Bashandy A. A.1, Etman Z. A.1, 2, Azier H. Y.3

1Associate Professor, Civil Eng. Dep., Faculty of Engineering, Menoufia University, Egypt

2Associate Professor, Civil Eng. Dep., Higher Institute of Engineering and Technology, Menoufia, Egypt

3Civil Engineer and M. Sc. Candidate 1

Correspondence to: Azier H. Y., Civil Engineer and M. Sc. Candidate 1.

| Email: |  |

Copyright © 2019 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

Lightweight concrete is an excellent alternative in terms of decreasing the dead load of the structure, while self-compacting concrete eases the pouring and compaction during construction. Combining the advantages of both types is a new field of research. Considering its lightweight structure and ease of placement, lightweight self-compacting concrete may be the answer to the increasing construction requirements of heavily reinforced structural elements. The main variables in this research are lightweight expanded clay aggregate LECA replacement ratio, using superplasticizers. The proposed approach is based on the modified mix design and incorporates the possibilities to realize a LW-SCC in function of two major parameters: density class and compressive strength class. To accomplish this, a total of 12 concrete mixes were used. Tests were performed on concrete specimens to determine the compressive strength, modulus of elasticity, and tensile strength. The unit weight was also measured. These tests provided an understanding of the behaviour of lightweight self-compact concretes under chloride or sulfates attacking. Results indicated that the better strength obtained as using a replacement ratio of 50% with a lower weight by about 30% compared to normal weight self-compacted concrete. Also, it showed that it is possible to manufacturing structural lightweight concrete self-compacting with sufficient durability. Hence it can be used for construction purposes and precast concrete elements with a moderate cost and satisfaction strength.

Keywords:

Lightweight self- compact, Concrete, Durability, LECA

Cite this paper: Bashandy A. A., Etman Z. A., Azier H. Y., Durability of Lightweight Self-compacted Concrete, International Journal of Construction Engineering and Management , Vol. 8 No. 5, 2019, pp. 127-135. doi: 10.5923/j.ijcem.20190805.01.

1. Introduction

Achievements in modern concrete technology have led to the introduction of lightweight concrete (LWC) and self- compacting concrete (SCC). LWC as a structure mass reducing which is well known in the construction industry as an excellent solution for decreasing the dead load of the structure, while SCC as workable concretes is a modern concrete that facilitates the pouring and cast of concrete elements without compaction. In recent years, some efforts have been made to combine the advantages of these two types of concrete in one package called lightweight self-compacting concrete LW-SCC [1]. The three major characteristics of concrete are workability, strength, and durability. It is believed that workability is related to the fresh concrete while strength and durability are related to the hardened concrete. In other words, mix design and the fresh concrete properties are the most critical points to control concerning the mechanical characteristics of hardened concrete [2]. Generally, the compressive strength of LW-SCC is a fundamental parameter to estimate its other mechanical properties. In spite of available studies on the advantages of LW-SCC associated with its high performance in the fresh state, there are less available studies regarding the expected hardened properties for mechanical responses like compressive strength. LW-SCC is highly sensitive to changes in mix component properties and their proportions; therefore it requires increased quality control. The typical characteristics of LW-SCC mix proportions, which are necessary to ensure adequate fresh properties, can have significant effects on hardened concrete properties like strength, dimensional stability, and durability [3]. The early evaluation of hardened concrete properties is very important. The problem is that following the hardening process, the quality and mechanical properties do not improve. The structural behavior of concrete relies on mixing proportions and material properties of the composite system and these factors do not change after hardening. Despite different codes of practice about LWC mix design and some rare publications about SCC in the literature, there is no reference and technical draft about LW-SCC mix design and its application. However, owing to the expected advantages of LW-SCC in terms of cost efficiency and reduced construction time, research to comprehend the complicated nature of this new material is increasingly growing in different parts of the world. LWAC mixed with other lightweight aggregates also shows advantages for structure weight, anti-seismic ability, and fire protection and prevention. Thus, it is more energy-efficient, is beneficial for disaster prevention, ideal for high-rise buildings requiring anti-seismic structures, and reduces energy consumption. In addition, the properties of LWAC include high strength, heat insulation, sound absorption, water resistance, fire prevention, high durability, volume stability, ease of use, and cost-efficiency [4] For instance, the compressive strength of the LW-SCC is influenced by the aggregate type and the water to cement and water to total powder [5]. The relation between cement paste and aggregates is very important in the mix design of concrete. SCC has a higher paste amount than conventional concrete and LWC to facilitate the flowing of aggregates to fill any voids inside the formwork. Paste coating of aggregates to reduce the friction and direct touching between aggregates can improve the flowability of fresh concrete. Controlling the water to cement ratio results in a denser and stronger concrete. In LW-SCC, this problem is even more obvious due to insufficiencies in the initial energy of lightweight aggregates in relation to moving along with the lightweight aggregates in the cement paste [6]. To keep the balance among the proportions of LW-SCC is therefore important to achieve the required flowability in the fresh state and the planned density and high quality in the hardened state. Packing density theory is a method of concrete mix design that has been successfully used in LW-SCC by determining the optimum mortar to aggregates packing voids ratio [6]. The main steps to attain the LW-SCC mix design in this method are: (a) minimizing the voids volumes related to the coarse aggregate, (b) minimizing the water to cement ratio, (c) maximizing the density of the cementations materials and (d) optimizing the flowability and requirements of the fresh concrete. Now with a range of proprietary LWA available, manufactured mainly using industrial by-products such as fly ash and blast furnace slag, LWC in the strength range of 30–80 MPa can be easily made. Previously, the authors have evaluated and reported the long term strength development and durability characteristics of LWC made with lightweight coarse and lightweight fine aggregates [6]. Durability studies on lightweight aggregate Self Compacting Concrete (SCC) made with expanded clay aggregate (LECA) partially replacing conventional coarse aggregate. Investigations carried out by different researchers using some lightweight aggregates in SCC have proved that Light Weight Self Compacting Concrete LW-SCC can be manufactured and used by judiciously choosing the LWA type [8]. The durability studies include chlorides and sulfates resistance. The densities of LW-SCC varied from 1870 kg/m3 to 1950 kg/m3. Durability is a very important engineering property of concrete. In the present investigations, some of the durability properties of the normal concrete SCC and lightweight concrete SCC like chemical attack (chlorides attack and sulfates attack), capillary water absorption by the sorptivity test were studied. The paper describes the details of investigations and results on LECA based LW-SCC. The basic criteria are required to achieve self-compacting light concrete: high deformability, high passing ability or resistance to segregation [9].

2. Research Significance

There is a wide range of publications about LWC concerning different lightweight aggregates and mix proportions. However, SCC is a completely new topic in the construction industry and it has therefore attracted increasing research interest especially during the last decade. Since LW-SCC is a combination of two materials and one part is not fully investigated, it needs much more market research.The importance of this study is to identify the performance of LW-SCC compared to conventional SCC concrete on the attacking of chlorides and sulfates. The outcome of this study is expected to decrease the concrete weight by avoiding the undesired results of concrete strengths loss due to attacking. Despite the limited number of publications, the collected data gives the impression of being adequate for valid and useful systematic assessment of the variety of mix parameters and properties in statistical expressions. Above all, this will develop the idea of what can be expected with LW-SCC or prospective users and researchers. This also gives interested and involved people a context in which to assess their own practices and to inform other researchers about their products. Since LW-SCC is a novel topic in the construction industry, a comprehensive collection of data to date, accompanied by analytical comparisons will be a key starting point for upcoming investigations and the application of LW-SCC in real projects. The main objectives of this study are; evaluate the feasibility of using some valid lightweight aggregates as a partial replacement of convential aggregates to have a structural lightweight self-compacted concrete LW-SCC and study the durability of this concrete type under the attack of chlorides and sulfates as long term behavior. The outcomes of this research can be used to produce a lightweight self-compacted concrete to combine the advantages of both types together in the field of construction.

3. Experimental Program

All tests were carried out in the Construction Materials Laboratory in the Civil Engineering Department, Faculty of Engineering, Menoufia University.

3.1. Materials

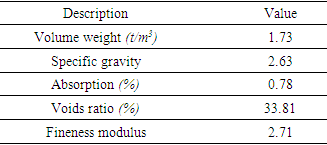

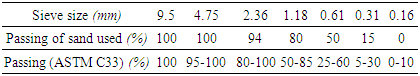

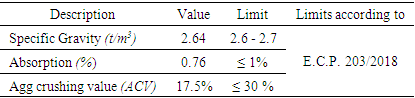

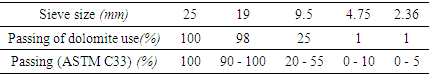

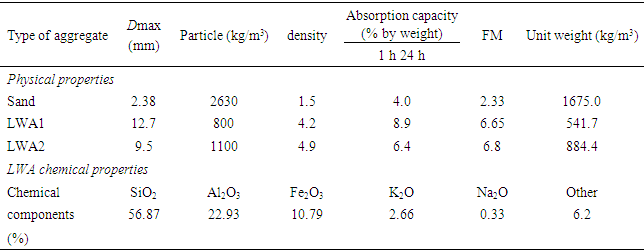

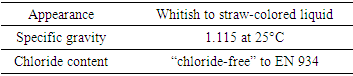

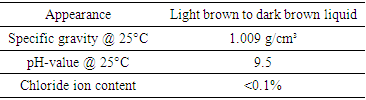

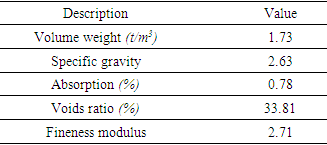

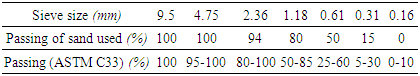

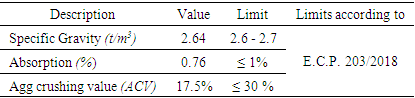

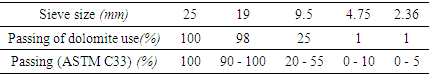

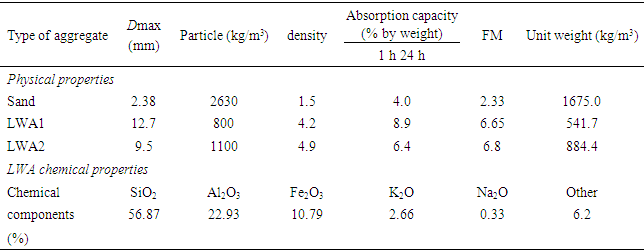

The cement used is the ordinary Portland cement CEM I 52.5 N from the Suez factory satisfied the Egyptian Standard Specification (E.S.S. 4756-1/2012) [10]. The fine aggregate is natural siliceous sand which satisfies the (E.S.S 1109/2008) [10]. The mechanical properties of fine aggregates are shown in Table (1) and grading is shown in Table (2). The coarse aggregate is a natural crushed dolomite with a maximum size of 10 mm satisfying ASTM C-33 [10] as shown in Tables (3) and (4). The expanded clay aggregates (LECA) as lightweight aggregate with properties indicated in Table (5) was used. It was manufactured in a rotary kiln is lined internally in the firing zone with refractory. Micro silica (silica fume) is a product of the ferrosilicon alloys industry. The product is a rich silicon dioxide powder where the average particle size is around 0.1micrometers. BASF MasterGlenium SKY 504 and Master matrix 110 A chemical polycarboxylic ether superplasticizer (SP) for the production of high-quality ready-mix concrete with low water-cement ratio and exceptional workability were used as viscosity-enhancing agent (VEA). It contains a polycarboxylic -based copolymer-based mixture and modified cellulose product to achieve the dual-action effect of high-range water reducer and viscosity-modifying admixture, respectively. It meets the requirements for superplasticizers according to European specification [EN934-2], and American specification [ASTM- C-494 type G and F). Mechanical and physical properties are given in Table (6) and (7).Table (1). Physical and mechanical properties of sand used

|

| |

|

Table (2). Grading of fine aggregate according to (ASTM C33) and grading of natural sand used

|

| |

|

Table (3). Physical and mechanical properties of dolomite used

|

| |

|

Table (4). Grading for coarse aggregate according to ASTM C33 and grading of the natural dolomite used

|

| |

|

Table (5). Chemical and physical properties of aggregates

|

| |

|

Table (6). Technical information of MasterGlenium SKY 504" (as provided by the manufacturer)

|

| |

|

Table (7). Technical information of MasterMatrix® 110" (as provided by the manufacturer)

|

| |

|

3.2. Concrete Specimens

Tests were performed on concrete specimens to determine the compressive strength, modulus of elasticity, and tensile strength. The unit weight was also measured. These tests provided an understanding of the behavior of these lightweight Concretes. Standard concrete cubes of 100x100x100 mm side lengths and of 150x150x150 mm side lengths with embedded bar of 12 mm diameter were used to determine the compressive strength (FCU) and the bond strength (Fb) respectively. Standard concrete cylinders 100x200 mm, indirect tension test (splitting method) and 150x300 mm were carried out to determine the tensile strength and modulus of elasticity strength respectively of concrete mixes. Prisms of dimensions 100x100x500 mm were cast and used as a flexure test specimen (fcr). Reinforced LW-SCC beams of dimensions 100x150x1000 mm were cast to study the behavior of reinforced concrete beams cast using this concrete type as shown in Fig. (1).  | Figure 1. Concrete specimens |

3.3. Concrete Curing

The curing is conducted conventionally (curing by water) for conventional concrete samples that the samples were kept at molds for 24 hours then they were removed and immersed in clean curing water at room temperature with a range of 25-32°C until testing age.

3.4. Sulfate Attack Simulation

To simulate the sulfate attack, the samples were immersed in a 20% concentration MgSO4 solution for periods up to 4 months continuously of immersion and cycling of immersion. All samples are immersed then tested after 2 and 4 months respectively. Results are compared to control samples of LW-SCC A5 as a control mix. The tested samples are standard cubes, cylinders, and prisms to obtain compressive, splitting tensile and flexure strength values. The effects of sulfate attack are obtained in terms of compressive, splitting tensile and flexure strengths.

3.5. Chloride Attack Simulation

In these experiments, the simulation of chlorides attack was performed by continuously of immersion and cycling of immersion of the samples in 5% concentration HCL solution for 4 months. All samples are immersed then tested after 2 and 4 months respectively. Results are compared to control samples of LW-SCC A5 as a control mix. The tested samples are standard cubes, cylinders, and prisms to obtain compressive, splitting tensile and flexure strength values. The effects of sulfate attack are obtained in terms of compressive, splitting tensile and flexure strengths.

3.6. Test Procedures

The experimental program was conducted in two stages. The first stage was performed to get a structural LW-SCC. That was conducted by two methods; one, Mix A of LW-SCC, by replaced conventional coarse and fine aggregate with a lightweight aggregate (expanded light weight aggregate LECA) as a partial replacement (as 10%, 20%, 30%, 40%, 50%, 60% of dolomite used) and the other, Mix B of LW-SCC, by using air entrained admixtures.. The second part was conducted to evaluate the durability of LW-SCC under sulfate or chloride attack. Tests were drive in terms of fresh concrete properties and hardened concrete properties. A slump test was carried out to evaluate the plastic consistency of the fresh mixes according to the Egyptian Code of Practice (E.C.P. 203/2018) [10] as shown in Fig (2) and Table (8) indicates the slump results. The hardened concrete properties were obtained in terms of compressive, splitting tensile, and flexure strengths. | Figure 2. J-ring and flow test of LW-SCC |

4. Result and Discussion

4.1. Main Properties of LW-SCC Samples

The fresh and hardened concrete properties of LW-SCC control mixes were obtained. A development by using LECA as coarse aggregate with 12 trail mixes to improve lightweight self-compacted concert as shown in Fig. (1). A compressive strength of 70MPa was obtained. A comparison between LW-SCC mixes to obtain mix design within a specific weight less than 1900 kg/m3 and a compressive strength of more than 28 MPa.

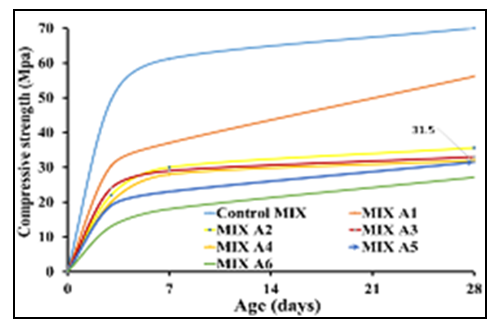

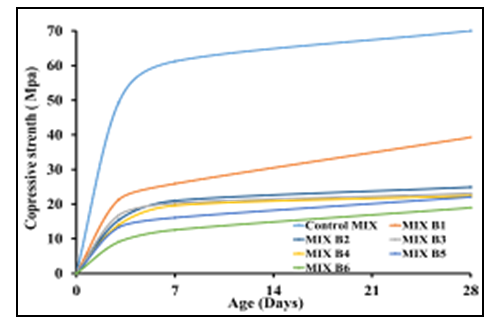

4.1.1. Compressive Strength

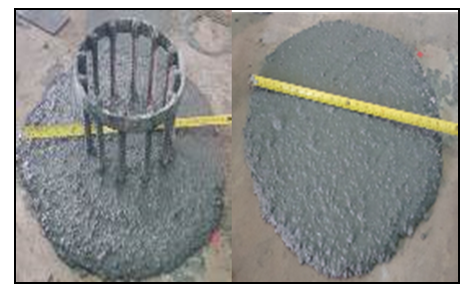

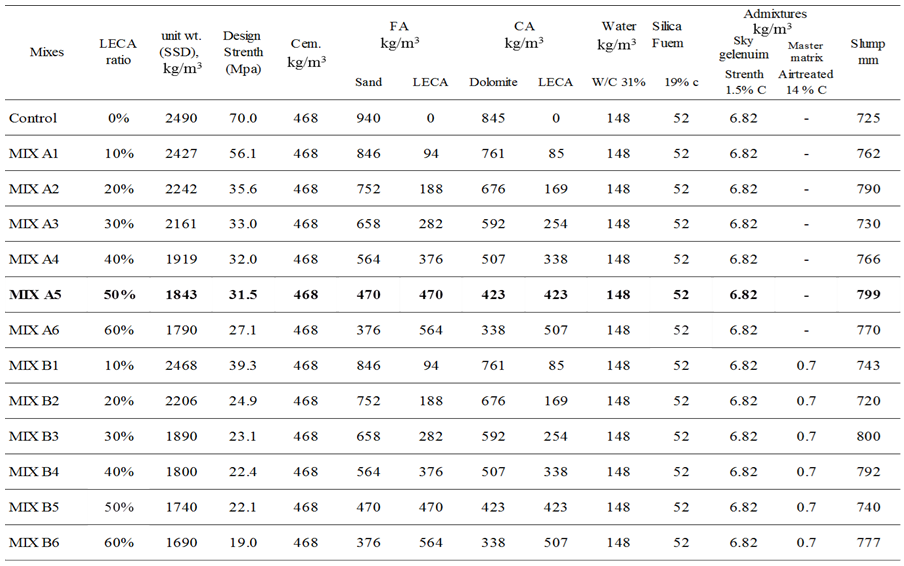

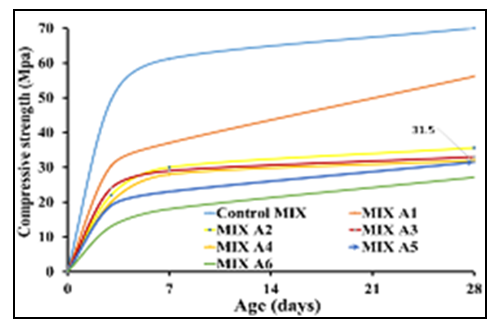

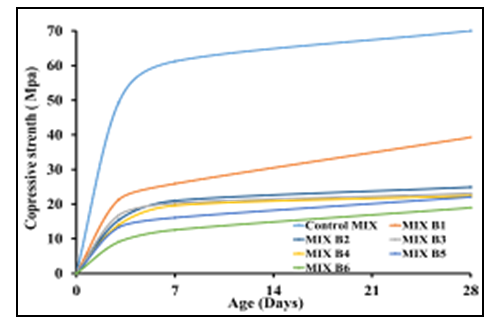

The compressive strength of LW-SCC cubes at the ages of 3, 7, and 28 days was obtained as shown in Fig. (3). the compressive strength values were taken as a mean of 3 identical cubes. Obtained test results indicated that the compressive strength for the A5 mix is as shown in Figs. (7) and (8). The result shown that the LW-SCC is always less than the conventional ones according to the percentage of aggregates replacement to LECA start from 10%, 20%, 30%.40%, 50%, and 60%, the compressive strength reduced by 19.39%, 28.33%, 35.1%, 39.1%, 42.22% and 45.14% respectively and due to aerated admixture the compressive strength reduced by 22.1%, 32.02%, 39.81%, 45.7%, 52.02%, and 61.04% respectively. The strength values were recorded as shown in Table (8). | Table (8). Mix proportions of NW-SCC and LW-SCC mixes used |

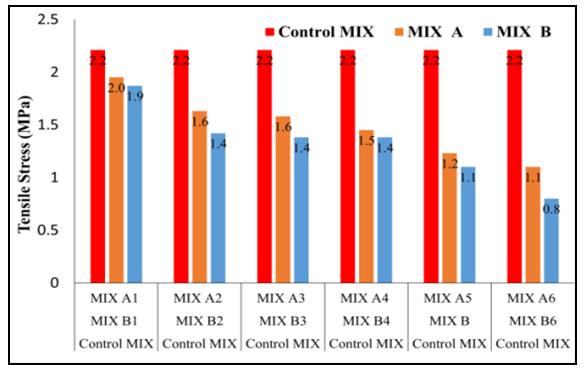

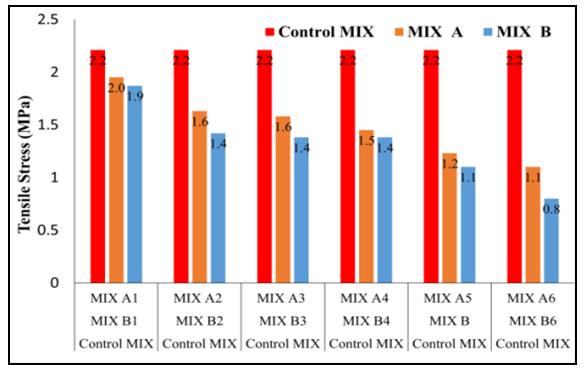

4.1.2. The Splitting Tensile Strength

The splitting tensile strength of LW-SCC cylinders at ages 28 days was obtained as shown in Fig. (5). the splitting tensile strength values were taken as a mean of 3 identical cylinders. The result shown that the LW-SCC is always less than the conventional ones related to the percentage of aggregates replacement to LECA start from 10%, 20%, 30%.40%, 50%, and 60%, the splitting tensile strength reduced by 10%, 27.3%, 27.3%, 31.8%, 45.5% and 50% respectively and due to aerated admixture the splitting tensile strength reduced by 22.1%, 32.02%, 39.81%, 45.7%, 52.02%, and 61.04% respectively. The strength values were recorded as shown in Fig (9). | Figure 3. Compressive Strength test |

| Figure 4. Modulus of Elasticity test |

| Figure 5. Splitting tensile Strength test |

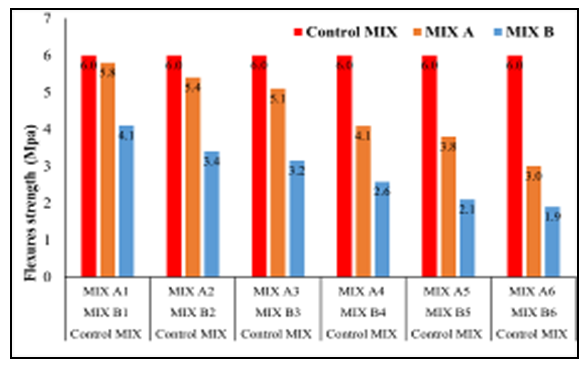

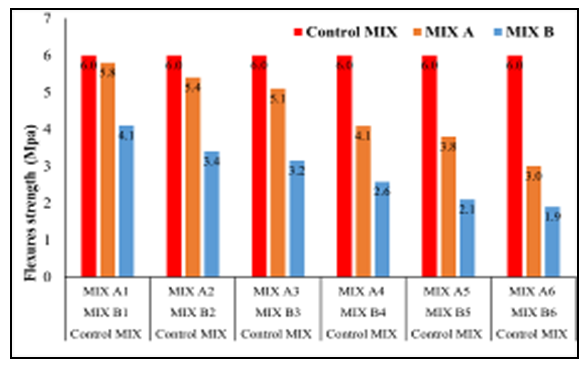

4.1.3. Flexural Strength

The flexural strength of LW-SCC prisms at ages 28 days was obtained as shown in Fig. (6). the flexural strength values were taken as a mean of 3 identical prisms. | Figure 6. The flexure strength test on Concrete prisms 100*100*500 mm |

| Figure 7. Compressive strength of group "A" of LW-SCC samples of different ages |

| Figure 8. Compressive strength of group "B" of LW-SCC samples of different ages |

The result shown that the LW-SCC is always less than the conventional ones related to the percentage of aggregates replacement to LECA start from 10%, 20%, 30%.40%, 50%, and 60%, the flexural strength reduced by 3.33%, 10.4%, 15.12%, 22.8%, 35.5% and 41.1% respectively and due to aerated admixture the splitting tensile strength reduced by 12.11%, 19.3%, 28.31%, 34.7%, 42.02%, and 48.25% respectively. The strength values were recorded as shown in Fig (10). | Figure 9. Splitting tensile strength values for control mix, "A" mixes, and "B" mixes after 28 days |

| Figure 10. Flexural strength values for control mix, "A" mixes, and "B" mixes after 28 days |

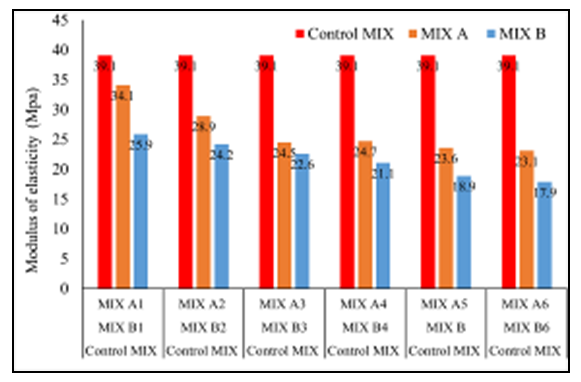

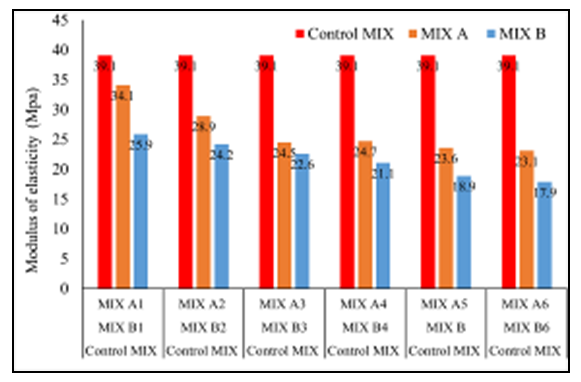

4.1.4. Modules of Elasticity

The modules of elasticity of LW-SCC cylinders at ages 28 days were obtained as shown in Fig. (4). the modules of elasticity values were taken as a mean of 3 identical cylinders. The result shown that the LW-SCC is always less than the conventional ones related to the percentage of aggregates replacement to LECA start from 10%, 20%, 30%.40%, 50%, and 60%, the modules of elasticity reduced by 12.78%, 28.1%, 38.12%.38.8%, 40.2%, and 45.1% respectively and due to aerated admixture the modules of elasticity reduced by 28.27%, 31.12%, 37.50%, 41.8%, 48.9% and 51.06% respectively. The strength values were recorded as shown in Fig (12).

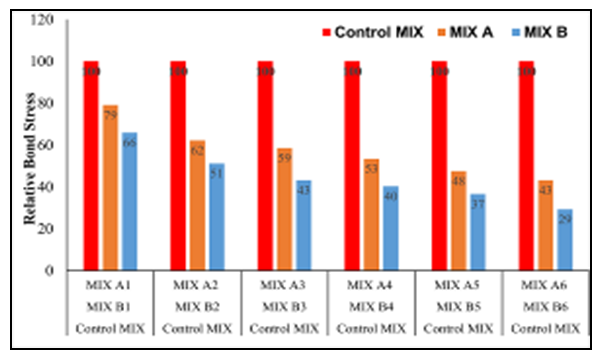

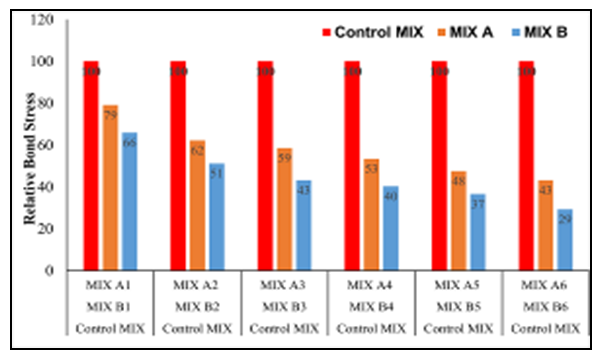

4.1.5. The Relative Bond Strength

The relative bond strength of LW-SCC cubes embedded 12mm diameter at ages 28 days were obtained that the LW-SCC is always less than the conventional ones related to the percentage of aggregates replacement to LECA start from 10%, 20%, 30%.40%, 50%, and 60%, the stress reduced by 21%, 32%, 41%, 47%, 52%, and 57% respectively and due to aerated admixture the stress reduced by 35%, 41%, 57%, 60%, 63% and 71% respectively. The relative bond strength values were recorded as shown in Fig (11). | Figure 11. Relative bond stress values for control mix, "A" mixes, and "B" mixes after 28 days |

| Figure 12. Modulus of elasticity strength values for the control mix, "A" mixes, and "B" mixes after 28 days |

4.2. Durability of LW-SCC Samples

This investigation was performed mainly to investigate the durability of LW-SCC due to chloride 5% concentration and sulfate 20% concentration ingress, corrosion potential characteristics were studied.

4.2.1. LW-SCC under Chloride Attack

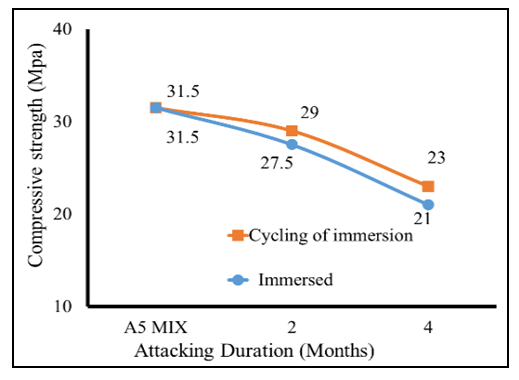

The "A5" LW-SCC mix was chosen as a better mix to study its durability under chloride attack.The compressive strength of the LW-SCC samples decreased after chloride attack for 2 months, for continuously immersed and cycling immersed in chloride solution by about 12.6% and 7.94%, respectively compared to control samples A5 as shown in Fig. (13). After 4 months, the compressive strength of the LW-SCC samples decreased for immersed and cycle immersed in chloride solution by about 33.3% and 26.98%, respectively compared to control samples A5 as shown in Fig. (13). | Figure 13. Compressive strength of LW-SCC, "A5" mix, under the attack of 5% concentration chlorides after 2 and 4 months |

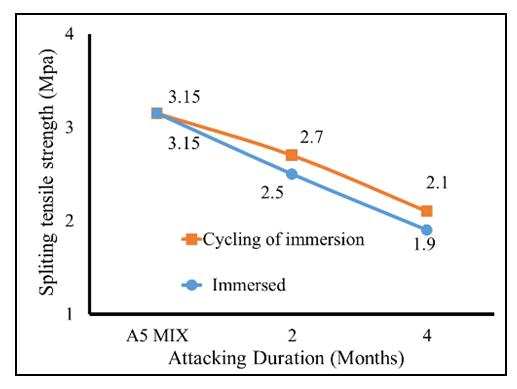

The splitting tensile strength of LW-SCC decreased as it attacks by chlorides (in rang of the study). The splitting tensile strength values of immersed and cycle immersed samples decreased by about 21.6% and 19.3%, respectively after 2 months and by about 29% and 26.2%, respectively after 4 months compared to control samples "A5" as shown Fig. (14). | Figure 14. Splitting tensile strength of LW-SCC, "A5" mix, under the attack of 5% concentration chlorides after 2 and 4 months |

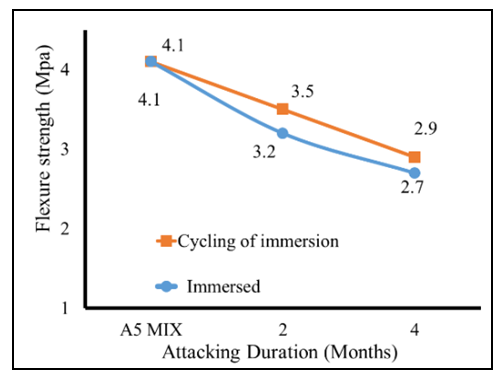

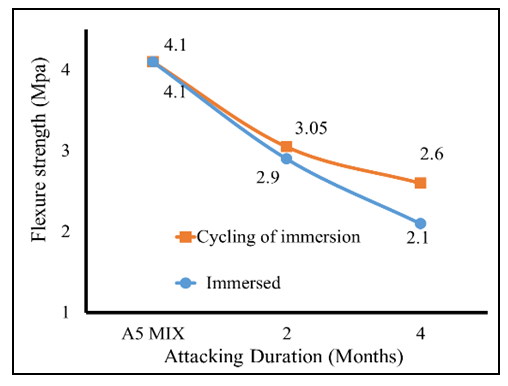

The flexure strength of prism samples immersed and cycle immersed in chlorides decreased by about 27.3%, 23.3%, respectively after 2 months and by about 31.5% and 37.5%, respectively after 4 months compared to control samples A5 as shown Fig. (15). | Figure 15. Flexure strength of LW-SCC, "A5" mix, under the attack of 5% concentration chlorides after 2 and 4 months |

4.2.2. LW-SCC under Sulfate Attack

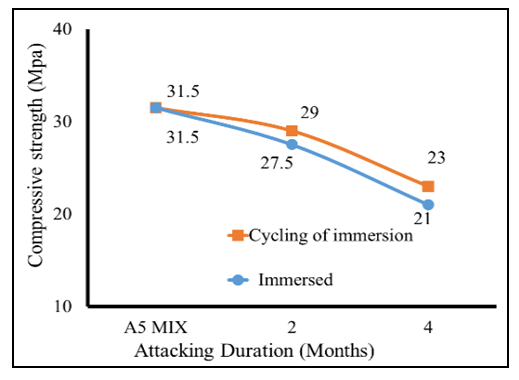

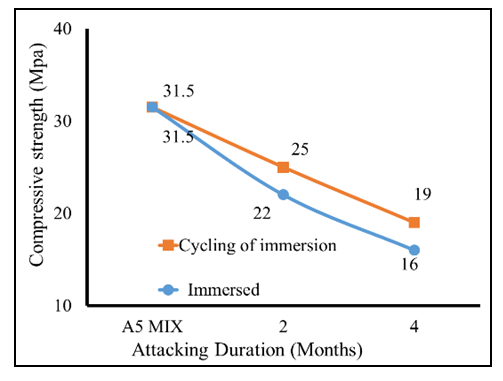

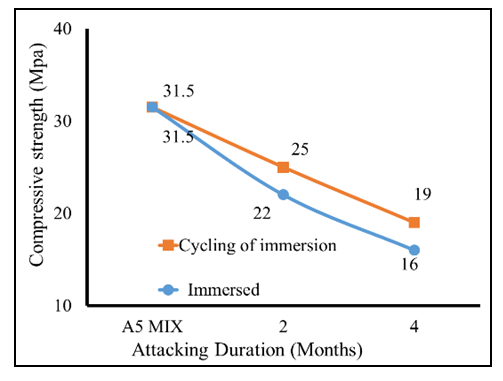

The "A5" LW-SCC mix was chosen as a better mix to study its durability under sulfate attack.The compressive strength of the LW-SCC samples decreased after sulfate attack for 2 months, for continuously immersed and cycling immersed in sulfate solution by about 30.1% and 20.6%, respectively compared to control samples A5 as shown in Fig. (16). After 4 months, the compressive strength of the LW-SCC samples decreased for immersed and cycle immersed in sulfate solution by about 49.2% and 39.7%, respectively compared to control samples A5 as shown in Fig. (16). | Figure 16. Compressive strength of LW-SCC, "A5" mix, under the attack of 20% concentration sulfates after 2 and 4 months |

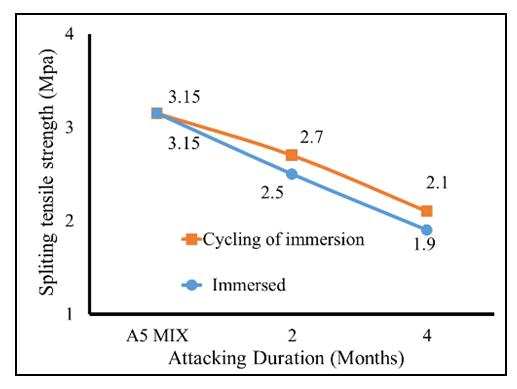

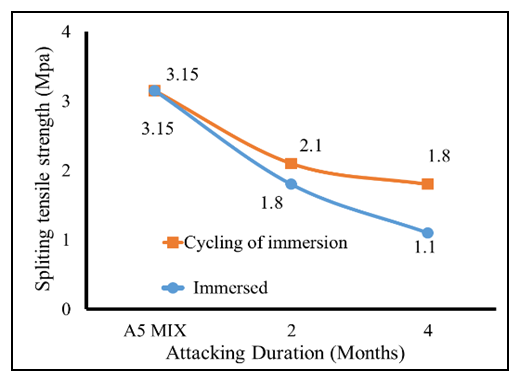

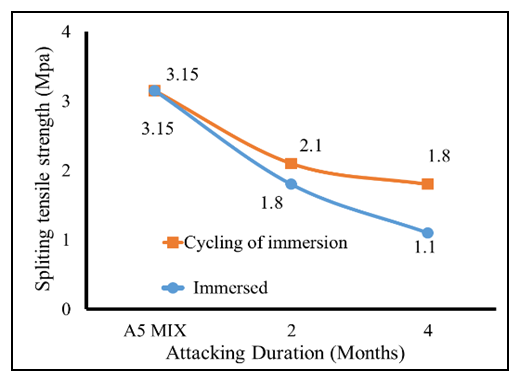

The splitting tensile strength of LW-SCC decreased as it attacks by sulfate (in rang of the study). The splitting tensile strength values of immersed and cycle immersed samples decreased by about 27.3% and 23.3% respectively after 2 months and by about 31.5% and 37.5% after 4 months compared to control samples "A5" as shown Fig. (17). | Figure 17. Splitting tensile strength of LW-SCC, "A5" mix, under the attack of 20% concentration sulfates after 2 and 4 months |

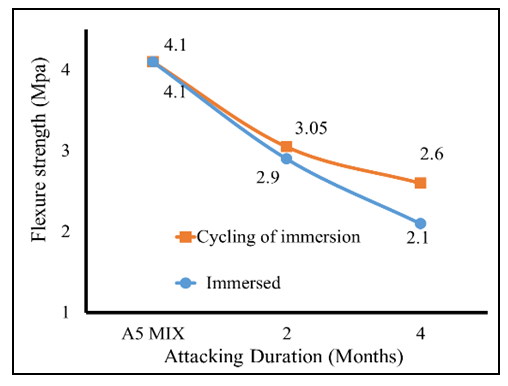

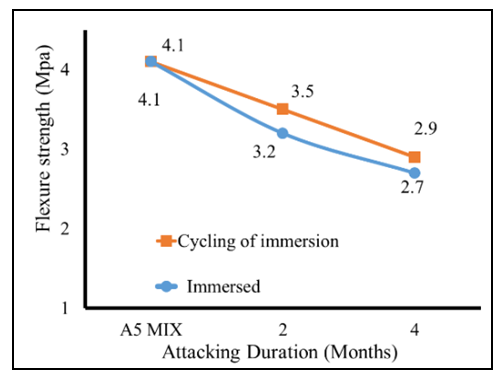

The flexure strength of prism samples immersed and cycle immersed in sulfates decreased by about 27.3%, 23.3%, respectively after 2 months and by about 31.5% and 37.5%, respectively after 4 months compared to control samples A5 as shown Fig. (18). | Figure 18. Flexure strength of LW-SCC, "A5" mix, under the attack of 20% concentration sulfates after 2 and 4 months |

5. Conclusions

In this research, a series of experiments have been performed to investigate the behavior of LW-SCC. The results obtained from this study can be summarized as follow:1. Structural LW-SCC concrete can be obtained using expanded clay aggregate (LECA). 2. The density of obtained LW-SCC varied from 1870 to 1950 Kg/m3, which is less than the weight of conventional concrete having a density of 2450 Kg/m3.3. The compressive strength of LW-SCC decreased by up to 33.45% compared to the control concrete mixture. The splitting tensile strength and elastic modulus had a similar manner.4. The reinforced LW-SCC beams behave in the same manner as conventional concrete beams.5. The durability of LW-SCC mixes are affected by the aggregate proportion of LWA.6. Under chloride attack, the compressive strength decreased up to 33.3%, splitting tensile decreased up to 29%, flexure strength decreased up to 37.5% compared to their control samples. 7. Under the sulfate attack, the compressive strength decreased up to 49.2%, splitting tensile decreased up to 37.5%, flexure strength decreased up to 37.5% compared to their control samples. 8. The durability of the lightweight self-compacted concrete "LW-SCC" is sufficient enough compared to that of normal weight self-compacting concrete "NW-SCC" with a redaction for LW-SCC under the attack of chlorides and sulphate by about 33.3% and 49.2% respectively.Generally, laboratory investigations confirm the feasibility of producing structural LW-SCC. Using it is efficient where the lightweight concrete with self-compaction characteristics is needed such as shells and decorative concretes. Based on durability tests; LW-SCC is suggested to be used under low to medium aggressive conditions. In case of aggressive conditions the concrete protection/isolation is needed.

References

| [1] | B.Vakhshouri, S.Nejadi, Mix Design of Lighweight Self-compacting Concrete Case Studies in Construction Materials 4 (2016) 1–14. |

| [2] | P. L. Domone, self-compacting concrete: an Analysis of 11 Years Of Case Studies, Cement Concr. Comp. 28 (2006) 197–208. |

| [3] | E. P. Koehler, D. W. Fowler, ICAR Project 108: Aggregates in Self-consolidating Concrete, Aggregates Foundation For Technology, research, and education (AFTRE) (2015). |

| [4] | P. Y. Lin, Y. Y. Chang, C. J. Chen, S. B. Wen. Preparation of Lightweight Aggregate From The Mixture of Low Water Content Reservoir Sludge And Dry Powders. In: TCI 2007 concrete technology conference and exhibition, Paper; 2007 [N-5]. |

| [5] | S. Jardin, G. Baloevi’c, A. Harapin, Experimental Testing of The Effects of Fine Particles on The Properties of The Self-compacting Lightweight Concrete, Adv. Mater. Sci. Eng. 2012 (2012) 8 Article ID 398567. |

| [6] | M. Kaffetzakis, C. Papanicolaou, Mix Proportioning Method for Lightweight Aggregate SCC (LWSCC) Based on The Optimum Packing Point Concept, Innovative Mater. Tech. Concr. Constr. (2012) 131–151. |

| [7] | H. Y. Wang, K. C. Tsai. Engineering Properties of Lightweight Aggregate Concrete Made From Dredged Silt. Cem Concr Compos 2006; 28 (5) 481–5. |

| [8] | T. Sonia1, R. Subashini1 (2015) “Experimental Investigation on Mechanical Properties of Light Weight Concrete Using LECA” ISSN (Online): 2319- 7064 Index Copernicus Value (2015) 78-96. |

| [9] | M. Hubertova, Self-compacting Light Concrete with Labor Aggregates. Proc. of Intern. Conf., Univ. of Dundee, Scotland, UK. 7th July 2005. |

| [10] | E.C.P.203/2018, "Egyptian Code of Practice: Design and Construction for Reinforced Concrete Structures," Research Centre for Houses Building and Physical Planning, Cairo, Egypt, 2018. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML