-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Energy Engineering

p-ISSN: 2163-1891 e-ISSN: 2163-1905

2016; 6(1): 8-15

doi:10.5923/j.ijee.20160601.02

Analytical Study of Forced Convection in Fluid Cooling Use Nanofluid Al2O3 – Water on Nuclear Reactor Core Based Fuel Cylinder with Hexagonal Sub Channel

Kisman M. Mahmud 1, Sri Anastasia Yudistirani 2, Anwar Ilmar Ramadhan 3

1Informatics Engineering Department, Faculty of Engineering, Universitas Muhammadiyah Jakarta, Jakarta, Indonesia

2Chemical Engineering Department, Faculty of Engineering, Universitas Muhammadiyah Jakarta, Jakarta, Indonesia

3Mechanical Engineering Department, Faculty of Engineering, Universitas Muhammadiyah Jakarta, Jakarta, Indonesia

Correspondence to: Anwar Ilmar Ramadhan , Mechanical Engineering Department, Faculty of Engineering, Universitas Muhammadiyah Jakarta, Jakarta, Indonesia.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Development and use of nuclear energy is currently growing very rapidly, in order to achieve increasingly advanced technology, both in terms of design, economic factors and safety factors. Thermal-hydraulics aspects of nuclear reactors should be done with calculation and near-perfect condition. Including today began development of a nuclear reactor with low power below 300 MW, or commonly called the Small Modular Reactor (SMR) as similarly of Hexagonal Sub Channel. One is CAREM-25 developed by Argentina with a power of 25 MW. In this research, analytic study of thermal-hydraulics nuclear reactor SMR CAREM-25, when the nanofluid Al2O3 – Water used as cooling fluid in the cooling system of a nuclear reactor. Further to this analytic modeling will be done on CFD. Analytic modeling with CFD to determine the flow phenomena and distribution as well as the effect of nano-particles of Al2O3-Water based on the volume fraction (1% and 3%) by forced convection.

Keywords: Nanofluid, Nano-Particles, Forced convection, Thermal-Hydraulic, Sub channel of hexagonal

Cite this paper: Kisman M. Mahmud , Sri Anastasia Yudistirani , Anwar Ilmar Ramadhan , Analytical Study of Forced Convection in Fluid Cooling Use Nanofluid Al2O3 – Water on Nuclear Reactor Core Based Fuel Cylinder with Hexagonal Sub Channel, International Journal of Energy Engineering, Vol. 6 No. 1, 2016, pp. 8-15. doi: 10.5923/j.ijee.20160601.02.

1. Introduction

- Safety is a major concern in the design, operation and development of a nuclear reactor. Therefore, the analysis method used in all these activities must be thorough and reliable so as to predict a wide range of operating conditions of the reactor, both under normal operating conditions and in the event of an accident [1]. In addition neutronic aspect, thermal-hydraulic aspect is an important aspect for the safety of the design and operation of a nuclear reactor. Magnitude thermal-hydraulic such as pressure, coolant flow rate and temperature of the fuel needs to be known through predictive calculation [2].Currently begun development of nuclear power plant or nuclear power plants around the world by type of Small Modular Reactor (SMR) is a mini nuclear reactor with power below 300 MW. Where an excess of Small Modular Reactor (SMR) is more flexible in matters of design, the cheaper the price development and also the price of treatment, as well as the advantages of SMR did pooling system thermal-hydraulic of 2-loop system cooling into the cooling loop in other words the use of integral system loop on SMR. SMR cooling fluid using fluid (H2O) in the reactor coolant loop integral system. Studies related to the use of other types of nanofluid as coolant into the study and research are interesting and important to optimize heat transfer in the SMR, becoming thermal-hydraulic important aspect in the cooling system in a nuclear reactor [3].One study that is currently a research priority in the cooling system is the use of nano-particles that are mixed with a fluid to improve the performance of decision-calorific. Theoretically nanofluid including nanoparticles has high thermal conductivity value than ordinary light fluid, so as to absorb and transfer heat better. Buongiorno and his team at the Massachusetts Institute of Technology (MIT) in the United States has conducted research related to nanofluid, it has been proven that the value of Critical Heat Flux (CHF) nanofluid greater than fluid water [4, 5].This research was developed for the use of nanofluid as coolant fluid in a nuclear reactor with the type SMR CAREM-25, made in Argentina. The research activities focused on assessing the deeper aspects thermal-hydraulic that occurred in the cooling system of a nuclear reactor CAREM-25 using nanofluid Al2O3 – Water as coolant fluid. So that later acquired the flow characteristics of natural circulation cooling system used by the SMR. Heat generation process from the beginning, the temperature distribution in the fuel element, in order to obtain an analytical model for the safety performance of the reactor type CAREM SMR-25 with forced convection.

2. Research Method

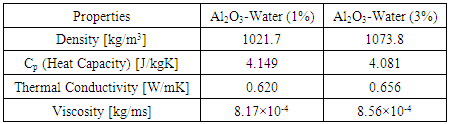

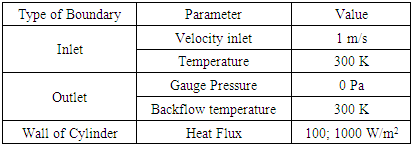

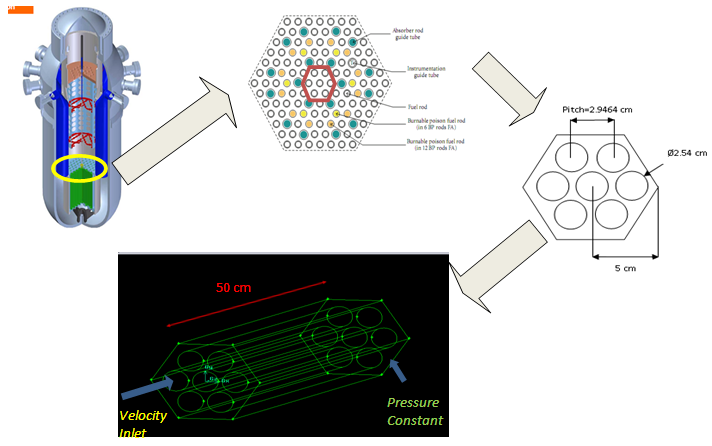

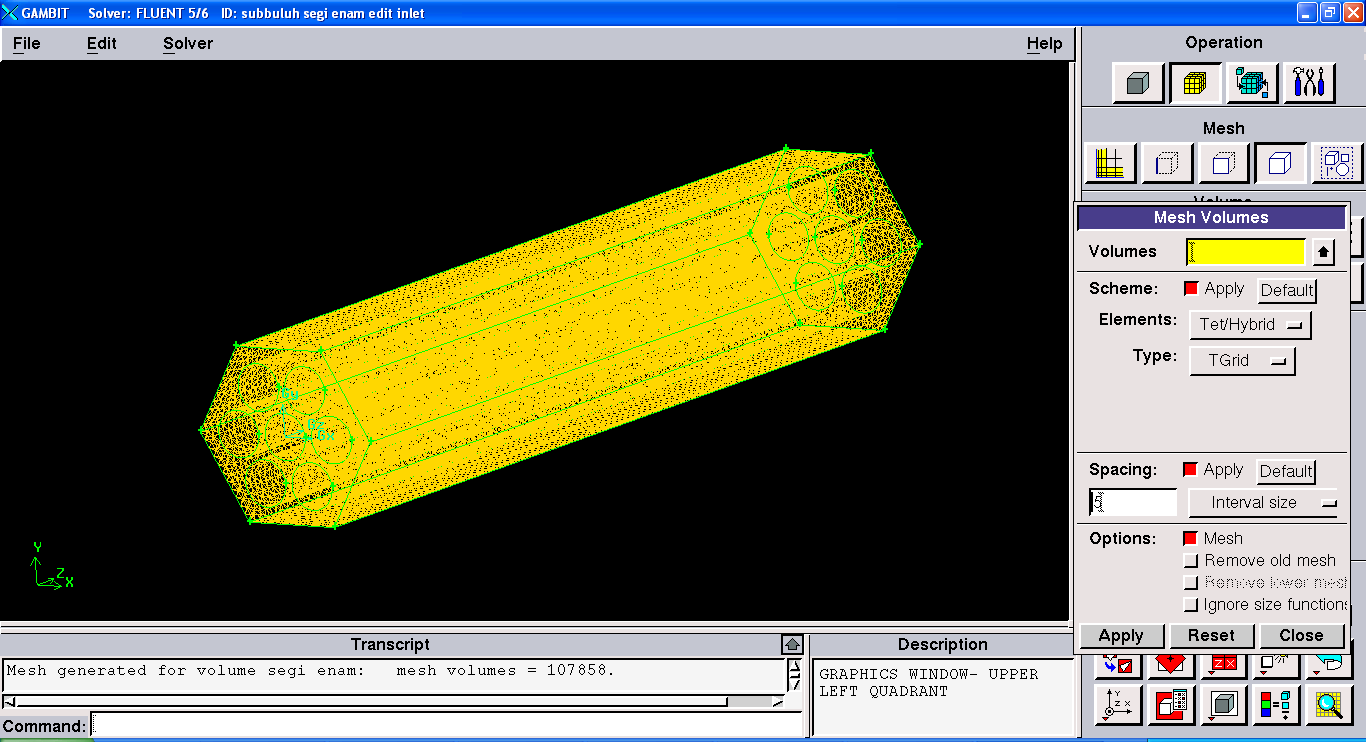

- Modeling of Core Nuclear Reactor of Small Modular Reactor (SMR) with Hexagonal of Sub ChannelIt needs to be done first before doing the simulation process is to create a model that happens to sub-channel arrangement of hexagons. In this case the model is made is in the form of volume models. Simplifying assumptions made model that is considered a model sub-channel arrangement of hexagonal Sub Channel is similar to the SMR reactor core type hexagonal and uniform heat flux generated. In the manufacture of this model using CAD program as modeling. And models to be simulated in this research are as follows:MeshingMeshing is the process by which the overall geometry is divided into small elements this will act as a control surface or volume in the calculation process and then each of these elements will be input to the element next to it. This will happen over and over again until the fullest domain. In meshing elements that would have been tailored to the needs and geometric shapes. In this thesis meshing application used is CAD. In this study all types of configuration elements are smulated using hybrid or tetrahedron elements. Below are images meshing with volume meshing configuration and size interval by 5.Numerical modeling with CFD CFD is one type of CAD program that uses finite volume method. CFD mesh provides complete flexibility, so as to resolve the case of fluid flow with unstructured mesh even with a relatively easy way. CFD mesh types supported are the type of triangular-quadrilateral 2D, 3D tetrahedral- hexahedral-pyramid-wedge, and mesh mixture (hybrid). CFD also provides facilities to refine or enlarge an existing mesh. In general, the steps in performing analysis by using CFD.The type of fluid used is nanofluid. Nanofluid physical properties such as density, viscosity, thermal conductivity, and thermal types are modeled as a function of temperature.

| Figure 1. Modeling of sub channel hexagonal |

| Figure 2. Results meshing in CAD |

|

|

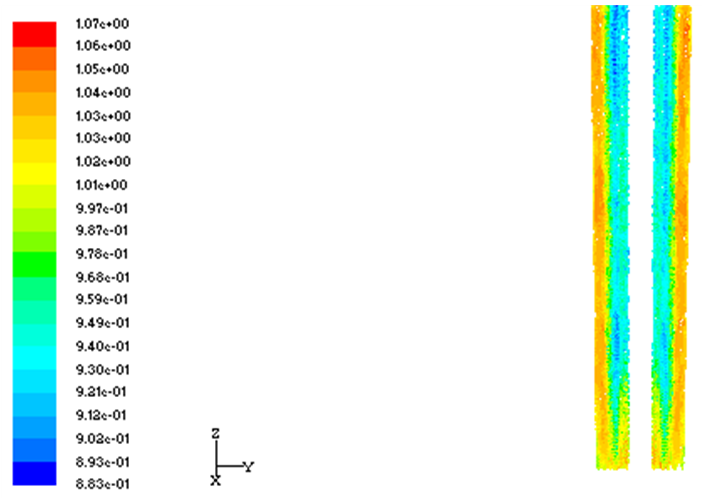

3. Results and Discussion

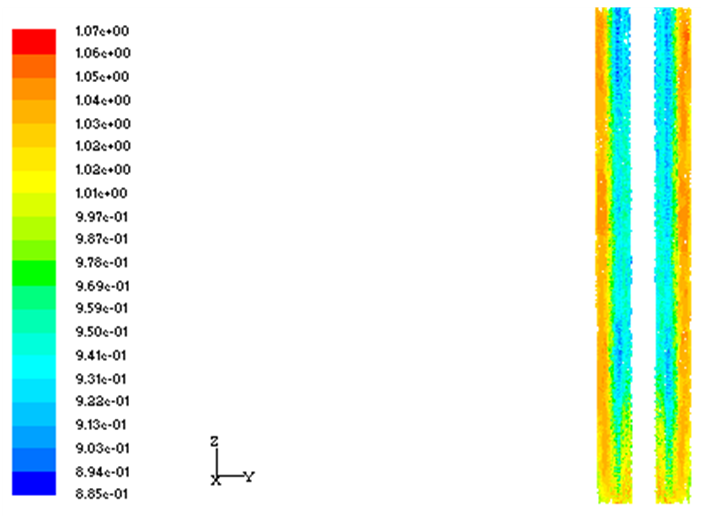

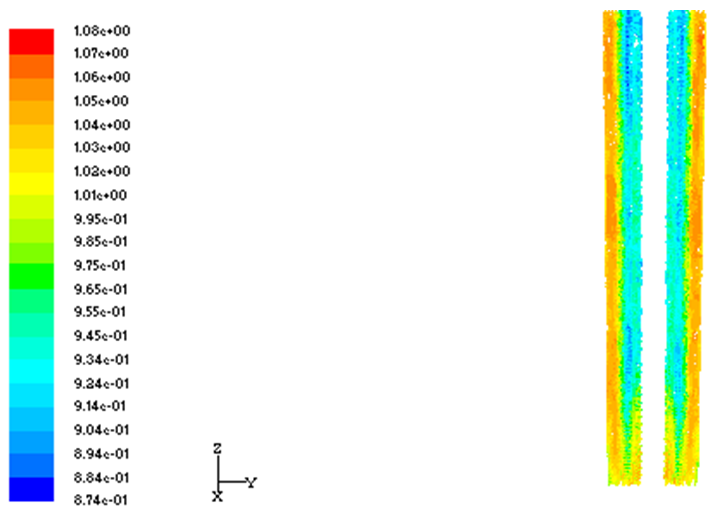

- Velocity flow characteristics on Sub Channel Hexagonal Characteristic patterns of movement flow of nanofluid as coolant fluid by convection forced occurring in a nuclear reactor core types Small Modular Reactor (SMR) with sub channel hexagonal, can be seen in Figure 3 and Figure 5 below:

| Figure 3. Velocity vector of nanofluid Al2O3 – Water (1%) with heat flux of 1000  |

| Figure 4. Velocity vector of nanofluid Al2O3 – Water (3%) with heat flux of 1000  |

| Figure 5. Velocity vector of H2O with heat flux of 1000  |

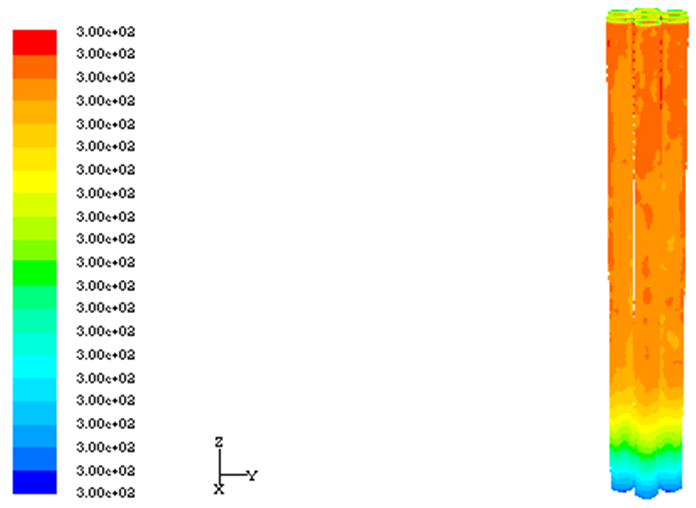

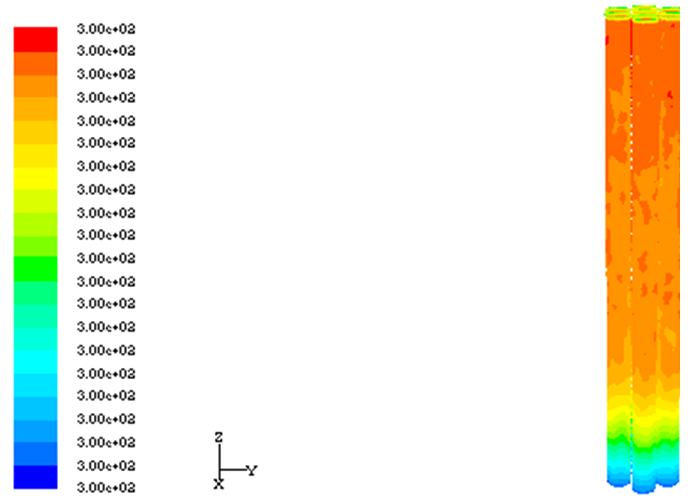

| Figure 6. Contour of temperature distribution of nanofluid Al2O3 – Water (1%) with heat flux of 1000  |

| Figure 7. Contour of temperature distribution of nanofluid Al2O3 – Water (3%) with heat flux of 1000  |

| Figure 8. Contour of temperature distribution of H2O with heat flux of 1000  |

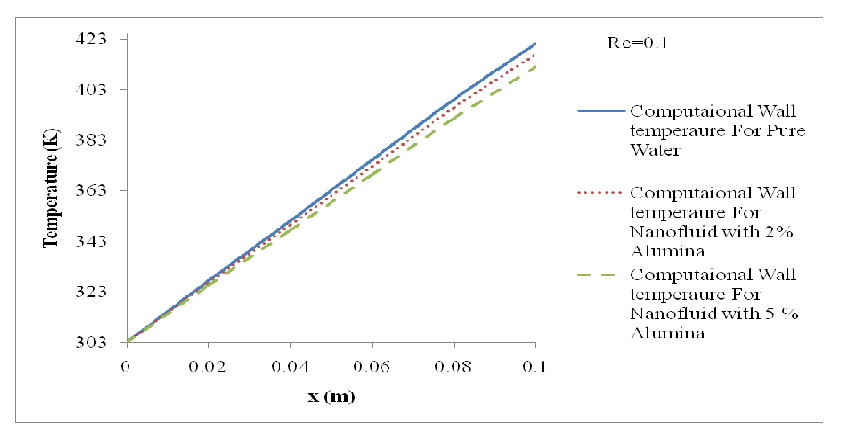

| Figure 11. The relationship of the distribution of the wall temperature of the position (m) in the micro channel [7] |

4. Conclusions

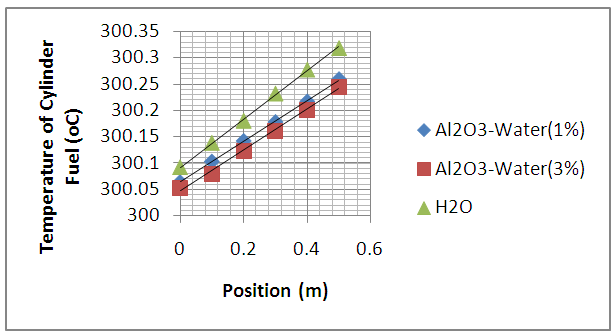

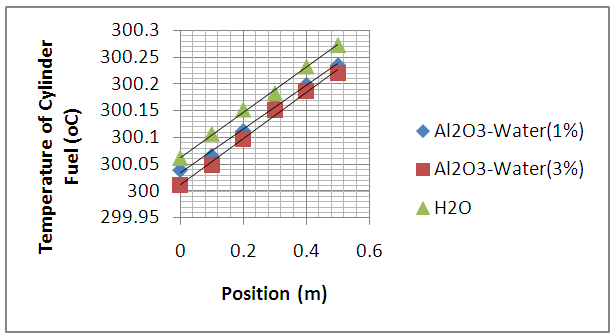

- From these results provide the following conclusions:1. Distribution patterns of flow rate in each cooling fluid (fluid water (H2O) and Al2O3 –Water of nanofluids (1% and 3%) had a similar pattern, which is beginning to experience a great pace, in line with the height of forcibly became a natural where a decline in the flow velocity at the threshold of the cylinder.2. Distribution of temperature on the wall on the analysis of heat transfer occurs in sub channel of hexagonal showed a significant upward trend and approaching the increase linearly in the direction of the z-axis position, and proves also that the fluid water has a temperature distribution value wall that is larger than Al2O3 –Water of nanofluids (1% and 3%).

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML