-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Construction Engineering and Management

p-ISSN: 2326-1080 e-ISSN: 2326-1102

2020; 9(4): 119-125

doi:10.5923/j.ijcem.20200904.02

Received: Aug. 24, 2020; Accepted: Sep. 15, 2020; Published: Sep. 26, 2020

Assessment on the Effect of Using Different Types of Formwork Materials on Building Construction: A Case Study in Benshangul Gumuz Region

Miskir Gebrehiwot1, Tewodros Getachew2

1Department of Civil Engineering, Assosa University, Assosa, Ethiopia

2Department of Construction Technology and Management, Assosa University, Assosa, Ethiopia

Correspondence to: Miskir Gebrehiwot, Department of Civil Engineering, Assosa University, Assosa, Ethiopia.

| Email: |  |

Copyright © 2020 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Concrete is a construction material which is a composition of coarse aggregate, fine aggregate, cement and water. The steps in Concrete production are Proportioning, mixing, placing and curing. Formwork material is a material used in casting process of fresh concrete to give the desired shape and surface. Due to the application of bad form working, a corrective work is required for the concrete surface. This process will require additional time and labor costs. This study intended to assess the effect of using different types of formwork materials on building construction of Benshangul Gumuz region. The general objective of this research is to assess the effect of using different types of formwork materials on different building construction works in Benshangul gumuz region. And the specific objectives are, to assess the materials and methods used for concrete formwork, to assess the major concrete finish quality problems related to form working and to assess formwork materials considering cost. The research follows both qualitative and quantitative approaches. Data was collected by interview and questionnaire and the data was analyzed by using charts and simple statistical formula of arithmetic mean calculation for a frequency distribution. According to the responses 69% of the respondents said that the most available formwork material is timber formwork. And 96% of the respondents agree that the method of form working applying is formwork set up of timber and eucalyptus connected by using nails and wires. Among the concrete quality problems related to form working, misplaced surface was the most rated problem with mean value of 4.7. According to the answer of the respondents, 78.43% said that timber is the cheapest form work material in the zones. The formwork material which permits many times of reuse is steel formwork. These implies even if the initial cost of timber formwork is lower, in long run steel formwork has better advantage in cost due to number of reuse.

Keywords: Cost, Formwork material, Method of form working

Cite this paper: Miskir Gebrehiwot, Tewodros Getachew, Assessment on the Effect of Using Different Types of Formwork Materials on Building Construction: A Case Study in Benshangul Gumuz Region, International Journal of Construction Engineering and Management , Vol. 9 No. 4, 2020, pp. 119-125. doi: 10.5923/j.ijcem.20200904.02.

Article Outline

1. Introduction

- Concrete is the most commonly used construction material for load bearing and non-load bearing elements. Its ability to be shaped and reflect the surface against which it is placed enables it to provide an extensive range of decorative and architectural off-form finishes which can eliminate the need for additional, and often costly, applied finishes using other materials [1]. Since cost-efficiency is one of the most crucial points of good concrete construction, Identification of factors which can increase the costs required to gain specified quality of the concrete product will help to improve the cost effectiveness of construction operations. With very few exceptions, concrete elements are formed by a casting process: the fresh concrete is placed and compacted in formwork or a mold which is essential to concrete construction. It molds concrete to the desired size and shape and control its position, alignment, and surface shape and many kinds of interaction between concrete and formwork combine to affect the quality of concrete product. Using improper formwork materials and workmanship during casting can result in many concrete finishing problems such as discoloration, stains, and dusting are attributed to concrete formwork. Also, some deformed concrete surfaces are due to deformed formwork systems caused by repetitive reuse of formwork and inadequate support of formwork [2]. After forms are removed repairing concrete structure is not an easy duty task hence they call of a heavy duty tools, most concrete cavities such as tie rod holes should be filled unless they are intended for decorative purposes. Honeycombed area must be repaired and stains removed to present a concrete surface that is uniform in color, it needs for the use of jack hammer or hammer drill, chisel and other tools. All of these operations can be minimized by formwork type selection and exercising care in constructing the formwork and placing the concrete. In general, the use of improper formwork, Repairing the surface and lack of good workmanship during placing concrete leads to use additional labours, materials and special tools maximize the cost of construction/ productivity, result in high costs per unit. Concrete surface finishing process takes relatively longer time to provide a uniform appearance. The quality of concrete surfaces is mostly not good since formworks are not designed and constructed properly. Hence, the use of quality as well as decorated formworks which solves the above problem is very mandatory to have better concrete surface without affecting the strength and durability of concrete. Therefore, this case study is to analyze the costs of the construction by using different types of formwork and to assess the techniques bringing quality and low cost of formed surface finish.In Ethiopia even if different types of formwork are available there is a lack of due consideration of cost, quality, time and safety criteria on the selection of Formwork materials. And care is not given on the off form finish. Formwork materials which do not fulfil good quality criteria are commonly used with many repetitions. There is misunderstanding on the costs difference while using good and poor quality formwork.Forms should be accurately set, clean, tight, adequately braced, and constructed of or lined with materials that will instruct the desired of the form finish to the hardened concrete. Wood forms, unless oiled or otherwise treated with a form-release agent, should be moistened before placing concrete, otherwise they will absorb water from the concrete and swell. Forms should be made for removal with minimum damage to the concrete. With wood forms, use of too large or too many nails should be avoided to facilitate removal and reduce damage. For architectural concrete, the form-release agent should be a non-staining material ACI Committee 347 (1999) [3].Burnt oil as a form release agent is most commonly used but it results discolouring the concrete surface by making blotchy appearance on it. This will affect the final concrete product and leads to additional expenses to cover the defected surfaces.During fixing the formwork there is a lack of trained workmanship and a lack of attention on detail of formwork this will leads leakage of concrete paste at the joint and produce below the specified finishing quality, then considerable corrective works such as chiselling, additional plastering and coating is required.Chiselling the surface of concrete considered as a habit. And there is lack of knowledge on chiselling. Chiselling the surface of concrete structure affect the strength and disturbs the bond between the concrete constituents and between the concrete and the reinforcement bars which in turn creates macro cracks and reduce the durability of concrete structure.During correcting the surface of concrete by chiselling the persons who engaged for this work and the workers on the site exposed for different damages and handicappers, since there is safety and health problem. In Benshanguel gumuz region there are many building constructions owned by governmental and privet institutions. One of the major causes of poor quality concrete finishes on building construction is the quality of formwork materials and methods applied during form working.The finished surface quality of the concrete is directly affected by the formwork and form working materials. Poor workmanship and a lack of attention to details while installing formwork leads to concrete leakage and rough finishes.If the forms do not produce the specified finish, considerable corrective work such as grinding, patching, rubbing, or coating may be required.If the forms move out of place, the misalignment destroys the integrity of the structure or affects installation of the structural frame, the building’s façade or building equipment. Formwork must stay in place until the concrete is strong enough to carry its own weight and any external loads. Some of the bad effects that forms can potentially have on the surface are bad form joints, offsets or poor facing material [7].

1.1. Form work Materials

1.1.1. Timber Formwork

- Timber used for shuttering for exposed concrete work should have smooth and even surface on all faces which come in contact with concrete. Timber mostly used for Form-face supports such as studs, bearers, joists and Wallers.Among the advantages of timber formwork are as follow:• Easy handling because it’s light • Easy to disassemble • Damaged parts can be replaced with new one • Very flexible Among the disadvantages of timber formwork are as follow:• Can only be re-used 5 or 6 times.• If the timber is dry, it will absorb moisture from wet concrete which could weaken the resultant concrete member. • Timber with high moisture content (more than 20% moisture content), wet concrete will shrink & cup leading to open joints & leakage of grout. [5]

1.1.2. Steel Formwork

- This consists of panels fabricated out of thin steel plates stiffened along the edges by small steel angles. The panel units can be held together through the use of suitable clamps or bolts and nuts. The panels can be fabricated in large number in any desired modular shape or size. Steel forms are largely used in large projects or in situation where large number reuses of the shuttering are possible. This type of shuttering is considered most suitable for circular or curved structures. If the form is rusty, you might get rust on the surface of your concrete [6].Advantages• Steel forms are stronger, durable and have longer life than timber formwork and their reuses are more in number. • Steel forms can be installed and dismantled with better ease and speed as compared to timber formwork. • Steel formwork does not absorb moisture from concrete. • Steel formwork does not shrink or warp.Disadvantages• Limited size or shape.• Excessive loss of heat. • A very smooth surface will be produced which give problems during finishing process. • Limited fixing [6]. The quality of the resulting concrete is dictated by the quality of formwork materials and workmanship. Many concrete related problems such as discoloration, stains, and dusting are attributed to concrete formwork. Also, some deformed concrete surfaces are due to deformed formwork systems caused by repetitive reuse and inadequate support of formwork. The quality of surface finish of concrete is affected by the formwork materials used [12].The materials used will determine the perfection of concrete surface. Formwork materials must be impermeable to ensure the perfection of the concrete surface and the finished concrete shape will not be altered. To ensure the high quality of concrete, materials which are impermeable, have smooth surfaces and will not easily shrink or swell should be used to construction formwork. This is to ensure the water tightness and regularities of formwork so that the concrete produced will have smooth surfaces, even colour and correct dimension and shape of concrete.Timber which is a common formwork material is a porous material which can absorb water. The porosity of the timber is various and thus leading to variable degree of concretes mix water absorption. This might cause significant differences of colour tone in the concrete surface. When timber absorbs bleed water from the concrete surface, the moisture content of the timber formwork will increase consequently with the time of the formworks are reused. If unpigmented plain concrete is used, the differential moisture content of timber formwork will cause a distinct variation in shade of the stripped concrete from dark on initial pours, to light on subsequent pours. Other than that, a mixture of old and new timber as formwork materials very often accentuates uneven colour of concrete surface. Besides that, timber has organic substances such as lignin which can result in discolouration of the concrete. This will cause the uneven colour of the concrete and affect the aesthetics of the concrete surface [13].Furthermore, as timber formworks are erected from pieces of timber; it is difficult to make the joints water tight. In addition, if we use dry timber formwork, it will absorb the moisture from fresh concrete and swell and bulge. These problem will give unwanted profile for the finished concrete. If timber with high moisture content is used, it will shrink and cup which will cause the open joints. If we use open joints, the mortar will leak and results in the disfigurement of the concrete such as honeycombing. Furthermore, common defect in timber such as bow, crook and twist caused by improper drying will cause poor alignment and finally result in uneven concrete surface or concrete disfigurement. Plastering is need for levelling the uneven concrete surface before applying the floor finishes such as tiles and paints. If the leakage is serious, it might properly affect the strength of concrete. Steel can provide a strong, impermeable, large and uniform formwork [15].Good quality, straight stock is need for timber formwork to ensure the perfection of concrete cast. A layer of mould oil should be applied to the inside surface of formwork to reduce the uneven colour of concrete. But, mould oil will increase the risk of blow holes. Blow holes are small holes, of less than 15mm in diameter, caused by air being trapped between the formwork and concrete face [14].But, a very smooth surface produced by steel formwork might also will bring problems for process concrete finishing. To make sure the quality, materials and equipment should be checked on arrival to make sure they are what is required by the designer. They should be examined for reduction of section or deterioration, particularly if they have been previously used. It should be ensured that components, such as pins, are to the manufacturer’s specification. All materials and items of equipment should be checked to ensure that they are in the intended place, and of the proper type. Material may be of the wrong grade or incorrect cross-section. Dimensions should be checked, to ensure that the form is in the right place and spacing are not too great. It is important that all connections are done up tightly, so that any movement is minimal and leakage is kept under control [15].

2. Research Methodology

- Both qualitative and quantitative research approaches were used for this study. But most widely the qualitative approach was used and the data was analysed quantitatively.During collecting data, the current and previous trends of selecting formwork materials on different selected sites were described. Both primary and secondary data were collected. The primary data was collected by observation, interview and questionnaires and the secondary data was gathered by reviewing literature from books, journals, related research works and other sources.

2.1. Population

- The population of the study was all building construction projects which are owned by government in Assosa zone and Metekel zones of Benshanguel gumuz region.

2.2. Sample Size and Sampling Procedure

- The sampling procedure was purposive sampling approach. Among all building construction projects, only the ongoing construction projects were selected because observing the finished surface and method of form working is vital for this study. According to the data gathered from construction work and urban development bureau there are 21 ongoing building construction project sites in Assosa and Metekel Zones. From the selected construction projects, 2 contractor’s representatives, 2 consultant’s representatives, and 2 site carpenters were selected for data collection. Therefore, a total of 6 individuals per site were selected.

2.3. Data Processing and Analysis

- The major work inputs for a given research work are the data collected by the researcher. The data then was carefully analysed to get the effective output. The number of the respondents and their response was analysed by using charts, and mean value calculation.

2.3.1. Mean Value Determination

- The rating given by different respondents were collected and mean values are determined for each using equation (1) simple statistical formula of arithmetic mean calculation for a frequency distribution, with minor modifications. The modification here is that the rating for these paper was from 5 to 1. The rates given as a choice were 5-strongly agree, 4-agree, 3-neutral, 2-disagree and 1-strongly disagree.

| (1) |

3. Result and Discussion

3.1. Questionnaire Response Rate

- The total number of questionnaires distributed to respondents were 126. Among these, 66 questionnaires distributed in assosa zone for contractor, consultant and site workers. out of 66 questionnaires, 56 of the questionnaires were collected and 52 of them were considered valid. The validity is determined based on adequacy of the responses given. If the questionnaires are not answered fully and partially, responses are considered invalid. Accordingly, from the 60 questionnaires distributed to respondents in metekel zone, 52 questionnaires were returned and 50 of them were considered valid. Accordingly, a total of 126 questionnaires were distributed to respondents and 108 of them were collected out of which 102 questionnaires with valid responses were collected with 80.95% response rate. This response rate is significant and representative enough as compared to what Richard Fellows and Anita Liu in 2008 have stated. They mentioned that a useable response rate of 25-35% is expected from postal questionnaires [16].

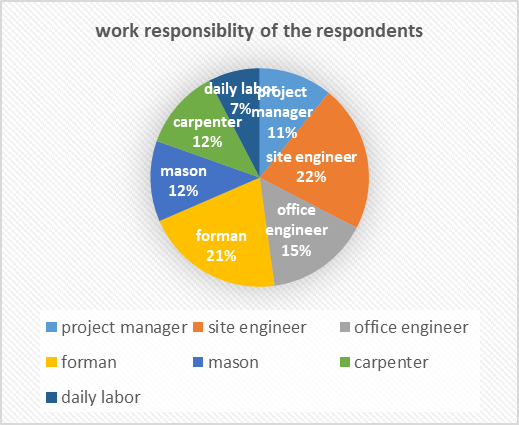

3.2. General Information of the Respondents

- The total number of questionnaires which are accepted as valid were 102. Among these, 52 were from assosa town ongoing construction sites and the rest 50 were from metekel zone ongoing construction sites.

| Figure 1. Work responsibility of respondents at the site |

3.3. Material and Methods of Form working

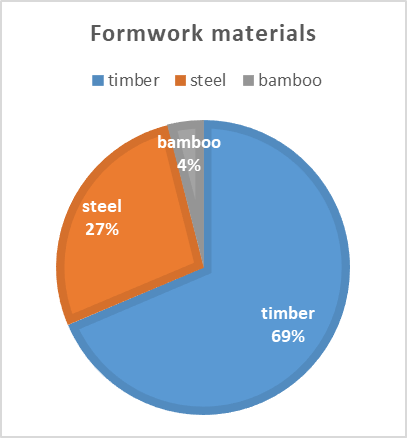

- During assessing the materials and methods of form working, 70 respondents said timber is the available formwork material, 28 respondents said metal and the other 4 said bamboo formwork materials are the most available around the region.According to Figure 2, 69% of the respondents agreed that the most available formwork material is timber. The second available formwork material is steel or metal formwork since 27% of the respondents said so. The left 4% respondents said the most available formwork material is bamboo.

| Figure 2. Formwork material available in the region |

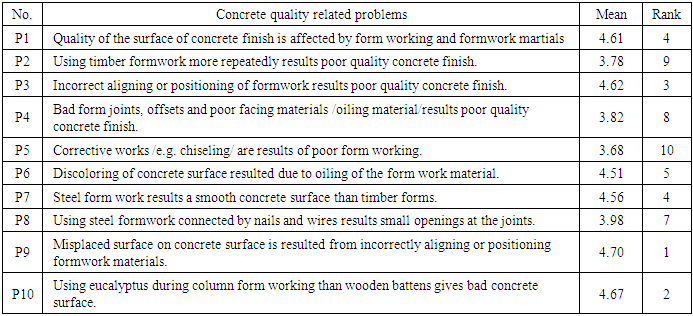

3.4. Quality of Concrete Finishes

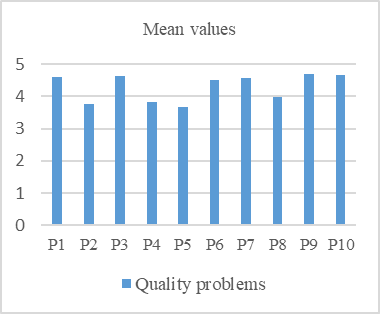

- The different points related to concrete finish quality were raised on the questionnaires to be rated by the respondents. The rates were 5-strongly agree, 4-agree, 3-neutral, 2- disagree and 1-strongly disagree.“The quality of concrete finish is affected by form working and formwork materials.” (P1) was the first issue that was raised on the questionnaire. Accordingly, among the total 102 respondents, 90 of them were strongly agree, 10 were agree, 2 of them were neutral.“Using timber formwork more repeatedly results poor quality concrete finish.” (P2) was the second issue that was raised on the questionnaire. Accordingly, among the total 102 respondents, 50 of them were strongly agree, 30 respondents were agree, 10 were disagree, and 12 of them were neutral.“Incorrect aligning or positioning of formwork results poor quality concrete finish.’’ (P3) was the third issue that was raised on the questionnaire. Accordingly, among the total 102 respondents, 88 of them strongly agree, 12 respondents were agree, 2 were disagree.“Bad form joints, offsets and poor facing materials /oiling material results poor quality concrete finish.” (P4) was the fourth issue that was raised on the questionnaire. Accordingly, among the total 102 respondents, 45 of them were strongly agree, 30 respondents were agree, 10 were disagree, 10 were neutral and 7 of them were strongly disagree.“Corrective works /e.g. chiselling/ are results of poor form working.” (P5) was the fifth issue that was raised on the questionnaire. Accordingly, among the total 102 respondents, 10 of them were strongly agree, 20 respondents were agree, 50 were disagree, 12 respondents were neutral and 10 of them were strongly disagree.“Discolouring of concrete surface resulted due to oiling of the form work material.” (P6) was the sixth issue that was raised on the questionnaire. Accordingly, among the total 102 respondents, 83 of them were strongly agree, 5 respondents were agree and 12 were neutral.“Steel form work results a smooth concrete surface than timber forms.” (P7) was the seventh issue that was raised on the questionnaire. Accordingly, among the total 102 respondents, 75 of them were strongly agree, 10 respondents were agree, 5 respondent were disagree, 7 were neutral and 5 of them were strongly disagree.“Using steel formwork connected by nails and wires results small openings at the joints.” (P8) was the eighth issue that was raised on the questionnaire. Accordingly, among the total 102 respondents, 50 of them were strongly agree, 30 respondents were agree, 10 were disagree, 2 respondents were neutral and 10 of them were strongly disagree.“Misplaced surface on concrete surface is resulted from incorrectly aligning or positioning formwork materials.” (P9) was the ninth issue that was raised on the questionnaire. Accordingly, among the total 102 respondents, 92 of them were strongly agree and 10 of them were agree.“Using eucalyptus during column form working than wooden battens gives bad concrete surface.” (P10) was the tenth issue that was raised on the questionnaire. Accordingly, among the total 102 respondents, 65 of them were strongly agree, 20 respondents were agree, 10 were disagree, and 7 of them were neutral. By applying equation (1), the mean values and rank of the ten problems were determined.

| Figure 3. Mean values of the responses for the quality problems |

|

3.5. Cost of Form Working

- In assessing the cost of formwork materials, 80 respondents (78.43%) said that timber has the lowest cost. whereas 20 respondents (19.6%) said that coated plywood has the lowest cost and 2 of the respondents (1.96) said steel has the lowest cost. Other choices like bamboo, barrel and prefabricated /modular formwork materials were not selected by any of the respondents as a cheapest formwork material. From the above finding timber is the cheapest formwork material.The cost inquired by corrective actions on concrete surface affects the initial direct cost of the construction. From the respondents 98 of them agree with this situation. Whereas, the rest 4 respondents said this has no effect on the construction cost. These implies if the form work material and form working is not good, additional cost for plastering, chiselling or other corrective works are inquired. Additionally, using timber formwork more repeatedly will result in alignment problem. To overcome such problems care should be given in selecting formwork materials and form working methods.

4. Conclusions

- The main objective of these research was to assess the effect of using different types of formwork materials on different building construction projects in Benshangul Gumuz region. And specifically to assess the materials and methods used for concrete formwork, to assess the major concrete finish quality problems related to form working and to assess form work materials considering cost. In considering the parameters which are material and methods, concrete finish quality problems and cost of formwork, data analysis has been done for the collected data. Accordingly, the following conclusions were made.Ø The most available and applicable formwork material is timber.Ø Method of form working in the most construction sites are formwork set up of timber and eucalyptus connected by using nails and wires. On some of the construction sites eucalyptus replaced by wooden battens which results in better joints and good alignment.Ø Misplaced surface on concrete is resulted due to bad form working and it is the most rated concrete quality problem with mean value of 4.7. Ø Timber formwork is the cheapest form work material than steel formwork initially. But since steel form work can be reused many times, it is more economical to use steel form work in the long run.Ø The cost inquired by corrective actions on concrete surface affects the initial cost for construction.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML