transportation sector.

| Figure 1. World primary energy demand by fuel type (IEA, 2009) |

2. Materials and Methods

2.1. Materials/Equipment

2.1.1. Ethanol

- The chemical formula for ethanol is C2H5OH, sometimes written EtOH or C2H6O. It is also known under the names ethyl alcohol or hydroxyethane and is the type of alcohol found in alcoholic beverages. Ethanol is a rather simple organic molecule consisting of a group of carbon and hydrogen atoms, with a hydroxyl group (oxygen and hydrogen atom) attached. The ethanol molecule is small and light, having a molecular weight of 46 g/mol [3].The ethanol used in the research was produced from sawdust of Masonia (Masonia Altissama) wood using simultaneous saccharification and fermentation (SSF) processes.

2.1.2. Biodiesel

- Biodiesel, by definition, are the methyl esters of long chain fatty acids. When compared to petro diesel, biodiesel has many advantages such that it is a renewable source of fuel, no engine modifications required for using biodiesel blends, lower CO2 and other exhaust gas emissions, etc. Most commonly used feedstock for biodiesel production currently are canola oil, soybean oil, rapeseed oil and corn oil oil. Since usage of edible oils for biodiesel production raises issues regarding food security especially in the developing countries, a lot of research are carried out using non-edible oils [4].The biodiesel was produced from neem oil, which was extracted from neem seeds (Azadirachta indica), by transesterification method.

2.1.3. Diesel Fuel

- Diesel fuel is a mixture of hydrocarbons obtained by distillation of crude oil. The important properties which are used to characterize diesel fuel include cetane number (or cetane index), fuel volatility, density, viscosity, cold behavior, and sulfur content.Diesel fuel originated from experiments conducted by German scientist and inventor Rudolf Diesel for his compression-ignition engine he invented in 1892. Diesel originally designed his engine to use coal dust as fuel, and experimented with other fuels including vegetable oils, such as peanut oil, which was used to power the engines which he exhibited at the 1900 Paris Exposition and the 1911 World's Fair in Paris [5]. The diesel fuel used for this research was purchased at AYM Shafa filling station along Abubakar Tafawa Balewa Road, near Yelwa Bauchi, Nigeria.

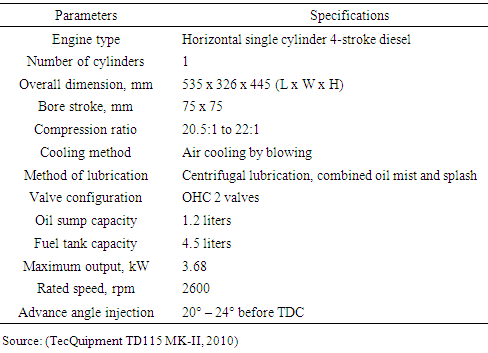

2.1.4. Automotive Emission Analyzer

- It is simply used by inserting a probe into the exhaust pipe and press a key to initiate measurements. Readings appear on a back-lit liquid-crystal display on the front of the analyzer.Emissions of unburned hydrocarbons (HC), concentrations of carbon monoxide (CO) and carbon dioxide (CO2), oxides of nitrogen (NOX) and oxides of sulfur (SOx) were measured using NHA-506EN Automotive Emission Analyzer (Nanhua), which was obtained from the Nigerian Institute of Transport Technology (NITT), Zaria, Kaduna State – Nigeria.The Engine Test Bed (ETB) and the Automotive Emission Analyzer (AEA) used to conduct the experiments are shown in Plate 1 and Plate 2 respectively, while the details of the ETB are given in Table 1.

| Plate 1. Diesel engine test bed |

| Plate 2. NHA-506EN automotive emission analyzer |

|

2.2. Methods

2.2.1. Blending of the Samples

- The biodiesel, the ethanol and the diesel were blended in dry flask equipped with a magnetic stirrer. The biodiesel-ethanol-diesel blends were produced with (%, v/v) 5, 10, 15, 20, 25, 30 and 35% ethanol with 85, 80, 75, 70, 65, 60 and 55% diesel, and biodiesel was kept at 10% throughout. Thus, the blends were labeled as BED5, BED10, BED15, BED20, BED25, BED30 and BED35, respectively.

3. Results and Discussions

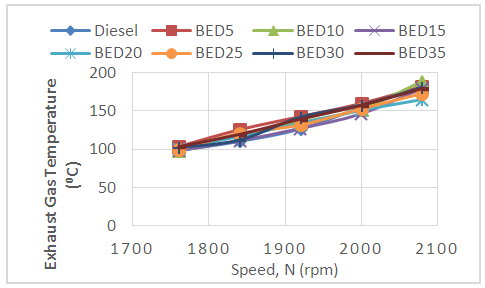

3.1.1. Exhaust Gas Temperature

- The exhaust gas temperatures from the test engine are higher with all the fuel blends than with diesel fuel due to the higher heating value of the blends. The exhaust gas temperature of BED30 appeared to be similar to that of the diesel at all speed conditions, except at 1920 rpm, where it is a bit higher (127°C for the diesel and 142°C for the BED30). The BED30 also appeared to be the best among the blends due to the lower heating value at all speed conditions. The variation of the exhaust temperature with engine speed tend to be linear, except for BED15, BED20 and BED30, and the highest value was below 200°C at all the speed conditions as shown in Figure 2; this confirmed with the study carried out by [6].

| Figure 2. Exhaust gas temperature for the blends and diesel at different speeds |

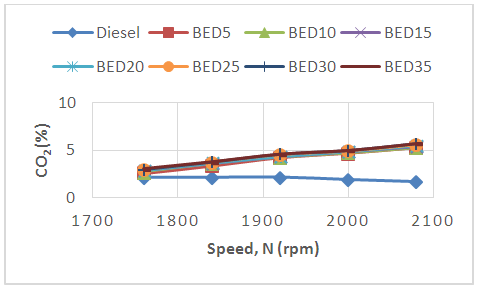

3.1.2. Carbon Dioxide (CO2) Emission at Different Speed Conditions

- The carbon dioxide emission depends upon the complete combustion of the fuel. Since all the blends have more oxygen content than diesel because of the presence of ethanol, this results in complete combustion. Due to the complete combustion of the fuel blends, carbon dioxide emission also increases. It can be seen from Figure 3 that the carbon dioxide emission using diesel fuel is lower because of the incomplete combustion as compared to the blends. At all speed conditions, BED30 and BED35 exhibited the highest values of CO2 emission, because of the complete combustion and are the best among the fuel blends as indicated in Figure 3. The increase in CO2 is directly propositional to the increase in the amount of ethanol as shown in Figure 2; this is because ethanol contained more oxygen.

| Figure 3. Carbon dioxide (CO2) emission for the blends and diesel at different speeds |

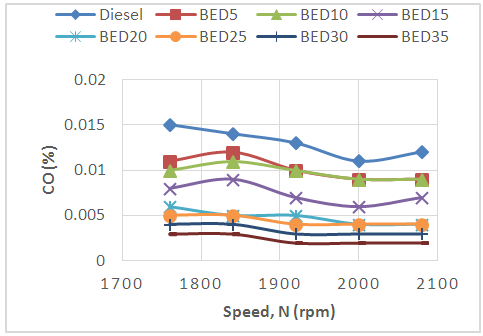

3.1.3. Carbon Monoxide (CO) Emission at Different Speed Conditions

- The results for the carbon monoxide emission of the blends and diesel at different speed conditions are shown in Figure 4. The carbon monoxide emission depends upon the oxygen content and cetane number of the fuel. The blends have more oxygen content than the diesel fuel; so, the blends having more oxygen content are involved in complete combustion process. The maximum carbon monoxide emission was observed at 1760 rpm of the engine speed when run on diesel fuel. So, it can be seen clearly that the fuel blend BED35 gives low carbon monoxide emission than the other fuels at all speed conditions.

| Figure 4. Carbon mono (CO) emission for the blends and diesel at different speeds |

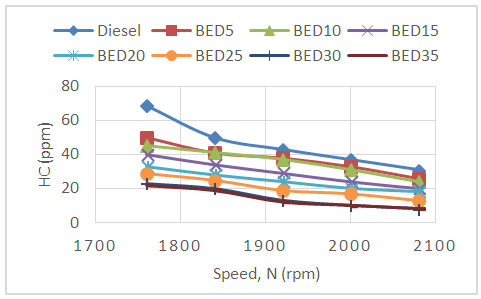

3.1.4. Hydrocarbon (HC) Emission at Different Speed Conditions

- The hydrocarbon emissions of the blends are lower than that of standard diesel due to complete combustion process. When percentage of ethanol increases in the blend, hydrocarbon decreases. Figure 5 clearly shows that fuel blend BED35 gave lower hydrocarbon emissions than the other blends. BED5 at all speed conditions gave an amount of hydrocarbon close to that of BED10, while that of diesel fuel is higher at all the speeds. The HC of diesel decreases with increase in speeds; the trend is the same with the remaining fuel blends. BED30 and BED35 have almost the same values at all speeds, as indicated in Figure 5.

| Figure 5. Hydrocarbon (HC) emission for the blends and diesel at different speeds |

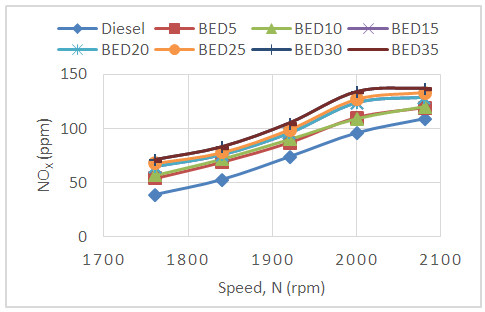

3.1.5. Oxides of Nitrogen (NOX) Emission at Different Speed Conditions

- NOX emissions depend on the oxygen concentration and the combustion time. At all speeds conditions, NOX emission of the blends is always higher than that of standard diesel due to the oxygen concentration and combustion timing. Since ethanol has very low cetane number, the cetane numbers of the blends are lower than that of standard diesel. This causes increase in the NOX emission of the blends. The shorter ignition delay could be a reason of increased NOX emission. BED15 and BED20 show similar values at all speed conditions. Similarly, ED30 and ED35 show the same trend. All the fuel blends have values of NOX which is above 110ppm at high speed (above 2000 rpm), while that of diesel was below this value at the rate of the same speeds (Figure 6).

| Figure 6. Oxide of Nitrogen (NOX) emission for the blends and diesel at different speeds |

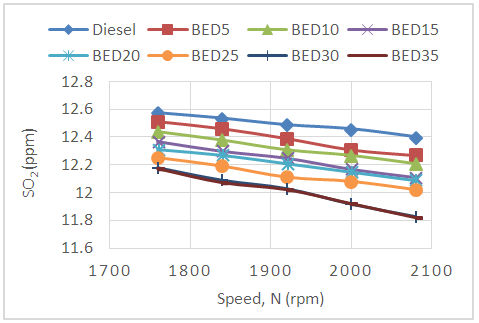

3.1.6. Oxides of sulfur (SOX) Emission at Different Speed Conditions

- Figure 7 shows the results for the oxide of sulfur emission of the blends and diesel at different speed conditions.

| Figure 7. Oxide of sulfur (SO2) emission for the blends and diesel at different speeds |

4. Conclusions

- From the experimental investigation the following conclusions may be drawn:1) There was a considerable increase in exhaust temperature with the blends compared to the diesel, but the exhaust temperatures of the blend were higher than that of the diesel fuel in the study. The maximum value of exhaust temperature was obtained with the BED35 (194°C) followed by the BED30 (192°C), at 1760 rpm. However, there is a steady rise of this temperature as the power of the engine is increased;2) The CO2 generally increases with increase in engine speed. At 1760 rpm the CO2 emission of BED5 is lowest but the diesel has the lowest CO2 at 2080 rpm. At 2000 rpm the CO2 emission is almost same for all the blends, thus, CO2 emission indicates how efficiently the fuel burns inside the combustion chamber;3) The increase in the amount of ethanol in the fuel blend reduces the CO as the BED35 has the least CO. This is possible because of the additional oxygen present in the ethanol, which assist in making the combustion, will tend to move the combustion process in coming to completion;4) The BED30 and BED35 had shown a consistent low level of HC emission when compared to both the rest of the blends and the diesel at all the speeds;5) At 2080 rpm, BED35 has more NOx emission than all the blends, with BED5 having the least. As the speed is increased, so does all NOx emission in all the blends. However, the diesel gave the least NOx emission at speed of 1760 rpm, because at low speeds, engine block and cylinder temperature was not very hot; therefore, little amount of NOx was produced; and6) The SO2 decreases with increase in the speed of the engine and BED30 and BED35 appeared to be the best candidates with lowest SO2 emission when compared with diesel and the blends.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML