-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Energy Engineering

p-ISSN: 2163-1891 e-ISSN: 2163-1905

2011; 1(1): 9-11

doi: 10.5923/j.ijee.20110101.02

Power Transformer Insulation Lifetime Estimation Methods

M. A. Taghikhani

Department of Electrical and Computer Engineering, Saveh Branch, Islamic Azad University, Saveh, Iran

Correspondence to: M. A. Taghikhani , Department of Electrical and Computer Engineering, Saveh Branch, Islamic Azad University, Saveh, Iran.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Mineral oil in the power transformer has an important role in the cooling, insulation aging and chemical reactions such as oxidation. Oil temperature increases will cause quality loss. The oil should be regularly control in necessary time. Studies have been done on power transformers oils that are used in different age in Iranian power grid to identify the true relationship between age and other characteristics of power transformer oil. In this paper the first method to estimate the life of power transformer insulation (oil) is based on Arrhenius law. The Arrhenius law can provide loss of power transformer oil quality and estimates remaining life. The second method that is studies to estimate the life of power transformer is the paper insulation life prediction at temperature160℃.

Keywords: Power Transformer, Transformer Oil, Arrhenius Law, Estimated Life of Insulation

Cite this paper: M. A. Taghikhani , "Power Transformer Insulation Lifetime Estimation Methods", International Journal of Energy Engineering, Vol. 1 No. 1, 2011, pp. 9-11. doi: 10.5923/j.ijee.20110101.02.

Article Outline

1. Introduction

- Different stresses including thermal, electrical and chemical influence on insulation of the power transformer. Life of a transformer is equal to its insulation life which depends on mechanical and electrical reliability. The main factors that determine the insulation life of oil-immersed liquid-cooled transformers are the transformer load, ambient temperature, moisture content and oxygen content in oil[1]. If the winding hottest spot temperature is increased 6℃ related to the nominal value, the age of the power transformer is reduced by half and its electrical properties is changed[2].Accelerated degradation examination that be called acidity value examination or neutral value examination is test of acid in oil or oxidation resulting in oil. Acid content is expressed as the amount of milligrams of potassium hydroxide (KOH) that making neutralize of acids in one gram oil sample. In an alternative method to acidity measuring 20 ml of oil sample is replaced into a cylinder and potassium hydroxide solution added to the oil[3]. The solution color will change after became emotionless. Paper insulation deterioration with 1% moisture is ten times faster than the 0.1% moisture. The acids that by oxidation oil have been produced can help to rising metal corrosion in the power transformer[4]. Moisture in oil service should be monitored at least once a year. Many methods have been investigated to measure the quantity of moisture in oil[5].Accelerated corrosion testing of power transformer is used to show the effect of temperature on oil paper insulation systems of power transformer[6]-[10]. Several samples prepared for 24 hours at 120℃ temperature and vacuum pressure in the drying ovens. Carbon monoxide and carbon dioxide are produced at high temperatures and have a lot of influences on the corrosion rate of oil.

2. Carbon Monoxide Concentration in Oil

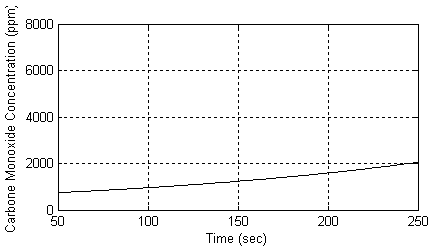

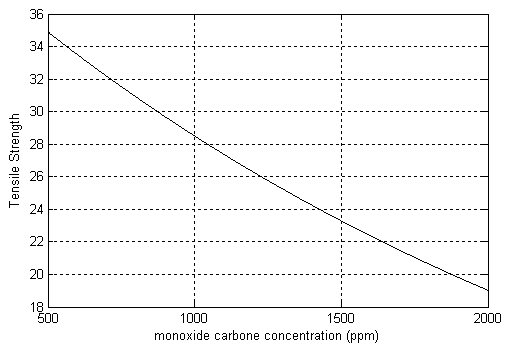

- To measure carbon monoxide in oil in certain prescribed times and according to IEC 60567 standard gas chromatographic analysis was performed to determine the concentration. Figure 1 shows result of this measurement. According to Figure1 with increasing temperature the aging time is increased due to paper thermal degradation. Figure 2 shows paper destruction with decreasing mechanical strength when monoxide carbon concentration increases in oil.

| Figure 1. Changing of the carbon monoxide concentration dissolved in oil |

| Figure 2. Paper tensile strength verses carbon monoxide concentration of oil in temperature 160℃ |

3. Carbon Dioxide Concentration in Oil

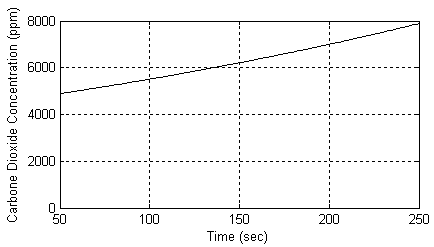

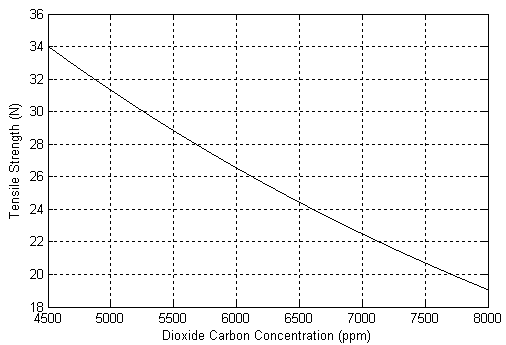

- Figure 3 shows measurement result of solution carbon dioxide in the oil and gas chromatography (IEC 60567). Carbon dioxide concentration in old oil to new oil has increased during heat stress. The aging time is increased due to increasing temperature. Figure 4 shows paper destruction with decreasing mechanical strength when carbon dioxide concentration increases in oil.

| Figure 3. Changing of the carbon dioxide concentration dissolved in oil |

| Figure 4. Paper tensile strength verses carbon dioxide concentration of oil in temperature 160℃. |

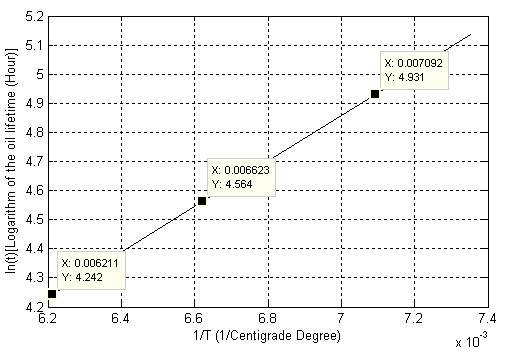

4. Arrhenius Law

- Arrhenius law is an experience-mathematically law which is dependent on temperatures effects on chemical reaction rate. According to this law, the reactions are dependent on temperature[4]:

| (1) |

| Figure 5. Arrhenius diagram to accelerate aging in an oil sample at different temperatures. |

| (2) |

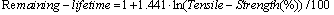

5. Prediction of Paper Insulation Life at Temperature 160℃

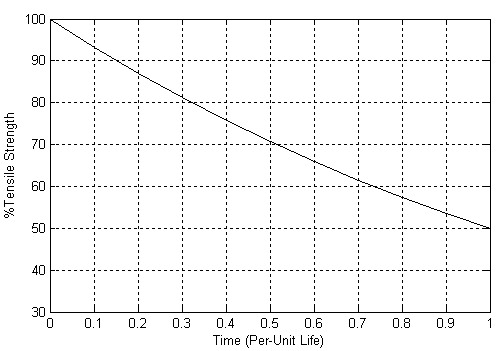

- One of the important mechanical parameters for cellulose insulation (paper) in the power transformers is tensile strength (the loss of mechanical strength) that causes the short circuit fault[5]. Therefore, this parameter can be an important criterion in determining the end of life of paper insulation. Paper tensile strength change verses the per unit life at temperature 160℃ is shown in Figure6. Low paper tensile strength (50% of its initial value) is considered end of its life. Therefore the remaining life of the paper at temperature160℃ would:

| (3) |

| Figure 6. Paper tensile strength verses time at temperature 160℃. |

6. Conclusions

- In this paper have been measured acidity and moisture content of power transformer insulating oil - paper under thermal stress. Most experiments conducted in accordance with changes in electrical properties. The first method to estimate the life of the power transformer insulation (oil) is based on Arrhenius law. The Arrhenius law can provide loss of power transformer oil quality and estimates remaining life. The second method that estimates the life of the power transformer insulation is the paper insulation life prediction at temperature 160℃.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML