A. N. Basavaraju1, Mallikappa2, B. Yogesha3

1Department of Automobile Engineering, Malnad College of Engineering, Hassan, Karnataka, India

2Department of Mechanical Engineering, NMAM Institute of Technology, Nitte, Karnataka, India

3Department of Mechanical Engineering, Malnad College of Engineering, Hassan, Karnataka, India

Correspondence to: B. Yogesha, Department of Mechanical Engineering, Malnad College of Engineering, Hassan, Karnataka, India.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

Internal combustion engines in the modern times their extensive use in Automobiles and other power generating applications has been one of the major contributors to pollution. This research is to investigate the performance of SI engine by using pre-heated fuel with carburetor aimed at making the air-fuel mixture more homogeneous, to reduce the fuel consumption and gives way for improvement of efficiency of the engine. Research was conducted by using a 350cc four-stroke, spark ignition, air-cooled, single cylinder engine. Gasoline is used as a test fuel. The test stand consisted of a small dynamometer coupled to the engine. The engine is tested to conduct performance tests and investigate the emission characteristics with the normal mode engine operation and with the aid of carburetor. The test has been conducted under no load and at different loads maintaining the speed at a constant value of 2250rpm throughout the test. The results concluded that, spark advance at preheating fuel temperature with the aid carburetor are feasible. Based on the performance and emission characteristics the pre-heated fuel gives improvement than unheated fuel.

Keywords:

Pre-heated fuel, Spark-ignition engine

Cite this paper: A. N. Basavaraju, Mallikappa, B. Yogesha, Performance of SI Engine by Using Pre-heated Fuel with Carburetor, International Journal of Energy Engineering, Vol. 6 No. 1, 2016, pp. 16-24. doi: 10.5923/j.ijee.20160601.03.

1. Introduction

The internal combustion engine has been around for more than 100 years. It is currently the main source of propulsive power for automobiles and provides power for equipment including weed trimmers, chainsaws, backup power generators, boats, and small airplanes. The internal combustion engine is widely used because of its high power density. The method for mixing the fuel and air, type of fuel, method of initiating combustion of the mixture and control of the flow in and out of the combustion chamber are all factors that differentiate different types of internal combustion engines. The two most regular sorts of the internal combustion engine are the spark ignition engine and the compression ignition engine. Nikolaus Otto developed the first spark ignition engine in 1876 [1]. A.C. Alkidas et. al., [2] have discussed the recent combustion advancements made in gasoline engines for the reduction of fuel consumption and engine-out emissions, and the technologies associated with these advancements. R.K. Maurya and A.K. Agarwal [3] have conducted the experiment on combustion and emission characteristics of an HCCI engine fuelled with ethanol were investigated on a modified two-cylinder, four-stroke engine. The experimental results indicate that the air- fuel ratio and intake air temperature have a significant effect on the maximum in-cylinder pressure and its position, gas exchange efficiency, thermal efficiency, combustion efficiency, a maximum rate of pressure rise and the heat release rate. O.A. Kutlar et. al., [4] have investigated the methods for increasing efficiency at part load conditions and their potential for practical use are investigated. This investigation shows that the potential for increasing the efficiency of SI engines at part load conditions is not yet exhausted. The most promising methods to decrease the fuel consumption at part load conditions are stratified charge and variable displacement engines. F.N. Alasfou [5] has investigated the effect of using a 30% iso-butanol–gasoline blend on NOx emission in a spark ignition engine. The influence of preheating inlet air on NOx emission was also investigated at different fuel/air equivalence ratio. The experimental investigations were performed under different values of inlet air temperatures. Preheating the inlet air above ambient temperature causes the NOx emission level to increase for all fuel/air equivalence ratios. For 30% iso-butanol–gasoline blend experimental results show that preheating inlet air causes knock and misfire to occur at less advanced ignition timing. J. Jones and J. Gagliardi [6] have experimented emissions were measured on vehicles using a pre-mixed and pre-heated air- fuel charge supplied by a steam jacketed, nine cubic foot vaporization tank. Application of exhaust heat to this mixing chamber accomplished little in improving the cylinder-to-cylinder air- fuel distribution. M.A. Kalam and H.H. Masjuki et. al., [7] have investigated that preheating of crude palm oil (CPO) reduces its viscosity to the level of Ordinary diesel fuel (OD) that improves the fuel spray and atomization characteristics and produces complete combustion. However, preheated CPO increased NOx emission as compared to OD and CPO emulsified fuels. This is mainly attributed from the deposit characteristic result, and shows that preheated CPO increased the highest fraction of ash deposit as compared to OD and CPO emulsified fuels, which is the reason for increasing NOx emissions. L. Hildebrand et. al., [8] have worked intends to approach the use of pre-heated ethanol direct injection through Otto type engine cylinders during the compression of air and under low pressures (600 kPa). A system of direct injection was developed and incorporated to the engine, which was submitted to tests. Results revealed that the partial fuel vaporization during the isoentalpic expansion process which happened in the nozzle during the fuel injection was responsible for a significant decrease in specific consumption and an increase of the engine's thermal efficiency in comparison to the same engine using carburetor or cold ethanol direct injection (at room temperature).It is well documented in the literature that the preheated fuels have some positive influence on the performance and emission characteristics of engines. The proposed investigation is basically gone for making the air- fuel blend more homogeneous by utilizing preheated fuel.

2. Methodology and Experimentation

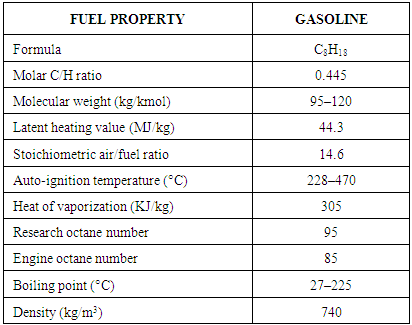

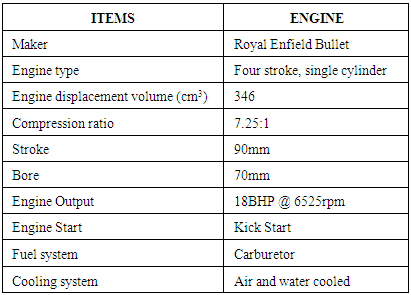

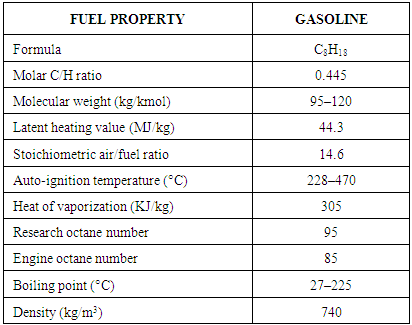

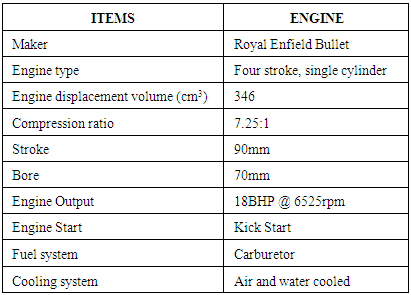

In order to conduct the experiment, a single cylinder, four stroke 350cc SI Engine is considered. To introduce the fuel injection to this engine at different choices were considered as to take the force from the camshaft and from the crankshaft. Taking the power from the crankshaft was found to be more suitable and invaluable from the alternator side of the engine. The fuel pump needs to pass on high weight fuel once in the midst of each two revolt of the crankshaft, therefore a speed diminishing drive has been made and vitality to this drive is taken from the crankshaft particularly. A suitable camshaft has been recognized which has a cam gives a rising of 8mm and which is found to be suitable to drive the fuel pump. The fuel pump is mounted recognizing a suitable territory for the level stood up to follower to keep up contact with the cam. The entire social gathering has been presented in the engine and is found to be working pleasantly. Concerning the foundation of atomizer or fuel injector, the present opening suggested for decompression valve had been to mount the fuel injector in the engine head. The flash fitting inferred for ignition has been arranged in its individual opening. The flash fitting is arranged in a way that it can without quite a bit of a stretch fire the fuel implanted by the atomizer. Gasoline is used as a test fuel in this investigation. Table 1 shows the physical and chemical properties of gasoline. The experiment was conducted on a single cylinder four stroke spark-ignition engine. The engine specifications are listed in Table 2.Table 1. Properties of gasoline

|

| |

|

Table 2. Technical data of the test engine

|

| |

|

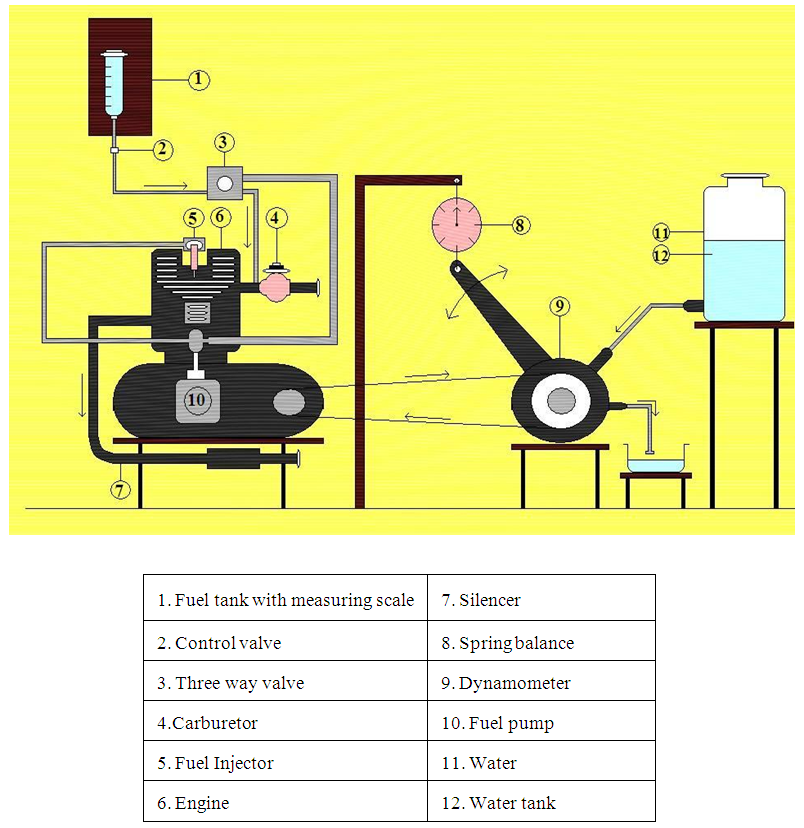

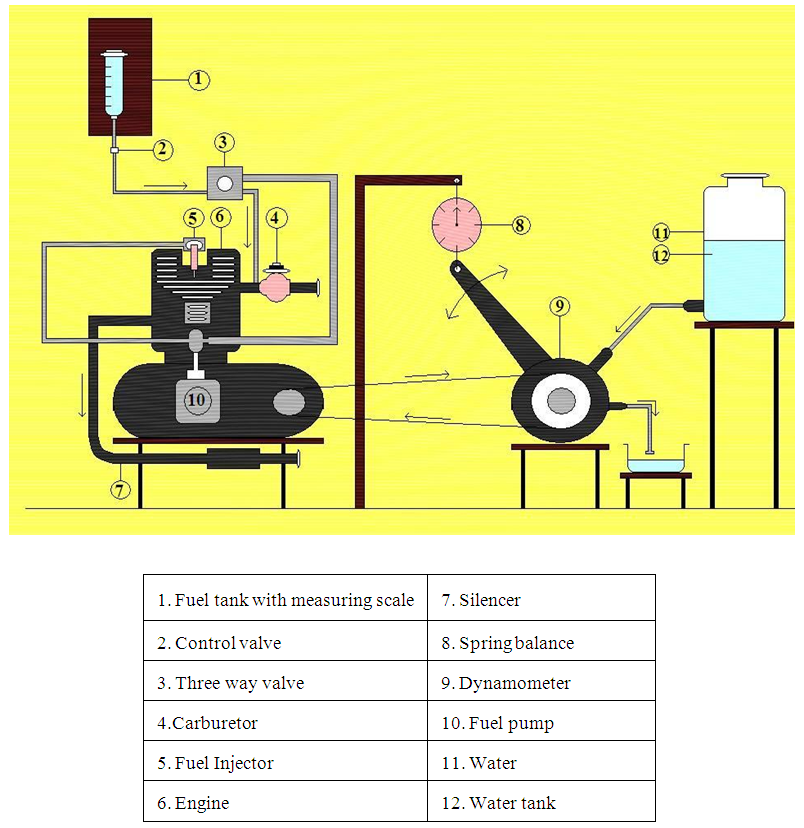

3. Experimental Set up

The trial setup indicated in Fig.1 comprises of a 350cc four stroke single cylinder engine and a pressure driven dynamometer for stacking and to quantify the brake force of the engine for diverse burdens. A mileage tank is connected with measure the fuel usage of the engine. The execution test on the engine is finished by the different ways using a conventional carburetor, using fuel injector and by preheating the fuel. In standard carburetor system the engine gets the air fuel mix through the common carburetor. The gas analyzer is extraordinarily fundamental to center the outflow attributes of the engine. This gas analyzer gives the, HC, CO and other outflow readings of the engine. | Figure 1. Schematic layout of experimental set up |

4. Results and Discussion

The interpretation of the results and comparison among various characteristics is presented.

4.1. Unheated Fuel with the Normal Mode Engine Operation

The test has been conducted with the normal engine condition at using unheated fuel at a room temperature around 25°C. The engine speed constant about 2250rpm for all load conditions. The test has been conducted with the normal engine condition at using unheated fuel at a room temperature around 25°C. The engine speed constant about 2250rpm for all load conditions.

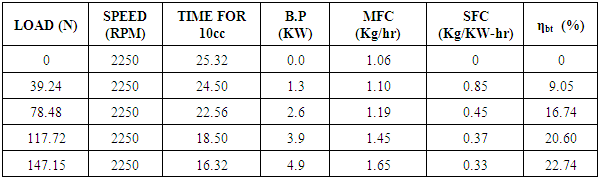

4.1.1. Performance Characteristics

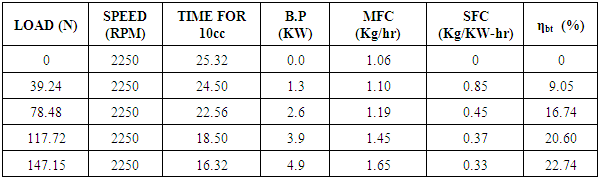

In the case of unheated fuel with the normal mode engine operation, as load increases at a constant speed the mass of fuel consumption rate increases with decreasing of specific fuel consumption. The brake thermal efficiency varies with the load condition. The performance characteristics of unheated fuel are tabulated in table 3.Table 3. Performance characteristics of unheated fuel

|

| |

|

4.1.2. Emission Characteristics

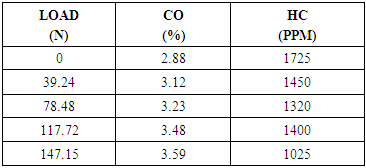

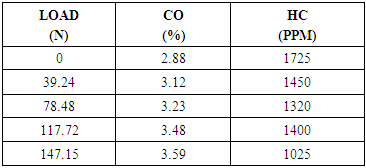

In the case of unheated fuel with the normal mode engine operation, as load increases the percentage of CO emission is increased and HC emission is decreased. Table 4 shows emission characteristics of the unheated fuel.Table 4. Emission characteristics of unheated fuel

|

| |

|

4.2. Pre-heated Fuel Mode with the Aid of the Carburetor

The test has been conducted with pre-heated fuel at different temperatures like 30°C, 35°C and 40°C for each spark advance at 2, 15 and 30 respectively. The performance and emission characteristics of pre-heated fuel with the aid of the carburetor are discussed below.

4.2.1. Performance Characteristics

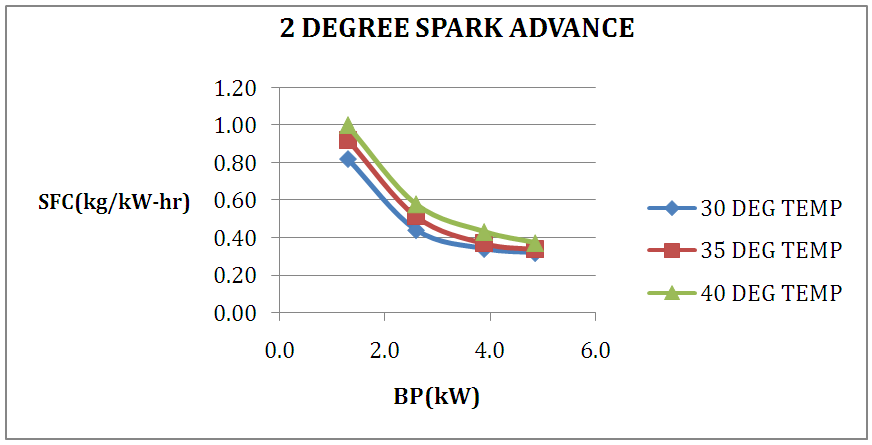

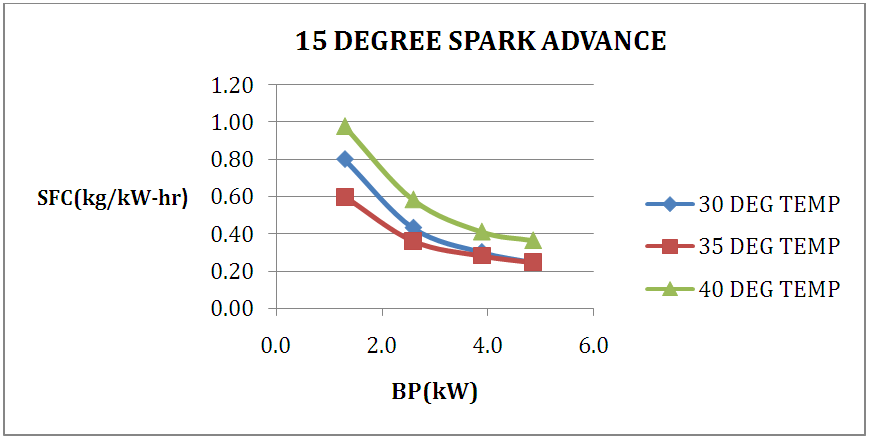

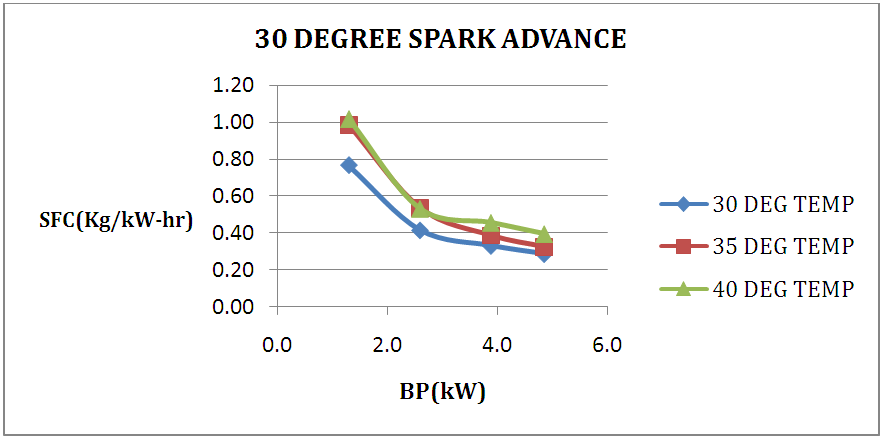

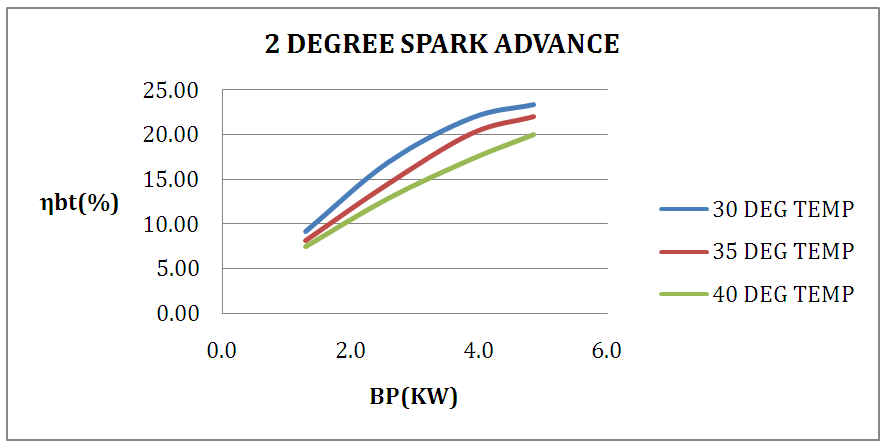

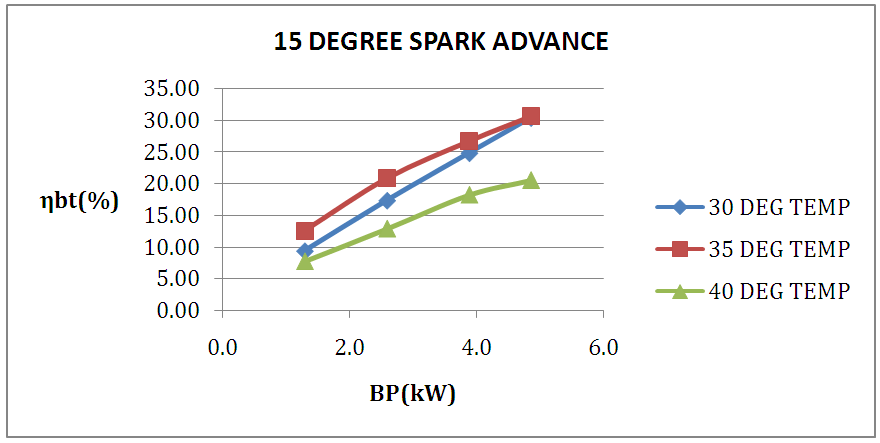

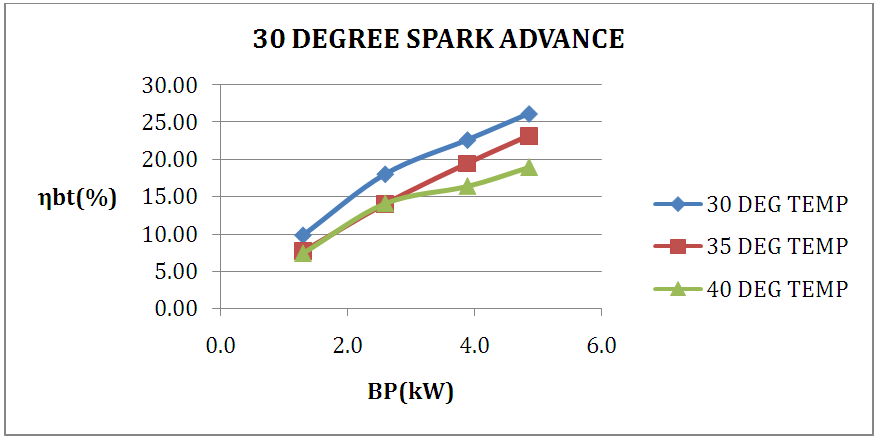

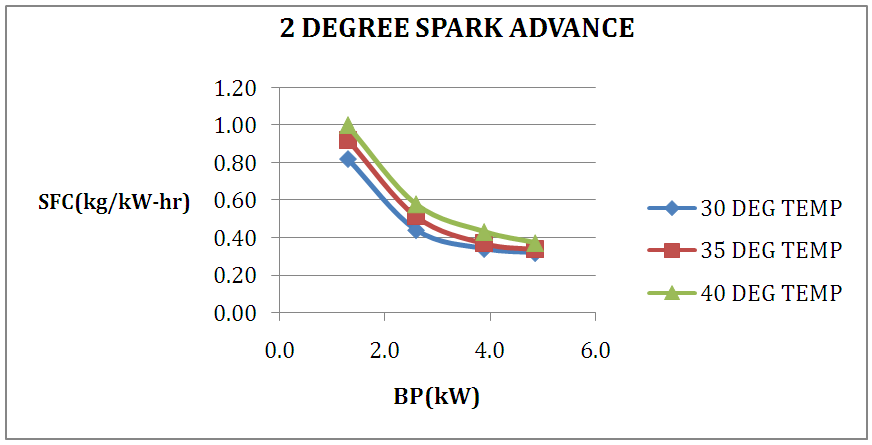

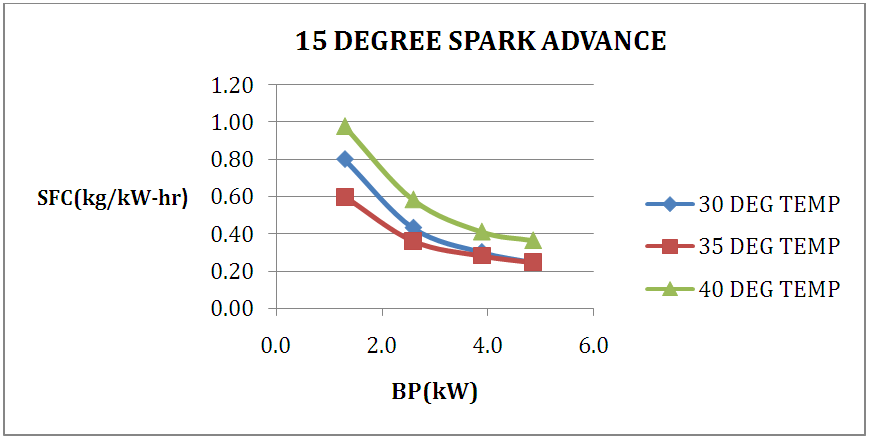

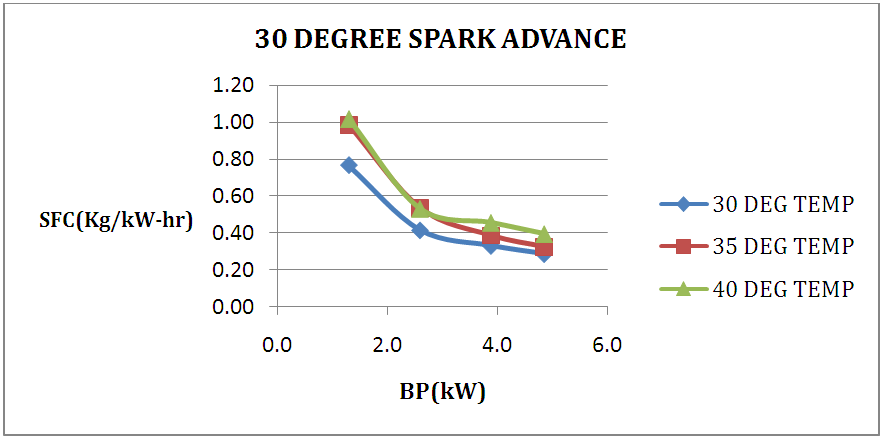

The performance characteristics of pre-heated fuel with different spark advances at various temperatures were carried out. The figures 2, 3 and 4 shows the performance characteristics curves of BP vs SFC and figures 5, 6 and 7 shows the performance characteristics curves of BP vs Brake thermal efficiency. The figures 2, 3 and 4 shows the performance characteristics of BP vs SFC for pre-heated fuel with the aid of the carburetor. In figure 2 i.e., 2 Spark Advance and figure 4 i.e., 30 Spark Advance shows as a temperature increases the SFC increases with the no change in brake power. Because when the fuel is heated, the density of the fuel reduces. It directly affects the carburetion i.e., the mass flow rate of fuel decreases from carburetor. This results in lean mixture preparation from carburetor as a result of this SFC increases.In figure 3 i.e., 15 Spark Advance, the SFC decreases as the increase in temperature, but with the increase in fuel temperature the SFC also increases. Because of the lean mixture at 35°C can give a better SFC as it has sufficient time as observed in p-θ diagrams.  | Figure 2. Performance Characteristics curve of BP vs SFC with 2 Spark Advance at various preheating temperatures |

| Figure 3. Performance Characteristics curve of BP vs SFC with 15 Spark Advance at various preheating temperatures |

| Figure 4. Performance Characteristics curve of BP vs SFC with 30 Spark Advance at various preheating temperatures |

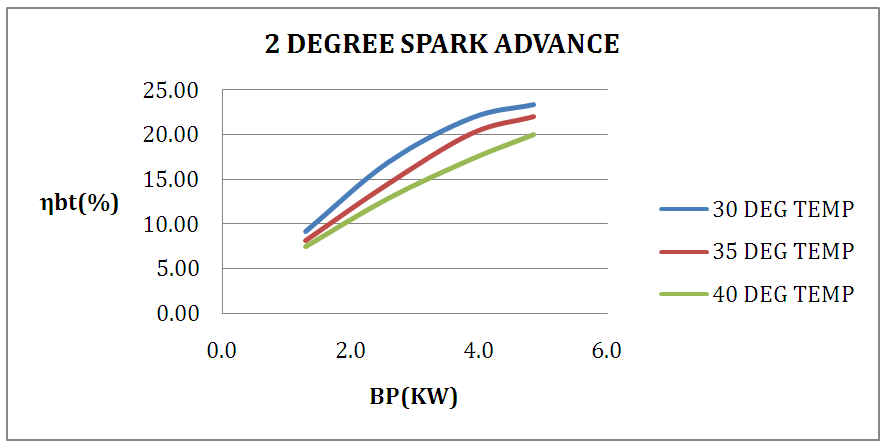

| Figure 5. Performance Characteristics curve of BP vs Brake thermal efficiency with 2 Spark Advance at various preheating temperatures |

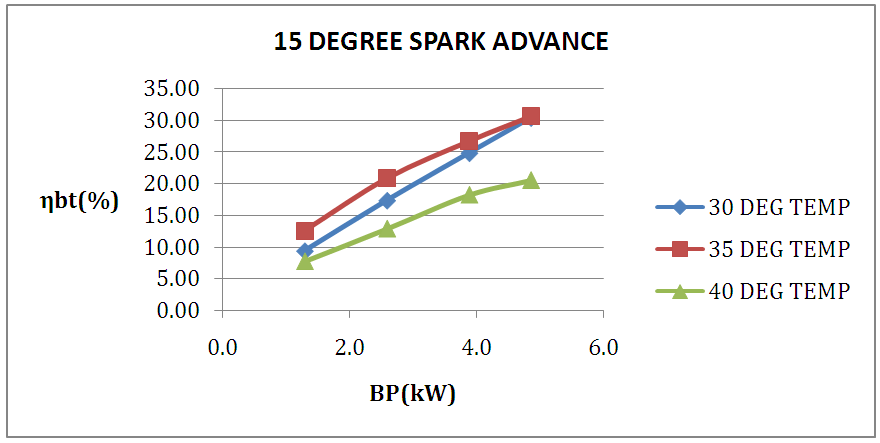

| Figure 6. Performance Characteristics curve of BP vs Brake thermal efficiency with 15 Spark Advance at various preheating temperatures |

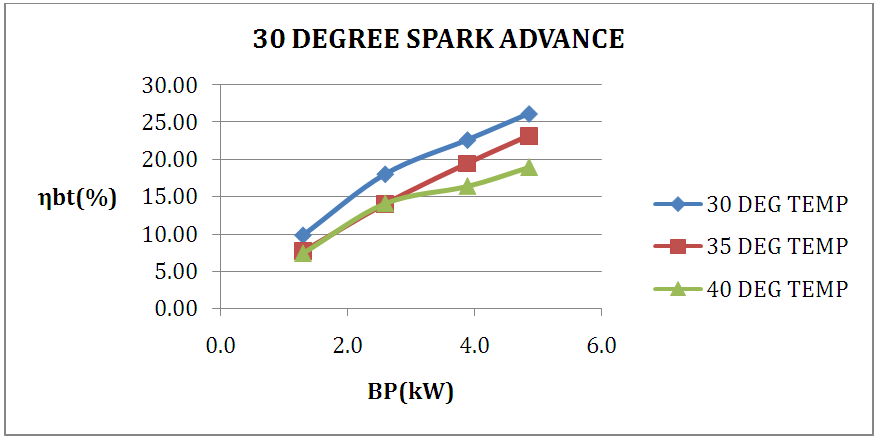

| Figure 7. Performance Characteristics curve of BP vs Brake thermal efficiency with 30 Spark Advance at various preheating temperatures |

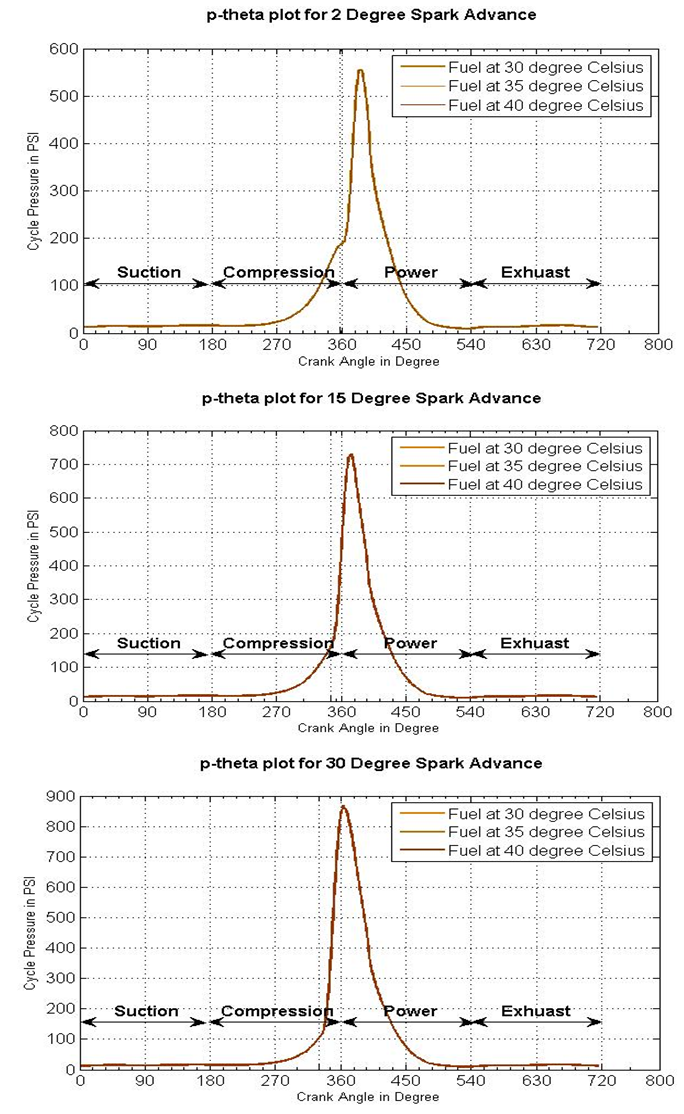

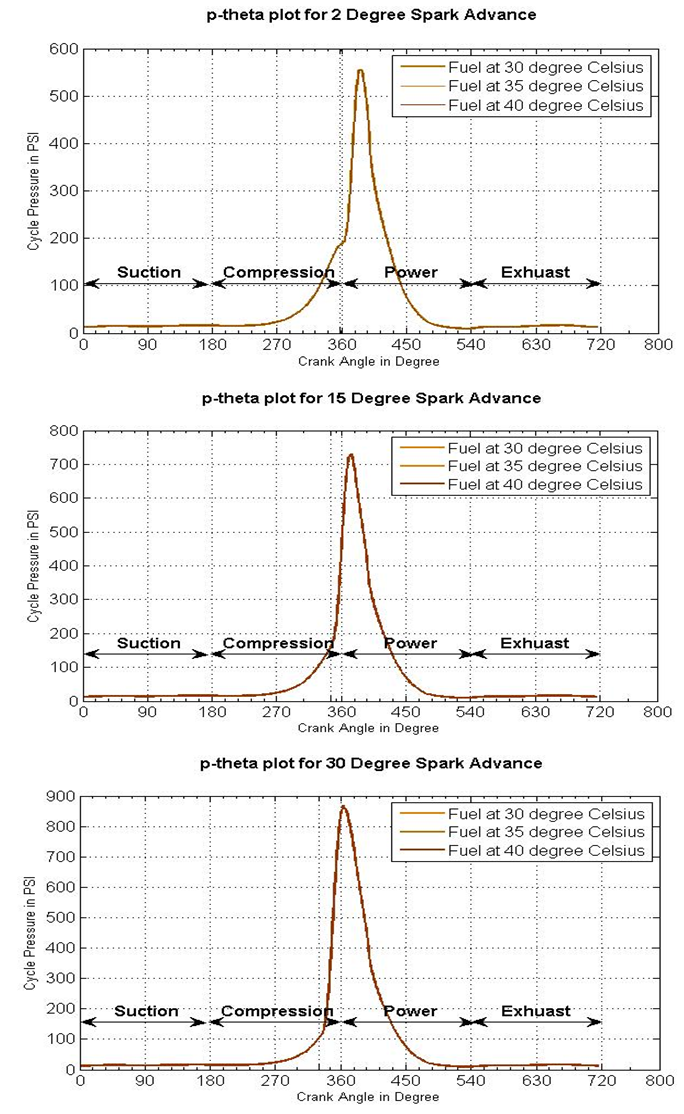

| Figure 8. p-θ diagrams for 2, 15 and 30 Spark Advance at various preheating temperatures |

The figures 5, 6 and 7 shows the performance characteristics of BP vs Brake thermal efficiency for pre-heated fuel with the aid of the carburetor. In figure 5 i.e., 2 Spark Advance and figure 7 i.e., 30 Spark Advance shows as a temperatures increase the Brake thermal efficiency decreases with the no change in brake power. In figure 6 i.e., 15 Spark Advance, initially Brake thermal efficiency increases as the increase of temperature, but further increase in fuel temperature the Brake thermal efficiency drops. It is because of insufficient time for proper mixture preparation of fuel in 40°C when it compared to fuel in 30°C and 35°C as it is observed in p-θ diagrams. Figure 8 shows p-θ diagrams for spark advance at 30°C, 35°C and 40°C. It can be observed that p-θ diagrams do not vary with fuel temperatures. But the maximum peak pressure is attained at 30 Spark Advance.

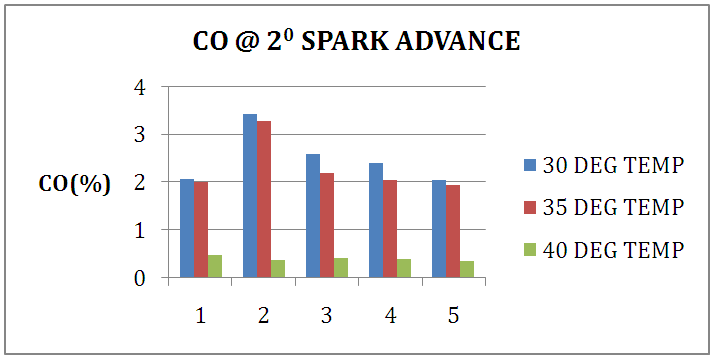

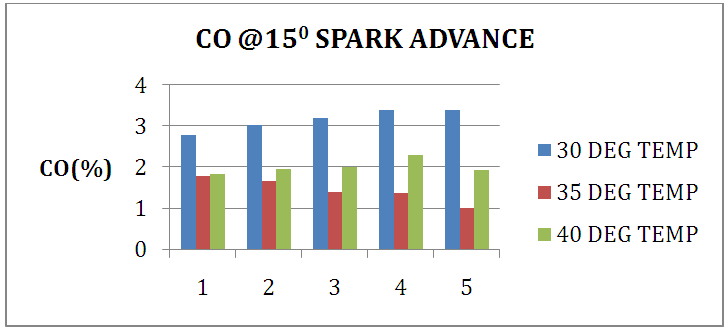

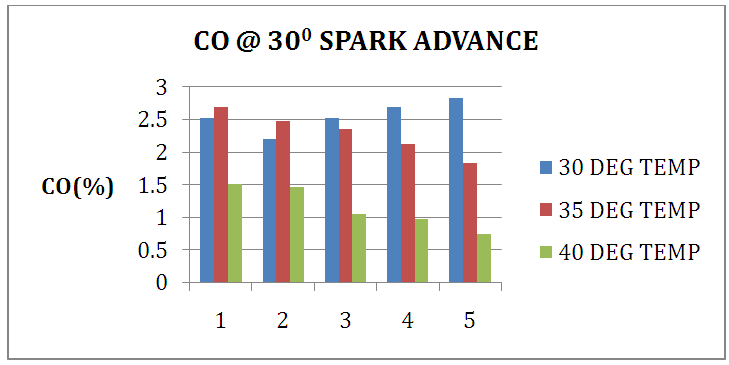

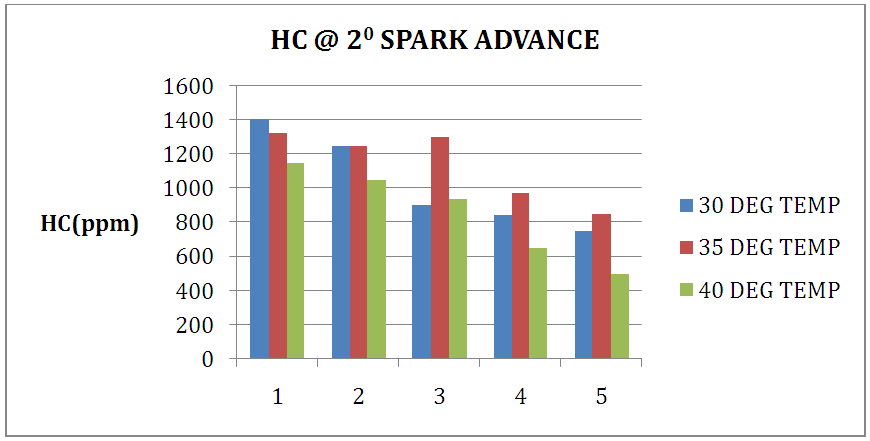

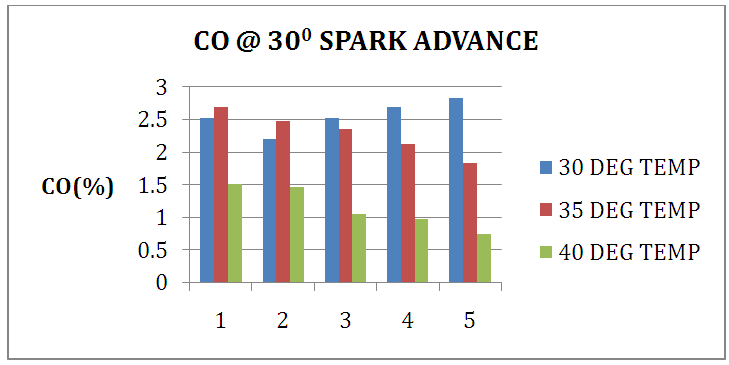

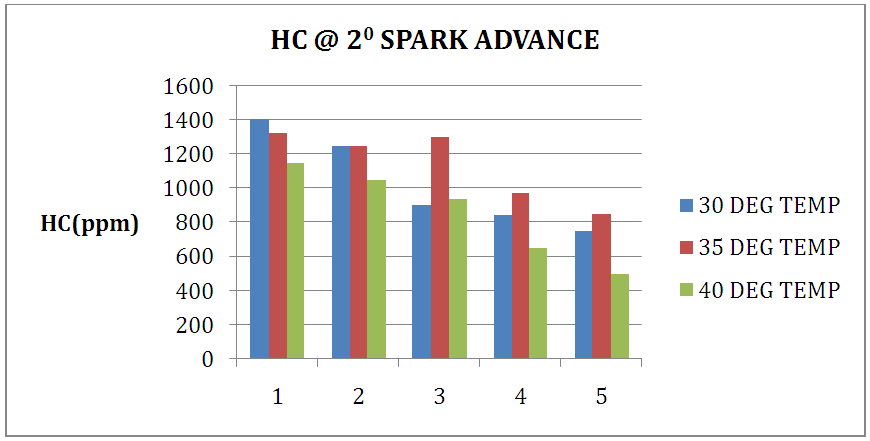

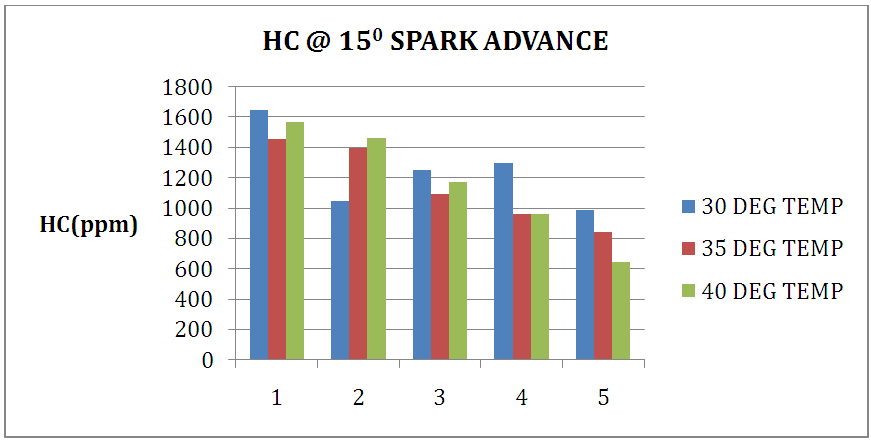

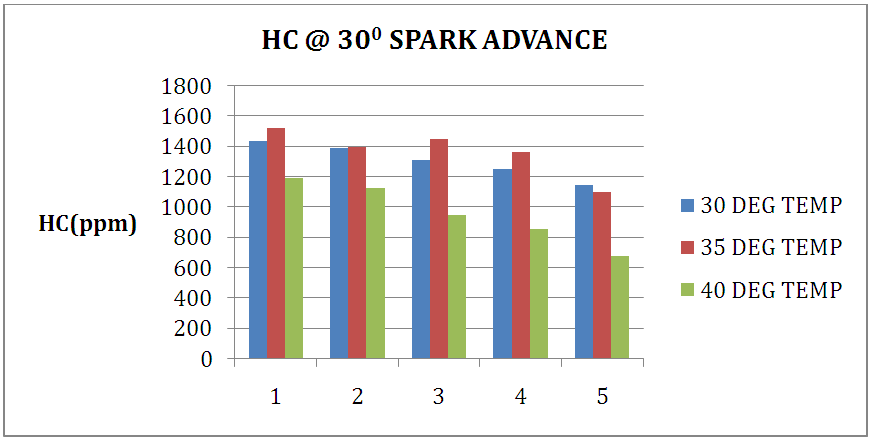

4.2.2. Emission Characteristics

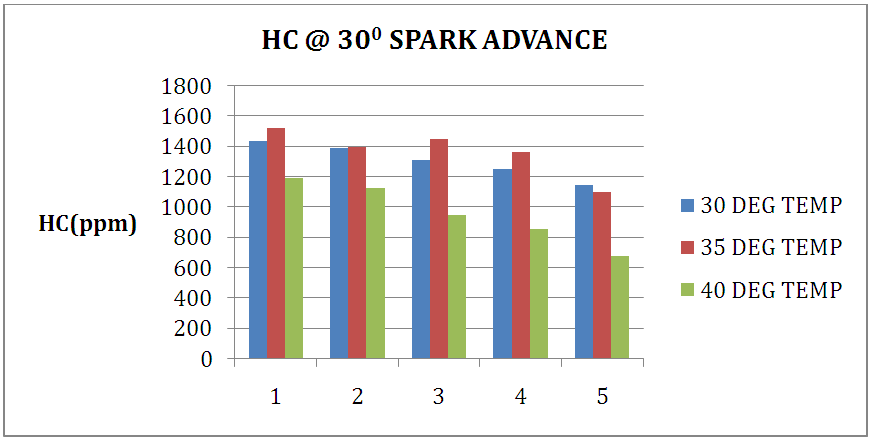

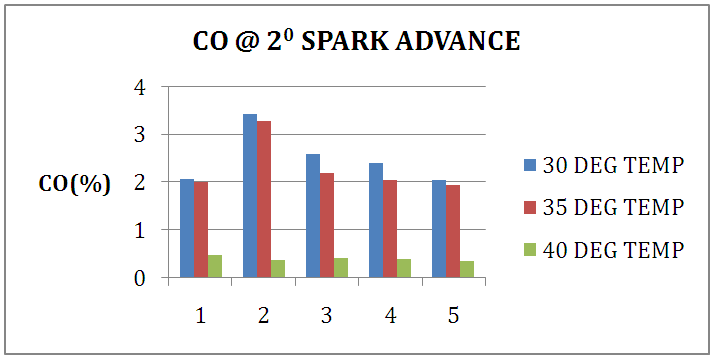

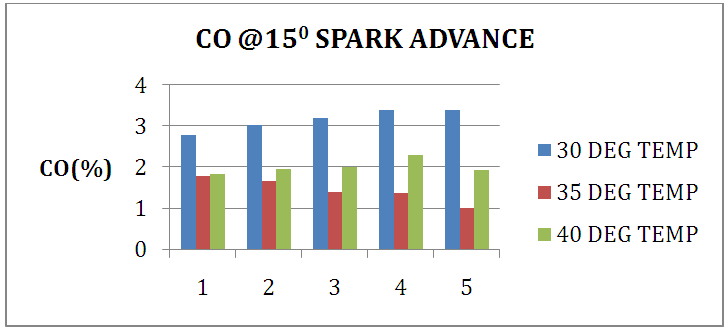

The emission characteristics of pre-heated fuel with different spark advances at various temperatures were carried out. The figures 9, 10 and 11 shows the emission characteristics chart of CO and figures 12, 13 and 14 shows emission characteristics chart of HC.The figures 9, 10 and 11 shows emission characteristics chart of CO at various temperatures for spark advance. With the increase in fuel temperature, the CO emission goes on reducing, this is because the fuel at higher temperature results in the preparation of lean mixture.  | Figure 9. Emission Characteristics chart of CO with 2 Spark Advance at various preheating temperatures |

| Figure 10. Emission Characteristics chart of CO with 15 Spark Advance at various preheating temperatures |

| Figure 11. Emission Characteristics chart of CO with 30 Spark Advance at various preheating temperatures |

| Figure 12. Emission Characteristics chart of HC with 2 Spark Advance at various preheating temperatures |

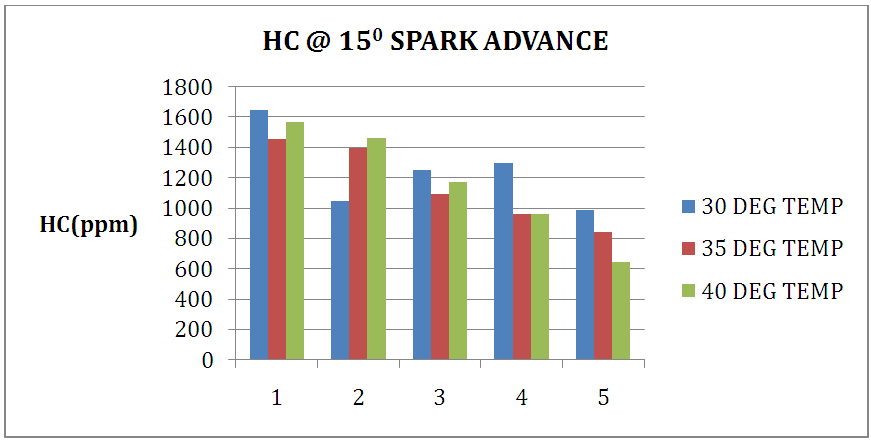

| Figure 13. Emission Characteristics chart of HC with 15 Spark Advance at various preheating temperatures |

| Figure 14. Emission Characteristics chart of HC with 30 Spark Advance at various preheating temperatures |

In figure 10 for 15 Spark Advance at 40°C fuel temperature shows higher CO emissions than 35°C. Because as the mixture gets lean it crosses partial burn limit and results in higher CO emissions. The figures 12, 13 and 14 shows emission characteristics chart of HC at various temperatures for spark advance. It is observed that the HC emissions are decreasing with increase in fuel temperature due to improper combustion.

5. Conclusions

In the present work, the performance and emission characteristics of a four stroke single cylinder SI engine by using unheated fuel with the normal mode engine operation and by using pre-heated fuel with the aid of the carburetor was analyzed. And also the relationship between temperature of the fuel and spark advance were studied. The following conclusions have been drawn. Ø In the unheated fuel with the normal mode engine operation case, the results show the performance and emission characteristics were not improved as compared to preheated fuel.Ø In the pre-heated fuel mode with the aid of the carburetor case, the 15 spark advance at 35°C preheating temperature shows a reduction of specific fuel consumption and improvement of brake thermal efficiency under different load conditions and the 2 spark advance at 40°C preheating temperature shows a reduction of CO and HC.Ø For a performance consideration, the 15 spark advance at 35°C preheating temperature with the aid carburetor and the 185 bar injector pressure at 35°C preheating temperature with the aid of injector are suitable.From above the points, the research work is concluded that the pre-heated fuel gives improvement in performance and emission characteristics.

References

| [1] | Ferguson. C. R, Kirkpatrick. A. T. (2001). Internal Combustion Engines Applied Thermosciences - 2nd Ed. New York: John Wiley & Sons, Inc. |

| [2] | Alex. C. Alkidas. Combustion advancements in gasoline engines. Energy Conversion and Management 48 (2007), pp. 2751–2761. |

| [3] | Rakesh Kumar Maurya, Avinash Kumar Agarwal. Experimental study of combustion and emission characteristics of ethanol fuelled port injected homogeneous charge compression ignition (HCCI) combustion engine. Applied Energy 88 (2011), pp. 1169–1180. |

| [4] | Osman Akin Kutlar, Hikmet Arslan, Alper Tolga Calik. Methods to improve efficiency of four stroke, spark ignition engines at part load. Energy Conversion and Management 46 (2005), pp. 3202–3220. |

| [5] | F. N. Alasfou. Nox Emission from a Spark Ignition Engine Using 30% Isobutanol ± Gasoline blend: Part 1 Preheating inlet air. Applied Thermal Engineering Vol. 18, No. 5, 1998, pp. 245–256. |

| [6] | J. Jones, J. Gagliardi, Vehicle Exhaust Emission Experiments Using a Pre-Mixed and Pre-Heated Air Fuel Charge. SAE Technical Paper 670485, 1967. |

| [7] | M.A. Kalam, H.H. Masjuki. Emissions and Deposit Characteristics of a Small Diesel Engine When Operated on Preheated Crude Palm Oil. SAE Technical Paper 2005-01-3697, 2005. |

| [8] | Hildebrand. L, Feitosa. M, Avila. M, Trinhain. A. Pre-Heated Ethanol Direct Injection Under Low Pressures to Otto Type Engines. SAE Technical Paper 2000-01-3193, 2000. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML