-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Energy Engineering

p-ISSN: 2163-1891 e-ISSN: 2163-1905

2013; 3(1): 7-14

doi:10.5923/j.ijee.20130301.02

Quality Enhancement of Dehydrated Products through the Modification of Solar Tunnel Dryer for Continuous Operation in Rural Communities

P. N. R. J. Amunugoda 1, N. S. Senanayake 2, R. S. Wilson Wijeratnam 1, K. D. G. Kulatunga 2

1Industrial Technology Institute, Bauddhaloka mawatha, 7, Colombo

2Faculty of Engineering Technology, The Open University of Sri Lanka, Nugegoda 10250, Sri Lanka

Correspondence to: N. S. Senanayake , Faculty of Engineering Technology, The Open University of Sri Lanka, Nugegoda 10250, Sri Lanka.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Solar dehydration of food crops is an important area for the economic development of rural communities in Sri Lanka. However, the economic gain is marginal because of inadequate product quality and quantities achievable with present drying methods. Present solar dryers need a few days of drying to reduce the moisture content of perishables to safe levels causing unfavourable product qualities. In this study a solar tunnel dryer was modified by the attachment of a supplementary biomass heating source for day and night operation to shorten the drying duration and to preserve the product quality. The dryer was tested in five different locations in Sri Lanka using local perishables and spices with the participation of local communities. The dryer was well received by the rural sector as an alternative to traditional sun drying. The dehydrated products produced were of acceptable quality in terms of sensory parameters and market acceptability.

Keywords: Solar Dryer, Dehydration Technologies, Innovations, Rural Community, Technology Transfer

Cite this paper: P. N. R. J. Amunugoda , N. S. Senanayake , R. S. Wilson Wijeratnam , K. D. G. Kulatunga , Quality Enhancement of Dehydrated Products through the Modification of Solar Tunnel Dryer for Continuous Operation in Rural Communities, International Journal of Energy Engineering, Vol. 3 No. 1, 2013, pp. 7-14. doi: 10.5923/j.ijee.20130301.02.

Article Outline

1. Introduction

- Innovation and technological progress in energy sector is an integral part of economic development in any country. In the long term the ability to develop technology and to manage technological changes effectively is decisive in determining a country’s international competitiveness and capacity to grow[1]. The technological growth and the diffusion of economic activities to the rural areas is the key to alleviate poverty and establish a knowledge based economy[2]. Sri Lanka is both a producer and a consumer of perishables. Today, agricultural crop production has been stimulated by increased demand for raw materials for dehydration and processing. Country will have a promising future in many competitive world food markets, provided a proper technology is introduced to enhance the food product quality and variety. Locally, food dehydration serves as a preventive measure for food scarcity as well as a means of generating high income through value added production. The cost and the quality are prime important factors in food dehydration as it is purely an energy process. In contrast to this situation, however, in the rural sector of Sri Lanka, at farmer level, open air sun drying of perishables is practiced which causes many problems. Open sun drying is a time consuming, with a likelihood of contamination, infestation and microbial attack. Compared to sun drying, solar dryers can generate higher air temperatures and lower relative humidity, which is both conducive to improved drying rates and lower final moisture contents of the dried product. As a result, the risk of spoilage is reduced, both during the drying process and in the storage. Even though required quality standards can be achieved by using electrical dryers, it is not economically feasible due to high cost and non-availability of national grid connection in the rural sector[3]. In Sri Lanka the consumption of petroleum and electricity in rural sector agriculture based industries has increased[4], but the use of these energy sources for dehydration industry at community level is not viable at present. Under these circumstances, food dehydration industry has shown a little progress in spite of its great potential for rural development. The only viable option to rectify this situation is to develop dehydration technologies with the use of renewable energy sources[5, 6], especially the solar[7–11] as it has the potential of fulfilling the energy needs in the rural sector without much efforts[12, 13]. In Sri Lanka, except in the mountain regions and particularly in the dry zone a great potential exists to utilize solar energy[14,15] for dehydration of fruits and vegetables. In spite of this, a penetration of solar dehydration technology into these areas is very minimal. Hence, the problems associated with solar dried fruits and vegetables remain unsolved due to lack of efforts in problem identification and proper technology transfer.Many solar dryers, in the absence of a proper mechanism to control extended drying periods due to the absence of heat during night time, produce dehydrated products with poor organoleptic qualities[16,17]. The solution to operate the solar dryer during non-available periods of solar radiation is to use a supplementary heat source, and obviously it should be biomass or fuel wood as it is abundant with a little cost in the rural areas of Sri Lanka. The main focus in the present study was to investigate the prototype solar tunnel dryer developed by the University of Hohenheim[18], and to modify it to suit for local requirements. In Sri Lanka fuel wood is used extensively in many industrial heat energy requirements including food processing. From the total energy needs of the industrial sector[3], 72% are met from fuel wood. In a study by carried out by the Swedish International Development Cooperation with the Asian Institute of Technology, on Energy, Environment and Climate Change in Sri Lanka, the non-plantation bio energy potential was estimated at 123PJ increasing up to 133PJ by the year 2010. The petroleum consumption for the period was estimated at only 106PJ. The annual energy potential of plantation biomass is estimated to vary from 30 to 150PJ in 2010. It is projected that the total energy consumption in Sri Lanka in 2010 will be 425PJ; thus the plantation biomass could supply about 7% to 32 % total energy consumption in 2010[19]. Therefore, fuel wood was favourably considered in this study as a supplementary heat source in the development of continuous solar dryer. In the commercialization process of solar dehydration, business development has a crucial role to play. It manages the risk of new technology based enterprise by creating a business environment for development as well as assisting in the speedy commercialization of research out puts. In some instances a direct transfer method emanating from technology is little used in practice because of weak or nonexistent links between technology developing institutions and potential users. It is difficult to predict whether a particular technology would be successful in commercial level due to market forces that play a major role in determining success[1], of solar dehydration of foods. Governments have shown an effective progress as a major role player in facilitating these transformations, and clustering of business and net working. However, a proper coordination is required among the relevant government authorities to ensure that development strategies in rural sector producers are in line with the government policy. Therefore, recognized expertise and experience is needed to surmount these obstacles. The objective of this study was to develop a commercial solar dryer based on tunnel dryer initially developed by the University of Hohenheim to meet drying requirements of the rural communities of Sri Lanka, with the possibility of day and night operation. Further, this study specifically addresses transferring of proposed solar dehydration technology, testing the performance in the rural sector and commercialization of the process to change from present open sun drying practice to solar dehydration. Thus, to identify the field problems that stands as obstacles for the speedy adoption of the technology for commercialization of the dehydration technology.

2. Materials and Methods

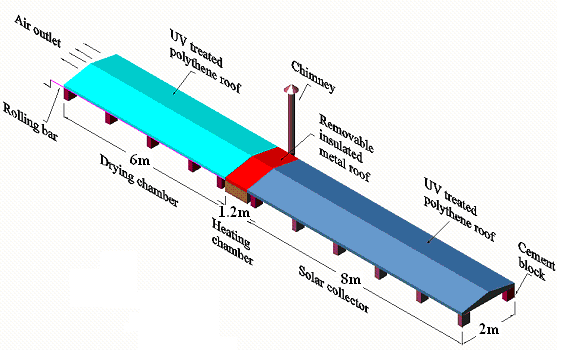

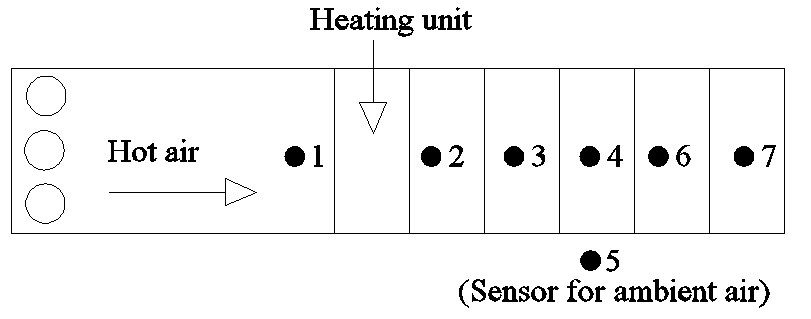

- A prototype of the Hohenheim solar tunnel dryer (Figure 1) was assembled at Industrial Technology Institute (ITI) in Colombo at East-West direction. A photovoltaic solar panel (model BP 255) was used to power two axial fans of 12V each to generate an air flow of 0.25m3s-1 through the drying bed. The temperature, humidity and air velocity along the drying length and across the tunnel were measured under no load conditions. The temperature and humidity sensor locations in the dryer are given in Figure 2. The temperature and relative humidity of the ambient air was measured by the sensor No. 1. The experiment was repeated three times to confirm the results.

| Figure 1. Schematic diagram of the modified solar tunnel dryer (Prototype solar tunnel dryer had no heating chamber) |

| Figure 2. Locations of temperature and humidity sensors |

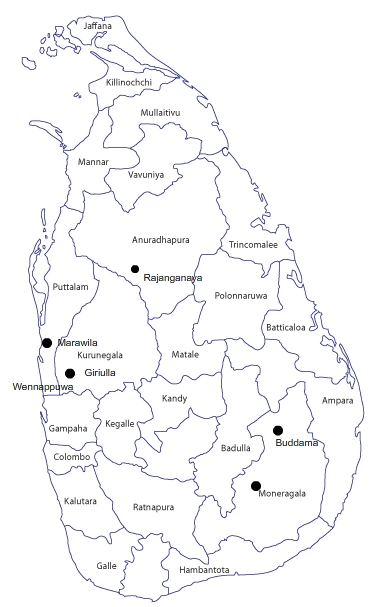

| Figure 3. Locations of dryer installation in Sri Lanka |

3. Results and Discussion

3.1. No-load Tests

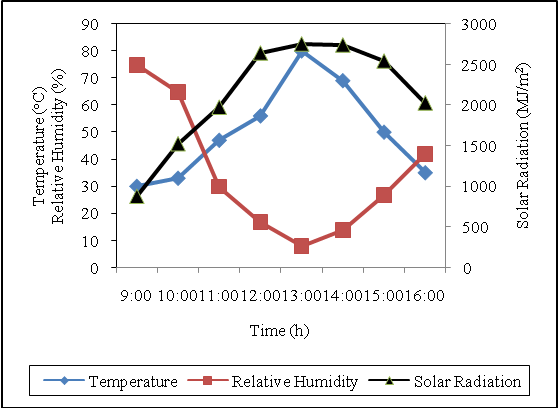

- Test trials of the prototype dryer and the modified dryer were carried out at the ITI premises in Colombo prior to the field testing in remote rural areas. The solar radiation intensity and temperature/humidity build up inside the drying chamber of the modified dryer in relation to sensor number 5 under no-load in a normal hot sunny day is presented in Figure 4.

| Figure 4. Solar radiation, temperature and relative humidity variation with time under no-load condition of the modified tunnel dryer |

3.2. Field Tests on Modified Dryer

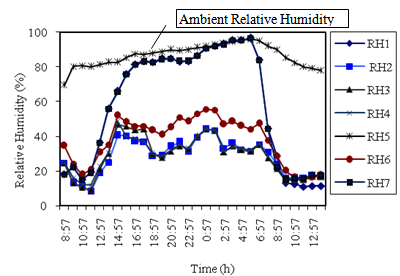

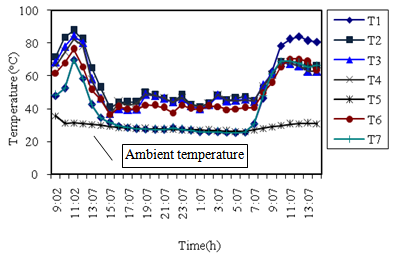

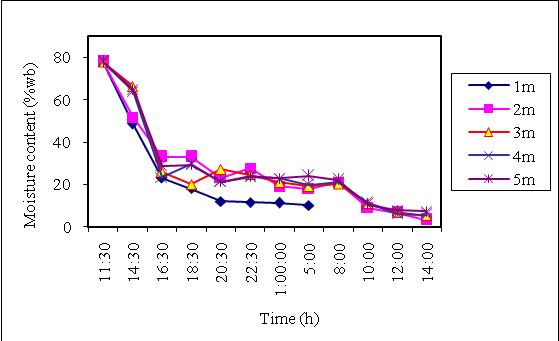

- During the solar hours of the trial period of the first day, products were exposed to high temperature (Figures 5 and 6). The initial airflow rate was in the range 0.30 - 0.33 m3s-1 (0.8 - 0.9 ms-1 air velocity) and gradually it was lowered to 0.08 - 0.09m3s-1 (0.2-0.24ms-1 air velocity) towards evening. Thereafter, this airflow rate was maintained throughout the night. In the morning of the second day, the airflow rate was gradually increased from 0.09m3s-1 to 0.22m 3s-1 (0.24ms-1 to 0.6ms-1 air velocity) and it was maintained until the end of the trial. Because of this gradual increment of airflow rate and the increasing solar intensity during the morning to noon of the second day, the temperature inside the drying bed was increased (Figure 6). During the night time, the temperature build up in the drying chamber was from 40℃ to 48℃. An important factor is that despite the absence of an optimum temperature level for drying i.e. 55℃, the supplementary heat source has been able to maintain the 22-23℃ temperature difference between the ambient and drying air during the night. Because of this heat, the relative humidity of the drying chamber lowered to 35-40% in the night (Figure 6). This drying potential was adequate to avoid the moisture re-absorption by the semidried products during the night and to reduce the moisture content to 30 to 20% on average.

| Figure 5. Variation of relative humidity with time |

| Figure 6. Variation of temperature with time |

| Figure 7. Variation moisture content of pineapple with time along the drying bed |

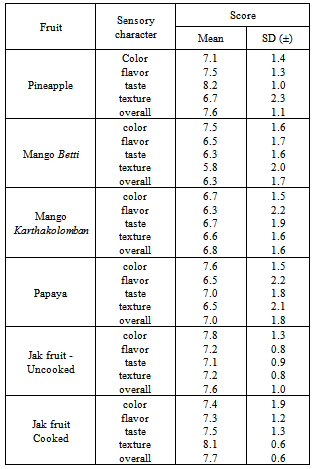

3.3. Sensory Analysis

- The results of sensory evaluation for different fruits are presented in Table 1.

|

| Figure 8. Solar dryer installed for field trials |

|

|

4. Conclusions

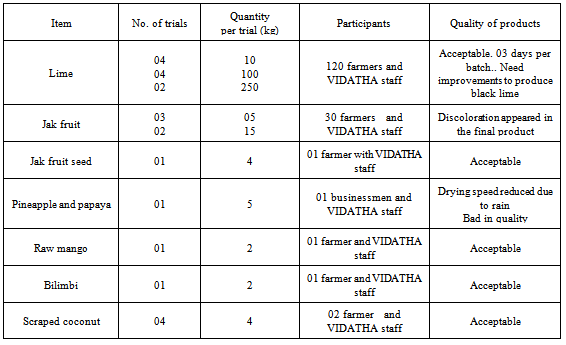

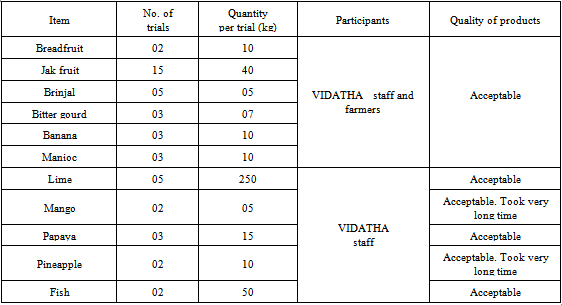

- A modification to the prototype of the Hohenheim solar tunnel dryer was made by the attachment of a supplementary heat source provided by biomass stoves and successfully tested. The supplementary heating unit proved to be easy to construct, and enabled easy handling during operation. All components can be made in a simple workshop. The heating unit was successfully operated using barrel stoves with saw dust as the most suitable biomass fuel available in the rural environment. Modification of the prototype dryer significantly reduced the drying duration by 1-1.5 days compared to prototype dryer. Physicochemical, microbiological and organoleptic parameters of dehydrated pineapple, papaya, mango and jak fruit from the modified dryer showed that the dryer was able to produce dehydrated products to match market standards. Field trials carried out by end users in remote rural areas showed that the quality of dehydrated products obtained from the modified dryer was acceptable quality. Hence the modified dryer is recommended for commercial drying requirements of perishables and spices in rural areas of dry zone of Sri Lanka. The use of powdered form of dehydrated fruits, vegetables, medicinal herbs and spices in the production of a variety of food items can be considered as supportive areas to boost the development of the dehydration industry. Supply of raw material inputs at affordable prices, market standards and facilitating links between these rural producers and the established private sector distributors with institutional mechanisms in place are vital for the establishment of solar food drying as a rural industry. The introduction of the modified tunnel dryer in a large scale, but with a proper training on the construction and the art of use certainly provides the rural community to successfully practice food dehydration using renewable energies in comparable with those produced with hot air dehydration systems.

ACKNOWLEDGEMENTS

- The support extended by the staff of the VIDATHA Centers of Sri Lanka and the local farmers and other participants is greatly acknowledged.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML