-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Ecosystem

p-ISSN: 2165-8889 e-ISSN: 2165-8919

2016; 6(3): 59-63

doi:10.5923/j.ije.20160603.03

The Influence of the Lead-Zinc Slags Fractional Composition and the Type of Microorganisms for the Processes of Metals Bioleaching

Akmaral U. Issayeva1, Alisa I. Zhumadullayeva2, Yerzhan B. Issayev3, Asel Ye. Tleukeeva1

1Institute of Ecology and Biotechnology, M. Auezov South Kazakhstan State University, Shymkent City, Kazakhstan

2Department of Agriculture, Chemistry and Biology, Shymkent University, Shymkent City, Kazakhstan

3Department of Biology, M. Auezov South Kazakhstan State University, Shymkent City, Kazakhstan

Correspondence to: Akmaral U. Issayeva, Institute of Ecology and Biotechnology, M. Auezov South Kazakhstan State University, Shymkent City, Kazakhstan.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Shymkent is one of the largest industrial cities of Kazakhstan with a lot of industrial wastes. These include lead-zinc slag, which has a strong anthropogenic stress on the environment. On the other hand, there is a large number of components concentrated in the waste. The possibility of using different groups of microorganisms for the recovery of valuable metals from a variety fraction of lead-zinc waste was investigated. It is found that the bioleaching of zinc-lead wastes of valuable components depends not only on the species of microorganisms, but also on the fractional composition of the waste.

Keywords: Zinc-lead slags, Bioleaching, Fractional composition

Cite this paper: Akmaral U. Issayeva, Alisa I. Zhumadullayeva, Yerzhan B. Issayev, Asel Ye. Tleukeeva, The Influence of the Lead-Zinc Slags Fractional Composition and the Type of Microorganisms for the Processes of Metals Bioleaching, International Journal of Ecosystem, Vol. 6 No. 3, 2016, pp. 59-63. doi: 10.5923/j.ije.20160603.03.

Article Outline

1. Introduction

- The high rate of production and processing of mineral raw materials has led to the formation of a large number of mining and industrial wastes. At the enterprises of mining production in Kazakhstan are dumps and tailings of more than 20 billion tons of man-made mineral formations, with annual accumulation of about 1 billion tons of new wastes (Karimova Z. et al., 2002).Waste concentrators and metallurgical plants are unstable and non-uniform composition. In a joint storage of wide types of rocks and ores, differentiating them by chemical composition and physical-mechanical properties, their agitation, oxidation and leaching during prolonged storage, make them undergo significant changes. Waste occupy large areas of land and are the source of dust and gas emissions and toxic entities, that pollute the atmosphere, soil, surface water and groundwater thus having a negative impact on the environment.Biotechnological methods to extract valuable metals of various types of ores and metal waste are known (Acevedo F., 2002). For example, the possibilities of microbial recovery of copper from chalcopyrite was investigated (Kutschke S. et al., 2015). Also the role of the salt-resistant types of metals bioleaching microorganisms with a high content of sodium and magnesium salts in solution are known (Rea S.M. et al., 2015). Identified limiting pH value on the life of thiobacteria Acidithiobacillus ferrooxidans (Ngoma E. et al., 2015) has been documented. According to Mitsunobu S. et al. (2016) the mechanisms underlying the contact leaching process in pyrite bioleaching by Acidithiobacillus ferrooxidans using scanning transmission X-ray microscopy (STXM) -based C and Fe near edge X-ray absorption fine structure (NEXAFS) analyses has been investigated. Attached A. ferrooxidans produces polysaccharide-abundant extracellular polymeric substances (EPS) at the cell-pyrite interface. A key role of Fe (III) in EPS is enhancing pyrite dissolution has been determined. Pretreatment of pyrite with the phospholipid, [1,2-bis (10,12-tricosadiynoyl) -sn-glycero-3 -phosphocholine, to form an adsorbed organic layer reduced the amount of pyrite oxidation in the absence of bacteria and in the presence of A. ferrooxidans (Hao J. et al., 2009). In Murad A et al. (2003) and Ghorbani Y. et al. (2007) investigations, the biological leaching of aluminum by isolated fungi Aspergillus niger and Penicillium notatum from low grade bauxite (<50% Al2O3.) was studied. It is repoted that fungi are involved in metal bioleaching processes indirectly by producing сitric and oxalic acid, dissolving the crystal lattice of minerals. The bioleaching behavior of rock phosphate was studied using different strains of Aspergillus niger (Saeed et al., 2002) and analysis revealed the presence of fluorapatite [Ca2(PO4) 3F] as the main source of phosphorus. Ahn H.-J. et al. (2013) investigated various factors, such as organic acid generation with fungi type, pH of the culture and pulp density. However, the influence of various groups of microorganisms to extract valuable metals from different fractions of man-made waste is insufficiently studied.In this regard, the purpose of this study was to investigate the ability of microorganisms to extract valuable components from various fractions of lead - zinc waste.

2. Materials and Methods

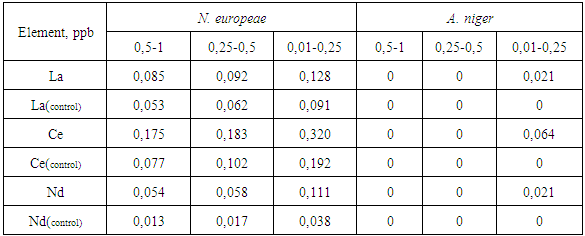

- 2.1 As the object of study, we used lead-zinc slags, located in the amount of a more than 2.0 million tons in the city of Shymkent in South Kazakhstan region (Figure 1). Wastes contain: Pb 0,01~2%, Zn 2~12%, Cu 0,8~11%, FеO36~40%, СаО12~14%, SIO2 24~26%.

| Figure 1. Location of lead-zinc waste in Shymkent city |

3. Results and Discussion

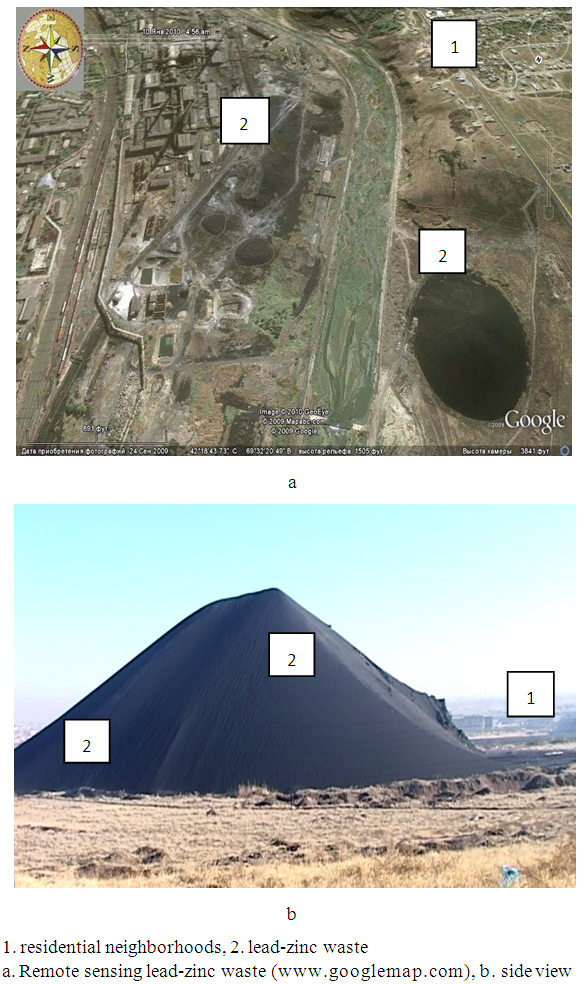

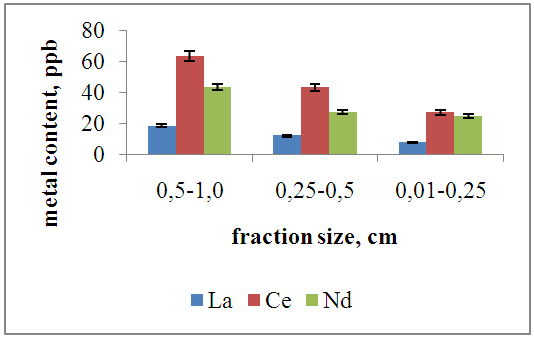

- X-ray phase analysis of waste samples taken from depths of 0-10, 10-20, 20-30, 30-40 cm rather the same type, has a semi-amorphous structure and is represented wustite FeO, d / n = 2,47-2,14- 1,51Ả, litharge PbO, d / n = 3,48-2,96-1,74 Ả and cosalite Pb2Bi2S5, d / n = 2,14-2,95-2,02-1,80 Ả.As a result of researches it is established that the processes of leaching of valuable components from metal-containing wastes not only depend on the kind of used microorganisms, but also on the fractional composition of the waste. It is revealed that each group of microorganisms selectively remove metals. For example, when using nitrifying bacteria Nitrosomonas europeae for leaching manganese, nickel, selenium, strontium, cadmium and tellurium optimal size fraction of lead-zinc waste is 0.25-0.5 mm. Figure 2 shows the results of the leaching of manganese and strontium. Set, the fraction of 0.5-0.1 cm of manganese is extracted at 77,92% more than the control variant without the use of microorganisms. In an embodiment, a fraction of 0.25-0.5 cm exceeding the extraction of manganese is 85,61% in comparison with the control variant. The least amount recoverable manganese observed for a fraction of 0.01-0.25 cm, where the extraction of manganese with the use of nitrifying bacteria exceeded the control variant by 44.37%. In the extraction of strontium the use of microorganisms has allowed to extract the strontium from factions 0,5-1,0; 0,25-0,5; 0,01-0,25 cm by 34.56; 52,72 and 29,01% higher than in the control samples. The reduction of particle size leads to a decrease in the extraction of metals from waste.

| Figure 2. Influence of the fractional composition of waste at extraction of metals from lead-zinc slag using nitrifying bacteria |

|

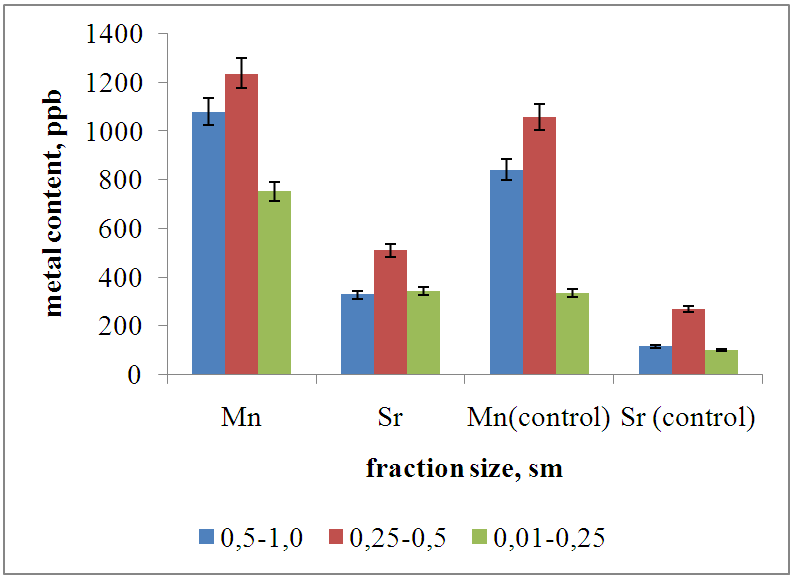

| Figure 3. The extraction of REE from the fraction 0.5-1 mm of lead-zinc waste |

4. Conclusions

- It is found that the bioleaching of zinc-lead waste of valuable components depends not only on the species of using microorganisms, but also on the fractional composition of the waste. It revealed that using nitrifying bacteria Nitrosomonas europeae for leaching manganese, nickel, selenium, strontium, cadmium and tellurium optimal size fraction of lead-zinc waste is 0.25-0.5 mm. The reduction of particle size leads to a decrease in the extraction of metals from waste.The using the culture of micromycetes Aspergillus niger with the same fraction is optimal for the extraction of titanium, vanadium, strontium, silver, cadmium, tellurium, thallium. On the other hand, a decrease in the fractional composition of waste contributes to the extraction solution of the lanthanum, cerium and neodymium by both types of microorganisms.It revealed that the using acidophilic microorganisms Acidithiobacillus ferrooxidans showed the optimality of the use of fraction 0,5-1 mm for the extraction of valuable metals, including REE from lead-zinc wastes in acidic medium.

ACKNOWLEDGMENTS

- The studies were performed in the framework of the grant of MES RK "Development of a method of biological leaching of lanthanum, cerium and neodymium from complex, phosphorous, lead and zinc wastes of the South of Kazakhstan" (2015-2017).

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML