Hiroshi Koseki

National Research Institute of Fire and Disaster, Japan

Correspondence to: Hiroshi Koseki , National Research Institute of Fire and Disaster, Japan.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Abstract

Recent proposed various biomass fuels are reviewed from safety aspects. Many biomass materials are proposed to use as fuel, such as RDF (=Refuse derived fuel), wood chip. And these fuels have high energy and possibility to make fires, explosion or other incidents. We experienced many incidents of biomass materials, such as biomass fuel, rubble produced from destroyed houses by the great earthquake in March 2011, in Japan. Rubble includes various organic materials, and sometimes causes fire, which is used for fuel of power plants. It is very difficult to extinguish fire of biomass fuel in storage facilities. Here current studies on heat generation for these materials and proposed an evaluation test method for these new developing materials in Japan are introduced, which is to use high sensitive calorimeters such as C80, MS80, or TAM, and gas emission test. And cause investigation work for post-earthquake fires by rubble, conducted by author is introduced. High sensitive calorimeters can detect small heat generation between room temperature and 80 ℃, due to fermentation or other causes. This heat generation sometimes initiated a real fire, and produced some combustible gas, which may explode if fuel is stored inside silo or indoor storage.

Keywords:

biomass fuel, rubble, thermal flow measurement, high sensitive calorimeter, gas emission test

1. Introduction

Recently various biomass solid materials are proposed to use fuel[1, 2], such as RDF (=Refuse derived fuel), RPF (=Refuse paper & plastic fuel), wood chip, coal-wood mixture, chicken dung, soy sauce squeezing residue(SSSR) etc., because of crude oil price increasing and environment aspects, to reduce CO2 emission. And these fuels have high energy potentials and possibility to make fire and explosion[3-8]. We experienced many incidents with these materials in Japan. The great earthquake and tsunami in March 11, 2011 damaged houses in Tohoku area of Japan and produced huge amount of various rubble which sometimes ignited and the fires continued for several days. Wooden rubble is used for fuel of power plants. It is very difficult to extinguish these materials when they are stored in huge piles, or storage facilities. We did cause investigation of the fires from biomass fuels and rubbles, and it was proposed an evaluation test method for these new developing materials. The method is to use high sensitive calorimeters such as C80, MS80 or TAM which can detect small heat generation between room temperature and 80℃, caused with fermentation or other reason.This heat generation sometimes initiated a real fire, and also produced some combustible gas, which may explode if fuel is stored inside silo, indoor storage or indoor treating process[9]. Because biomass fuels are developing, so it is sometimes difficult to prepare enough amount of sample for tests. Therefore these tests have some advantage because they do not need large amount of fuel[10].

2. Examples of Biomass Fuel

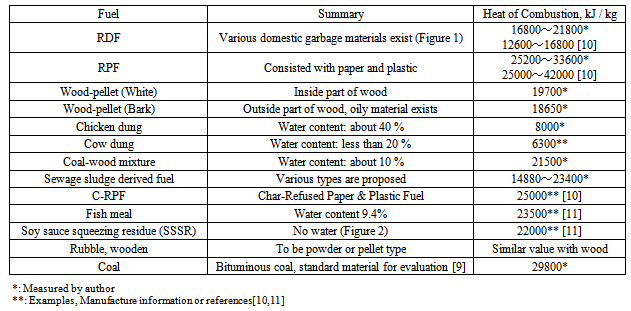

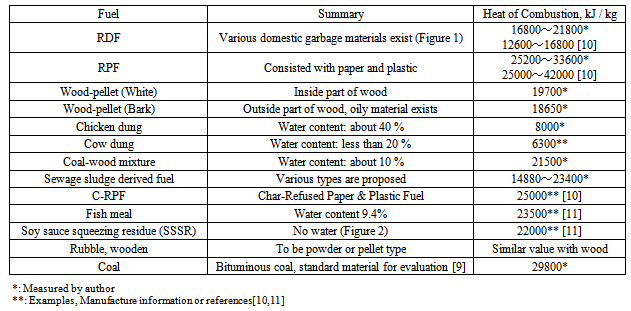

Various materials are proposed as biomass fuel, and Table 1 shows examples of biomass fuel. | Figure 1. Picture of RDF |

3. Incidents in Japan

Table 1. Examples of biomass fuel and coal

|

| |

|

| Table 2. Comparison between RDF and RPF[12-14] |

| | | RDF(Refuse Derived Fuel) | RPF(Refuse Paper & Plastic Fuel) | | Raw materials | Home waste | Industry waste | | Heat of combustion, kJ / kg | 12600~16800 | 25000~42000 | | Water content | Large, ~about 8% | Small |

|

|

Some examples of incidents of biomass fuels and rubbles in Japan are shown.1) RDF and RPF firesRDF is a cylinder type fuel, shown in Fig. 1 and Tables 1, 2. We started constructing RDF energy plants in Japan, at around early 2000. RDF was used as fuel in these energy plants, but poor operation might be conducted because of lack of knowledge. And huge amount of RDF was stored in silo and other storage facilities. It sometimes made heat generation and initiated a fire. One explosion occurred during fire-fighting against heat generation in a RDF silo, and two firemen were killed by explosion in August 2003[6,9]. An explosion occurred in the silo because methane was produced by anaerobic organism. After this explosion, we started cause investigation and studied danger of various biomass fuel, not only RDF. We understand that RDF produces heat by mostly fermentation, which also produces methane in the lack of air[11].RPF has a similar figure with RDF (Tables 1, 2). However it does not make heat generation like to RDF because it consisted with plastic and paper, and micro-organism may not exist in RPF. Sometimes it made fires because they caught fire from heat generation by friction during transportation or other process in plants.2) Wood chips firesRecycle and reuse is recommended in construction industry, but was not worked smoothly, which might cause huge amount of wood chip pile appearance in Japan, around 2002-2005. These piles sometimes made fires due to accumulations of the emitted heat, and they are not extinguished easily. One example of fire was occurred in Chiba, Japan starting August 2003. It was 60,000 m3 pile and its height was about 16 m, the fire continued for several months Three firemen were slightly injured. Cause of the fire is unknown, but heat accumulation in the pile is one of the possibilities of cause of fires. There aerobic organism existed in these piles and made heat generation especially after rain which is larger than that of emitted through the surface[14].3) SSSR and fish mealSoy sauce squeezing residue (SSSR), shown in Fig. 2, and fish meal made sometimes fire and incidents. When they are stored in indoor storage, they make fermentation and consume oxygen. So circumstance of inside of storage facilities is lack of oxygen. So workers involved in incident of shortage of oxygen as well as fire or explosion. | Figure 2. Picture of SSSR |

| Figure 3. Pictures of Tatami, sampled at Eastern Japan where was damaged by the Earthquake, 2011 |

4) Rubble firesAfter the great earthquake in March 11, 2011, huge amount of rubbles were produced. They came from destroyed houses by earthquakes and tsunami, and was consist of various materials including organic materials such as wood, tatami (Japanese style mattress, Fig. 3), wooden furniture. Some of them are used for fuel of energy plants. Because of delay of treatment them, huge piles existed, and sometimes they ignited and burned, but it is difficult to extinguish fires (Fig. 4). We did cause investigation of these fires, and found fermentation and self-ignition of organic compounds, such as Tatami, were major causes of fires. | Figure 4. A rubble fire occurred in Tohoku areas after about six months from March 11, 2011, where was damaged by tsunami (Picture was taken by author) |

4. Cause Investigation and Mechanism of Heat Generation

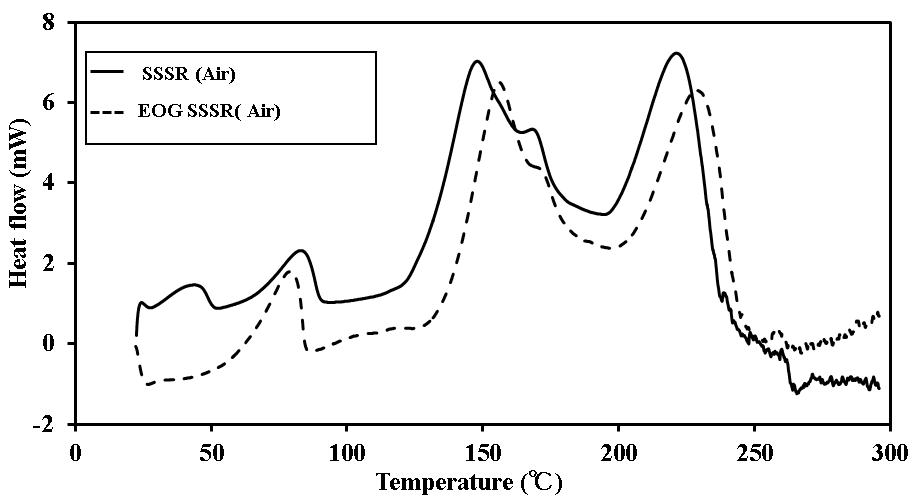

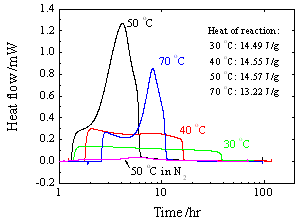

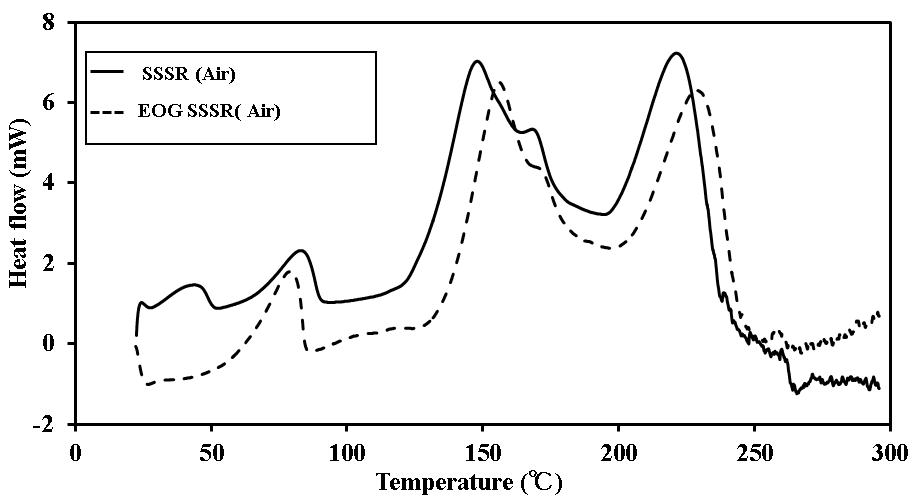

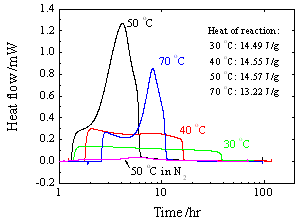

Based on the results of cause investigation of the above incidents, we found mechanism of combustion of these materials. That is, there existed three steps; 1) Faint heat generation between room temperature and about 60℃, 2) Oxidation and heat generation of fatty acid ester which existed in materials, up to about 100℃3) Combustion of cellulose or other organic materials. And most important step is first one. It includes faint heat generation by fermentation of microorganism which existed in the materials and water absorption on the surface of materials. Fermentation is mostly occurred in the temperature between 30℃ and 60℃. When water is added to the material, much more active fermentation is occurred. Microorganism is classified into aerobic organism and anaerobic organism. Heat generation is made by first one at relatively high temperature, under 60℃, and methane and other combustible gas are produced mostly by second one at lower temperature. Figure 5 shows heat generation by fermentation of SSSR in C80, and Figure 6 shows TAM isothermal experiment for wood chips. In N2 circumstance, there was nearly no heat generation, and heat generation was made in the air, and it produces the maximum at around 50 ℃. After they consumed oxygen, their reaction and heat generation stopped. Therefore total oygen consumption and total heat generation at various temperatures, are similar value.To make sure of heat generation of fermentation, we used ethylene oxide gas (EOG) to diminish microorganism. Figure 5 shows C80 test results of SSSR. For SSSR, we observed heat generation around 25-50℃, but no heat generation for EOG treated SSSR. Over 50℃, there were not large difference for samples. | Figure 5. C80 results for SSSR (Scanning rate: 0.1 K/min) |

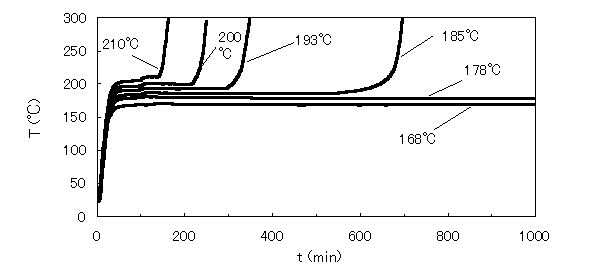

| Figure 6. TAM isothermal test results of wood chips (Sample: about 2 g) |

Absorption of water and chemical reactionWhen materials absorb water, it sometimes emits the heat, which is quicker than that of fermentation. Therefore we measure heat generation in various situation at 50℃ with TAM[12] (Figure 6). Sometimes quick heat production was observed which might be due to water absorption and fermentation. When it was sterilized with EOG, there was no heat generation by fermentation. And when water was added to the sterilized materials, it produced heat at the start of measurement, which might be due to absorption of water. Chemical reaction may also occur, and make heat generation. For example, acid and alkali reaction might occur, because biomass fuel includes sometimes calcium, and water might be some acid.Second step is more complicate, and Shimizu et al.[4] explained that peroxide was produced from fatty acid ester which might exist in RDF or other biomass fuel. We need more research. Third one is normal chemical reaction of wood production at the high temperature.

5. Evaluation of Biomass Fuels

The aim of the evaluation is to estimate heat generation and possibility of fire occurrence for new biomass fuel with small samples. Characteristics of coal were studied because it might be standard material[11].

5.1. Test Methods in the UN Recommendations

There is not a clear test method for such biomass fuels. The wire mesh test, Division 4.2 in the UN(United Nations) Recommendations on the transport of dangerous goods, Manual of tests and criteria[15], was used to evaluate self-heating substances. Here 1 L samples is used for each run.The Dewar vessel, Test H series in the UN recommendations, was able to use for estimation of the SADT (Self-accelerating decomposition temperature) of biomass fuel, but most of them do not have the SADT and some of them have very high values. The flash point is one of parameters to evaluate combustible materials, but most biomass fuel did not have low flash points. There is no method to find very small heat generation of fermentation or other heat generation which is much related with cause of the fire.Therefore we proposed tentative test method for estimate of danger of biomass fuel using high sensibility calorimeters with small amount of samples.

5.2. Evaluation with Thermal Methods and Gas Emission Test

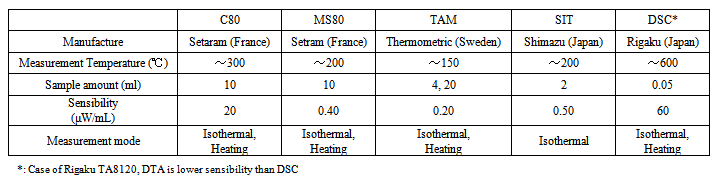

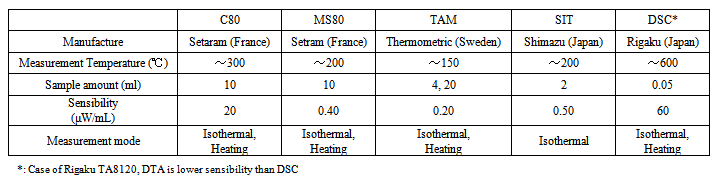

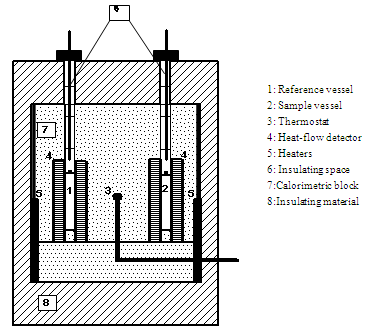

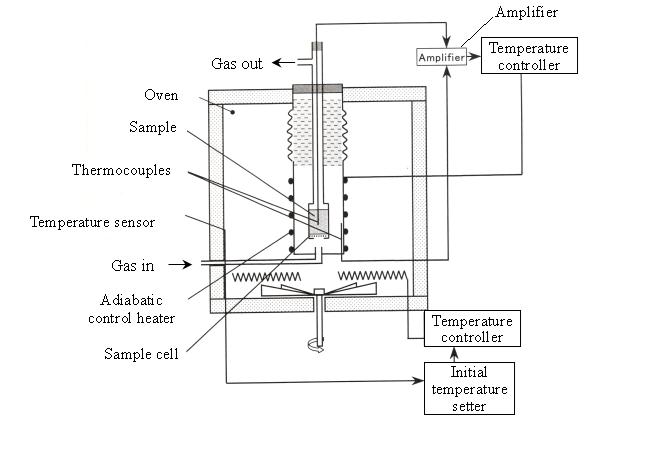

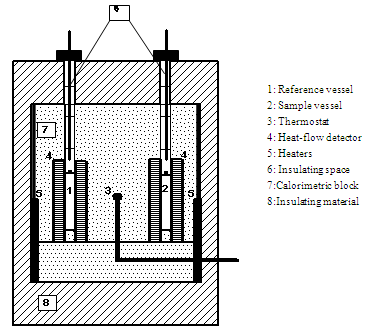

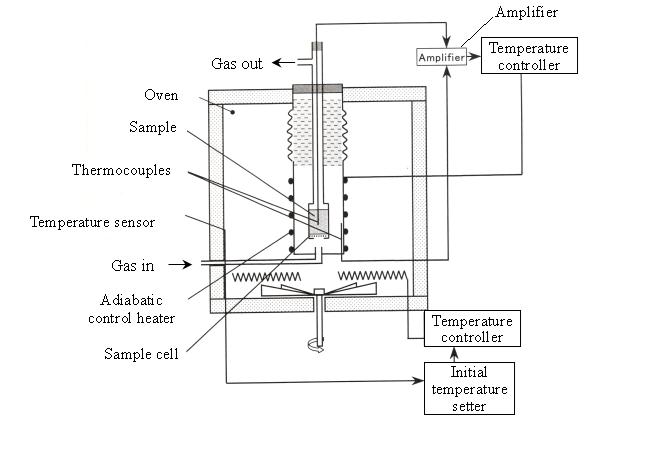

The test method using high sensitive calorimeters and gas emission tests was proposed by the National Research Institute of Fire and Disaster (NRIFD), Japan. Our understandings of process of fires are that; faint heat generation inside the biomass fuel near room temperature, may cause fire when it existed in adiabatic condition, such as huge pile. So the TAM is one of the most sensitive calorimeter, was used for evaluation of biomass fuels after the screening test with the TG-DTA. These tests need only small amount fuel though most tests in the UN Recommendations need large amount samples. The high sensitive calorimeters as well as C80, TAM, detect micro-order heat generation (micro J/g)(Table 3), which are widely used to find trigger of reactions by chemical materials. Therefore high sensitive calorimeters are able to apply to materials which are under developing because sample amounts are very small. Table 3 shows summary of these instruments comparing DSC. We used SIT for confirming increase of temperature after heat generation and cause of fire. Figures 7 and 8 show outlines of C80 and SIT, respectively.Table 3. Comparison of high sensitive calorimeters

|

| |

|

| Figure 7. Schematic of C80 |

| Figure 8. Schematic diagram of the spontaneous ignition tester |

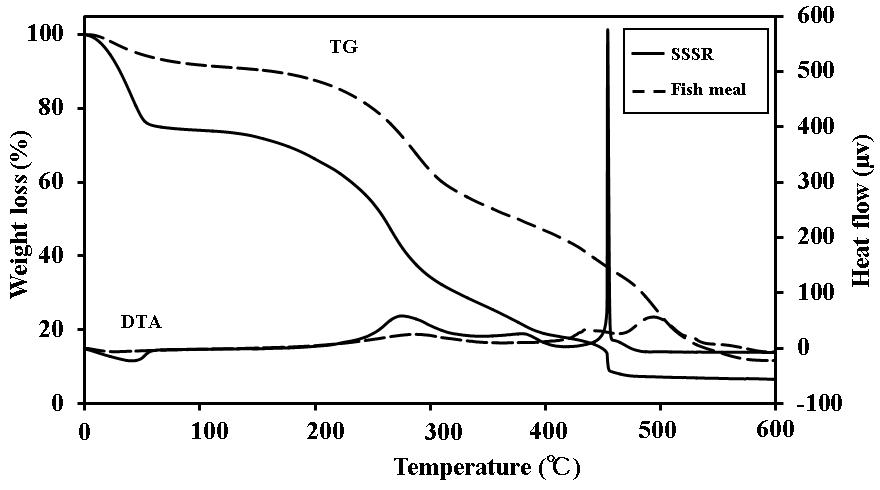

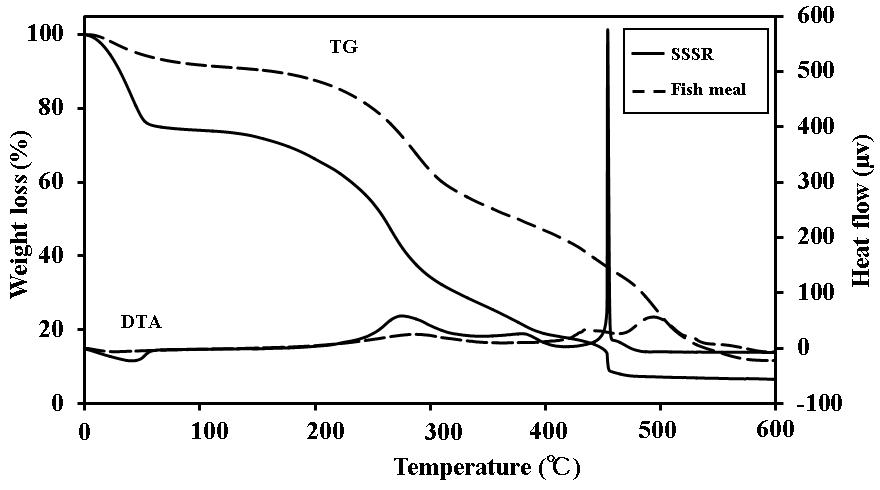

| Figure 9. TG-DTA curves of SSSR and fish meal (Sample: 20 mg, Scanning rate: 2K/min) |

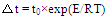

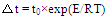

(1) Thermal analysis and high sensitive calorimeter1) TG-DTAThe TG-DTA is widely used, and is used for screening test of thermal properties with small amount of materials even though its sensibility is lower than that of DSC. SSSR and fish meal were measured in the TG-DTA, shown in Figure 9. There were not large heat generation until about 200℃, but we could not conclude only with TG-DTA data that they do not produce small heat generation which is related with causing fire. Therefore we should do heat generation test with high sensitive calorimeter.2) High sensitive calorimeterBecause the DTA and DSC have not high sensitivity, so we used high sensitivity calorimeters, C80, MS80 or TAM (Table 3). Figure 6 shows results of RDF with/without water. When water was added to materials, heat generation was observed after a few hours because added water promotes fermentation. 3) Adiabatic tester, SIT and critical height in huge pileTo assure ignition with small heat generation, we detected the heat by high sensitive calorimeters. We used adiabatic testers, SIT and/or ARC. Figure 9 shows SIT test results. When RPF was hold at higher than 160℃, its temperature increased after several hours.The reaction of RPF follows the Arrhenius law. The relationship of the induction time, ∆t [min], and the spontaneous ignition temperature, Ts [K], in the SIT : Here, E is the Activation energy, R is the gas constant.SIT data assure the critical height to increase its temperature and be ignited in a huge pile using the Frank-Kammenetskii equation. Heat generation and critical height is expressed with the following equation.δc=(ΔH・E・r2・A/λRTc2)・exp[-E/RTc]Here, δc is the Frank-Kamenetskii parameter, Tc is the critical ignition temperature, λ is the thermal conductivity, E is the Activation energy, r is the critical height、A is the constant.Calculation results of activation energy, E is 53.8 kJ/mol for RPF, which is larger than most biomass fuels. That is, RPF is safer materials.

Here, E is the Activation energy, R is the gas constant.SIT data assure the critical height to increase its temperature and be ignited in a huge pile using the Frank-Kammenetskii equation. Heat generation and critical height is expressed with the following equation.δc=(ΔH・E・r2・A/λRTc2)・exp[-E/RTc]Here, δc is the Frank-Kamenetskii parameter, Tc is the critical ignition temperature, λ is the thermal conductivity, E is the Activation energy, r is the critical height、A is the constant.Calculation results of activation energy, E is 53.8 kJ/mol for RPF, which is larger than most biomass fuels. That is, RPF is safer materials. | Figure 10. SIT results of RPF |

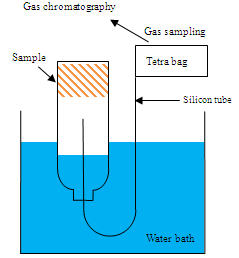

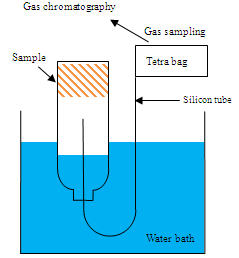

(2) Gas emission testMethane is produced with fermentation of anaero-activity, which may cause explosion in indoor storage. Therefore gas emission test (Fig. 11) is also important to evaluate biomass fuel. The test using about 10 - 20 g sample in 1 liter vessel is conducted under limited air condition in which firstly CO2 is mainly produced by aerobic organism as well as heat generation, and then methane and CO2 are produced by anaerobic organism in poor air circumstance. Emitted gas was analyzed by a gas chromatograph So the gas emission test gives global gas emission characteristics of biomass fuel. | Figure 11. Schematic of gas chromatography measuring device |

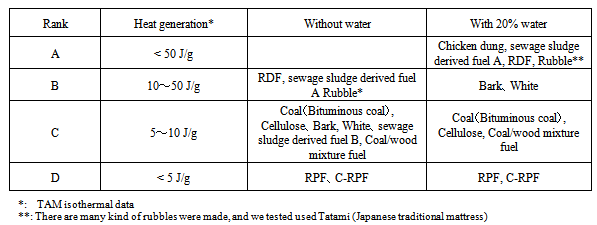

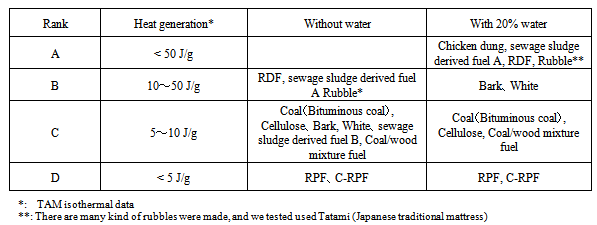

6. Evaluation Results

Totally about 40 samples were tested. Results are shown in Table 4. Hazard of heat generation and cause of fire is divided four ranks. Most hazardous materials (Rank A) are chicken dung, RDF, some of sewage sludge derived fuel, and rubble (tatami) when water are added in these materials. When water added into these materials they produced huge heat because of fermentation and water absorption. There are many types of sewage sludge derived fuel, and some of them can be ignited easily. Coal is able to be standard material, and belongs to Rank C in Table 4. The gas emission test gave that RDF, Chicken dung and rubble were most danger in regard to gas emission.Table 4. Examples of evaluation test results

|

| |

|

7. Conclusions

Recent incidents of biomass fuel and our cause investigation are introduced. And rubble made fire after the great earthquakes in Japan, March 2011. We found that water affects heat generation at near room temperature, and fermentation sometimes causes heat generation and makes fire. After these incidents, we did evaluation for various biomass fuels under developing, and we proposed test methods using thermal analysis, high sensitive heat flux measurement and gas emission test.RPF, C-RPF did not make heat generation at near room temperature, which means no fermentation or other chemical reaction occurred in these fuels, and they are safer. Some rubles make heat generation because of fermentation, and cause fires. So to take care them is very important when they are used for fuel of energy plants.

References

| [1] | Xin-Rui Li, Woo-Sub Lim, Yusaku Iwata, Hiroshi Koseki, Thermal characteristics and their relevance to spontaneous ignition of refuse plastics/paper, Journal of Loss Prevention in the Process Industries, 22(1), pp.1-6, 2009 |

| [2] | Xin-Rui Li, Woo-sub Lim, Yusaku Iwata, Hiroshi Koseki, Thermal behavior of sewage sludge derived fuels, Thermal Science12(2) pp.137-148, 2008 |

| [3] | Yoshitada Shimizu, Masahide Wakakura, Mitsuru Arai, Heat accumulations and fire accidents of waste piles, Journal of Loss Prevention in the Process Industries, 22 pp.86-90 2009 |

| [4] | Shadi Moqbel, Debra Reinhart, Ruey-Hung Chen, Factors influencing spontaneous combustion of solid waste, Waste Management, 30 pp.1600-1607, 2010 |

| [5] | Silo fires require special tactics and equipment, Industrial Fire Journal 81 pp. 32-35, 2010 |

| [6] | Atsushi Matumaga, Akio Yasuhara, Yoshitada Shimizu, Masahide Wakakura, Takayuki Shibamoto, Investigation on the spontaneous combustion of refuse-derived fuels during storage using a chemiluminescence technique, Waste Management & Research, 26 pp.539-545, 2008 |

| [7] | Hiroshi Koseki, Evaluation and cause investigation of various solid biomass materials using thermal analysis and gas emission tests, Energies 4 pp.616-627, 2011 |

| [8] | Xin-Rui Li, Hiroshi Koseki, Yusaku Iwata, Risk assessment on processing facility of raw organic garbage, Journal of Hazardous Materials 154(1-3) pp.38-43, 2008 |

| [9] | Xin-Rui, Woo-Sub Lim, Yusaku Iwata, Hiroshi Koseki, Safety evaluation of sewage-sludge-derived fuels by comparison with other fuels, Fire and Materials, 33 pp.187-200, 2009 |

| [10] | Naoharu Murasawa, Hiroshi Koseki, Yusaku Iwata, Journal of Food Research, 1(1) pp. 320-329, 2012 |

| [11] | Xin-Rui Li, Hiroshi Koseki, Yusaku Iwata, A study on spontaneous ignition of bituminous coal, Thermal Science 13(1) pp.105-112, 2009 |

| [12] | http://www.jrpf.gr.jp/rpf-5.html |

| [13] | Zhi-Min Fu, Xin-Rui Li and Hiroshi Koseki, Heat generation of refuse derived fuel with water, J. of Loss Prevention in the Process Industries, 18(1) pp.27-33, 2005 |

| [14] | Xin-Rui Li, Hiroshi Koseki, Michihiko Momota, Evaluation of danger from fermentation-induced spontaneous ignition of wood chips, J. of Hazardous Materials, A135(1) pp.15-20, 2006 |

| [15] | United Nations, Recommendations on the transport of dangerous goods, Manual of tests and criteria, 4th revised edition, United Nations, 2003 |

Here, E is the Activation energy, R is the gas constant.SIT data assure the critical height to increase its temperature and be ignited in a huge pile using the Frank-Kammenetskii equation. Heat generation and critical height is expressed with the following equation.δc=(ΔH・E・r2・A/λRTc2)・exp[-E/RTc]Here, δc is the Frank-Kamenetskii parameter, Tc is the critical ignition temperature, λ is the thermal conductivity, E is the Activation energy, r is the critical height、A is the constant.Calculation results of activation energy, E is 53.8 kJ/mol for RPF, which is larger than most biomass fuels. That is, RPF is safer materials.

Here, E is the Activation energy, R is the gas constant.SIT data assure the critical height to increase its temperature and be ignited in a huge pile using the Frank-Kammenetskii equation. Heat generation and critical height is expressed with the following equation.δc=(ΔH・E・r2・A/λRTc2)・exp[-E/RTc]Here, δc is the Frank-Kamenetskii parameter, Tc is the critical ignition temperature, λ is the thermal conductivity, E is the Activation energy, r is the critical height、A is the constant.Calculation results of activation energy, E is 53.8 kJ/mol for RPF, which is larger than most biomass fuels. That is, RPF is safer materials.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML