-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Energy Engineering

p-ISSN: 2163-1891 e-ISSN: 2163-1905

2013; 3(2): 37-44

doi:10.5923/j.ijee.20130302.01

Other Sources for Biomass Energy

Heider Naszer1, Ákos Rédey2, Irina Golubeva2

1Department of Botany and Plant production, University of Kaposvár, Kaposvár, H-7401, Hungary

2Institute of Environmental Engineering, Faculty of Engineering, University of Pannonia, Veszprém, H-8201, Hungary

Correspondence to: Heider Naszer, Department of Botany and Plant production, University of Kaposvár, Kaposvár, H-7401, Hungary.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Nowadays, energetic utilization of biomass, biotechnology attracts a big attention not only from the environmental point of view but also have a social, political and economical impact. According to the Directive 2003/30/EC of the European Parliament and the European Council the emission of greenhouse gases can be reduced by 49% using bioethanol produced by a manufacturing process based on corn, instead of crude oil based fuels. Moreover in Hungary from 1st of July 2007 only gasoline with at least 4.4% bioethanol content is commercialized. In this article, some concrete examples of successful developments and/or implementation of biomass projects in Hungary are given such as the production of friendly raw synthetic materials at “Nitrokémia” and manufacture of bioethanol by “Hungrana” companies, bio-ethyl-tert-butyl-ether production and research on new generation of biofuels by MOL Pls. Danube Refinery. The main advantages and disadvantages as well motivations for further research and development of Hungarian bio-industrial and bio-consumer sectors are discussed.

Keywords: Agrorefinery, Biorefinary, Biofuels, Environmental Friendly Materials, Hungarian Bio-Industries

Cite this paper: Heider Naszer, Ákos Rédey, Irina Golubeva, Other Sources for Biomass Energy, International Journal of Energy Engineering, Vol. 3 No. 2, 2013, pp. 37-44. doi: 10.5923/j.ijee.20130302.01.

Article Outline

1. Introduction

- Recently, the utilization of the renewable energy sources can hardly reach a ratio of 3.6%. Simultaneously, renewable energy sources get more and more important role in the national energy-policy. By the year of 2020, 4% of electric power and 10-18% of the total energy is planned to come from renewable resources. This requires the energetic utilization of biomass in the first place. Previously, the use of mainly primer-biomasses (wood and agricultural waste from agricultural areas) was typical. During the first phase, in 1980s, there were large improvements in the Hungarian wood processing and agricultural plants. A total capacity of 100 MW heat power had been established, based on burning solid biofuels (wood waste, agricultural residuals). In the second period of program development, improvements began to be made in public heat supply system. Woodchip-based small and medium scale heat plants were built, with a total capacity of 40 MW[1].In the past 5 years, there was no significant development in heat production. Furthermore - because of the special economical conditions of public heat supply - the profitableness of wood-chip based heat power has been decreasing. As a result of the changes occurred in the Hungarian wood industry and agricultural plants, some biomass-based heat power plants were closed. At the same time, a most meaningful development has begun in electric power production on wood base. Between 2003 and 2005, three of the former coal-based power plants had been changed over to wood-chips. Their total capacity is 100 MW. The waste heat generated in the process of power production is used in public heat supply. The fuel-demand of the tree power plants is about 800 000 t/year energy-wood. By the building of these plants, Hungary made a large step ahead in the green development of the national energy-sector. In the next period, large improvements are expected. With regard to the EU-regulation on renewable sources, the right valuation of biomass-based energy production and its correct recognition (as a way of contributing to proper land use, rural development, new places of work, etc.) may be realised in the near future in Hungary. In the developments advised by the scientists, the utilization of secondary and tertiary biomasses is also included[2]. The results of the analyses show that Hungary has a large potential of biomass, which can be even enlarged by growing energy plants (wood and other agricultural products). Besides, there is a major potential of secondary and tertiary biomass sources. The role of the technologies by which waste problems can be also solved (e.g. biogas production from waste biomass), is also expected to grow. The recently available biomass would be enough to reach the ratio of 12% of it in the domestic energy supply. In the long term, even the ratio of 17-20% seems to be realistic[3].

2. Agrorefinery

- Hungarian agriculture can increase its output in industrial feedstock in two ways, by: A The promotion of existing agro-feedstock, mostly by improving the quality and decreasing the costs. However, this, in general, will not lead to any breakthrough, but may only result in a slow growth of the markets. B The development of completely novel kinds of feedstocks, including the required infrastructure. Usually a crop will not be applicable for industrial use. The industry is only interested in a certain part, or in a chemical or physical component of the crop, which therefore has to be processed in the agrorefinery. The different fractions produced by the agrorefinery are to be sold to various industries, or partially recycled for agriculture, as cattle feed or as organic fertilizer. The feedstock prepared for industrial application may be chemicals (bulk chemicals like oils, carbohydrates, rubber and gums and fine chemicals like essential oils and intermediates for chemical specialties, pharmaceuticals, pesticides and special polymers) or physicals (like fibers for textile, papermaking pulp, as a major reinforcement element in wood extenders, like fiberboard, building materials etc., or as a filter in rubber, plastics, adhesives and printing ink). Biopolymers for industrial programs have been developed by the University of Pannonia[4-7]. Depending on its function, the agrorefinery may apply simple mechanical and physical processes and may operate on a large scale. Occasionally, the first phase of the processing may begin with mobile total harvesting units, pretreating the crop in the field, separating fractions of interest like crude juices, fibrous fractions etc., which can be transported efficiently to regional plants for further processing. The agrorefinery has to fill the gap between agriculture and the agroindustrial production chains[8].The new Hungarian bio-based economy is being established under the following criteria: use of renewable bio-resources (mostly cereals), eco-efficient (bio)-processes and eco-industrial clusters. The latter ones, as the Integrated Regional Biorefinery, will provide the basis for state, provincial and municipal governments which, together with the industrial and research communities, will stimulate innovation at a local level using local biomass feedstocks and capabilities. These clusters link local research organizations headed by the University of Pannonia in the Transdanubian Region of Hungary, they will provide the infrastructure for the development of bio-products consortia focusing on eco-efficient processing of biomass into an array of value-added bio-products, as a refinery does with petroleum. Special interest should be put in the Transdanubian region regarding the use of glycerol and lactic acid as platform chemicals from which many types of products could be obtained (glycerol esters, ethers and glycerol-carbonates, etc.). Additional companies would co-locate to take advantage of cost savings and synergies with companies and research organizations already in the cluster. As a result, it would be easier for companies in the cluster to attract investment because of improved access to services, technology and opportunities for strategic alliances[8],[9].

3. Implementation of Biotechnology at “Nitrokemia” Chemical Plant

- “Nitrokemia” industrial complex situated near to Lake Balaton was one of the most important Hungarian chemical plants in the last century. Nowadays the main strategy of the Nitrokemia, Closed Share Company, by Hungary, is the implementation of environmentally safe industrialtechnologies such as biorefinery. The biorefinery project aims at the manufacture of lactic acid, environmentally friendly raw synthetic material, obtained from bio-processing of national agricultural crops, for lactic ester solvents production with the utilization of all technology by-products.

3.1. Advantages of the Biotechnology

- -bio-products are environmental friendly materials;-wrapping material made from poly-lactic acid can be recycled; -poly-lactic based materials are suitable for full substitution of existing wrapping materials made from PET, polyethylene, polystyrene; -residues of the non-recycled wrapping material decompose into CO2 and H2O under ambient condition; the degradation time is about 3-4 months under composting conditions; -the energy consumption for production of lactic acid is at least by 30 % lower than that one for production of concurrent synthetic materials; -poly-lactic based solvents can replace existing toxic hydrocarbon solvents with non-toxic ones;-the products can be utilized for biogas production and as a fertilizer for agricultural utilization.

3.2. Short Description of Applied Biotechnology

- The starch suspension for usage in saccharification is produced by wet separation of the gluten in flour processing unit connected to the mill. The bran obtained from milling of corn is utilized as an energy source. The glucose is produced with a help of lactic acid bacterium after the saccharification and the dissolution process of the starch suspension in the presence of enzymes. The lactic acid fermentation of glucose is achieved by ammonium hydroxide neutralization. The ammonium lactate solution of high purity is obtained by applying several stages separation method including micro-, ultra-, nano-filtration. The collected bacteria after filtration, dissolved proteins, oligosaccharides and other non recyclable by-products are used for biogas production. The three-stage evaporator is applied for concentration of filtrated ammonium-lactate solution. It should be mentioned that the concentrated ammonium-lactate itself is already a market product. The addition of butanol to the concentrated ammonium-lactate produces the butyl-lactate. The obtained solution is purified by the distillation process or could be converted to ethyl-lactate by esterification[9],[10]. High purity lactic acid solution is generated by hydrolysis of butyl-lactate. It is worth to mention that the polymer manufacturing is planned to produce up to 20,000 t/year biodegradable poly-lactic acid and the polymerization technology as well as whole polymer manufacture is ready for implementation. Moreover, the water treatment facilities, the cooling system, bran remained from the milling process and all liquid wastes for utilization in biogas production as well as the power facility for generating biogas are additional units of the biorefinery plant. The dehydrated sludge or bio manure is another product of the biogas plant which can be used in the agriculture. The chosen technology combines the advantages of existing processes. The technology developed allows establishing cost-effective production and can be used easily for further improvement of plant structure.

4. Production and Utilization of Bioethanol in Hungary

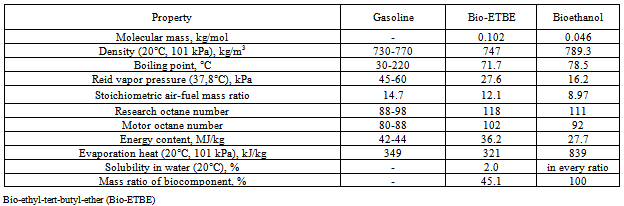

- In Hungary bioethanol is produced by two enterprises, the HUNGRANA Co. Ltd. (Szabadegyháza) and the Győr Distillery Co. Ltd. At the second one, 27-30 thousand tons of food quality alcohol is produced a year. The Hungrana Co. Ltd., which is owned by the British East starch and the Austrian Agrana-team in 50-50% ownership, produces principally starch, isosugar and alcohols from corn. The corn processing capacity of the plant, which was enlarged, updated and delivered in the summer of 2008, is more than 1 million t/year. From a part of this amount of corn, 135 thousand tons of bioethanol are produced. The rest of the products are mainly the starch (to food and packaging industry and to the production of corrugated paper) and the isosugar (that is the natural sweetening agent of soft drinks, milk and fruit products). From the corn cooking oil, from the high fiber and protein containing part of the corn forage can be produced. The Hungrana Co. Ltd. has the biggest isosugar quota of the European Union (27%, 220 thousand t/year). One of the most important environmental programs of the European Union is the reduction of the rate of consumption of fossil fuels. One of the possible solutions is the utilization of bioethanol in transportation, which is dehydrated alcohol, produced from renewable organic material. The biggest environmental advantage of biofuels is that burning them does not result in extra carbon dioxide because during the reproduction of the plant it is consumed. Considering vehicles with average consumption and the complete process of alcohol production, by the utilization of bioethanol, the global carbon-dioxide emission can be reduced by 50% compared to the use of fossil fuels. According to the operative European and Hungarian standards, bioethanol can be blended into the gasoline. One alternative is the blending of low quantity alcohol, the other one is (MSZ CWA 15293) the E85 fuel, which approximately contains 85 % of bioethanol and 15 percent of gasoline.In Hungary from the 1st of July 2007 only gasoline with at least 4.4% bioethanol content is commercialized (In case of lower bioethanol content extra excise tax has to be paid). The bioethanol can be blended stand-alone or as a component part of the molecule (e.g. bio-ethyl-tert-butyl-ether). From the middle of 2005 the MOL Plc. Danube Refinery (Százhalombatta) produces 55 thousand tons of the latter. According to the directive 2003/30/EC of the European Parliament and of the European Council the emission of greenhouse gases (GHG) can be reduced by 49% by using bioethanol produced by manufacturing process based on corn, instead of crude oil based fuels. The 49% is a basic value accepted by the EU, but by means of the favorable Hungarian agricultural facility and the front-rank manufacturing process of the Hungrana Co. Plc., the company in Szabadegyháza could realize more favorable GHG-savings, than the average value of 56% of the similar European plants. By the utilization of 135 thousand tons of bioethanol produced, and the replacement of gasoline with the same energy content, the carbon dioxide emission of Hungary would be lower by some 150 thousand tons per annum.

|

5. Production and Utilization of Fuels from Vegetable Oil Derivatives

- In Hungary, there is near 200 thousand tons of fatty acid methyl ester (FAME, biodiesel) production capacity per annum. There are two small plants (<10,000 t/year), one middle plant in Bábolna (>15,000 t/year), and a 150,000 t/year capacity plant operates in Komárom. Their feedstock is sunflower oil, rapeseed oil, used frying oils and fats, and triglycerides from some other sources. In every plant the alcoholysis (transesterification) is carried out on alkaline catalyst. Approximately 80% of the production is blended into diesel gas oil at the MOL Plc. The biodiesel plant in Komárom was established by Rossi Biofuels Plc. The MOL Plc. has 25% share of the plant, the other 75% is owned by the Austrian ROSSI Beteiligungs GmbH. The cost of the investment is 40 million Euros. Estimated by MOL, vehicles using (approximately 5 v/v%) biodiesels (produced from renewable energy sources) containing fuels emit to the atmosphere 200 thousand tons less CO2 than vehicles using conventional diesel fuel. In Hungary, from the 1st of January 2008 diesel fuel has to contain at least 4.4 v/v% biodiesel, otherwise extra excise tax has to be paid.

6. Research and Development of New Generation Biofuels

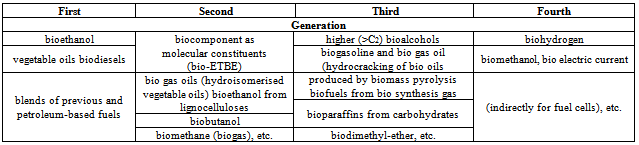

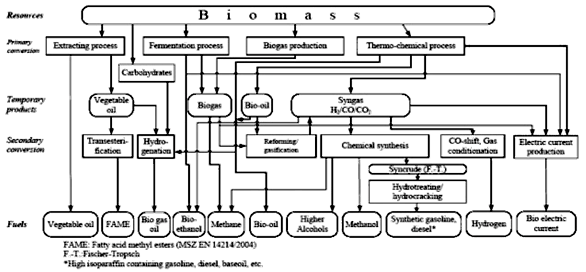

- To eliminate the numerous disadvantages (high installation cost, unfavorable properties in use, not unequivocally positive energy balance related to whole life cycle, insecurity of feedstock, etc.) of conventional biofuels (bioethanol produced from “sugar plants” and cereals, fatty acid methyl esters which are transesterified vegetable oils, called biodiesel), the recognition, the research and development and the adaptation of a new generation of biofuels is needed[10-12].Table 2 summarized an arbitrary classification of biofuels according to the chronology of recognition, production or rather probable introduction of these. The four generations delineated, the system of short, middle and long term economical producible and usable biofuels are represented in Figure 1, it shows, that all known fuels can be produced from biomass[11].In Hungary bioethanol production based on conventional feedstock, and also on lignocelluloses could play an important role in the future, because there are 6-8 million t/year cereal crops. Regarding the oilseeds the case is different. After satisfying the domestic frying oil demand, there are approximately (300-400) 103 t/year of vegetable oil which can be used for other goal.There are also (40-60) 103 t/year of used frying oil and fat, in addition significant quantity of triglyceride containing feedstock from other sources (e.g. slaughterhouse’s adiposes). The high feedstock price of vegetable oils, the expensive processing and conversion of other cheap feedstock into FAME, the performance properties, and work out new processes to produce them. Research and development activities were based on system approach recognition. Accordingly the most favorable fuels of Diesel engines are n-paraffins having high cetane number (Figure 2). At the same time flow properties of n-paraffins having high carbon number are bad. (The C17 and higher carbon number hydrocarbons are solids at 20°C and ambient pressure. The iso-derivatives of these n-paraffins have lower freezing-point by 15-30°C, although their cetane numbers are lower by 10-20 units. So that at the University of Pannonia, at the Department of Hydrocarbon and Coal Processing, the main aim of our research and development activity was to produce mixtures of n- and i-paraffins from vegetable oil and/or triglycerides, which have a high cetane number (>75-90) and good cold flow properties (CFP value: from -10 to -20°C). The new product was named bio gas oil.

|

| Figure 1. Production possibilities of motor fuels from biomass |

| Figure 2. Changing of the cetane number of different compound types in function of carbon number |

| Figure 3. The reactions taking place under the catalytic hydrogenation of triglycerides |

7. Synthetic Bio Gas Oils

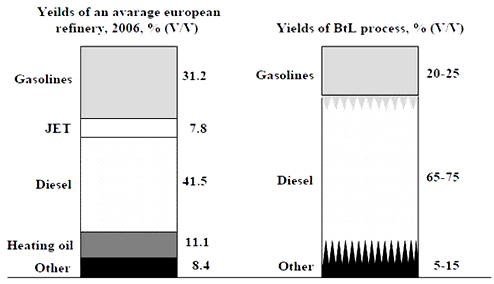

- Beside bio gas oils, synthetic bio gas oils have to be mentioned as well. These could be produced from bio synthetic gas of biomass origin. The bio synthetic gas is extracted from bio origin feedstock (including waste) by some different gasification technologies. From this cleaned mixture of gas, the product mixture containing also bio gas oil is produced by Fischer-Tropsch synthesis. Figure 4 contains the summarized block scheme[12],[13].Figure 5 demonstrates the product yields of a plant which process heavy residue (>360°C) by also isomerisation hydrocracking compared to that of an average European oil refinery. Based on the foregoing data it could be stated, that bio gas oil could be produced in better quality and higher yield from synthetic gas than from crude oil. This is very important because of the growing demand of middle distillate and of the strict quality expectations (free of sulphur and of aromatic compounds, high cetane number, clean burn, etc.). In Diesel engines, because of numerous performance disadvantage and high installation cost of the first generation biofuels (vegetable oils, biodiesels) it is needed to produce and apply more valuable new generation products with better quality. In short and middle term the spread of bio gas oils (mixture of n-and i-paraffins produced from triglycerides by catalytic hydrogenation) and of synthetic bio gas oils (mixture of n- and i-paraffins produced from bio synthetic gas) is expected. Performance properties of these are significantly more favourable (cetane number: 70-85, cold flow properties CFP value without additives: -10°C (-) -35°C, free of sulphur, nitrogen and olefin, higher energy content, etc.) compared to those properties of first generation vegetable oils and their derivatives. In a refinery the production cost of the bio gas oil is not higher than the production cost of biodiesel, considering its value and net cost it is uniquely competitive with diesel fuel. Nowadays the production cost of synthetic bio gas oil exceeds the production cost of others, but around 2015-2020 it would be competitive in a further stage of development. In case of biofuels, there are different possibilities according to geological regions and nations. Everybody has to make decision considering his own national interest to import the feedstock of fuels or insure oneself at least part of proper feedstock. In Hungary 16 million tons of grains have been grown in an average year, approximately half of it is used in food industry. In case of the rest 8 millions t/year, we have to take the decision to what ratio is it economical to export or to produce biofuels. In case of growing of oilseeds, the main problem is that a remarkable quantity of non-food rapeseed oil and used frying oil is exported. After satisfying the total demand of Hungarian food industry, there is approximately 400-500 thousand t/year of oilseed available.

| Figure 4. Block scheme of the Carbo-V® process and of the hydrocarbon synthesis |

| Figure 5. Comparing the product yields from crude oil and of BtL technology |

8. Conclusions

- Evaluating home results and international developing trends of agriculture originated renewing energy-carrier production, agro-technical possibilities and technical-economical conditions, the next comprehensive conclusions have to be made: Looking at natural endowments, potential stocks of Hungary and evaluation of their practical use, biomass can be considered as the most important energy-resource in Hungary; Renewing potential energy-resource produced by anaerobic fermentation of animal water manure and other wastes is significant (0.3-0.5MtOE, Million Tonnes of Oil Equivalent), complex technologies serving environmental protection and energy-generation purposes need development; Further potential liquid bioenergy carrier producing ability is about 0.5-1.0MtOE of agro-sectors depending on the size of areas given for that purpose;Future potential energy generating ability of agro-sectors is 3.0-4.0MtOE without any deleterious effect on food-supply and conditions of soils; Energetically use of agricultural and forestry by-products in 10-15% measure does not endanger the organic content and structure of soil;Energetically use of biomass, plantation of energetic forests and energetic plant production significantly repairs the energetic factors micro- and macro regions; Technologies for economical use of biomass firing are available, however the technical-economical effectiveness of energy producing and conversion technologies need improvement; Biomass based fuel production, producing and processing methods, producing technologies and their profitability need further technological development; Economically operating water manure and waste-water treatment technologies serving environmental protection purposes are to be developed in connection with the biogas production direction; Biomass energy-carrier production extension is reasonable for improving environmental factors and extending the application of renewing energy-resources; For evaluation of biomass energy-resource efficiency, considering the economical effect of environmental factors new methods would be required, while strategic evaluation of biomass originated energy-resource production and utilization, consideration of rational leasehold and employment in the county has got special role; Technological and economical substantiates of biomass originated energy-carrier production representing the same order as crude oil production, requires significant central developing resources. The elaboration of this extremely complicated ecological, biological, technical and economical tasks can be realized only within the frame of a national agro-energetically strategic Research & Development program, while certain processes, application of equipment and investments can be done only if we know the exact local endowments in detail and we have an evaluation and analysis of it. EU-FP-7 project seems to be a powerful tool for the development.

ACKNOWLEDGMENTS

- The research and development project (the whole innovation chain), the MOL Plc. supported by the NORT (National Office for Research and Technology) established a consortium. Members of this consortium are: • MOL Plc. (Head of consortium) • OLAJTERV Plc. • KITE Agricultural Service and Trade Co. • Biodiesel Ltd. University of Pannonia, Faculty of Engineering.Chemical Research Centre of the Hungarian Academy of Sciences.Hungarian Institute of Agricultural Engineering Department of Mechanization of Plant Production.Regional Innovation Centre of Veszprem Public Utility Company.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML