-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Energy Engineering

p-ISSN: 2163-1891 e-ISSN: 2163-1905

2018; 8(1): 12-18

doi:10.5923/j.ijee.20180801.02

Investigating the Effect of Selected Parameters on Moisture Removal Rate of an Experimental Forced Convection Solar Grain Dryer

1Department of Industrial and Energy Engineering, Egerton University, Nakuru, Kenya

2Department of Agricultural Engineering, Egerton University, Nakuru, Kenya

Correspondence to: Booker Osodo, Department of Industrial and Energy Engineering, Egerton University, Nakuru, Kenya.

| Email: |  |

Copyright © 2018 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Although forced convection solar grain dryers achieve greater drying rates than natural convection dryers, optimum air velocity, grain layer thickness and drying air temperatures are necessary for improved performance. Number of trays used also affects performance. This study investigated the moisture removal rate (ratio of mass of moisture removed to mass of wet grain per hour) of a solar grain under different drying conditions. The effect of air velocity, layer thickness, number of trays and temperature on moisture removal rate (MRR) was investigated. MRR increased with increase in both drying air velocity and temperature at constant layer thickness. For 0.02 m thickness, MRR increased from 0.048 to 0.061 kg moisture / (kg wet grain. hour). However this increase was only significant at lower temperatures (below 45°C). Changing from 40 to 45°C caused a significant increase, but increasing temperature above 45°C did not. Also, MRR decreased with increase in layer thickness at constant air velocity. At 0.408 m/s air velocity, as layer thickness increased from 0.02 to 0.08 m, MRR decreased from 0.061 to 0.022 kg moisture / (kg wet grain. hour). Finally, when drying a given layer thickness, use of two trays did not significantly improve MRR.

Keywords: Forced convection grain dryer, Moisture removal rate, Air velocity, Grain layer thickness, Number of trays, Temperature

Cite this paper: Booker Osodo, Daudi Nyaanga, Investigating the Effect of Selected Parameters on Moisture Removal Rate of an Experimental Forced Convection Solar Grain Dryer, International Journal of Energy Engineering, Vol. 8 No. 1, 2018, pp. 12-18. doi: 10.5923/j.ijee.20180801.02.

Article Outline

1. Introduction

- The problem of food loss, though a global one, is particularly significant in developing countries where food losses are estimated to be of the order of 40%, but can rise to be as high as 80% under very adverse conditions. A significant percentage of these losses is related to improper and, or untimely drying of foodstuffs such as cereal grains, meat, tubers and fish [1]. One reason for loss of grain after harvesting is spoilage resulting from high moisture content. Postharvest loss of maize in Kenya in 2007 was 21.1% [2]. Drying of the grain is necessary to avoid loss between harvesting and consumption. High moisture content encourages loss due to attacks by insects, pests and increased respiration. This is in addition to fungus infection, which renders it unusable [3, 4]. According to [3, 5], drying of crop helps to achieve better product quality, longer safe storage and reduction of post-harvest loss hence ensuring more food is available for the growing world population. Also, drying using solar energy leads to conservation of conventional energy sources.Various researchers have evaluated the performance of solar dryers on the basis of different criteria. [6], use dryer thermal efficiency, drying rate and specific moisture extraction rate as their basis, while [7] base their evaluation solely on dryer efficiency. Uniformity of drying in different trays, and even within the same tray, is also important in evaluating dryer performance [8]. This research focused on drying rate as performance criteria.When a kernel of grain dries, two processes occur simultaneously: transfer of heat from the air to the kernel to evaporate water and transfer of mass as internal liquid and vapour move from kernel to air. Several theories have been advanced to explain movement of moisture within the kernel. All may occur simultaneously, but one may be predominant at any one time. Also, different ones may be predominant at different times. The diffusion theory relies on Fick’s law [eq. (1)] to explain liquid diffusion within the kernel. In this equation, P is the rate of permeation while k, A and

represent diffusion constant, cross sectional area and concentration gradient respectively [9].

represent diffusion constant, cross sectional area and concentration gradient respectively [9]. | (1) |

is given by eq. (2) [4],

is given by eq. (2) [4],  and

and  being initial and final moisture fractions, respectively.

being initial and final moisture fractions, respectively. | (2) |

2. Materials and Methods

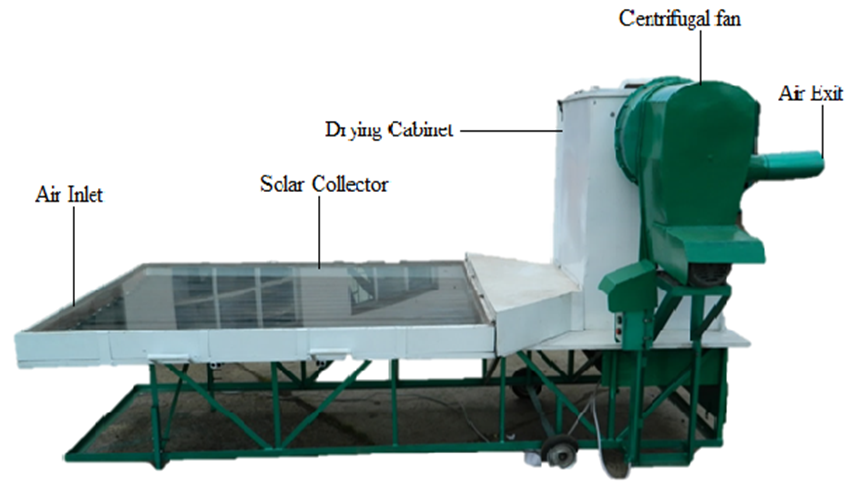

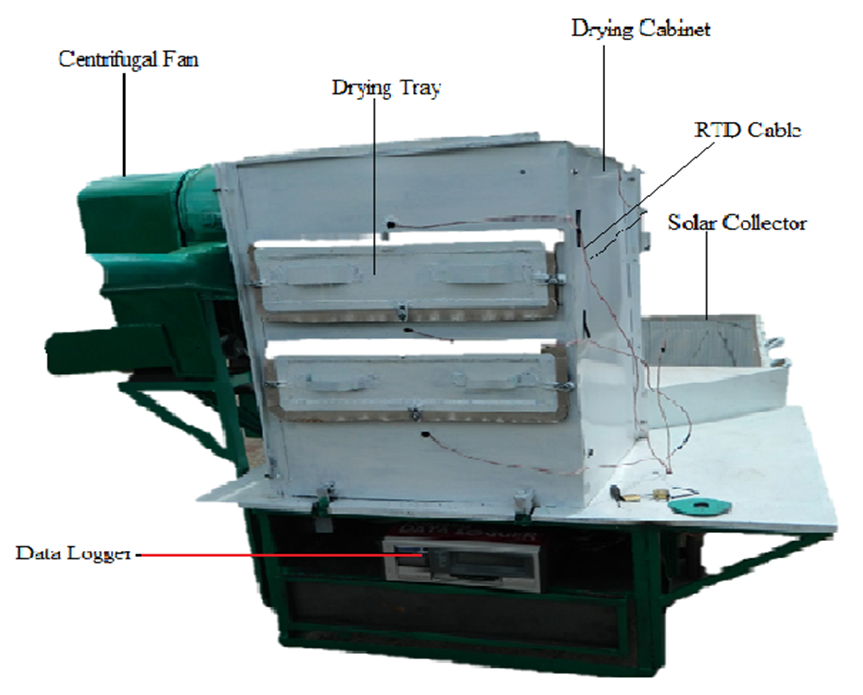

- The experimental solar grain dryer (Figures 1 and 2 consisted of a flat plate solar collector (air heater) and a drying cabinet with a centrifugal fan to force the air into the dryer. The solar collector area was 1.2 m x 1.8 m, and the air vent was of height 0.1 m. The absorber plate comprised of black painted corrugated iron sheet. The glass cover was of 5 mm thick glass, the air heater sides and back plate being made of 5 mm thick ply wood. The drying chamber was of dimensions 0.5 m x 0.5 m x 1 m, with a 1.25 mm MS sheet metal casing. Its sides consisted of double plates, 40 mm apart with polystyrene in between for lagging. A centrifugal fan was fixed at the upper section of one side. The plenum chamber was covered with a perforated plate 0.2 m from the bottom of the drying cabinet. Two drying trays, whose sides were of 1.25 mm MS sheet metal, with bottoms of wire mesh, were used. The first was 0.1 m above the perforated plate, and the second 0.2 m from the bottom of the first.

| Figure 1. Side View of Experimental Solar Grain Dryer |

| Figure 2. Rear View of Experimental Solar Grain Dryer |

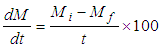

2.1. Determination of Moisture Removal Rate

- To determine moisture removal rate (Rmr), moisture loss in each drying session was calculated from the difference between the mass of grain before and after drying, weighed using a digital balance. Rmr was determined using eq. (3), and was defined as the mass of moisture mm, lost during a drying session of time t for every unit mass of wet grain mw.

| (3) |

2.1.1. Effect of Air Velocity

- To determine effect of air velocity on moisture removal rate, the dryer was tested at air velocities of 6.8 m/s, 8.6 m/s, 11 m/s and 13 m/s, measured at the dryer exit using a thermo-anemometer. A grain layer thickness of 0.02 m was used in each case, the dryer being ran for 3 ½ hours. Using eq. (4), the equivalent air velocities within the drying cabinet, of cross sectional area 0.5 x 0.5 m, were 0.212 m/s, 0.272 m/s, 0.344 m/s and 0.408 m/s respectively.

| (4) |

2.1.2. Effect of Grain Layer Thickness

- To determine effect of grain layer thickness on moisture removal rate, the dryer was tested at air velocities 0.212 m/s and a grain layer thickness of 0.02 m, using a procedure similar to section 2.1.1. This procedure was repeated for 0.04 m, 0.06 m and 0.08 m thick layers.

2.1.3. Effect of Number of Trays

- The solar dryer was tested to determine whether its performance would be affected by the use of more than one drying tray. First, a 0.04 m thick grain layer was dried in one tray using an air velocity of 0.408 m/s, and the moisture removal rate determined. The experiment was repeated, using two trays each with 0.02 m thick grain layer at the same air velocity, again determining the moisture removal rate, which was compared to the result for a single tray. This procedure was repeated for an air velocity of 0.212 m/s.

2.1.4. Effect of Drying Air Temperature

- To determine the effect of temperature on dryer performance, experiments were done under laboratory conditions, where drying air temperature was controlled. A 1.8 kW heating coil, connected to a Proportional Integral Derivative (PID) controller was used to heat air to the required temperature. Temperature was measured using J-type thermocouples. First, a 0.02 m grain layer thickness was dried at an exit air velocity of 0.408 m/s and 40°C, determining the moisture removal rate. Samples of the grain were retrieved every 30 minutes for 3 ½ hours. This was repeated at 45°C, 50°C and 55°C, maintaining the same grain layer thickness and exit air velocity in order to observe the effect of temperature on the MRR. Variation of MRR with temperature was analysed using ANOVA and LSD. As a control, the same experiment was repeated for the same grain layer thickness but with natural convection at 40°C and the performance compared to that of forced convection (0.408 m/s).

3. Results and Discussion

3.1. Effect of Selected Parameters on Performance of Experimental Dryer

3.1.1. Effect of Air Velocity

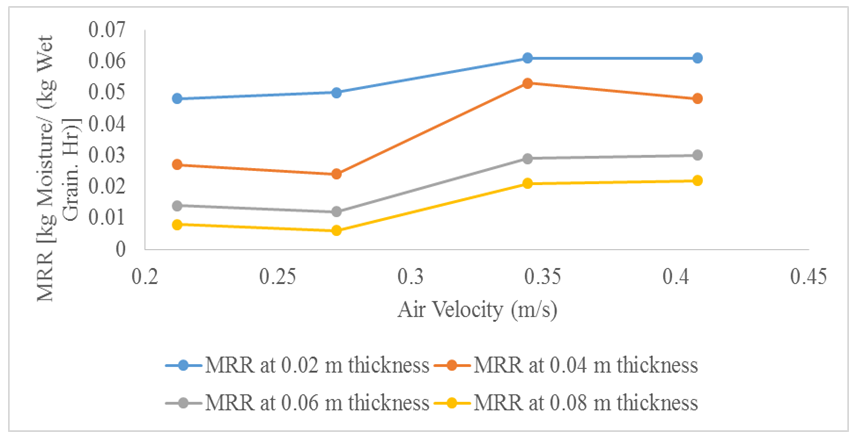

- Variation of moisture removal rate (MRR) with air velocity for given grain layer thicknesses are presented in fig. 3. It is notable that MRR generally increased with increase in air velocity for a given grain layer thickness. This is because at greater velocity, the air was able to carry away more moisture. [18, 20, 21]. [25, 26] reported similar results, although theirs were with respect to drying rate, a criteria similar to moisture removal rate. The highest MRR for 0.02 m grain layer thickness was 0.061 kg moisture/ (kg wet grain. hour) at 0.408 m/s air velocity, while the lowest was 0.048 kg moisture/ (kg wet grain. hour) at 0.212 m/s. It is, however, evident that for 0.04 m, 0.06 m and 0.08 m grain layer thicknesses, there is a slight decrease in MRR from 0.212 m/s to 0.272 m/s. This could have been due to a decline in temperature, which was not controlled during the experiment.

| Figure 3. Moisture Removal Rate vs. Air Velocity |

3.1.2. Effect of Grain Layer Thickness

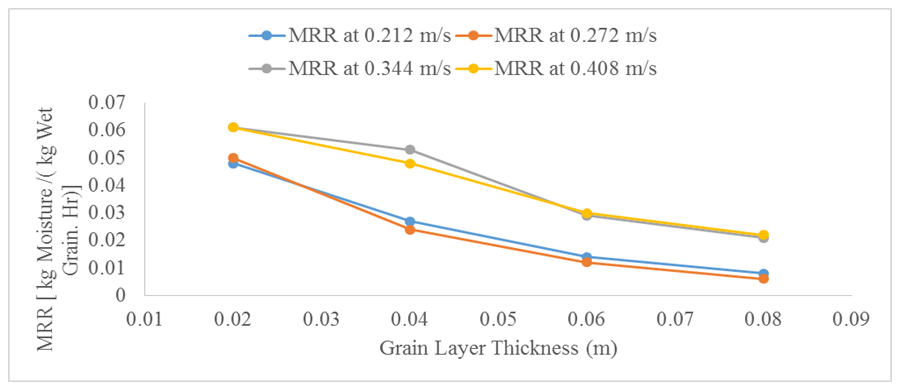

- Fig. 4 shows how moisture removal rate varied with grain layer thickness at constant air velocity. It may be seen that for any given air velocity, moisture removal rate decreased as the grain layer thickness increased. These results are similar to those of [25, 26]. The possible explanation is that as grain layer thickness increased, the air absorbed more and more moisture as it was rising up. It thus became more humid resulting in a decline in its capacity to remove more moisture. Also, applying Fick’s law [(eq. (1)], the rate of permeation was lower for a greater layer thickness since the quantity

decreased, as the denominator (thickness) increased in spite of the numerator (concentration) remaining unchanged. It was also noted that the moisture removal rates at 0.212 m/s and 0.272 m/s on one hand, and for 0.344 m/s and 0.408 m/s on the other, were very close. This was probably because the intervals for air velocities were not uniform, that between 0.272 m/s and 0.344 m/s, for example being greater than that between 0.212 m/s and 0.272 m/s.

decreased, as the denominator (thickness) increased in spite of the numerator (concentration) remaining unchanged. It was also noted that the moisture removal rates at 0.212 m/s and 0.272 m/s on one hand, and for 0.344 m/s and 0.408 m/s on the other, were very close. This was probably because the intervals for air velocities were not uniform, that between 0.272 m/s and 0.344 m/s, for example being greater than that between 0.212 m/s and 0.272 m/s. | Figure 4. Moisture Removal Rate vs. Grain Layer Thickness |

3.1.3. Effect of Number of Trays

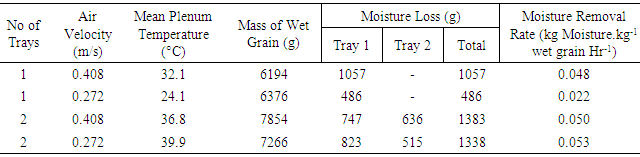

- Table 1 is a comparison of the MRR of the dryer when 0.04 m grain layer thickness was dried as a single layer in one tray on one hand, and as two single layers of 0.02 m each in two trays, on the other. The mean drying temperatures also changed since the maize was dried on different days.

|

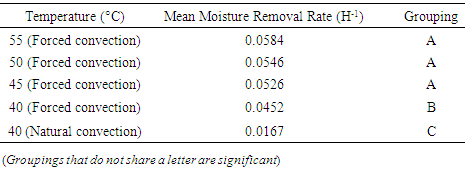

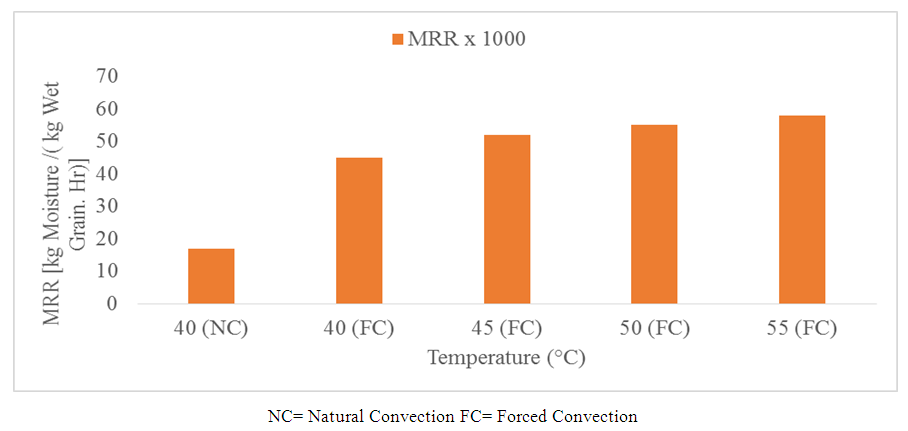

3.1.4. Effect of Temperature

- Fig. 5 shows the variation of dryer performance with Moisture removal rate, which, increased with drying air temperature, and was also lower for natural convection than forced convection. [20, 21, 23], reported similar results, though with respect to drying rate. MRR is a measure of drying rate and is expected to vary in a similar manner.

| Figure 5. Effect of Temperature on Moisture Removal rate |

|

4. Conclusions

- Effect of air velocity, number of trays, grain layer thickness and drying air temperature on dryer performanceŸ Moisture removal rate increased with air velocity if grain layer thickness was kept constant. For example, for a grain layer thickness of 0.02 m, moisture removal rate increased from 0.048 to 0.061 kg moisture / (kg wet grain. hour). Ÿ There was no significant difference in moisture removal rate when number of drying trays was increased from one to two.Ÿ Moisture removal rate decreased with increase in grain layer thickness as long as air velocity was kept constant. For 0.212 m/s flow rate, as grain layer thickness increased from 0.02 to 0.08 m, moisture removal rate decreased from 0.061 to 0.022 kg moisture / (kg wet grain. hour). Ÿ Moisture removal rate increased with increase in temperature. However, the increase was only significant at lower temperatures (below 45°C). For example changing temperature from 40 to 45°C caused a significant increase. However, increasing temperature from 45 to 50°C, and 50 to 55°C, in each instance had no significant effect on moisture removal rate.

ACKNOWLEDGEMENTS

- This research was funded by the National Council for Innovation, Science and Technology.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML