-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Energy Engineering

p-ISSN: 2163-1891 e-ISSN: 2163-1905

2014; 4(2): 26-31

doi:10.5923/j.ijee.20140402.02

Anaerobic Co-digestion of Sewage Sludge with Cheese Whey under Thermophilic and Mesophilic Conditions

Camino Fernández1, Daniel Blanco2, Julio Fierro1, Elia Judith Martínez1, Xiomar Gómez1

1Institute of Natural Resources (IRENA), University of León, León, Avda. De Portugal 41, 24009, Spain

2Bioenergía y Desarrollo Tecnológico, (ByDT), León, Avda. de Portugal 41, 24009, Spain

Correspondence to: Xiomar Gómez, Institute of Natural Resources (IRENA), University of León, León, Avda. De Portugal 41, 24009, Spain.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

Anaerobic digestion of sewage sludge (SS) and co-digestion with cheese whey (CW) was evaluated in batch conditions under mesophilic and thermophilic regimens. Results indicated that the co-digestion can be successfully attained despite some inhibitory stages that may be initially present due to the accumulation of volatile fatty acids. Degradation of the mixture SS-CW followed a similar pattern without influence of the temperature. Tests in thermophilic conditions performed better, with the absence of inhibitory stages associated with fatty acids accumulation. Moreover, a significant increase in the rate of biogas production was obtained along with a great reduction of the time necessary for digestion. However, lower methane yields were obtained under thermophilic temperatures.

Keywords: Co-digestion, Sewage Sludge, Thermophilic, Cheese Whey

Cite this paper: Camino Fernández, Daniel Blanco, Julio Fierro, Elia Judith Martínez, Xiomar Gómez, Anaerobic Co-digestion of Sewage Sludge with Cheese Whey under Thermophilic and Mesophilic Conditions, International Journal of Energy Engineering, Vol. 4 No. 2, 2014, pp. 26-31. doi: 10.5923/j.ijee.20140402.02.

Article Outline

1. Introduction

- The biological treatment of municipal wastewater has significantly improved the quality of environment. However, the disposal of sludge is still a problem of growing importance, representing up to 50% of the current operating costs of a wastewater treatment plant (WWTP) [1].Anaerobic digestion is a suitable technology for attaining the reduction of the putrefaction potential of sludge. This technology produces biosolids as by-product, which are susceptible of valorisation by land application as long as legal restrictions are fulfilled. Biogas is usually valorised by means of energy and/or heat generation. Anaerobic digestion is the most widely biological method used for the stabilisation of sewage sludge (SS) [2] and it is expected to remain one of the most widely applied technologies in the near future due to its capacity for reducing greenhouse gases emissions [3]. In addition, biosolids have strong fertilising value and may cover part or all of the nutrient requirements of crops [4].The digestion of SS has been usually characterised by low volumetric productions of biogas due to the inherent difficulties in digesting secondary sludge which present a lower methane yield than that of primary sludge [5]. Different pre-treatment options have been studied in order to improve the digestibility of waste activated sludge (WAS) [6]. Mechanical, chemical and thermal pre-treatments, the application of ultrasounds [7], and more recently the use of microwave have been proposed as pre-treatment options to increase the hydrolysis of complex material and solubilisation of organic matter [8,9]. Another effective way to increase biogas yields is the increase in the organic loading rate (OLR) by the addition of co-substrates with high methane potential. The addition of an organic substrate with high biodegradability increases biogas production and thereby reduces the consumption of external energy needed for plant operation. The valorisation of biogas by the use of a combined heat and power unit provides a useful way to reduce the operating costs due to the production of electricity and the use of heat to maintain the temperature of the digester. Several studies have been focused on the co-digestion of SS with different types of wastes [11-12]. Cheese whey (CW) has been proposed as a suitable substrate for valorisation under anaerobic digestion [13] and dark fermentation processes for hydrogen (H2) recovery [14]. However, these alternatives have proven difficult of operating due to the need of nutrient or alkalinity addition in the first case [15] and problems, in the second case, associated to the microbial prevalence of non H2 producers when operating under continuous conditions [16].CW is a liquid effluent obtained from cheese factories during the process of precipitation and removal of milk casein. This waste stream presents a high content in easily biodegradable organic matter. This makes it a suitable co-substrate when added to digestion systems treating manures [17, 18]. Recently, research interest has been focus in the co-digestion of CW and sewage sludge [19, 20]. However, the effect of the temperature over the digestion process in an important parameter when considering the addition of readily biodegradable substrates, due to the possible inhibitory effect caused by volatile fatty acid build-up. The higher the temperature, the faster the degradation and this fact may translate into inhibitory problems if not proper feeding control is established.The temperature of the digestion system is commonly set at 36 – 40ºC. However, WWTP managers are increasing digestion temperature as a way to increase digester productivity and therefore revenues. The thermophilic digestion of SS has been studied by several authors reporting an increase in biogas production [11, 21]. However, this increase in efficiency of the digestion was not always related to a higher volatile solid (VS) destruction [21]. In addition, Bayr and Rintala [11] in their study of co-digestion of SS with pulp and paper mill primary sludge reported a small increase in biogas production when operating at thermophilic conditions. Similar results were obtained by Chi and co-workers [22] when digesting thickened WAS, and Nges and Liu [23] when digesting dewatered-sewage sludge.Based on previous comments, the objective of this research was to assess the biogas potential of a suitable co-substrate such as cheese whey (CW), in order to be co-digested with SS under mesophilic and thermophilic conditions. The novelty of the present work is to perform the evaluation of this mixture under different temperature conditions and determine the effect of the increase in the temperature of digestion over methane yield and degradation rate when CW is used as co-substrate in a sludge digestion system.

2. Materials and Methods

2.1. Substrate and Inoculum

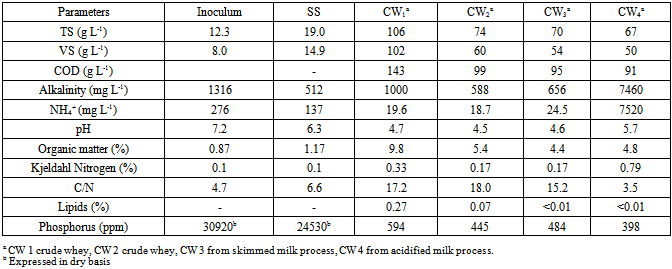

- SS was obtained from the WWTP of Cáceres (Spain). The plant has an anaerobic digester for the treatment of SS. The digester is fed with a mixture of primary and secondary sludge and operates under mesophilic regimen. Its anaerobic digested sludge was used as inoculum.CW was studied as suitable co-substrate for the digestion process based on the availability of this residue near the location of the WWTP. The area is characterised by the presence of several cheese factories. For this reason, different types of CW were collected from local cheese factories in the surrounding area. The chemical characteristics of the material used in this study are presented in Table 1.

|

2.2. Batch Digestion Experiments

- Batch experiments were performed to determine the biochemical methane potential of individual substrates and a mixture of CW and SS. For this purpose, batch reactors (Erlenmeyer flasks of 250 mL volume) were filled with inoculum and the corresponding amount of individual substrate or a mixture of two substrates, according to the desired ratio of VS inoculum:substrate (I:S). Tap water was added to complete 250 mL volume when needed. A batch experiment was also carried out in a reactor containing only inoculum, to determine its endogenous biogas production. All batches were performed in duplicate. Experiments were carried out until the cessation of gas production was observed. The temperature of digestion was set at 34°C for mesophilic and 55ºC for thermophilic tests. The temperature was controlled by a water bath. Agitation was provided by means of magnetic stirrers.The Erlenmeyer flasks were inoculated using a ratio of VS (I:S) in the range of 2.5:1 - 1:1. The ratio was selected based on the substrate in order to avoid the need of adding alkali solutions for pH control. Digestion systems were denoted in accordance with the substrate being digested, this is: SS, CW with this being preceded by the label of the temperature regimen. Co-digestion of sludge was evaluated for CW1 at 5% (v/v). This co-substrate was selected based on availability and proximity to the WWTP.Digestion tests under thermophilic conditions when treating SS individually were performed using mesophilic inoculum obtained from the digester of the WWTP. Based on poor results obtained under thermophilic conditions, the thermophilic inoculum was adapted for a period of 3 months to be used as inoculum in the following set of thermophilic batch tests. The adaptation consisted in semi-continuous feeding of the system with SS during the 3 months period and kept at 55ºC. The OLR applied was 1 g VS L-1d-1 and systems were fed twice a week. Before using this inoculum in batch tests, the feeding was suspended for a 2 weeks period.

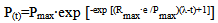

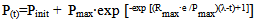

2.3. Kinetic Analysis

- Methane produced was fitted to the modified Gompertz equation [24].

| (1) |

| (2) |

2.4. Analytical Techniques

- Total solids (TS), VS, pH, ammonia and alkalinity were determined in accordance with APHA Standard Methods [25]. Chemical oxygen demand (COD) was determined using a Hanna Instruments Series C99 multi-parameter photometer. The homogenised sample was digested in the presence of dichromate at 150ºC for 2 h in a Hanna C9800 reactor. The production of biogas from reactors was measured using a reversible liquid displacement apparatus. Measurements were corrected to standard temperature and pressure (STP), 0ºC and 760 mmHg, respectively.Nitrogen concentration was determined by the Kjeldahl method. Organic matter was analysed in accordance with the Walkley-Black method [26]. Lipid content was determined by Soxhlet extraction using Velp Scientifica SER 148/3 in accordance with the APHA Standard Methods [25]. Total phosphorus in the extract was quantified by inductively coupled plasma-atomic emission spectroscopy (ICP-AES) using Perkin Elmer Optima 2000 DV.Biogas composition was analysed using a gas chromatograph (Varian CP 3800 GC) equipped with a thermal conductivity detector. Columns used were HayeSep Q 80/100 (4 m long) followed by a molecular sieve column (1 m). The carrier gas was helium and the columns were operated at a pressure of 331 kPa and a temperature of 50ºC. Volatile fatty acids (VFAs) were determined on the same gas chromatograph, using a flame ionization detector (FID) equipped with a Nukol capillary column (30m×0.25mm ×0.25m) from Supelco. Injector and detector temperatures were 220 and 250ºC, respectively. The oven temperature was set at 150ºC for 3 min and thereafter increased to 180ºC. Samples were previously centrifuged (10 min, 3500×g) and the supernatant filtrated through 0.45 μm cellulose filters.

3. Results and Discussion

3.1. Batch Experiments of SS

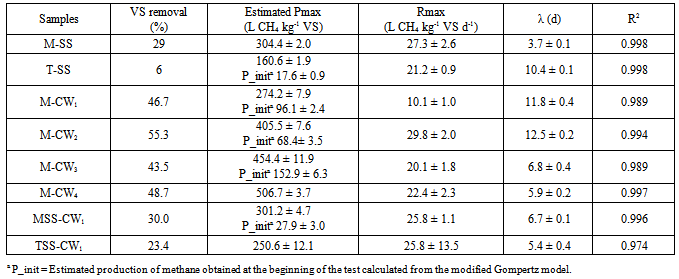

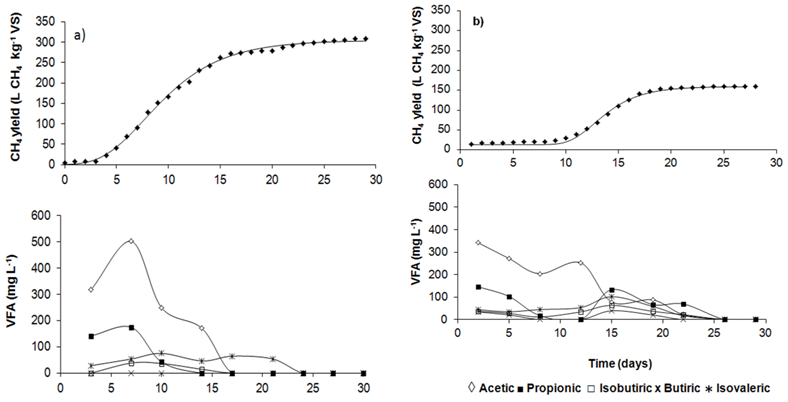

- Figure 1 presents the results obtained from batch digestion experiments of SS. The digestion of SS was initially performed under mesophilic conditions at an I:S ratio of 1. However, the rapid acidification of SS prevented the further digestion of the substrate (data not reported). A second experiment was then performed, in this case with an I:S ratio of 2. Results are shown in Figure 1a and indicate an initial accumulation of VFAs that were degraded subsequently. On the contrary, the thermophilic digestion process (Figure 1b) was successfully carried out using an I:S ratio of 1. After the lag phase period was overcome, the thermophilic system seemed to show a greater capacity to degrade the substrate at the I:S ratio initially set. The conversion of the organic material was achieved in a short time although the final value obtained for the specific methane production was much lower than that at mesophilic conditions. The thermophilic experiment was performed using mesophilic inoculum; thereby an extended lag phase was to be expected in this experiment. The poor result may probably be explained by the prolonged inhibitory state experienced by this reactor and by the fact that the experiment was performed using a non-adapted inoculum to thermophilic conditions. Furthermore, the VFAs content in the thermophilic system was lower even though the organic load applied was higher, indicating that the system was not fully degrading the substrate. With regard to the destruction of VS, the mesophilic system achieved a value of 29%, while the thermophilic reactor reported a value of only 6% which was in accordance to the poor performance of this fermentation system.The extended lag phase that was observed in the thermophilic test took place after having produced biogas on the first day of the experiment. This first gas sample was characterised by a high content of CO2. From that day onwards the volume of gas produced was small until the system was able to overcome this lag phase. Unlike the mesophilic system, whose gas production could be adjusted to the modified Gompertz model, the thermophilic system presented a sigmoid type gas production curve. These experimental data were adjusted to the modified Gompertz model by considering the initial volume of methane produced as an additional parameter according to equation 2. Parameters obtained from the model are presented in Table 2. The values of Rmax were similar for both digestion tests, in this sense the non-adapted thermophilic inoculum did not present a better performance than its mesophilic counterpart.

| Figure 1. CH4 yield and VFA concentration during batch digestion tests of SS under - (a) mesophilic - (b) thermophilic conditions |

|

3.2. Batch Experiments of CW

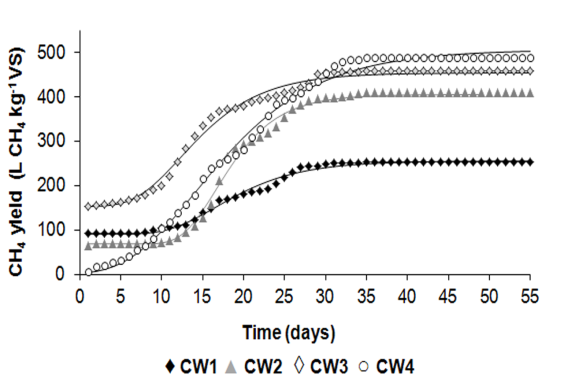

- Results obtained from batch digestion tests under mesophilic regimen for the different CWs tested are presented in Figure 2 and table 2. The digestion tests were performed with a ratio I:S of 2.5:1 in order to avoid inhibitory conditions due to pH drops. The shape of the cumulative curves obtained for the different CWs tested followed a similar pattern, with an initial production of gas on the first day of the experiment and then followed by an extended lag phase which was finally overcome by microorganisms. The exception being CW4, obtained from an enzymatic acidification process of milk. The higher alkalinity and ammonium content of this substrate may have aided in buffering the liquid phase, thus resulting in a biogas curve presenting a continuous production with almost a linear shape.

| Figure 2. CH4 yield of the different substrates studied during batch digestion tests |

3.3. Batch Experiments of Co-digestion

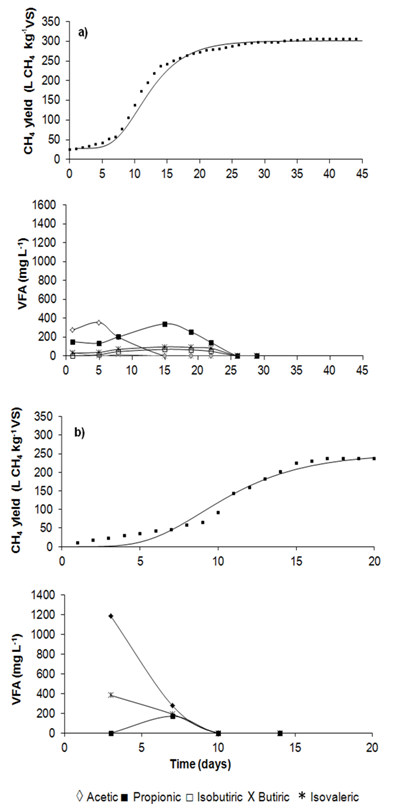

- Considering the successful results reported by different authors, additional batch digestion tests were performed for evaluating the co-digestion of SS with CW1. Results from mesophilic co-digestion tests are presented in Figure 3a. CH4 yield remained about the same of that obtained from the mesophilic digestion of sludge. This indicates that the benefits of co-digestion when adding this co-substrate would be associated to the increase attained in OLR and thus in the effective use of the volume of reactor, rather than to an increase in the specific methane production. During the initial stage of digestion, an accumulation of VFAs was observed which was associated to the lag phase observed in cumulative gas curves.Figure 3b presents results obtained from co-digestion tests of this substrate under thermophilic conditions. In this case, the results from co-digestion with CW1 demonstrated a high acidification at the initial stage which was responsible for the low rate of gas production obtained during the first eight days of the experiment. Biogas production increased when a significant reduction in VFAs was attained. Methane yield obtained was 248 ml CH4 g-1 VS. This value was much lower than the one obtained under mesophilic conditions. This behaviour may be explained by the higher values of VFAs measured under thermophilic regimen which may have partially inhibited methanogenic activity, thus resulting in a poor performance of the digestion system. However, values of Rmax were similar under both regimens of temperature.

| Figure 3. CH4 yield and VFA concentration during batch co-digestion tests of SS and CW under - (a) mesophilic - (b) thermophilic conditions |

4. Conclusions

- Thermophilic and mesophilic digestion of SS was attained under batch digestion tests. The process was characterised by similar degradation rate compare to its mesophilic counterpart. On the other hand, methane yields obtained were higher for mesophilic systems. Results related to co-digestion tests, indicated that under thermophilic conditions methane yield was also lower. Maximum VFAs concentration measured in this system may have favoured a partial inhibition of methanogenic bacteria. However, Rmax values were similar under both temperature conditions.

ACKNOWLEDGEMENTS

- This research was possible thanks to the financial support of the Spanish Ministry of Science and Innovation through FEDER funds IPT-2011-1519-310000.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML