-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Construction Engineering and Management

p-ISSN: 2326-1080 e-ISSN: 2326-1102

2021; 10(4): 89-100

doi:10.5923/j.ijcem.20211004.01

Received: Aug. 10, 2021; Accepted: Aug. 20, 2021; Published: Aug. 25, 2021

Measures for the Challenges of Sustainable Procurement in the Construction Industry

Sudersan Ambalam Vassen

Lead Project Manager, Volmar Construction Inc, Brooklyn, USA

Correspondence to: Sudersan Ambalam Vassen, Lead Project Manager, Volmar Construction Inc, Brooklyn, USA.

| Email: |  |

Copyright © 2021 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The construction sector has made a significant contribution to global environmental problems, both directly and indirectly, while forging an inextricable bond with society and country's economy. Nevertheless, as the industry's demands for climate change mitigation and resource efficiency expand, sustainable procurement has emerged as a corporate concern. Building construction is intrinsically prone to changes in the construction industry because it is a key sector of the construction industry. By incorporating sustainable components into the procurement process, building constructions are becoming more sustainable, and sustainable procurement has become a major turning point in the building industry's evolution. Nonetheless, the efficacy of sustainable procurement is dependent on the positive and demonstrable control of challenges, which limits the sustainable procurement of buildings. The paper includes a detailed literature review highlighting the importance of sustainable procurement, as well as its benefits, drivers, barriers, and measures. For the successful fulfillment of targeted objectives, a quantitative research approach has been used. A questionnaire survey was conducted, focusing on 30 professionals with some practical experience with sustainable procurement. The questionnaire survey's results were then analyzed using descriptive statistics and the relative relevance index (RII). The analysis showed that sustainable procurement is challenged by aspects such as difficulty in tender evaluation by considering the cost of the entire product/service life cycle, lack of support from the senior management on the implementation of the concept, and lack of sustainable procurement policies. Furthermore, promoting a positive context for implementing of sustainability practices, establishing measurable sustainable procurement goals. Moreover, conducting procurement post-review to detect overlooked environmental concerns could be the preferable measure to address barriers to sustainable procurement.

Keywords: Construction Industry, Sustainability, Procurement, Sustainable Procurement

Cite this paper: Sudersan Ambalam Vassen, Measures for the Challenges of Sustainable Procurement in the Construction Industry, International Journal of Construction Engineering and Management , Vol. 10 No. 4, 2021, pp. 89-100. doi: 10.5923/j.ijcem.20211004.01.

Article Outline

1. Introduction

- The construction industry has a huge impact upon several countries' economic and social development, as well as causing significant environmental damage [58]. Because when humans discard harmful chemicals, do not save energy, or cause social turmoil that leads to resource misuse or damage, their actions have a detrimental influence on the environment [12]. Furthermore, the construction industry has a proven record of poor performance regarding health and the environment [48]. According to [57], society is also coming to understand the importance of sustainable development or environmental and industrial development synchronization. Moreover, the enormous growth in the number of green buildings completed annually over the previous two decades, as per [49], confirms the increasing importance of sustainability within the construction sector. The notion of sustainable design was characterized by [52] as an outgrowth of our caring for others and their right treatment, which necessitates that we use the resources and abilities to try to call in a manner that provides a habitable environment for future and distant generations. Since of increased concerns about sustainability, it has been noted that individuals have changed their behaviors and become greener over the last two decades [59]. As it appears to be affected by construction works [25], sustainability is a major consideration in the construction industry. Balancing between the triple bottom line of sustainability (i.e., environmental, social, and economic factors) is essential to ensure sustainable development. The current focus of sustainable development is on society, intending to incorporate environmental factors into the direction of societal transformation, particularly through changes in the economy [6]. The process of obtaining products and services for constructing of a project as per predetermined standards is known as construction procurement [45]. However, conventional construction procurement processes have been criticized for disrespecting the environment, society, life cycle costs [55], and non-compliance with existing policies and procedures [24]. Traditional procurement techniques have been identified as a source of difficulties, and sustainable procurement has arisen as a possible solution. In recent years, there has been a dramatic change in building procurement from lowest cost to best value procurement, as well as an amended program for understanding high policy goals associated with social or environmental sustainability [41]. Sustainable procurement allows the construction industry to meet economic development and social equity while minimizing environmental damage and contributing to the wider vision of attaining sustainable development [34]. According to [35], traditional procurement comprises the pursuit of value for money, but sustainable procurement is concerned with value for money across the entire life cycle, considering the economic, social, and environmental components. However, even as organizations make headway in integrating sustainability into their operations, it is becoming clear that businesses are bound by market expectations and are having difficulty quantifying and capturing the business value of sustainability [44].

2. Procurement in Construction Industry

- Many successful organizations now view procurement as a strategic function [13]. Procurement systems manage the delivery procedures of a construction project in various ways and are crucial in deciding a project's successes and failures [31]. Moreover, procurement is a method used by public and private organizations to purchase goods, services, and works in even the most efficient way possible [23]. External organizational issues such as customer expectations, competitiveness, and increased environmental consciousness, according to [5], have contributed to this shift in priority. Further, in general, procurement can be seen as a vital part of any construction project, encompassing all operations linked to the provision of goods, services, and consultations required to meet project's objectives. As per [17], non-discrimination, fair treatment, mutual awareness, symmetry, honesty, freedom to deliver service, and installation flexibility, are fundamental principles in performing the procurement function. The procurement system how the project will be carried out and on pre-contract activities related to the employer's human and financial resources, risk transfer concerns, and obligations under the contract. Thus, choosing a procurement process for a building project is one of the most crucial selections construction clients should undertake.Nonetheless, choosing the best procurement system is challenging since even highly experienced clients may not be aware of all the potential advantages or problems associated with each system [51]. As a result, the procurement selection approach includes a thorough examination of complicated and dynamic variables such as cost certainty, responsiveness, efficiency, adaptability, and the like [30]. Although a suitable procurement system may increase the likelihood of project success [38,46], some decision-makers could have difficulty determining the appropriateness of possible existing procurement methods, as it is practically impossible for them to collect a varied continuum of procurement options, client qualities, wants, characteristics of the project, and external environments via their experiences of past projects [28]. Furthermore, Several UK construction companies have expressed dissatisfaction with the capacity of the construction sector and accessible procurement systems for some years system [51].

3. Sustainable Procurement in Construction Industry

- According to [20], sustainable procurement applies of sustainable development concepts to procurement, which is critical in achieving a habitable planet that provides people with a better quality of life. It is critical to think about an organization's consumption and production practices [56]. Sustainable procurement, in the context of construction, is a process in which the client and engaging organization adopt development and design standards in a manner that delivers value for money over time, generating advantages not just for project participants as well as for the economy and society while minimizing environmental damage [3]. Sustainable procurement is referred to as the process by which organizations purchase assets, supplies, and/or services while considering a range of aspects, such as conventional factors like price, quality, availability, and features; sustainability elements (i.e. the product's overall environmental impact); and socially responsible factors [33]. Many countries, like the United Kingdom [15], the European Union [11], and the United States, have adopted sustainable procurement policies and national strategies [32]. The notion of sustainable procurement emphasizes a company's responsibilities for activities that occur beyond its organizational boundaries [34]. The four main goals of sustainable procurement, as defined by [10], are minimizing the influence of procured items (goods, services, and works) throughout the life cycle by supply chains; reducing resource use through purchase enhancement, resource-efficient product lines, re-use, and recycling of materials; and using good purchasing. Further, growing demand in sustainability, and thus sustainable procurement processes, is influenced by several factors, and to retain their reputation, companies employ sustainable procurement to ensure that their supplier chain meets ethical and environmental standards [9]. As per [32], via public funds to cover social and environmental goals, sustainable procurement could help the government achieve goals such as fostering innovation in domestic production marketplaces. Even though sustainable procurement is a viable option for the future, it is typically neglected by project stakeholders [45]. According to [49], there is a lack of client interest and contractor unwillingness to use sustainable systems in building projects. Local variables play a major role in the difference in sustainable procurement strategies worldwide [42]. Organizations across industries have undertaken various transformation programs to deal with sustainable procurement activities to adapt to key stakeholders' expectations and implement sustainable procurement initiatives [44].

3.1. Drivers to Sustainable Procurement

- Currently, initiatives to adopt sustainable procurement concepts into the construction sector have begun to arise, and some factors that comprise the business plan for sustainable procurement are outlined in the entire development process [9]. Sustainable procurement is being implemented by the private construction industry voluntarily, based on increased sustainability awareness and more adjustable private industry norms [1]. Driving forces in the implementation of more sustainable procurement are client acceptance [16] and placing more emphasis by corporate clients on their supply chains to enhance sustainability initiatives [21]. The greater utilization of whole life costing techniques minimizes expenses over the lifetime of the building. Hence value for money is recommended as a driver for sustainable procurement. Even then, the construction firm, or in many situations, the client, is reluctant to see the value of whole life costing [9]. The existence of a company's financial and technological resources has been identified as a crucial motivator of long-term sustainable procurement uptake [22].Moreover, increased collaboration, managerial attention, criterion simplification, and more environmentally labeled items were highlighted as primary drivers [13]. Further [40] listed comply with regulations, innovation, technology, organizational processes and practices, investment in education, political willingness, enactment of a strategic vision, the expertise of sustainable procurement, legal structure, supervising, market potential, governmental policies, credibility, and client requirements are all identified as drivers of sustainable procurement by researchers. One of the major drivers of organizational sustainability adaptation is top management commitment. According to [22], top management is the main factor for sustainable practices since they are accountable for the organization's activities and affect its culture: and their support is positively associated with sustainable procurement commencement, adopting decisions, and execution. On the other hand, government assistance was found to be significant but negatively correlated with large-scale enterprises' application of sustainable practices by [7], even though that a favorable policy environment is greatly involved in sustainable procurement emergence, application, and deployment by large firms. Competitive pressure is mentioned in the literature on sustainable procurement implementation as one of the primary elements in the environmental context, and it is frequently used in competitive pressure scenarios since it better equips businesses to respond to new challenges [60].

3.2. Barriers to Sustainable Procurement

- Notwithstanding the passion for sustainable development, progress toward sustainable procurement in the construction sector remains inconsistent [43]. More barriers arising from all aspects of sustainable procurement might then be identified, along with their linkages to an effective implementation approach. Clients may be hesitant to adopt sustainable solutions due to the obvious significant risk (Nelms et al., 2005) associated with inexperienced techniques, a lack of prior experience, additional construction inspection and testing, an absence of supplier and manufacturer assistance, and a lack of effective data [38]. Moreover, sustainable procurement difficult to implement due to several uncertainties in the pre-construction period [53]. The literature has mainly ignored the obstacles of sustainable procurement, with only a few studies focusing on the topic. The following obstacles were identified by [1]: a desire to stay constant; behavior influenced by culture; priority dispute; a shortage of training and education; an absence of research and innovation; scarce resources and sustainable practices; poor quality; a lack of investment; details, dedication, demand, and guidelines; and a lack of awareness, understanding, information, commitment, demand, and guidance; a lack of maturity and long-term assessment, connectivity and integration, the impression of applying sustainability; and a rise in capital expenses. For sustainable procurement, ethics is a major consideration. [37] highlighted the value of following ethics in building procurement, identifying a lack of information as the biggest barrier to ethical action. The key barriers for establishing sustainable practices, according to [39], are building an appropriate supply chain and overcoming traditional views in the construction industry. As per [8], most procurement change attempts fail since they concentrate on only one significant organizational component instead of the interrelationships among various prominent variables. In addition to the motives of sustainable procurement adoption, such as those stated above, some obstacles that deter organizations from doing so [9]. Additional cost increased effort, and inadequate supply chain communication are the most widely mentioned instances of these constraints [47]. Moreover, according to the findings of [13], 60% of the tender documents included some form of environmental parameter, yet 1/3 of them were problematic. This revealed that five primary obstacles to sustainable procurement were indeed a lack of information, a focus on financial concerns and product functionality, and job pressure [13].

3.3. Advantages of Sustainable Procurement

- The construction sector is still discovering the advantages of sustainable procurement and how to put it into practice. The prime benefit of implementing sustainable procurement, according to [45], is long-term cost reductions Other advantages of sustainable procurement include reducing the impact of harmful materials on human health and, as a result, assuring societal benefits and maintaining public rights. Sustainable procurement is thought to save money and minimize waste by assessing the need to purchase, lowering quantities where possible, conserving energy and water, encouraging re-use and recycling, reducing packaging, and improving transportation efficiency [40]. Besides that, [55] believe that the concept of sustainable procurement is compatible with sustainable development, which asserts ensuring that communities develop healthily with deep care for plants and humans living, while also taking into account environmental boundaries and governance, the latter of which is achieved via buying and the supply chain entities. Gives respect and reputation to the organization, increases the workforce's health, safety, and security, as well as the local community's and citizens', increases income and strengthens the local economy, generate job opportunities, saves money, and pollution and waste are reduced to a minimum are stated as main advantages of sustainable procurement by [2]. Moreover, the rewards of sustainable procurement include ensuring value for money and the effective and efficient use of natural assets while lowering waste and energy emissions [2]. Furthermore, government sector stakeholders stated that sustainable procurement enables them to choose the most environmentally friendly form of action for delivering constructed assets utilizing taxpayer money. Moreover, it minimizes adverse health effects on residents, enhances social benefits, and fulfills the organization's responsibility to society and the stakeholders. It focuses more on long-term cost savings to increase profitability for the shareholders [45]. It was discovered that a cost-benefit analysis of sustainability expenditures would reveal long-term benefits in terms of brand image, tax incentives, good social impact, and contributions towards a more resilient economy. Earlier in the procurement cycle, such an analysis can define sustainable procurement objectives and the best outsourcing techniques [18]. Sustainable procurement is widely recognised as a potent opportunity for change and a fundamental instrument for driving public policies that enable governments to avoid negative sides of consumption and production [14].On the other hand, [4] highlighted more aids of sustainable procurement practices including assisting socially disadvantaged groups reinforcing the workers to meet the company's future needs. It comes by examining the entire LCC, save money in the long run, fulfilling international duties procurement procedures must be made more efficient and transparent, stimulating the market for sustainable development, mitigating the consumption of natural resources, and complying with current and future legislation related to the climate change program. Moreover, project management structures in sustainable procurement benefit from requiring suppliers to conform to sustainability requirements and reducing procurement risks arising from various technical and quality issues [36]. These dangers are intertwined and are likely to have significant consequences for sustainability goals.

3.4. Strategies for Better Use of Sustainable Procurement

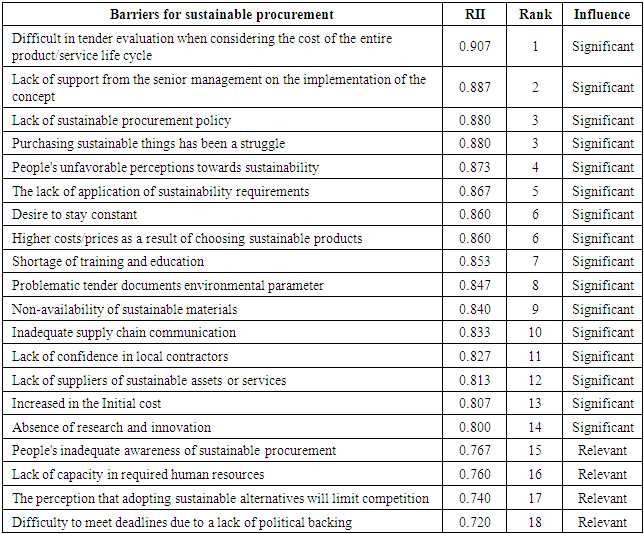

- Strategy design and implementation must extend throughout an organization's supply chain to achieve truly sustainable development [21]. Firms trying to enhance their environmental sustainability, for instance, might engage with suppliers to reduce the toxicity of products or the quantity of packaging used in supply. The need to explore beyond an organization's perimeter emphasizes procurement's critical role in sustainable development, as evidenced by a large number of case studies on green supply chain management and sustainable procurement. Various guiding principles that define sustainable development metrics at the international, national, and local levels underlie sustainability strategies. These rules demonstrate the subject's scope and intricacy. Such breadth and diversity in sustainable procurement are likely to cause concern and ambiguity at the operational level, contributing to stagnation among those in charge of procurement decision-making. One area where individuals in charge of implementing sustainable procurement strategies might acquire insights is innovation management [34]. Sustainability in procurement is typified by a ‘policy-resistant dynamical system' [29], focusing on strategy development in terms of policymaking instead of implementation via operations. [18] summarized below measures to improve the effectiveness and efficiency of sustainable procurement adoption within the construction industry.• Allocating and keeps track of the activities undertaken by each stakeholder serving to the sustainable procurement process• Setting quantifiable sustainable procurement targets and converts them into indicators and limits• Allocating and maintains track of the tasks assumed by each party contributing to the sustainable procurement process• Prevent communication breakdown, re-work, and clash and each team member's task demarcations must be stated clearly• Exposure to the experience of previous project activities • Getting to decide on the best possible planning frameworks and brings them into practice• Backing to make sure that sustainability principles are fully integrated into the assessment of various suppliers and tender selection• Performing quality assurance following sustainability guidelinesMoreover, it supports the notion that integrating sustainability into supply chain management is difficult [26]. Auditing and ISO 14001 are not present or intended actions for policing policies. In order to achieve better co-operation in the procurement process, the author suggested classifying products and making more environmentally friendly alternatives noticeable, as well as supporting initiatives for Environmental Management Systems and standards and attempting to make Sustainable Procurement as easy as possible [13]. [34] recommended a six-step strategic approach involving sustainable procurement as shown in Figure 1.

| Figure 1. Six-step strategic approach for sustainable procurement (Source: [Meehan and Bryde, 2015]) |

4. Methodology

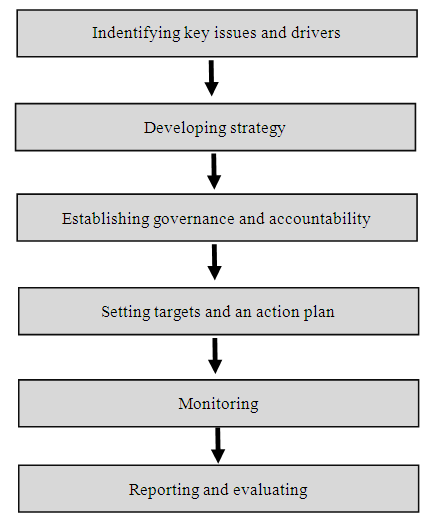

- According to [27], research methodology is a systematic strategy to achieving research aims and objectives. Consequently, it can be understood as determining the outcome of a given problem on a specific subject or problem, often known as a research problem. In methodology, the researcher employs a variety of criteria to solve/search the given research problem. The research approach, also known as the research strategy, is the method for pursuing the study purpose. According to [14], there are three primary approaches to conducting research: qualitative, quantitative, and mixed methods.The study aimed to identify the major obstacles to sustainable procurement as well as ways to overcome them. As a result, a literature review was undertaken to identify benefits, drivers, obstacles described above, initiatives, and other relevant elements. Subsequently, a questionnaire survey was conducted to rank these obstacles and strategies in order of preference of the industry practitioners. Statistical data analysis tools were afterward used to identify the most significant obstacles and measures during data analysis. This reflects the research's quantitative nature. As a result, a quantitative research approach was used within the study. Quantitative research techniques were used during data collecting because the study was based on a quantitative research strategy. A total of 40 surveys were distributed to professionals who had already been engaged in sustainable procurement practices. Only 30 of 40 industry practitioners answered with completed surveys including Project Managers, Engineers, and Architects as shown in Figure 2.

| Figure 2. Respondent composition based on the type of occupation |

Where,W = Weightage given to each variable based on the respondents’ level of agreementA = Highest weight on the scaleN = Total number of respondentsAs a result of the factors included in the extensive questionnaire survey, the most acceptable factors were chosen. Table 1 criteria were used to determine the variable's importance and relativeness.

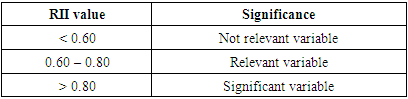

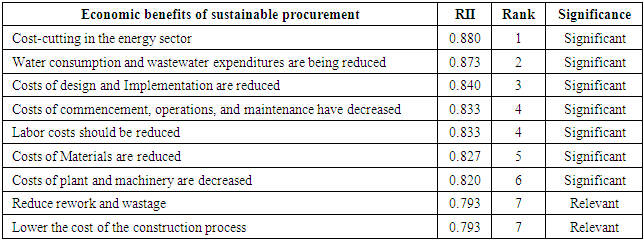

Where,W = Weightage given to each variable based on the respondents’ level of agreementA = Highest weight on the scaleN = Total number of respondentsAs a result of the factors included in the extensive questionnaire survey, the most acceptable factors were chosen. Table 1 criteria were used to determine the variable's importance and relativeness.

|

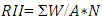

| Figure 3. Respondent work experience of respondents |

5. Results and Discussion

- This section depicts the research findings of the study, and the analysis and explanation of those findings. There were 25 project managers, five engineers, and one architect in the sample. The questionnaire was developed using the outcomes of the literature review. The questionnaire was conducted amongst different construction industry experts who were exposed to sustainable procurement. The majority of them had worked in the construction industry for 5 to 10 years. The questionnaire consists of five sections, each of which contained closed-ended questions. In essence, the Profile aims at identifying the respondent's experience and position. Then the focus of sustainable procurement in construction projects was aided in identifying the factors influencing sustainable procurement and the benefits in terms of environmental, social, and economic considerations. Following that, sustainable building standards were utilized to determine which sustainable building standards were now in use in the construction business. Finally, challenges for sustainable procurement were assessed based on industry experts' perspectives, which aided in identifying measures to address the assessed challenges for sustainable procurement. Consequently, to reach the core objectives of this study, the quantitative data produced from the questionnaire survey were analyzed using MS Excel and SPSS software.

5.1. Industry Perception to Implement Sustainable Procurement in Construction Projects

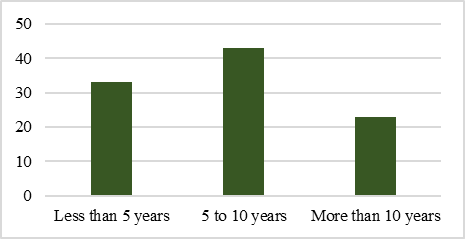

- The respondents' opinions on sustainable procurement were evaluated out whether it has become a prerequisite in today's construction sector as shown in Figure 4. The SBP should be implemented into building projects was unanimously agreed upon by 97% of responders. While no one said implementing sustainable procurement is unnecessary, 3% of respondents have a neutral perception regarding this idea.

| Figure 4. The necessity of sustainable procurement |

5.2. Key Factors Affecting the Adoption of Sustainable Procurement

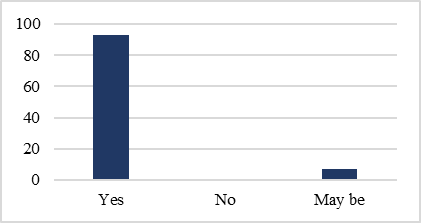

- Respondents to the questionnaire survey were requested to rate their level of agreement with each of the driving factors for the adoption of sustainable procurement. According to the survey's findings, Figure 5 described "Global warming" as the most key factor influencing the necessity of sustainable procurement, with 30% of respondents rating it as such, and 27% agreeing that "Scarcity of resources" has an impact on the adoption of sustainable procurement. Furthermore, with only 3% responses, "recognized sustainability concern" and "peer pressure" were the least influencing variables for sustainable procurement adoption.

| Figure 5. Influencing factors for sustainable procurement in the construction industry |

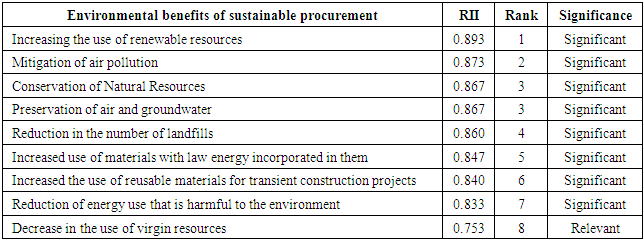

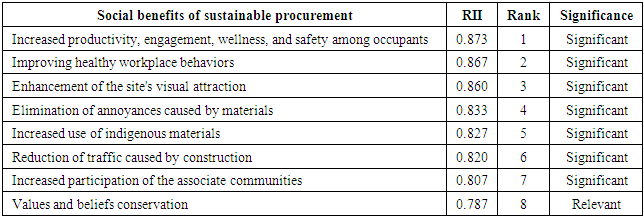

5.3. Evaluation of Environmental Benefits of Sustainable Procurement

- RII was used to understand the perception of environmental, social, and economical benefits, and the results are shown in Table 2, Table 3, and Table 4. The literature review established nine potential environmental benefits, eight potential social benefits, and nine potential economic benefits of sustainable procurement adoption. Then, as per Table 1 criteria, determine the importance and relativeness of environmental, social, and economic benefits. The RII value for each environmental benefit is shown in Table 2 based on each respondent's concurrence on given advantages during the survey. According to the analyzed results given in Table 2, the most favorable environmental advantage in implementing a sustainability building procurement in the construction industry is ‘increasing the use of renewable resources’ with RII 0.893. Out of the nine environmental potential advantages, air pollution mitigation, conservation of natural resources, preservation of air and groundwater, reduction of landfills, and increased use of materials with law energy incorporated in them were outlined as the next top six. 'Decrease in the use of virgin resources' (RII-0.753) is the least beneficial environmental aspect in implementing a sustainable procurement paradigm, according to professionals responses.

|

|

|

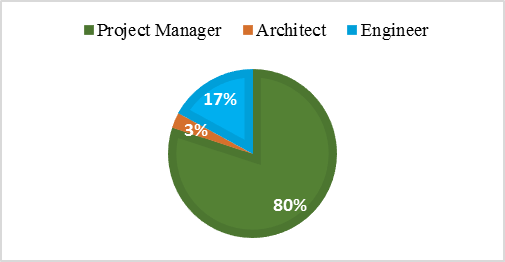

5.4. Analysis of Barriers for Sustainable Procurement

- The most crucial barriers to sustainable procurement in the construction industry are identified using a quantitative methodology in this study. The RII value was used to execute factor analysis on twenty items as barriers to sustainable procurement. These barriers are tabulated in Table 5, representing the statistical data derived from the respondents’ opinions. The sixty barrier factors extracted for as significant which accounted for more than 0.800 RII value. Among them, the proposed barrier ‘tender evaluation can be difficult when considering the cost of the entire product/service life cycle’ identified as the most significant barrier for sustainable procurement in the construction industry. This was evidenced by the RII value of 0.907. Besides, ‘Lack of support from the senior management on the implementation of the concept’ was ranked as the second place in RII based ranking, acquired RII value of 0.887. ‘People's inadequate awareness of sustainable procurement’, ‘lack of capacity in required human resources’, ‘the perception that adopting sustainable alternatives will limit competition’, and ‘difficulty to meet deadlines due to a lack of political backing’ barriers obtained RII values between 6.00 and 8.00. Thus, these were considered as relevant barriers to sustainable procurement in the construction industry.

|

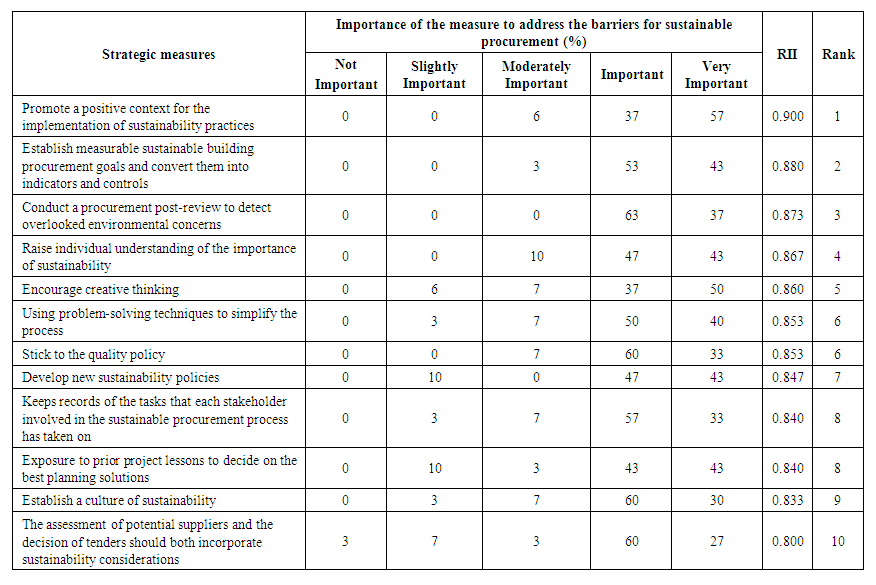

5.5. Evaluation of Strategic Measures to Address the Barriers for Sustainable Procurement

- Through the literature survey, twelve possible measures to address the barriers to sustainable procurement were identified and they were subjected to respondents’ opinions during the questionnaire survey. Table 6 presents these measures and the statistical data derived from the respondents’ opinions corresponding to each measure. Accordingly, Table 6 demonstrates the percentage of respondents for each measure based on five degrees of importance, RII value, and significance based on the RII of ranks given by each respondent.

| Table 6. Measures to address the barriers for sustainable procurement |

6. Conclusions

- The construction sector is a massive business that has a considerable impact on a country's economic growth. Construction procurement accounts for a large share of the construction sector, with civil engineering and other infrastructure operations accounting for the remainder. Individuals in the present era are hurrying to achieve sustainability to benefit themselves and society as a whole and the planet itself. Due to the construction sector's new concept, the sustainable procurement system faces several obstacles that must be carefully addressed to undertake a project within sustainability guidelines effectively. Thus, it is critical to investigate the advantages, drivers, obstacles, and strategies for overcoming those challenges for the client and society. As a result, the study aimed to examine the characteristics above and design measures to overcome problems in the construction sector for sustainable procurement.The research identified sustainable procurement's economic, social, and environmental benefits and reflected them through data analysis. As a result, the considerable environmental benefits of sustainable procurement included increasing using of renewable resources, reducing air pollution, and conserving natural resources. Other social benefits of sustainable procurement include increased productivity, engagement, wellbeing, and safety among occupiers, improving healthy workplace practices, and improving the site's visual attraction. Cost-cutting in the energy sector, reducing water consumption and wastewater expenditures, and lower design and implementation costs have been key economic benefits. Then the challenges identified were statistically analyzed. As a result, challenging tender evaluation when considering the total cost of the product/service life cycle has emerged as the most significant barrier to sustainable procurement. The second and third most impacting barriers were recognized as a lack of senior management support for the concept's implementation and a lack of sustainable procurement policy. During the questionnaire study, necessary measures for overcoming barriers for sustainable procurement were identified, and they were prioritized in order of importance based on the responses. As a result, twelve variables were subjected to statistical analysis. Three specific measures were recognized as important indicators for the verified challenges: promote a positive context for implementing sustainability practices, establish measurable, sustainable procurement goals and convert them into indicators and controls, and conduct a procurement post-review to detect overlooked environmental concerns.The use of sustainable procurement in the construction industry provides the globe with enormous rewards. Clients are advised to meet their building demands through sustainable procurement, based on the findings of this study. It was discovered that the construction industry is short on new ideas and that innovations are not well received. As a result, the innovators have lost motivation, and sustainable procurement has been hindered. Thus, it is preferable to encourage designers, contractors, and subcontractors to develop unique ideas. In order to encourage and grow innovative solution providers, better incentive structures might be established.

ACKNOWLEDGEMENTS

- I would like to thank God, my daughter and wife for their support.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML