-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Energy Engineering

p-ISSN: 2163-1891 e-ISSN: 2163-1905

2015; 5(5): 95-101

doi:10.5923/j.ijee.20150505.02

Thermal Performance of a Reflector Based Solar Box Cooker Implemented in Ile-Ife, Nigeria

B. Z. Adewole, O. T. Popoola, A. A. Asere

Department of Mechanical Engineering, Obafemi Awolowo University, Ile-Ife, Nigeria

Correspondence to: B. Z. Adewole, Department of Mechanical Engineering, Obafemi Awolowo University, Ile-Ife, Nigeria.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

Different categories of solar cooker ranging from concentrator types, solar ovens, box type cookers with or without reflectors and indirect solar cookers have been designed and tested in Nigeria. The uses of different designs of solar cookers have not become acceptable in the rural areas due to number of reasons. It is either they are too expensive for individual family to afford or they are yet to be practically known. In view of these shortcomings, this paper presents thermal performance of low cost reflectors based solar box cooker implemented in Ile-Ife, Nigeria. The cooker was constructed with locally available materials. The thermal performance of the cooker in terms of figures of merits and cooker efficiency was evaluated based on Indian Standard (IS 13429:2000). Results of field evaluation show maximum insolation of 520 W/m2 at 2.00 pm and minimum of 246 W/m2 at 11.00 am. The average solar radiation and ambient temperature observed during the test periods were 403 W/m2 and 40°C respectively. The water temperature values between 60 and 67°C were observed at insolation values between 398 and 520 W/m2. These occur between the hour of 1:20 pm and 4:00 pm with the highest water temperature of 67°C at 3.00 pm. The performance of the cooker in terms of first figure of merit, second figure of merit and thermal efficiency show that the cooker compare favourably well with international standard. The cooker has a better heat retention capacity when compared with others found in the literature. The experimental results obtained for thermal performance of the cooker demonstrated its suitability for cooking even during fluctuating weather conditions.

Keywords: Thermal performance, Reflector, Solar box cooker, Ile-Ife, Nigeria, Indian Standards

Cite this paper: B. Z. Adewole, O. T. Popoola, A. A. Asere, Thermal Performance of a Reflector Based Solar Box Cooker Implemented in Ile-Ife, Nigeria, International Journal of Energy Engineering, Vol. 5 No. 5, 2015, pp. 95-101. doi: 10.5923/j.ijee.20150505.02.

Article Outline

1. Introduction

- Energy for cooking comprises 90% of total household energy consumption in developing countries [20]. Large percentages of energy requirement for cooking are met by non-commercial fuels such as firewood and agricultural waste in rural area. Despite numerous advantages of solar and other renewable energy in meeting thermal energy demands of rural dwellers, the rural population still depends heavily on fuel wood. High rates of deforestation couple with environmental concern now accelerate an increasing demand for other sustainable energy sources such as solar cookers.Nigeria lies within a high sunshine belt and the country solar radiation is fairly distributed well. The annual average of total solar radiation varies from about 12.6 MJ/m2-day (3.5 kWh/ m2-day) in the costal latitudes to about 25.2 MJ/ m2-day (7.0 kWh/ m2-day) in the far north [8]. This gives an average annual solar energy intensity of 1934.5 kWh/ m2-yr [8]. Thus, over a whole year, an average of 6,372, 613 PJ/year (approximately 1, 770 thousand TWh/ year) of solar energy falls on the entire land area of Nigeria [8]. Ile-Ife, Nigeria is located on latitude 7.52° N, longitude 4.52° E. The intensity of solar radiation received at Ile-Ife’s surface is high all year round. The maximum intensity is found at about 13:00 LT, with values of 1100 and 800 Wm-2 for March and August, respectively [5]. Measurements of hourly averaged net all-wave radiation data [4] for a complete three-year period (2010-2012) at a meteorological station located inside the Obafemi Awolowo University campus, Ile-Ife, revealed that hourly maxima of the net radiation occurred at 14:00 LT (GMT + 1). The values increased considerably from 337.6 ± 146.4 Wm–2 in July, which is the peak of the wet season, to 441.7 ± 82.4 Wm-2 in March.Different categories of solar cooker ranging from concentrator types, solar ovens, box type cookers with or without reflectors and indirect solar cookers have been designed and tested in Nigeria. The uses of different designs of solar cookers have not become acceptable due to number of reasons:(a) individual family cannot afford their high cost;(b) they are yet to be traditionally acceptable because they have not been practically known;(c) their handling is not easy (the cookers can only have cooking done under the direct sun radiation;(d) they can be difficult to use at night periods;(e) the heat produced cannot be stored up for future use;(f) the reflectors can cause damage to the eyes;(g) it is not easy to use them in cloudy weather; and(h) the locally available solar cookers are not disseminated to give opportunity to users. All these reasons are comprehensive enough to make solar cookers remain in the dark for so long, hence their remaining unacceptable. Their acceptance still requires continuous workshops, education, training, more designs, testing and implementation.Solar box cooker is the simplest type of solar cooker available because it is relatively cheap, low-tech device [26]. The cooking time depends primarily on the materials being used, the amount of sunlight at the time of cooking, and the quantity of food that needs to be cooked. Air temperature, wind, and latitude also affect its performance [26].The use of solar box cooker is not popular among the rural dwellers in Ile-Ife, Nigeria due to some of the reasons highlighted above. The objectives of this work are to test and evaluate the thermal performance of a low cost, reflector- based solar box cooker in Ile-Ife, Nigeria and determine its suitability for cooking during high and low solar irradiation.

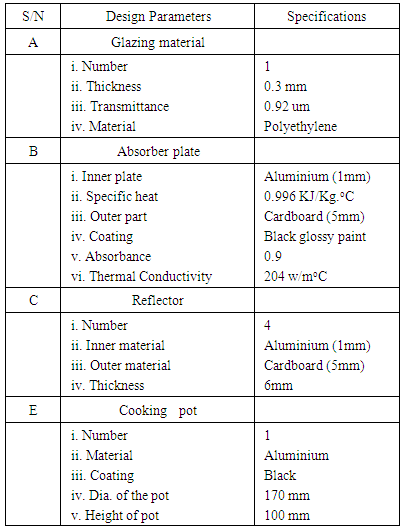

2. Description of the Solar Box Cooker

- Figure 1 shows the schematic diagram of the solar box cooker employed four non-tracking reflectors. Table 1 gives the design parameters and specifications for different components of the solar box cooker. The cooker consists of 5mm double walled cardboard box. The inner boxes were constructed using aluminum sheet. The space between the outer box and inner box was filled with compressed sawdust (insulator) of 50 mm thickness. Based on the above dimension, the volume of the cooker (the cooking space) was calculated to be 9.375 m3. The solar box cooker employed four reflectors, mounted on the box of the cooker to reflect incidence radiation onto the base of the absorber plate. The inner parts of the reflectors were constructed with 1 mm aluminum sheet and it’s covered at the outside by corrugated cardboard of 5 mm thickness. The tilt of the reflectors was fixed at 72.5o from the horizontal plane of the box cooker. The collector area and cooker surface area were calculated to be 0.0625 m2 and 0.0719 m2 respectively. The cooker concentration ratio is 1.667. The overall dimension of the cooker is 255 mm x 255 mm x 465.3 mm and its weight is 1.16 kg.

| Figure 1. Solar box cooker used for the experiment |

|

3. Performance Testing

- Difficulties in assessing numerous designs of solar cookers have led to the creation of three major testing standards for evaluating solar cookers throughout the world. They include: American Society of Agricultural Engineering (ASAE) Standard S580, The standard developed by the European Committee on Solar Cooking Research (ECSCR) and the Bureau of Indian Standards, based on work by [16]. Though, the three standards have their shortcomings, India standards provide testing standard based on thermal test procedures for box-type solar cookers. The performance of the reflector based solar box cooker implemented in this study was done based on India standard, IS 13429: 2000 [4]. The standard highlighted two methods of test: a stagnation test (test without load) and a load test. Test on the cooker was done in the Month of March when the solar irradiation was maximum [5]. The test was carried out between 11.00 am and 4.00 pm for three consecutive days in order to determine the maximum plate and water temperature in the cooker at this period.

3.1. Stagnation Test

- A number of tests without load were conducted on the cooker to determine its stagnation temperature and also to check the rise in temperature inside the cooker. The stagnation temperature, ambient temperature (Ta) and absorber plate temperature (Tp) were measured for different time of the day between 11:00 am and 4.00 pm during the operation of the cooker using Type K, mineral insulated grounded junction, 1.6mm diameter thermocouple with Elix digital thermometer (LX-6500) capable of reading temperature between -50°C and 750°C. Thermo Anemometer (PROVA Instrument, AVM 01) was used to measure wind speed (v) and solar radiation was measured using global radiation meter (GRM 100).

3.2. Load Test

- The loading test was done by placing a water-filled cylindrical pot covered by a lid, in the cooker. The test was conducted for three days with 1.0 kg of water in the first day, 1.5 kg of water in the second day and 2.0 kg of water in the third day. Each test was carried out on sunny day between 11:00 am and 4:00pm daily. The absorber plate temperature (Tp), ambient temperature (Ta), water temperature (Tw), solar radiation (Hs) and wind speed (v) were measured using the instrumentation described in section 3.1.

3.3. Performance Measures

- The performance evaluation of the solar box cooker involve estimation of the following parameters: First figure of merit (F1), Second figure of merit (F2) and cooker’s efficiency (η).

3.3.1. First Figure of Merit

- The first figure of merit (F1) of a solar box cooker is defined as the ratio of optical efficiency (ηo) and the overall heat loss coefficient (UL) [25]

| (1) |

| (2) |

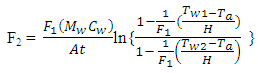

3.3.2. Second Figure of Merit

- The second figure of merit (F2) is evaluated under full load condition and can be expressed by the expression given by [18], as follows:

| (3) |

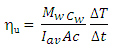

3.3.3. Cooker Efficiency

- The overall thermal efficiency of the solar box cooker is expressed mathematically by [14, 22] and reported by [12] as follows:

| (4) |

4. Results and Discussion

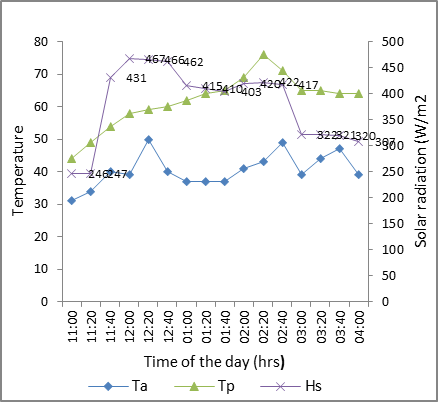

4.1. Stagnation Temperature Test

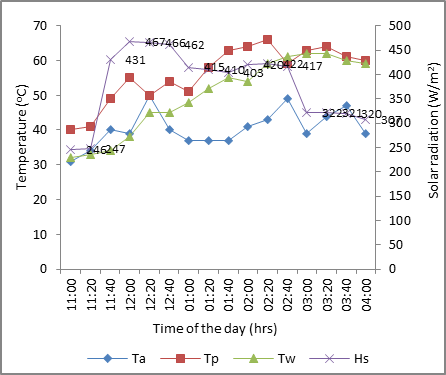

- The result of stagnation temperature under no load condition is shown in Figure 2. The graph reveals the variation in the solar radiation and ambient temperature and their effects on the stagnation temperature observed in the absorber plate of the solar box cooker. The average ambient temperature for the test day was 40.44°C. Maximum absorber plate temperature of 76°C was recorded at 2:20 pm and at an insolation value of 422 W/m2. Between 11:50 am and 2:50 pm, insolation was high and the plate temperature increases with increasing insolation even till 4 pm. The result shows that heat loss from absorber plate of the cooker is minimal and the absorber plate temperature is retained for a long time. This is desirable for heating water since major mode of heat transfer to the cooking vessels is by conduction from absorber plate.

| Figure 2. Thermal performance curve of the solar box cooker under stagnation test condition |

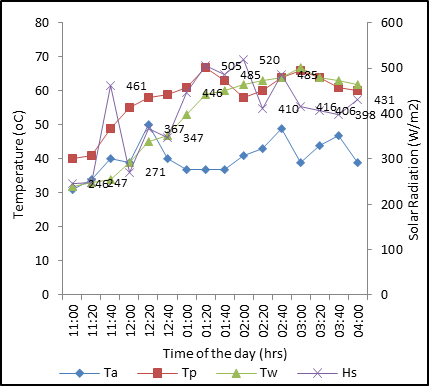

4.2. Sensible Heat Test

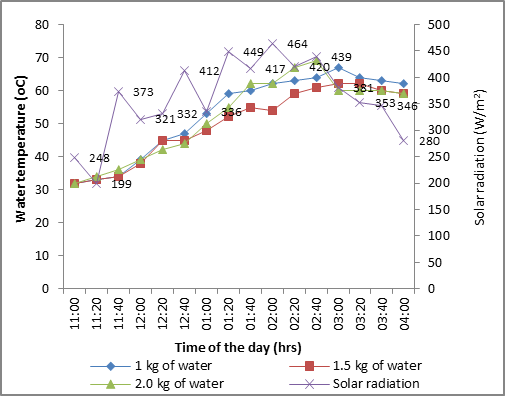

- Variation in solar radiation, ambient temperature, plate temperature and plate water temperature during sensible heat test of 1.0 kg (1 litre) of water are shown in figure 2. Periodic overcast of weather caused fluctuation in the solar radiation. The maximum insolation of 520 W/m2 at 2.00 pm and minimum of 246 W/m2 at 11.00 am were recorded. The average solar radiation and ambient temperature observed during the period of test were 403 W/m2 and 40°C respectively. The highest pot water temperature of 67°C was observed at 3:00 pm. [13] reported that most food can be fully cooked at the temperature range of 60-90°C. The water temperature during the period of test reached temperature values between 60- 67°C at insolation values from 398 W/m2 to 520 W/m2 between the hour of 1:20 PM and 4:00 PM. Figure 4 shows sensible heat test result for 1.5 kg water. The average solar radiation and ambient temperature during the period of boiling 1.5 kg of water were 380 W/m2 and 40°C respectively. The highest pot water temperature of 62°C was observed at 3:00 pm. The overcast of cloud during the period of test caused fluctuations in the value of plate temperature with the average value at 56°C. Despite the low plate temperature, there was a significant rise in water temperature up till 3:10 PM. This shows a good heat transfer to the cooking vessel from the absorber plate, as well as reduction of heat loses due to good insulation. Figure 5 illustrates the performance test of the cooker under sensible heat test of 2.0 kg of water. The result of the test presents the behaviour of pot water temperature and solar box plate temperature under high fluctuating weather condition namely: solar radiation and ambient temperature. Despite high weather fluctuation during the period of test, the plate temperature and water temperature increase significantly reaching maximum temperature of 74°C and 67°C at an insolation of 364 and 416 W/m2, respectively. The plate and water temperature attain temperature suitable for water heating at 1:20 PM and increase considerably till 4:00 PM. This and other results discussed above demonstrated the suitability of the designed solar box cooker for heating water even during fluctuated weather conditions.

| Figure 3. Thermal performance curve of the solar box cooker during sensible heat test of 1.0 kg of water |

| Figure 4. Thermal performance curve of the solar box cooker during sensible heat test of 1.5 kg of water |

| Figure 5. Thermal performance curve of the solar box cooker during sensible heat test of 2.0 kg of water |

| Figure 6. Variation of water temperature with time for different loads |

4.3. Performance Rating

4.3.1. First Figure of Merit

- The first figure of merit (F1) was calculated from equation (5) to be 0.08 at stagnation, with value of Tp = 76, Ta = 43 and Hs = 422. This corresponds to the maximum plate temperature of 76°C attained by the cooker during stagnation test. The low stagnation temperature corresponds to the low insolation attained during the period of test. The first figure of merit obtained was found to be lower than the multi reflector solar cooker (0.09) made with cardboard in India by [15]. It is also lower compared to commercial box cooker which ranges from 0.11 to 0.12 [3]. Based on Indian standards, any designed solar box cooker with F1 greater than 0.12 and above is classified as grade A and if otherwise, it is classified as grade B [21]. The low value of first figure of merit is as a result of low optical efficiency and low insolation, as well as high convection and radiation loses from the cooker.

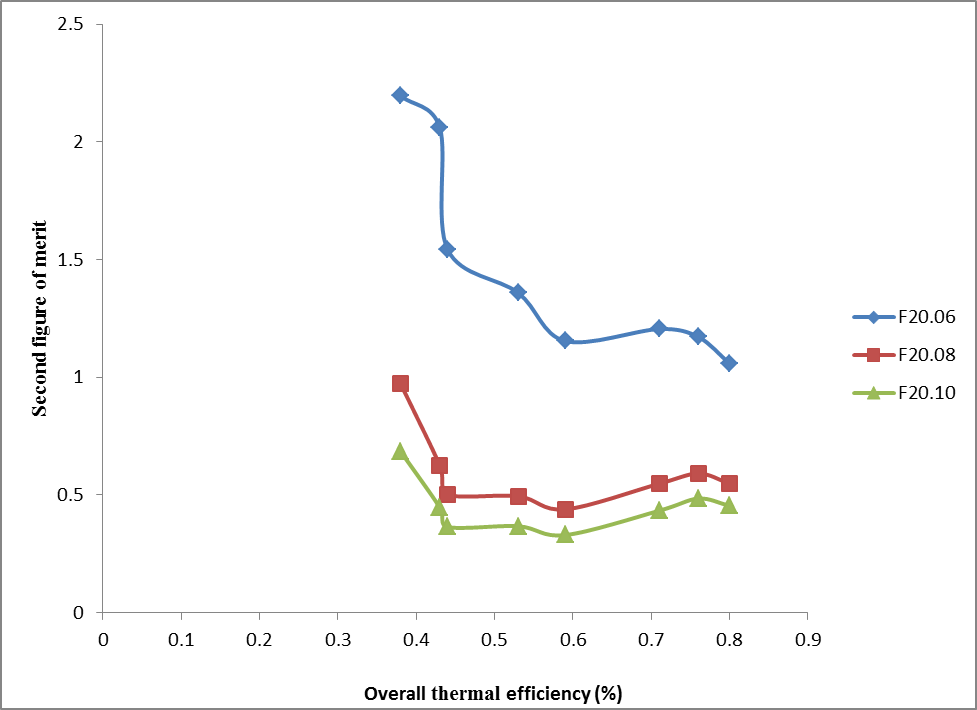

4.3.2. Second Figure of Merit

- The second figure of merit of the cooker (F2) which corresponds to heat transfer efficiency of the cooker at low heat capacity of cooker interior is calculated from sensible heat test (water heating test) of 1.0 kg of water in the cooker using equation (6). The variation in the water temperature placed in the cooker was shown in Figure (3). The time required to raise the temperature of 1.0 kg of water from 53°C to 67°C was about 120 minutes which corresponds to the second figure of merit (F2) calculated from equation (6) to be 0.54. In calculating the value of F2, [6] reported that some flexibility is allowed in the choice of Tw1 and the time interval (t). Value of Tw1> Ta was recommended by [25] while values of Tw2 lower than the boiling point was recommended by [19]. The criteria for F2 value by Indian standard is that F2 should be greater than 0.42. The F2 value of 0.54 obtained from this study compare favourably with the standard.

4.3.3. Overall Cooker Thermal Efficiency

- The Overall daily thermal efficiency of the solar box cooker (ηu) was calculated by equation (7) to be 33% (Mw =1 kg; Cw = 4220 J/kg/K; Ac = 0.0625 m2; I = 379.75 w/m2; ΔT= 26.7°C; Δt = 14400s). Different thermal efficiency achieved for solar box cooker was reported by [2]. The thermal efficiency measured by [10] was between 30 and 50%. Also, it was reported by [2] that thermal efficiency measured by [5] was 20%. [7] also reported efficiency of 30% for multi-step inner reflectors box-type solar cooker and the same authors in (1997) [8] developed an outer-inner reflectors box-type solar cooker with 31% efficiency. The thermal efficiency calculated for the implemented cooker competes well with those found in the literature and this is an indication of better heat retention ability of the cooker.

4.3.4. Relationship between Figures of Merit and Cooker Thermal Efficiency

- Figure 7 shows the relationship between first figure of merit and the overall thermal efficiency of the cooker plotted over temperature difference between the plate temperature and ambient temperature. It is observed that F1 increases as temperature difference increases and this is due to increase in plate temperature. However, there is a reduction in overall thermal efficiency of the cooker which is an indication of higher convective and radiative losses and increasing ambient temperature. This is similar to the results reported by [13] for cooker cooking power.

| Figure 7. Figure of merit and overall thermal efficiency plotted over temperature difference |

| Figure 8. Plot of F2 versus overall cooker thermal efficiency |

5. Conclusions

- The paper presented the test procedure and thermal performance of low cost reflectors solar box cooker implemented in Ile-Ife, Nigeria. Periodic overcast of weather were noticed throughout the test period and it caused fluctuation in solar radiation. The maximum insolation of 520 W/m2 at 2.00 pm and Minimum of 246 W/m2 at 11.00 am were observed. The average solar radiation and ambient temperature observed during the period of test were 403 W/m2 and 40°C respectively. The water temperature values between 60 and 67°C were observed at insolation values between 398 and 520 W/m2. These occur between the hour of 1:20 pm and 4:00 pm with the highest water temperature of 67 oC at 3.00 pm. The performance of the cooker in terms of first figure of merit, second figure of merit and thermal efficiency show that the cooker compare favourably well with international standard. The cooker has a better heat retention capacity when compared with others found in the literature. The experimental results obtained for thermal performance of the cooker demonstrated its suitability for cooking even during fluctuating weather conditions.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML