-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Construction Engineering and Management

p-ISSN: 2326-1080 e-ISSN: 2326-1102

2022; 11(1): 21-29

doi:10.5923/j.ijcem.20221101.03

Received: Jan. 17, 2022; Accepted: Feb. 16, 2022; Published: Apr. 15, 2022

An Investigation into the Delay Factors Affecting the Construction Projects in the Petrochemical Industries in Bahrain

Faisal Ebrahim Alali, Saad M. A. Suliman, Khaled Al-Shafie

Mechanical Engineering Department, College of Engineering, University of Bahrain, Bahrain

Correspondence to: Faisal Ebrahim Alali, Mechanical Engineering Department, College of Engineering, University of Bahrain, Bahrain.

| Email: |  |

Copyright © 2022 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

This investigation addressed the delay factors and the delay consequences in the construction projects in the petrochemical industries in Bahrain from two aspects; likelihood of occurrence, and severity level. Initially, 117 delay factors and 29 delay consequences were identified based on the analytical review of relevant literature. Then, the list was refined based on the relevancy to petrochemical industries in Bahrain to 42 delay factors, and 14 delay consequences. The ranking of the delay factors and delay consequences was developed by calculating the adjusted frequency index (FAII). Also, the risk matrix was developed to classify the delay factors and delay consequences under different risk zones. The study revealed late delivery of material or equipment, adoption of the lowest bid price system for awarding the contract, inadequate project planning, and late design changes as the main delay factors. Also, the extension of works beyond normal working hours, time overrun, cost overrun, and delay of other related projects were concluded as the main delay consequences in petrochemical industries in Bahrain. The contractor’s perception of the delay consequences was found to be significantly lower than the petrochemical industries employees. The recommendation stressed the importance of including the delay in the high-level objective and cascading it to all departmental objectives. Also, it emphasized on developing a criterion to rank the construction projects based on their importance and complexity during the planning stage.

Keywords: Delay Factors, Delay Consequences, and Petrochemical Industries

Cite this paper: Faisal Ebrahim Alali, Saad M. A. Suliman, Khaled Al-Shafie, An Investigation into the Delay Factors Affecting the Construction Projects in the Petrochemical Industries in Bahrain, International Journal of Construction Engineering and Management , Vol. 11 No. 1, 2022, pp. 21-29. doi: 10.5923/j.ijcem.20221101.03.

Article Outline

1. Introduction

- The delay in construction projects has a significant impact and consequences on the organizations in terms of profitability and competitiveness in the market. Petrochemical industries are not an exceptional situation in this phenomenon. The nature and complexity of the process of such companies necessitate more stringent management to control the process and mitigate the impact and consequences of the delay to the projects. This research aims to identify and assess the main delay factors and the main delay consequences in the construction projects in the petrochemical industries in Bahrain.

2. Previous Studies

- Several studies have been reviewed to identify the relevant delay factors and delay consequences in construction projects around the world. The delay in Iranian petrochemical industries constructions projects was studied by (Naimi et al., 2008) [1]. The study revealed that the delay in delivering the material, shortage of material, lack of competent and skilled manpower, inflation, and unrealistic planning during the bidding stage are the main contributors to the delay. As per Le-Hoai et al. (2008) [2], the planned duration and final cost at project closing are two important factors of successful projects and successful project management. Salama et al. (2008) [3] indicated that despite the similarity shared with construction projects, some factors might not apply to the oil and gas industry due to the distinction between the two areas. The methodology used after the literature review was interviewing experts in the oil and gas field. Khoshgoftar et al. (2010) [4] specified the successful project factors such as completion on time, within budget, within specified quality, and within client satisfaction. Since delay is regarded as a failure, then it was important for the researchers to investigate the causes of delay in Iranian construction projects. Pourrostam and Ismail (2011) [5] quoted that delays can only be minimized when the causes are identified. Abedi et al. (2011) [6] developed a paper aimed at identifying the effects of delay that could threaten project objectives in the construction field. The study identified six major effects of delay: time overrun, cost overrun, disputes, arbitration, total abandonment, and litigation. The time and cost overruns were analyzed to be the highest impacts. Mohammed and Isah (2012) [7] studied the delay in a Nigerian construction project and concluded that improper planning, lack of communication, design errors, and shortage of supply were the top-ranked causes of delay. Delay in projects is a universal phenomenon, which is not only affecting the construction industries but the overall economy of the countries as well (Mydin et al., 2014) [8]. Hasan et al. (2014) [9] investigated the delay factors for road projects in Bahrain and analyzed the delay factors with their frequency and severity. Pham and Hadikusumo (2014) [10] said that petrochemical plays a significant role in economic development and inferred that many of their projects suffered from schedule delays. One of the major contributors to project delays is rework, where it has been investigated in detail by (Hwang and Yang, 2014) [11]. Research on oil and gas construction projects in Oman done by Ruqaishi and Bashir (2015) [12] concluded the unique factor for the delay in the oil and gas industry, which was the poor interaction with vendors in the engineering and procurement stage. Srdić and Šelih (2015) [13] said that delay can have different origins. It can be compensable or not, and may appear concurrently or subsequently. Mahamid and Al-Ghonamy (2015) [14] concluded the significant delay factors from consultants point of view as a bid award system for lowest price, changes in material types and specification during construction, contract management, duration of the contract, market fluctuation, frequent changes, improper planning and lack of adequate manpower. Kumar (2016) [15] investigated the delays in Indian construction projects, identified 103 causes of delays, and categorized them into 8 different groups, from which, the most significant factors were found to be inadequate contractor’s work and experience, poor communication between project stakeholders, delay in material delivery and lack of early planning of the project. Also, a study was made for petrochemical projects in Saudi Arabia showed the most influencing factors that contributed to the schedule delay during the construction of petrochemical projects in Saudi Arabia by (Alhajri and Alshibani, 2018) [16]. These factors were as follows: poor site management, poor supervision by contractor, conflict arising between the main contractor and subcontractor, poor planning and scheduling of projects by contractor, delays in material delivery, and delay in handing over the construction site to contractor. The main consequences for the delay in the construction phase in oil and gas projects, according to Suppramaniam and Ismail (2018) [17] are abandonment, arbitration, cost overrun, disputes, litigation, and time overrun. A survey done by Seddeeq et al. (2019) [18] revealed the major causes of time and cost overrun in Saudi Arabia's oil and gas construction industry. The research showed that the change in design and scope by the owner during the construction stage is the main reason for time overrun while underestimating the cost to the benefit is the main reason for cost overrun. In pipeline construction projects in Bahrain, delay factors with their associated risk were identified by (Mohammed and Suliman, 2019) [19]. Delay factors were identified with their impacts and illustrated using a risk mapping matrix for the classification of delay factors under different zoning.

3. Methodology

- This study used a descriptive research design to identify and prioritize delay factors affecting the construction projects in petrochemical industries in Bahrain, and their associated impact and consequences. These factors were analyzed quantitively by using FI, RII, and FAII indices in order to rank the main delay factors, main delay consequences, and to develop risk matrix to classify the delay factors and delay consequences under different risk zones.

4. Data Collection

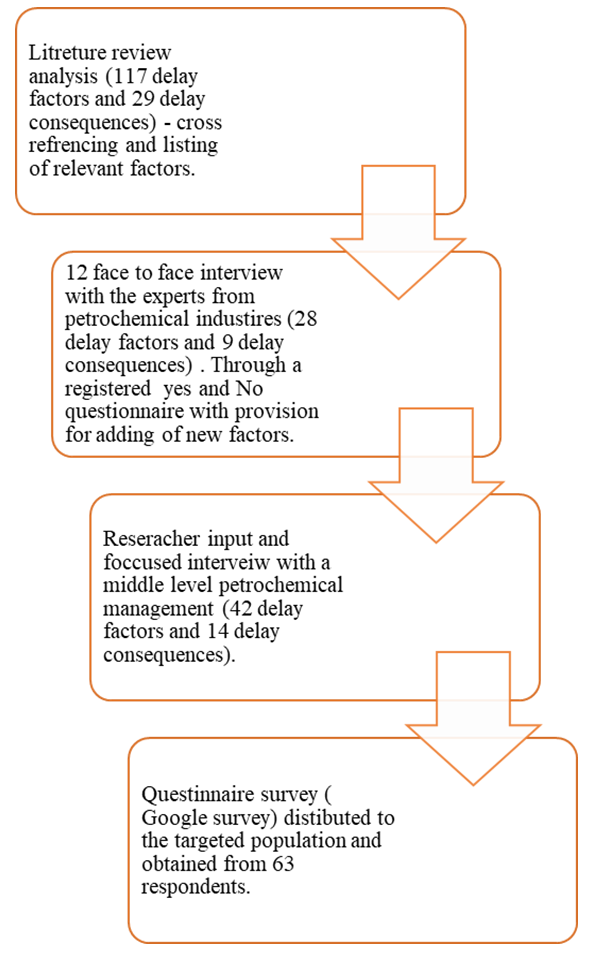

- The data collection process has been done as per the flow chart shown in Figure 1 in sequential order.

| Figure 1. Data collection flow chart |

5. Results and Analysis

- This section illustrated the results and analyzed them systematically and statistically.

5.1. Likert Scale Questionnaire

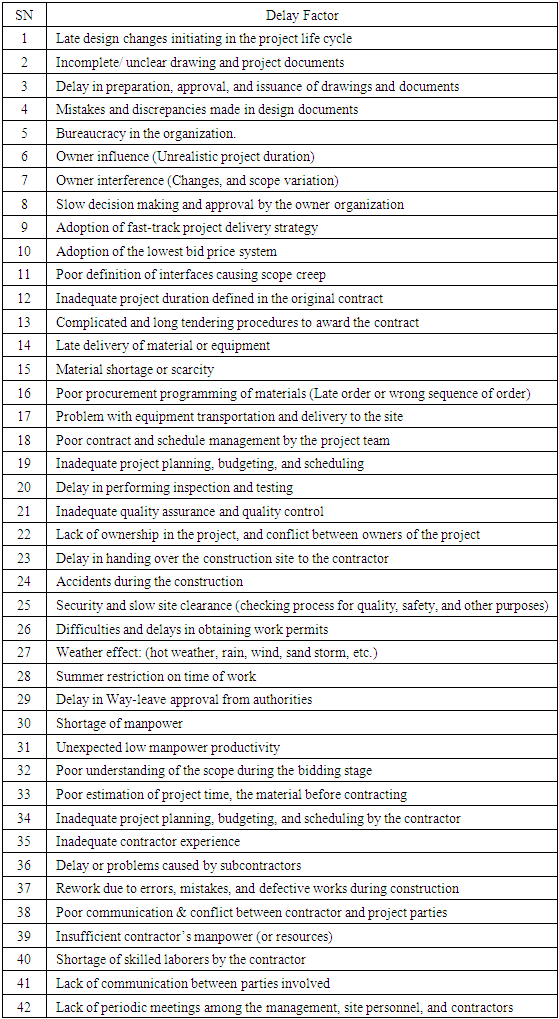

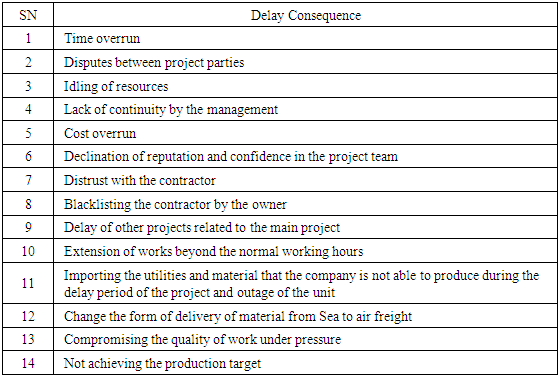

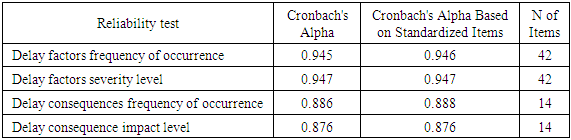

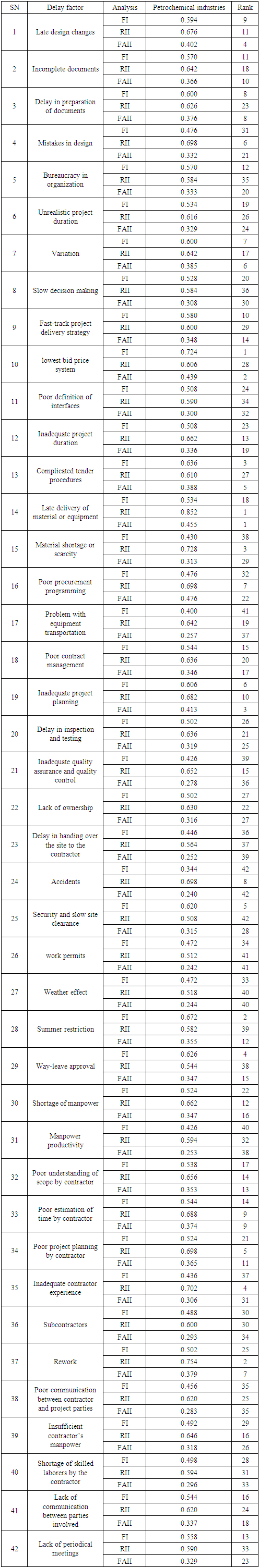

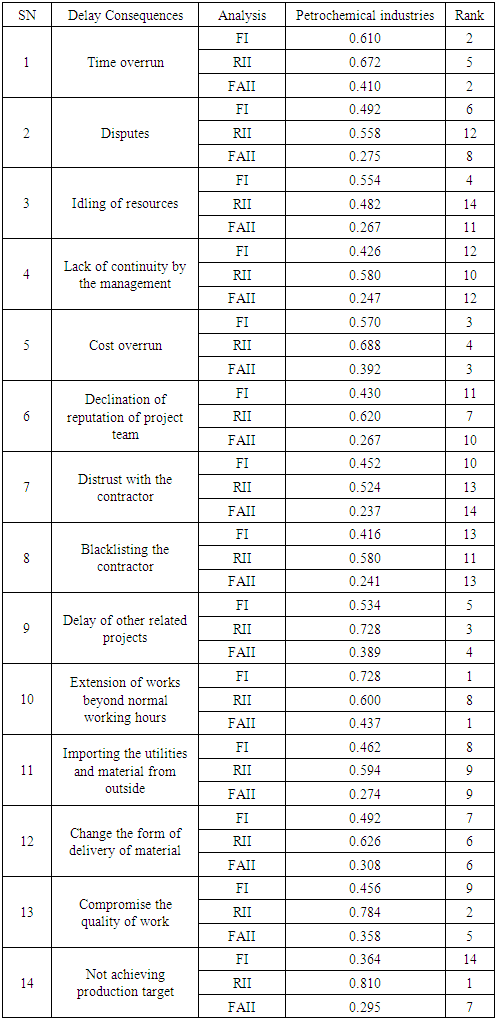

- The Likert scale questionnaire survey was designed and developed with 42 delay factors and 14 delay consequences as per Table 1. and Table 2.

|

|

|

5.2. Validity Test

- Pearson correlation test was used to assess the validity of the data when correlated with the overall composed sum of delay factors and delay consequences.The majority of the factors have shown a very high correlation with the total sum in terms of frequency and severity. For instance, the value obtained for [delay in preparation documents] was 0.634 which is significant at 0.01 level and 99% confidence interval. The only exception of all correlations (84 correlations) was the validity of the severity level of the [Late design change] which was found equal to 0.217 with P-value =0.088, while the Pearson value for the frequency of occurrence was 0.526 which is also significant at 0.01 level. Also, the analysis of the validity of the delay consequences in terms of the frequency and impact has shown that all the delay consequences constructed a high association with composed sum value of delay consequences. The Highest Pearson coefficient r was found to be equal to 0.780 for [Declination of reputation and confidence in project team] in the impact level correlation. The lowest correlation was obtained for the delay consequence impact level was for the delay consequence [Extension of works beyond the normal working hours] and equal r = 0.391 with p-value=0.002 which was still significant at 0.01 level.

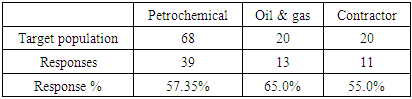

5.3. Reliability Analysis

- Reliability of the delay factors and delay consequences were evaluated through SPSS software by obtaining the Cronbach factor.The results indicated a very high internal consistency with a maximum 0.947 Cronbach Alpha value and a minimum of 0.886. Although the Cronbach factor for delay consequences was found on the lower side when compared with the result of the delay factors, it was still considered as a high value at 88.6% and 87.6% of consistency. The reliability analysis is detailed in Table 4.

|

5.4. Ranking of Delay Factors and Delay Consequences

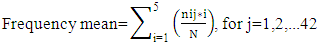

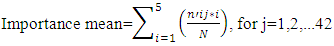

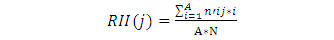

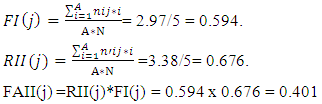

- Adjusted frequency index used to rank the delay factors and delay consequences based on their frequency of occurrence and severity level (importance).To compute the FAII, it is necessary to calculate both the frequency index of (FI) and relative importance index (RII) based on the responses obtained from the survey.

| (1) |

| (2) |

| (3) |

| (4) |

| (5) |

The entire calculation results were summarized in Table 5 and Table 6.

The entire calculation results were summarized in Table 5 and Table 6.

|

|

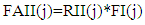

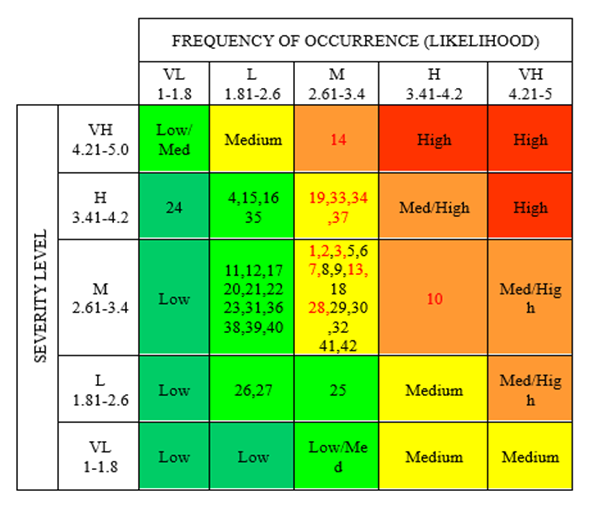

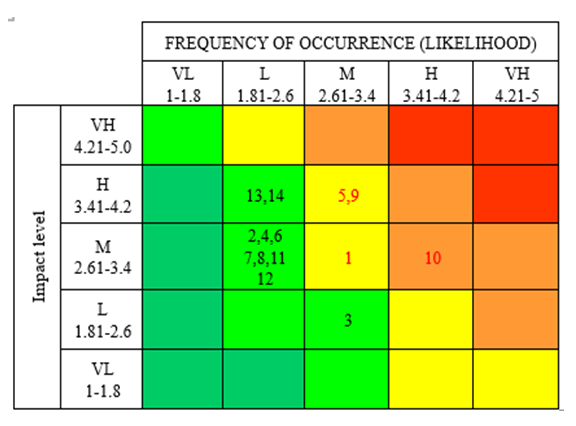

5.5. Risk Matrix Index

- The final analysis was to classify the delay factors by using the risk-based criteria for each factor (Frequency of occurrence, versus the severity level).Similarly, the risk mapping was deployed for the delay consequences in the term of (consequences of occurrence) versus the impact on the organization which represents the importance of the delay consequence.The risk matrix shown in Figure 2. and Figure 3.” included the delay factors and delay consequences obtained from the analysis of the FI and RII and classified under different risk zones.

| Figure 2. Risk Matrix for Delay Factors |

| Figure 3. Risk Matrix for Delay Consequences |

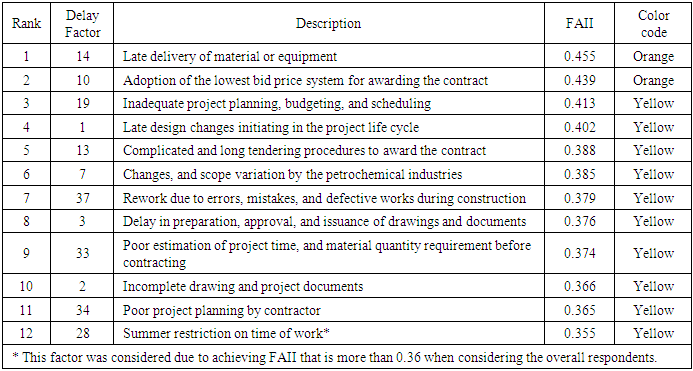

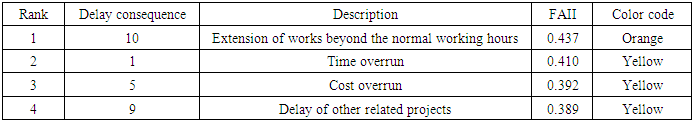

5.6. Ranking of Main Delay Factors and Consequences in Petrochemical Industries in Bahrain

- As a result of the FAII computation and the risk matrix development, Table 7 and Table 8 were formed to constitute the main delay factors and delay consequences respectively in construction projects in the petrochemical industries in Bahrain. These tables summarize the ranking of the delay factors and delay consequences according to their FAII and classify them according to their risk zones.

|

|

6. Conclusions and Recommendations

- This chapter covers the conclusion of the study and provides the final recommendations.

6.1. Conclusions

- The highest delay factor factors and delay consequences were ranked according to the adjusted frequency index (FAII) and were concluded as follows; For delay factors: late delivery of material or equipment, adoption of the lowest bid price system for awarding the contract, inadequate project planning, budgeting, and scheduling, late design changes initiating in the project life cycle, rework, and delay in approval, issuance of drawing and document. Also, the top-ranked delay consequences were concluded as: extension of works beyond the normal working hours, cost overrun, delay of other related projects, and time overrun.

6.2. Recommendations

- The findings from this research prompt various procedural recommendations toward addressing the way to control and mitigate the top rank delay factors and their associated delay consequences, as mentioned below:• Add the delay as a key performance indicator (KPI) in the high-level objective, and cascade it to departmental objectives. • Develop a criterion to rank the construction projects based on their importance and complexity during the planning stage. High-ranked projects shall follow different routes for bidding procedures and get the priority to complete the projects’ documents on time.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML