N. A. Adewole, K. O. Oladejo

Department of Agricultural and Environmental Engineering, Faculty of Technology, University of Ibadan, Nigeria

Correspondence to: N. A. Adewole, Department of Agricultural and Environmental Engineering, Faculty of Technology, University of Ibadan, Nigeria.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

The cost of managing ornamental and naturally growing trees in the University of Ibadan, Nigeria, is becoming challenging. Adding value to the residues from these trees with a view to enhance its economic value will minimize the management cost. This study adapted Earth Mound method of charcoal production to add value to tree residues generated in the University of Ibadan to enhance its economic value. Mixed residues of Acacianilotica (Acacia), Albiziazygia (Ayunre) and Meliciaexcelsa(Iroko) were retrieved from tree residues generated by the University of Ibadan Campus Tree Management Committee operation crew. Tree residues with varied moisture contents were arranged into mono-heap of (2.91 x 1.46 x 1.83)m, covered with sand and grass, and fired for 53hours to form charcoal that was harvested and bagged. The pilot heap of 7.8m3 by volume of tree residues yielded 800kg of lump charcoal. The cost involved in the pilot production: costs of 150 liters of water, labour and logistics was ₦7,350 ($36.75). The market worth of 50kg of charcoal produced at the time was ₦16,800 ($84). This study was able to add value to tree residues generated in UI campus using earth mound method for charcoal yield of about 67% without disturbance to the environment.

Keywords:

Tree residues, Charcoal production, Earth mound, Yield, University of Ibadan

Cite this paper: N. A. Adewole, K. O. Oladejo, Charcoal Yield from Urban-Tree Residues Generated in University of Ibadan, Nigeria using Earth Mound Method, International Journal of Energy Engineering, Vol. 6 No. 2, 2016, pp. 32-35. doi: 10.5923/j.ijee.20160602.02.

1. Introduction

Urban trees are inbuilt with number of constraints and hardly ever utilized to the best and highest value as observed by McKeever and Skog (2003). Urban trees are usually open grown and largely with shorter trunks, heavily branched as shown in Plate 1 and characterized with low wood quality due to presence of imbedded materials.  | Plate 1. Urban Grown Trees in University of Ibadan |

In practical term, urban tree is often regarded as having ‘zero’ value in view of the fact that removal of individual urban tree often generates billets rather than merchantable log. In some instance where it produces merchantable log length, it is usually difficult to have these logs satisfy buyers need except when there is storm or pest outbreak (Steve et al, 2008). Aside these limitations, urban tree removal generates mainly several species that are not conventionally valued in traditional timber markets as well as limited species varieties which limit potential buyers, utilization options, and markets (Sherrill and MacFarlane, 2007; Steve et al, 2008). For instance, in USA, McKeever (2003) estimated urban tree residues in 2002 as 16.2 million tons. Out of which only 3.2 million metric tons were “good wood” that is marketable for further processing. It was also noted that the tons of the urban tree residues was greater than the total estimated weight of timber harvested from U.S. National Forests during this same time. Also, the U.S. Environmental Protection Agency (2007) report shows that in 2006, the urban tree and woody residue portion of the yard trimmings amount was nearly 19 million tons (Bratkovich, 2001; McKeever and Skog, 2003). In developing countries like Nigeria, tree residues are also generated in large quantity. It is common to find many school premises heavily adorned with urban tress. Many were hitherto planted to produce shed or for ornamental purposes while many naturally grown. University of Ibadan (UI) which was established in 1948 and it covered over 2,550 forested acres of land in Ibadan, Oyo State, Nigeriais such a school premises with abundant urban trees (UI, 2015). The founding fathers in an attempt to beautify the whole campus also deliberately planted different species of ornamental trees to complement the naturally growing indigenous species.Most of the trees in UI are already mature while many had been under various stresses as a result of human activities and infrastructural development. Although, UI has Campus Tree Management Committee (CTMC) whose responsibility is to manage the vast tree resources on campus. As one of the members of CTMC for more than 10years, CTMC is often short-staffed and runs on self-raised tight budgets (Adewole and Oladejo, 2010). One of the major challenges of CTMC is the development and/or incorporation of new ideas to profitably dispose large volume of tree residues (Plate 2) that is been continuously generated through CTMC operation activities.  | Plate 2. Trees Residues in UI awaiting Disposal |

In many cases, CTMC is often forced to spend considerable amount to remove the tree residues from public areas to various gantries sited within the premises of the University. Occasionally the pressure on CTMC income often leads to abandonment of the residues at the same spot. The abandoned residues often ended up decaying or becoming wild animals’ nests as depicted in Plate 3. | Plate 3. Trees Residues Rotting at Gantry |

Although, when tree residue is left to decompose, it enriches the soil nutrients and contributes to the source of CO2 emission in the location (Seifritz, 1993; Okimori et al., 2003). This disposal approach may be appropriate in the forest and plantation, it often constitute a menace to environment in a place like school campuses. When the expenses used in evacuating tree residues in UI is appraised within the context of lack of enthusiasm by UI administration to fund the evacuation, the constraints of managing UI tree residues is enormous.It is therefore necessary to seek a mean of adding values to the tree residues with a view to turn waste to wealth. In a bid to find a way around this challenge, the CTMC has shown interest in creating viable utilization plan for the tree residues generated through her operation on campus. One of such plan is production of charcoal from the tree residues to complement energy sources supply on campus. Fuel is among the basic needs of man while charcoal, gas, briquette, firewood, fossil oil among enjoyed different rate of patronage. Charcoal is a form of amorphous carbon that is produced when wood, peat, bones, cellulose, or other carbonaceous substances are heated with little or no air present (Anona, 2015;. FAO, 2006) had observed that charcoal appears to be gaining more popularity in recent time, perhaps for its unique properties. The patronage of charcoal as household fuel in developing countries have been reported to be due to its suitability as a relative clean fuel for urban environments and low cost to the end-users (Antal and Gronli, 2003). The increasing patronage enjoying by charcoal in and around UI informed the purpose of this study. The production of charcoal from wood using earth mound approach may have dated back to ancient period (Antal and Gronli, 2003; Anona, 2015), the technology is yet used by natives living at extreme rural areas in Nigeria. Turning tree waste to charcoal may be a veritable option for CTMC, there exist the need to research on transferring the technology to achieve the CTMC aim. This constitutes the focus of this study that has been designed to investigate the viability of adapting earth mound method of charcoal production to add value to the abundant wood residues generated by CTMC activities in UI with a view of turning the tree residues waste into wealth.

2. Methodology

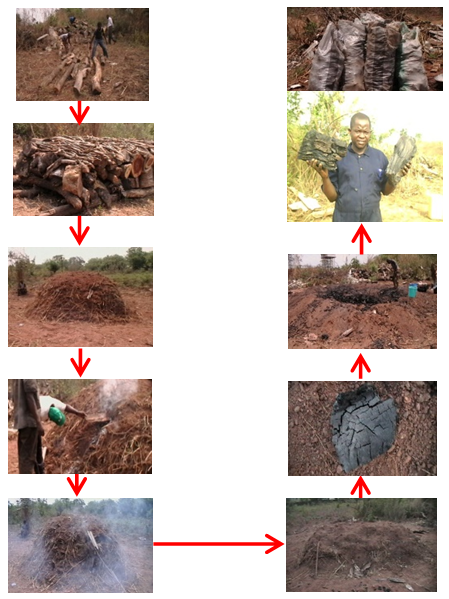

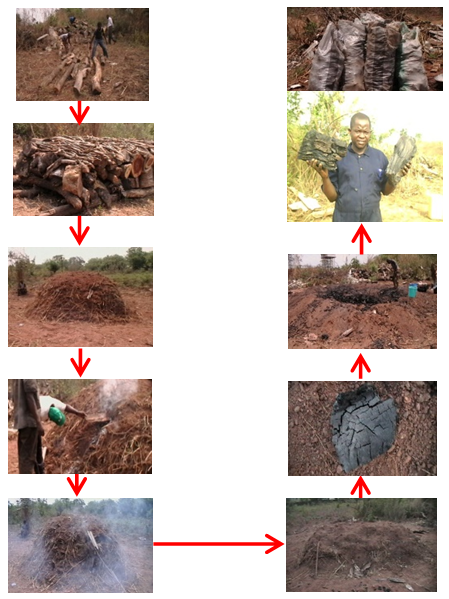

Most trees growing in UI are urban like in characteristics because their harvests hardly yield merchantable log length. Their harvests often generate large volume of residues inform of billets, twigs and heavy stumps. This study utilized residues of Acacia nilotica (Acacia), Albizia zygia (Ayunre) and Melicia excelsa (Iroko) obtained from CTMC gantry to investigate the viability of adapting earth mound method for turning the residues into charcoal. Production location was strategically sited to ease off logistic challenges. The tree residues used were of varied moisture contents. They were arranged into mono-heap of about 7.8m3 by volume an equivalent of (2.91 x 1.46 x 1.83)m by dimension. The mono-heap consists of piling billets of the wood species earlier mentioned, on their ends so as to form a conical pile depicted in picture flow chart in Plate 4. Openings were made at the bottom to admit air with a central shaft to serve as a flue. The whole pile is covered with grass and moistened clay. The firing is begun at the bottom of the flue, and gradually spreads outwards and upwards as depicted in Plate 4. Air inlet was made in the covered heap before setting fire into it. Complete pyrolysis of the heap took 6 days before the resulting charcoal was harvested and bagged. The moisture contents of the charcoal samples were taken using moisture meter while the sample charcoal was used to cook rice meal to evaluate the charcoal burning characteristics. | Plate 4. Picture Chart of Pyrolysis Processes using Earth Mound Method |

3. Results and Discussions

The result of the study carried out on the production of charcoal using earth mound method in University campus indicates that charcoal production from urban tree residues is visible in an urban setting. The critical needs for successful adaptation of this method however require a site carefully selected or earmarked for the purpose. Such location should make possible an unfettered access to water, moist soil and grass. The initial set up cost required to transfer Earth Mound Technology format that is currently practiced at rural locations in Nigeria was as low as Fifty Thousand Naira only ($312) by 2014. This cost included the cost of hiring a traditional expert in Oyo State, Nigeria for 6 days and who assisted in technology transfer process.One of the areas of technicality involved in earth mound method is the skill involved in tree residues setting up into heap. Tree residues have to be arranged according to their length similarity and in an alternate layout to create gap within the heap. The moist soil should be between 5mm-7mm thick before covering with grass. This was to control the oxygen intake to facilitate incomplete burning - pyrolysis. Ignition had to begin at the bottom to enable air flow to drive the burning and pyrolysis. The tree residues volume of 7.8m3 that was used for the investigation yielded 24 bags of charcoal seen in Plate 5. The entire 24 bags were re-packed into 16 bags, each weighing 50kg, being the selling standard around the study location. A 50kg bag of charcoal is offered at the rate of One Thousand and Six Hundred Naira Only ($10) in the study area as at 2014. Therefore, the cash worth of the charcoal obtained from 7.8m3 of tree residues used for the pilot study was Twenty- five Thousand and Six Hundred Naira Only ($160). If this cost is compared with the invested cost, the project could be rated as profitable despite being a pilot study through which technology transfer process was involved. This study was able to add value to the tree residues generated in UI campus using earth mound method for charcoal yield of about 37% by weight without disturbance to the environment. | Plate 5. Author Re-bagging the Charcoal Product |

| Plate 6. Samples of collected fragmented charcoal |

The moisture content of the charcoal produced ranges between 2.1% to 3.2%. If the input raw material was green, this yield may have increased because according to FAO (2006), the presence of moisture has positive influence on charcoal yield. The enhance moisture content could have acted as catalyst in charcoal formation (Antal and Gronli, 2003). Although the burning duration would have been negatively influence by increase moisture because heating of water and its evaporation could have taking extra time. During burning characteristics experiment, the charcoal produced from the mixed residues of Acacia nilotica (Acacia), Albizia zygia (Ayunre) and Melicia excelsa (Iroko) were a little harder to cook with as it heats hotter thus making it easy to sear food rather than cook it. This further confirms the earlier observation by Baker (1985) and Siemons et al, (2012). It also tends to become dusty and flake off perhaps because it is less dense compared with briquette.

4. Conclusions and Recommendations

This study was able to adapt earth mound method to convert tree residues generated in the University of Ibadan, Oyo State, Nigeria to lump charcoal. Although, earth mound method of charcoal production may be easy to transfer, it entails a lot of drudgery. This may justify while most of the people who engaged in charcoal making are men. Also, it was established that turning of the abundant tree residues currently generated in UI can be a profitable venture that will mitigate the current challenge of managing the huge waste. This study recommends that further study should explore means of improving the yield from earth mound method.

ACKNOWLEDGMENTS

The authors appreciate the funding and logistics support for the project by the University of Ibadan via the Campus Tree Management Committee (CTMC). We specially acknowledge the support of the Prof M. A. Onilude, the Chairman and all committee members of CTMC for facilitating the University support for this work.

References

| [1] | Adewole, N.A., Oladejo, K.O. (2010). Earth Mound; Exploration, Yield Factor Evaluation and Production of Charcoal From Tree Residues In University of Ibadan, B.Sc Project Submitted to the Department of Agricultural and Environmental Engineering, Faculty of Technology, University of Ibadan. 46pp. |

| [2] | Anona (2015) Chapter 3: Charcoal Retrieved 6:15pm, 19-06-2015 http://www.fpl.fs.fed.us/documnts/usda/agib666/aib66603.pdf. |

| [3] | Antal, M.J. and Gronli, M. (2003). The art science and technology of charcoal production, Ind. Eng. Chem. Res 42, 1619-1640. |

| [4] | Baker, A.J. 1985. Charcoal industry in the U.S.A. Proceedings, ICFRO Meeting; 1985; Pretoria, Republic of South Africa.Forest Products Laboratory, USDA Forest Service, One Gifford Pinchot Drive, Madison, WI 53705–2398.15 p. |

| [5] | Bratkovich, S. 2001. Utilizing Municipal Trees: Ideas From Across the Country. USDA Forest Service, Northeastern Area, State and Private Forestry, St. Paul, MN.NA-TP-06-01. 91 pp. Available at: http://na.fs.fed.us/spfo/pubs/misc/umt/index.htm. |

| [6] | F.A.O. (2006). Industrial Charcoal: Development of a Sustainable Charcoal Industry. 22pgs. |

| [7] | McKeever, D. 2003. Inventories of Woody Residues and Solid Wood Waste in the United States, 2002. USDA Forest Service, Forest Products Laboratory. Available at: http://www.fpl.fs.fed.us/documnts/pdf2004/fpl_2004_mckeever002.pdf. |

| [8] | McKeever, D., and Skog, K. 2003. Urban Tree and Woody Yard Residues: Another Wood Resource. USDA Forest Service, Forest Products Laboratory. Available at: http://www.fpl.fs.fed.us/documnts/fplrn/fplrn290.pdf. No.5: 405-407. |

| [9] | Okimori, Y., Ogawa, M. and Takahashi, F. (2003). Potential of CO2 emission reduction by carbonizing biomass waste of industrial tree plantation in south Sumatra, Indonesia. Mitigation and Adaptation Strategies for Global Change 8:261-280. |

| [10] | Seifrits, W. (1993) Should we store carbon in charcoal? Int. J. Hydrogen Energy. Vol.18. |

| [11] | Sherrill, S., and MacFarlane, D. 2007. Measures of Wood Resources in Lower Michigan: Wood Residues and the Saw Timber Content of Urban Forests. Southeast Michigan RC&D, Ann Arbor, MI. 178 pp. Available at: http://semircd.org/ash/research/sherrill_macfarlane_inventory_final.pdf. |

| [12] | Siemons, R. V., Loek Baaijens; B. V., Oldenzaal, 2012. An Inovative Carbonisation Retort: Technology and Environmental Impact TERMOTEHNIKA, 2012, XXXVIII, 2, 131‡138. |

| [13] | Steve B R, Bowyer J, Fernholz K, Linburg A, 2008. Urban Tree Utilization and Why it Matters. Published by Dovetail Partners INC. 8pgs. |

| [14] | UI, 2015 History of University of Ibadan. Retrieved 4pm; 19-06-2015 http://www.ui.edu.ng/uihistory. |

| [15] | United States Environmental Protection Agency. 2007. Municipal Solid Waste Generation, Recycling, and Disposal in the United States: Facts and Figures for 2006. EPA-530-F-07-030. Available at:http://www.epa.gov/epaoswer/non-hw/muncpl/pubs/msw06.pdf. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML