-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Energy Engineering

p-ISSN: 2163-1891 e-ISSN: 2163-1905

2015; 5(3): 41-47

doi:10.5923/j.ijee.20150503.01

Comparative Study of Production and Performance of Bio-fuel Obtained from Different Non-edible Plant Oils

Nikul K. Patel1, Anand K. Patel2, Ragesh G. Kapadia3, Shailesh N. Shah4

1Mechanical Engineering Department, Charottar University of Science and Technology, Changa, India

2India Mechancial Engineering Department, LDRP Institute of Technology & Research, Gandhinagar, India

3Mechancial Engineering Department, Shri S’ad Vidya Mandal Institute of Technology, Bharuch, India

4Chemistry Department, Faculty of Science, The M S University of Baroda, Vadodara, India

Correspondence to: Shailesh N. Shah, Chemistry Department, Faculty of Science, The M S University of Baroda, Vadodara, India.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

The demand of fossil fuels like coal, crude oil and natural gas for transportation and power generation increases continuously. Hence, fuel crisis and environmental concern have led to look for alternative fuels. Biodiesel is an alternative renewable fuel that has properties comparable to diesel obtained from petroleum processing. The major objective of the present investigations was to select the best available feedstock’s for oil production from available non-edible plant oils. The bio-diesel of Jatropha, Mahua, Karanj, Jojoba and Neem were compared and tried for various parameters such as economy, fuel properties, engine performance and exhaust emissions and air pollution. Seed yield (Kg/ha) and oil content (%) are deciding parameter for economic aspect and various fuel properties i.e. Calorific value, kinematic viscosity and flash point have been compared for different feedstock’s. The experiment has been carried out with a B-20 blend of biodiesel in four stroke diesel engines. Engine performance compared on the basis of brake thermal efficiency, brake specific fuel consumption and brake specific energy expenditure. Exhaust emission of CO and NOx has been measured experimentally for all five feed stocks. On the basis of desire value of parameters; credits were put to each of the above five feed stocks and full credits were calculated for finding out best economical feed stocks which can be used for the yield of biodiesel.

Keywords: Non-edible plant oil, Biodiesel, Economics, Emission, Engine performance

Cite this paper: Nikul K. Patel, Anand K. Patel, Ragesh G. Kapadia, Shailesh N. Shah, Comparative Study of Production and Performance of Bio-fuel Obtained from Different Non-edible Plant Oils, International Journal of Energy Engineering, Vol. 5 No. 3, 2015, pp. 41-47. doi: 10.5923/j.ijee.20150503.01.

Article Outline

1. Introduction

- Due to the gradual decrement of world petroleum reserves and the impact of environment pollution there is a need for suitable alternative fuels for use in diesel engines. Research has shown that fuel obtained from the vegetable oil is a safe alternative as fuel. In resent year lots of systematic attempts have been made by so many researchers in the management of the use of veggie oil as engine fuel. Biodiesel is an alternative renewable diesel fuel that has properties comparable to diesel obtained from oil processing. Since biodiesel is renewable and it produces less harmful exhaust emissions when combusted compared to that of petroleum diesel, the exercise of this fuel is a shift towards “sustainable energy”. Biodiesel can be created from diverse authors such as vegetable oil both edible oils (soy, cottonseed, palm, peanut, rapeseed, canola, sunflower etc.) and non-edible oils (Jatropha, Karanj, Jojoba, Mahua, Neem etc.) Through a chemical reaction called transesterification with short chain alcohols. Still, production of biodiesel from edible oil crops is not suitable. Using crops for energy and food compete with each other in many ways, but food always wins over energy. A less expensive, non-food grade vegetable oil is a possible feedstock’s for biodiesel production [1]. Oil provides energy for 95% of transportation in India and the demand of transport fuel continues to climb. The requirement of Motor Spirit is expected to rise from a little over 7 MMT in 2001-02 to over 10 MMT in 2006-07 and 12.848 MMT in 2011-12 and that of diesel (HSD) from 39.815 MMT in 2001-02 to 52.324 MMT in 2006-07 and just over 66 MMT in 2011-12. The domestic supply of crude will satisfy only about 22% of the demand and the rest will have to be assembled from imported crude [2]. The diesel fuel consumption in India is almost five times higher than gasoline fuel. The requirement of high-speed diesel has been calculated to be 66.9 MT for the year 2011–2012. The price of the diesel fuel increases due to the increase in petroleum oil price. Thus, it is necessary to adopt appropriate policy decisions in the land to fill future demand of diesel fuel in view of improving fuel quality and stringent emission norms. Thus, biodiesel is being seen to be supplementary fuel to the diesel in the country [3]. In countries like India, the use of edible oil to produce biodiesel in India is also not practicable in view of big gaps in demand and supply of such oils. Under Indian condition only such plants can be considered for biodiesel, which bring out non-edible oil in appreciable quantity and can be produced in large scale on non-cropped marginal lands and waste lands [4]. Hence extensive research is proceeding on to distinguish the non-edible feedstock’s suitable for bio-diesel production. Several investigators have identified several non-edible feedstock’s which is suited for bio-diesel production and experimentally investigates various properties of bio-diesel made from these feedstock’s’s and compared these properties to the bio-diesel standards to warrant their use as bio-diesel [5]. The bio-fuel policy of India emphasizes to make biodiesel from non-food feedstock’s to be grown on lands not suited for agriculture underlining its distinctiveness from current international approaches which could contribute to conflicts with food security [6]. Non-edible vegetable oils which are known as the second generation feedstock can be considered as promising substitutions for traditional edible food crops for the production of biodiesel. The use of non-edible plant oils is very significant because of the tremendous demand for edible oil as food source [7]. Hence extensive research is proceeding on to distinguish the non-edible feedstock’s suitable for bio-diesel production [8]. Biodiesel is biodegradable and nontoxic alternative fuel for diesel engine which have become more attractive to replace diesel fuel. The review on characteristic of the potential biodiesel and biodiesel blends fuel properties are very close to diesel fuels and satisfied ASTM 6751 and EN 14214 standards [9]. Have found that seed of Jatropha contain 50-60% oil and they investigate the bio-diesel of Jatropha on an engine test and concluded that Jatropha plantation on the available wastelands will enable our nation to become independent in the fuel sector by promoting and adopting bio-fuel as an alternative to crude oil fuels [10]. Have optimized the esterification and transesterification of Mahua (Madhuca Indica) oil for production of biodiesel. They concluded that the biodiesel produced from Mahua oil is cost effective and can be a viable alternative fuel in near future [11]. Have experimentally investigated the properties of Neem oil and found that ester of this oil can be utilized as an environmentally friendly alternative fuel for diesel engine creating a greener environment in the future. In present study effort has been established to distinguish non-edible feedstock’s which is suited for bio-diesel production. Jatropha, Mahua, Karanj, Jojoba and Neem has been compared and credit rating analysis has been run out based on several facts such as seed yield, oil content, Fuel properties, Engine performance and Exhaust emissions. The credit rating analysis is based on a 5 point scale where 5 – Excellent, 4 – Best, 3 – Better, 2 – Good, and 1 – Worst. All parameters will be compared with regard to credits given and which will assist in distinguishing the non-edible oil based biodiesel which will be useful for automobile engines.

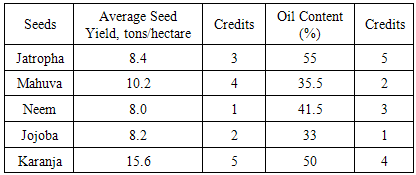

2. Seed Yield and Oil Content

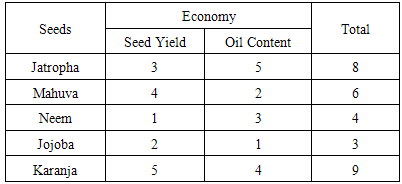

- Choice of feed stores is really significant as it bears upon the cost of biodiesel production. Thither is a huge variance in the cost of biodiesel production. The price changes from location to location, season to season depending on climatic conditions, nature of soil, geographic conditions, price variation in the market etc. Nevertheless, one of the parameter that affects the cost of biodiesel production is seed yield (Kg/ha) and oil content (%). Commonly called Jatropha, it belongs to Euphorbiaceae family and, though native of South America, it has long been spread by the Portuguese in their old settlements in Africa and Asia. It is a fast growing small tree capable of producing good amounts of seeds over tropical to semitropical regions under semi-arid to medium rainfall conditions. It is unpalatable to cattle on account of toxicity and is therefore a good hedge plant. It starts yielding early and reaches nearly full productivity in almost five years in well managed irrigated plantations [6]. It is seen as a major feedstock’s for bio-diesel production in India as it is non-edible, high oil yield and can grow in arid and waste ground. Cause found that seed of Jatropha contain 50-60% oil and they investigate the bio-diesel of Jatropha on an engine test and concluded that Jatropha plantation on the available wastelands will enable our nation to become independent in the fuel sector by promoting and adopting bio-fuel as an alternative to petroleum fuels [8]. The average seed yield in five years is 8.4 tons per hectare and the petroleum content of Jatropha seed is 55% as indicated in table 1. The Mahua tree belongs to the genus Madhuca. The tree, its seed and flowers have been very useful in Indian economic system for a long time. As per information obtained, the oil yield is 34-37% by small expeller. From the information obtained from the Centre for Jatropha promotion, the oil yield per hectare for Mahua plantation is estimated at 10.2 tons per hectare and oil content of the seeds is 35.5% as indicated in table 1. Neem (Azadirachta indica) belonging to Meliaceae family is one of the most desirable and valuable tree species found in India. It can grow on a spacious range of soils up to pH 10 which makes it one of the most versatile and important trees in Indian sub-continent. Due to its multifarious uses, it has been worked by Indian farmers since Vedic period and it has instantly become part of Indian civilization. As per data obtain, closer spacing of 5m × 5m accommodating 400 trees per hectare while the wider spacing of 7m × 7m accommodating about 200 trees per hectare. A mature tree produces 30-50 kg fruit per annum. Oil yield varies from 40-43%. The average seed yield is 8 tons per hectare and its oil capacity is 41.5% as indicated in table 1. Jojoba, [Simmondsia chinensis] is a new oil-producing industrial crop that has drawn much attention in recent years. Jojoba oil is antibacterial in nature. No other works are known to produce oil like jojobas. It is employed in the cosmetic, medical, pharmaceutical, food products, manufacturing, and automotive industries (as a lubricant). It is a renewable energy resource. It is remarkable to note that, in spite of the unevenness in size or where grown, each jojoba seed contains an average of 35% pure oil by volume [12]. The oil content available from jojoba oil is close to 32%, which is presented in table 1. A lot of the interest in jojoba worldwide is the consequence of the plant's ability to live in a harsh desert surroundings. Jojoba can be developed as an oil-producing cash crop. Jojoba is very drought-resistant and can be produced on marginal lands without replacing any existing crops, the average increase is 8.2 tons per hectare as shown in table 1. Jojoba is a multiyear crop by plantation of this the farmer is saved from repeated sowing. Granting to the notion of agriculture specialist it can be cultivated with low water, plant food and pesticide. Neither stray cattle, nor pet cattle eat its plant. Its good production gives very high income to the farmers as compare to the traditional farming. Pongamia pinnata is a legume tree with sees containing oils and fatty acids suitable for biodiesel production. It is a fast-growing evergreen tree which reaches 40 feet in height and spread, forming a broad, spreading canopy casting moderate shade. Withstanding temperatures slightly below 0°C to 50°C and annual rainfall of 5–25 cm, the tree grows wild on sandy and stony lands. All parts of the plant are toxic. The seed oil is an important asset of this tree having been employed as lamp oil, in soap making, and as a lubricant for thousands of years. The average seed yield over a period of 5 years is 15.6 tons per hectare and oil content of around 50% as indicated in table 1. Vivek Gupta and A. K. Gupta has found that the oil content of Karanj seed is 27-39%. They too examined the operation of a diesel engine fueled by bio-diesel produced from Karanj oil. The survey confirmed that Karanj oil can be applied as a crude fabric for getting bio-diesel which can be utilized as fuel in diesel engines [13]. It is observed from table 1 that seed yield is maximum for Karanj of about 15.6 tons per hectare so 5 credits is given to it. Karanj is followed by Mahuva, Jatropha, Jojoba and Neem with an average seed yield of 10.2, 8.4, 8.2 and 8.0 tons per hectare respectively. The credit allotted to Mahuva, Jatropha, Jojoba and Neem are 4, 3, 2, and 1 respectively. With deference to all content available in respective non-edible seeds Jatropha has a maximum of 55%, so allotted credit of 5. Jatropha is followed by Karanj, Neem, Mahuva and Jojoba with oil content of 50%, 41.5%, 35.5% and 33% respectively. The credit allotted to Karanj, Neem, Mahuva and Jojoba in case of oil content are 4, 3, 2 and 1 respectively.

|

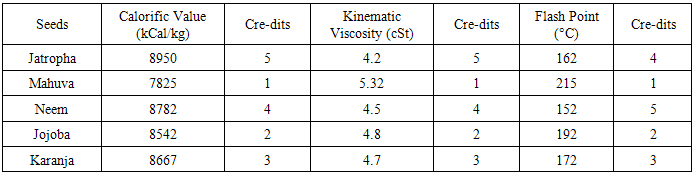

3. Fuel Properties

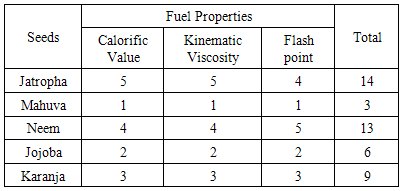

- It is really significant to see the behavior of fuel properties. Considerable efforts have been built to produce non-edible oil based biodiesel fuels that approximate properties and performances of Petro - diesel. Research has demonstrated that the properties of oil from which biodiesel has been prepared may vary significantly depending on their chemical composition and fatty acid composition, which gives obvious effects on engine operation and emissions. Thither are 11 important properties which are substantive with respect to use of it in engines flash point, water and sediment content, kinematic viscosity, sulphate ash content, sulphur content, cetane number, carbon balance, acid number, free and total glycerine, Phosphorous – calcium and magnesium content, and oxidative stability [14]. Jatropha biodiesel synthesized using conventional sodium methoxide and with heterogeneous catalyst, best yield was obtained using heterogeneous catalyst ZH3. All fuel properties are in agreement with ASTM D-975 (100%-Diesel), which demonstrates that it would be commercially viable to use in the field [15]. Suitability of any particular bio-diesel for engine application mainly depends on its fuel properties. In present study fuel properties i.e. kinematic viscosity, Calorific value, and Flash point of the selected feed stocks has been measured. Kinematic viscosity is measured by the U - tube method, Calorific value is measured using Bomb Calorimeter and flash point using the open cup method. The higher calorific value of fuel has been always desirable. Hence, the feed stock having highest Calorific value i.e. Jatropha has been given an excellent rating with credit 5, Neem is given a credit rating of 4, Karanj is given rating with credit 3, Jojoba is given rating with credit 2 and Mahuva is given rating with credit 1 which is shown in table 2. The higher is the Kinematic Viscosity of fuel, higher injection pressure is needed for proper atomization. Hence, lower value of Kinematic Viscosity is desirable. Hence the feed stock having lowest Kinematic viscosity i.e. Jatropha has been given an excellent rating with credit 5. Neem is a given credit rating of 4, Karanj is given rating with credit 3. Jojoba is given rating with credit 2 and Mahuva is given rating with credit 1 as depicted in table 2. The Flash point is the lowest temperature at which a fuel can vaporize to form an ignitable mixture in air. The lower Flash point is desirable for comfortable and quick combustion of fuel. Hence the feed stock having lowest Flash Point i.e. The Neem has been given an excellent rating with credit 5. Table 2 exhibits the flash point value for different feedstock’s. Jatropha, Karanj, Jojoba and Mahuva is given a credit rating of 4, 3, 2 and 1 respectively based on their value of flash point.

|

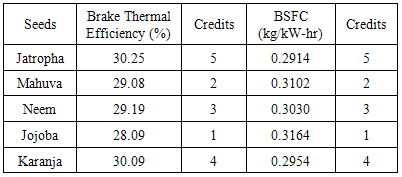

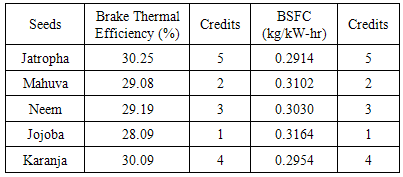

4. Engine Performance and Emissions

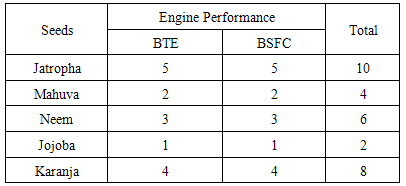

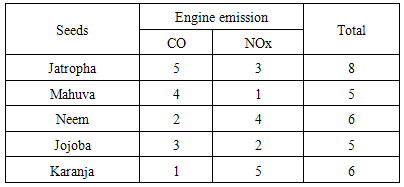

- Oil from non-edible seeds can be used as fuel in automobile engines without changing the engine technology. Blending of biodiesel in 10 – 20 % shows the similar engine performance as an engine operating on fuel with conventional petrol diesel [16]. Experimental analysis was conducted on 4-stroke, 4 cylinder CI engine using fuel as B20 (blend of 20% neem biodiesel and 80% Petro-diesel by volume) to analyse its performance. Brake Thermal efficiency was higher for biodiesel blend as compared to diesel and emissions of CO, NOx and SO2 is less with B20 fuel compared to petrol-diesel [17]. Engine performance studies using Karanj oil biodiesel were carried out using different blends such as K10, K15 and K20. Specific fuel consumption increases with the increase in the blend, but K15 has minimum brake specific fuel consumption due to similar properties of fuel as diesel [18]. Performance parameters like peak cylinder pressure is higher, peak heat release rate during premixed combustion phase is more down, ignition delay is lower for neat neem oil and neem oil methyl ester when compare with diesel at full load condition with a single cylinder diesel locomotive. Thither is a reduction in emission in NOx of neem oil and its methyl ester along with an increase in CO, HC and smoke emission whereas brake thermal efficiency is somewhat lower and combustion duration is higher [19]. Preheating of Mahuva oil up to 130°C resulting in a reduction in viscosity of oil, which not only raised the heat release rate but also improved the engine operation and emissions. NOx emission was marginally increased, but preheated Mahua oil can be applied as a diesel replacement for running automobile engines [20]. Addition of ester to ethanol-diesel blend showed that, the engine performance has been improved and there is considerable reduction in emissions also using the exhaust gas recirculation option reduction of NOx emission was observed [21].Four cylinder, four stroke, water cooled, the indirect injection CI engine is used for experimentation purpose. The engine spec is as follows: bore, 73 mm, stroke 88.9 mm, capacity 1489 cm3, compression ratio 23:1, lubricating oil SAE 30, maximum power 26.6 kW@4000 RPM, maximum torque 83.4 N-m@2250 RPM and clearance volume 16.913 cm3 per cylinder. The experiment has been extended out at constant 1500 RPM with variable load by changing excitation of electrical dynamometer. Engine performance has been evaluated for a B20 blend of Jatropha, Mahuva, Neem, Jojoba and Karanj. Several performances and emission parameters have been evaluated at different load and test fuel condition. Engine performance parameters such as Brake power, brake thermal efficiency, brake specific fuel consumption has been worked out from reading obtained. Exhaust gas analyser is utilized for measurement of different pollutants. It is capable to measure CO, CO2, HC, NOx, NO2, excess air and flue gas temperature. Brake thermal efficiency is the ratio of Brake power produced by the engine to the heat provided to the locomotive. The upper limit value of Brake thermal efficiency for each of the selected bio-diesel is shown in the table 3. Brake thermal efficiency should be higher for better engine operation. Hence the feed stock having higher Brake thermal efficiency i.e. Jatropha is given an excellent rating with credit 5 followed by Karanj, Neem, Mahuva and Jojoba with 4, 3, 2, and 1 respectively. Brake specific fuel consumption is defined as mass of fuel consumed by the engine per unit Brake power.

|

|

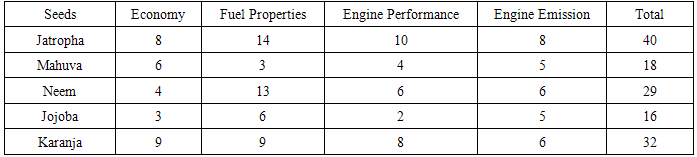

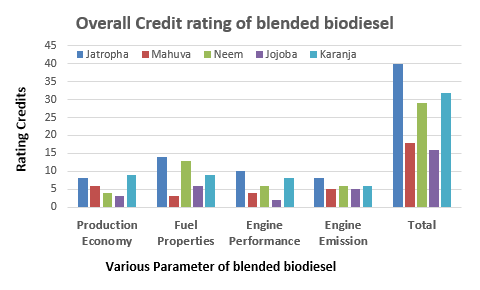

5. Overall Credit Rating

- Different aspects of production of biodiesel are very important to know for its feasibility. Various parameters such as economy, fuel properties, engine performance and engine emission covers all aspects of production to its application. As biodiesel produced will be used as fuel in internal combustion engine. As biodiesel is obtained from seeds that are in fruits and fruits grow on plants. What is the amount of seeds that can be yielded from a given hectare of land? As table 5 shows that best seed yield is Karanja but the best oil content available is from Jatropha. If we see the combined effect of seed yield and oil content best feedstock’s is Karanj followed by Jatropha, Mahuva, Neem and Jojoba as shown in table 5.

|

|

|

|

|

| Figure 1. Overall Credit rating of blended biodiesel |

6. Conclusions

- Jatropha is the best feedstock’s for all the aspects considered and hence it is most promising feedstock’s for biodiesel production. The next promising feedstock’s’s available are Karanj for biodiesel production followed by Neem, Mahuva and Jojoba respectively. Mahua and jojoba seems somewhat less attractive compared to other three feed stocks in overall aspects. Hence, it is suitable to produce large scale plantation of Jatropha and Karanj on the waste or marginal land. Moreover, it is likewise necessary to build a biodiesel production facility for volume production of biodiesel through the transesterification process from the oil of these feedstock’s’s. Once mass production of biodiesel starts, the monetary value of biodiesel will be fairly compatible to the Petro-diesel and hence, the common public would be promoted to utilize B20 blend in their vehicles. By these ways, we can generate multiple benefits such as decrease in crude imports and subsequent saving in valuable foreign currency, reduction in air pollution, rural employment and so on, this will empower our economy and help the government to achieve the target of 20% replacement of petrol diesel by suitable biodiesel.

ACKNOWLEDGEMENTS

- The authors acknowledge their families for giving support for carrying out research activity. Grateful thanks are due to The Dean, Head of Department - Mechanical Engineering Department and Chemistry Department, Faculty of Science, The M S University of Baroda for allowing the usage of their institutional facilities. The Gujarat Council on Science and Technology (GUJCOST), Department of Science & Technology, Government of Gujarat, India gave financial support under Minor Research Project Grant No. GUJCOST/MRP/2014-15/ 397 dated 30/6/2014.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML