-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Construction Engineering and Management

p-ISSN: 2326-1080 e-ISSN: 2326-1102

2018; 7(6): 193-206

doi:10.5923/j.ijcem.20180706.01

Factors Affecting Construction Labor Productivity for Construction of Pre-Stressed Concrete Bridges

Nourhane M. Montaser1, Ibrahim M. Mahdi2, Hesham A. Mahdi3, Ibrahim Abdul Rashid4

1M.Sc. Student, Department of Structural Engineering, Ain Shams University, Cairo, Egypt

2Associate Professor, Structural Engineering and Construction Management Department, Faculty of Engineering and Technology, Future University, Egypt

3Associate Professor, Minister of Transport, Cairo, Egypt

4Professor of Construction Management, Structural Engineering Department, Faculty of Engineering, Ain Shams University, Egypt

Correspondence to: Nourhane M. Montaser, M.Sc. Student, Department of Structural Engineering, Ain Shams University, Cairo, Egypt.

| Email: |  |

Copyright © 2018 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Purpose – Construction labor productivity in bridges of great interest to practitioners and researchers because it affects project cost and time overrun. This paper evaluates and ranks the importance, frequency and severity of project delay factors that affect the construction labor productivity for construction of Pre-stressed concrete bridges. Design/erection / methodology: A total of 50 respondents consisting of owners contractors, and consulting participated in this study. The respondents were asked to indicate how important each item of a list of many bridges project related factors was to construction labor productivity for construction of Pre-stressed concrete bridges. The data were then subjected to the calculation of important indices which enabled the factors to be ranked. Findings: The eleven most important factors identified by them were: design factor, equipment factor, execution and construction factor, external factor, financial factor, healthy and safety factor, labor factor, supervision factor, material factor, organization factor and other project factor. Originality/value: From this study could be used by the project managers to take these factors at an early stage, hence minimizing the time, cost and maximizing factors that affect the construction labour productivity for construction of Pre-stressed concrete bridges.

Keywords: Labor productivity, Pre-stressed Concrete, Bridges

Cite this paper: Nourhane M. Montaser, Ibrahim M. Mahdi, Hesham A. Mahdi, Ibrahim Abdul Rashid, Factors Affecting Construction Labor Productivity for Construction of Pre-Stressed Concrete Bridges, International Journal of Construction Engineering and Management , Vol. 7 No. 6, 2018, pp. 193-206. doi: 10.5923/j.ijcem.20180706.01.

Article Outline

1. Introduction

- Productivity is one of the most important factors affecting the overall performance of any organization, large or small (Kazaz and Ulubeyli, 2007). Productivity in construction sites is important because it influences time and cost objectives (Moselhi and Khan, 2010). In fact, the percentage of projects exceeding Cost or time forecasts is high (González et al, 2010, Johansen and Wilson, 2006). In Egypt has experienced a construction bridges boom during the past years, attracting construction professionals in bridges. According to the bridges and roads Ministry, However, construction Pre-stressed beams in bridges faces some critical problems like poor labour productivity. Labour productivity is simply defined as the amount of goods and services that a laborer produces in a given amount of time. This paper aims at identifying factors affecting labour productivity for Construction of Pre-stressed Concrete Bridges in Egypt from the owners and consulting and contractors’ perspective. The questionnaire shows changes in each of the following factors like the design factor, equipment factor, execution and construction factor, external factor, financial factor, health and safety factor, labour factor, supervision factor, material factor, organization factor and other project factor were ranked according to their impact level. These findings will guide efforts to enhance the performance of the construction of Pre-stressed Concrete beams Bridge.

2. Literature Review

- Pre-stressed concrete in bridges projects differ from conventional structural engineering projects mainly in the special problems that have to be considered during construction, transportation, installation, and operation. Pre-stressed concrete is the most recent of the major forms of the construction to be introduced into structural engineering, although several patents were taken out in the last century for various pre-stressing schemes they were unsuccessful because low strength steel was used and low productivity. The idea of pre-stressing or preloading is not new but in differs from conventional structural engineering projects mainly in the special problems that have to be considered during construction, transportation, installation, and fabrication. Through better utilization of available resources. Encyclopaedia (2010) a study carried out by Alinaitive, Mwakali and Hansson (2007) ranked incompetent supervision and lack of skills of the workers as the two most significant causes of low productivity of construction workers in developing countries. Similarly, Odusami and Unoma (2011) noted that the problems of low productivity can be directly linked to poor and inadequate training of construction skilled workers. Previous studies have identified various factors that affect labor productivity on construction sites. Therefore, this research aim was to find out the most significant factors affecting the productivity of a construction worker on a site and productivity of a qualified skilled worker at selected level per day, to analyses the relationship between working height and the productivity of worker on a construction site. AbolfazlSherafat (2013), “Designed a Model for Measuring Manpower Productivity in the Project based Service Organizations”, in the designed model, added-value is calculated so that all of the organizations outputs include current activities and also the investments that will be exploited in the future. As a result, the calculated value is overall reflects of the organizations performance and also manpower productivity is calculated actually. Since, manpower productivity is the ratio of added-value to the organizations manpower, it is possible to measure every units and employee’s productivity through determining every their role by organizational excellence models in creating the added-value and then determining their role in the units added-value. The designed model is implemented in an organization with the mission of supplying and distributing the electricity energy and then every unit’s productivity in this organization is calculated through this method. XiaolongXue, (2008), Measuring the Productivity of the Construction Industry in China by Using DEA-Based. Data envelopment analysis _DEA_ measures the relative efficiency of decision-making units and avoids any functional. Specification to express production relationship between inputs and outputs. DEA-based Malmquist productivity index _MPI_ measures the Productivity change over time. In this paper, the MPI is used to measure the productivity changes of Chinese construction industry from1997 to 2003. The results of analyses indicate that productivity of the Chinese construction industry experienced a continuous improvement from 1997 to 2003 except for a decline from 2001 to 2002... It is found that there are gaps in productivity development level among western, midland, eastern, and northeastern regions in the Chinese construction industry. JaideepMotwani Ashok Kumar Michael Novakoski (2000), Identifying and evaluating the factors which influence productivity are critical issues faced by construction managers. Martin Loosemore, (2014), Improving construction Productivity: a subcontractor's perspective. Study the relationship between subcontractors and contractors well and participation among them in the project phases to improve the productivity of construction, taking into consideration the subcontractors from project start to an end and providing data and full information for the project to subcontractors in a timely. George (2009), identify factors for improving productivity on future construction projects. It was recommended for improving construction productivity are categorized and tabulated into 10 major areas, Tarekzayed (2014), in this study a case productivity model for automatic climbing system he is observed that duration of activities is similar across floors except concrete pumping Time because it is a function of height. Sherif Mohamed (2014), studied the thermal environmental effects on construction worker’s productivity. Polycarp OlakuAlumbugu (2014), studied analysis the relationship between working height and productivity of masonry worker on construction site by investigating two project sites. Shah et al. (2014), studied analysis of factors influencing productivity in Central Gujarat Region of India, so it was identified and ranked the key factors affecting the project level productivity. Ibrahim Mahamid (2013), Principal Factors Impacting Labor Productivity of Public Construction Projects in Palestine. This study aims at identifying the factors negatively affecting labor productivity of public construction projects in the West Bank in Palestine from contractors’ viewpoint, The results show that the poor labor productivity of public construction is mostly affected by the materials and equipment. Osama Moselhi (2009), studied an analysis of labour productivity of formwork operations in building construction. Kazaz (2008), studied the factors influencing construction labour productivity in Turkey. Paul M Goodrum (2004), this paper examines how changes in equipment technology have influenced labor productivity in the U.S. construction industry over a 22-year time period in three parts. Makulsawatudom (2001), presented factors affecting construction productivity, and their potential for improvement for labor productivity, to make a questionnaire survey. Robert c Ford (2000), this study conducted that the weather has an influence on the productivity of people at work system. Seonghoon Kim (2015): Earthmoving Productivity in Urban Bridge Construction. This research also identified significant factors for the truck bunching and showed that the match factor from the urban earthmoving project does not linearly correlate with the productivity of each truck. Reducing the hauling distance for urban earthmoving projects was the principal method for improving productivity. AshwinMaru (2009), Construction of Bridge Decks with Pre-Cast, Pre-Stressed Concrete Deck Planks. The case study is that of the bridge deck replacements that were carried out by the Illinois Department of transportation in 1999-2000. The bridge deck replacements were done by means of PPCs. The research also aims to find whether the bridge deck replacements that were carried out had early performance issues. It was established that there were indeed early performance issues, but these could be mitigated by means of load testing and the use of high-grade materials. H Randolph (2003), Role of Workforce Management in Bridge super structure. This paper describes the results of four case studies of high way bridges construction performed by established contractors with little bridge building experience, in which workforce management had a significant negative effect on a labor productivity. The contractor’s lack of experience in bridge construction seemed to be the cause of several problems that plagued each of the four project. The baseline of productivity of each was calculated and the loss of labor efficiency was estimated to be 80, 75, 32 and 70% the schedule slippage on the four case study was estimated to be between 127 and 329%, SBWijekoon (2002) EVALUATION OF LABOUR PRODUCTIVITY IN BRIDGE CONSTRUCTION PROJECTS: The main objective of this study is to identify the factors influencing labour productivity in bridge construction projects; to compare actual labour productivity rates with estimated rates and to make recommendations for improving labour productivity in identified items in bridge construction project. Seonghoonkin, yongBai (2013), the main objectives of this paper is how to developing a model to enhance labor productivity using bridges construction by using many steps to developing in the bridges.

3. Research Method

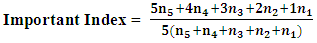

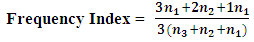

- The main eleven factors were tabulated into a questionnaire form affect labor productivity in the construction Pre-stressed bridges projects and then the draft questionnaire was discussed with three local experts in construction bridges owners, contractor and the consulting to evaluate the content of the questionnaire. Modifications and changes have been done. The questionnaire is divided into two main parts. Part I is related to the main factor that effect the productivity in Pre-stressed beams that includes the list of the identified factors, and Part II is related the sub main includes the list that explain the main factor factors.50 contractors working on construction bridges projects were successfully questioned. The questionnaire gave each respondent an opportunity to identify factors that they perceived as likely to contribute to poor labor productivity by responding on a scale from 5 (very high) to 1 (not high). For each factor, the mean value of the respondents’ importance rating was named the importance index. From calculating the important index we will calculate Frequency Index and Severity index.The factors were taken from relevant literature, as well as from the authors’ practical experience. The “importance index” was derived for each factor using the following formula (Lim and Alum, 1995):

Where n1 is the number of respondents who answered “strongly important”, n2 the Number of respondents who answered “important”, n3 the number of respondents who answered “neutral”, n4 the number of respondents who answered “not important”, and n5 the number of respondents who answered “strongly not important”.The respondents were then asked to rate the frequency of occurrence for each factor According to three ordinal scales: high (3), medium (2), or low (1). The “frequency Index” for each factor was derived from the following formula:

Where n1 is the number of respondents who answered “strongly important”, n2 the Number of respondents who answered “important”, n3 the number of respondents who answered “neutral”, n4 the number of respondents who answered “not important”, and n5 the number of respondents who answered “strongly not important”.The respondents were then asked to rate the frequency of occurrence for each factor According to three ordinal scales: high (3), medium (2), or low (1). The “frequency Index” for each factor was derived from the following formula: Where n1 is the number of respondents who answered “high”, n2 the number of respondents who answered “medium”, and n3 the number of respondents who answered “low”. Finally, an overall index, the multiplication of “importance index” by the “frequency index” was named the “severity index”. The severity index was used to rank the Overall implication of each factor on labour productivity for residential projects.“Severity index” = “Importance index” * “Frequency index”The questionnaire in this research is based on the first to range the main factors after that we ranged the sub main includes the list that explain the main factors.

Where n1 is the number of respondents who answered “high”, n2 the number of respondents who answered “medium”, and n3 the number of respondents who answered “low”. Finally, an overall index, the multiplication of “importance index” by the “frequency index” was named the “severity index”. The severity index was used to rank the Overall implication of each factor on labour productivity for residential projects.“Severity index” = “Importance index” * “Frequency index”The questionnaire in this research is based on the first to range the main factors after that we ranged the sub main includes the list that explain the main factors.4. Results of the Arrangement the Main Factors of Project Delay on Labour Productivity

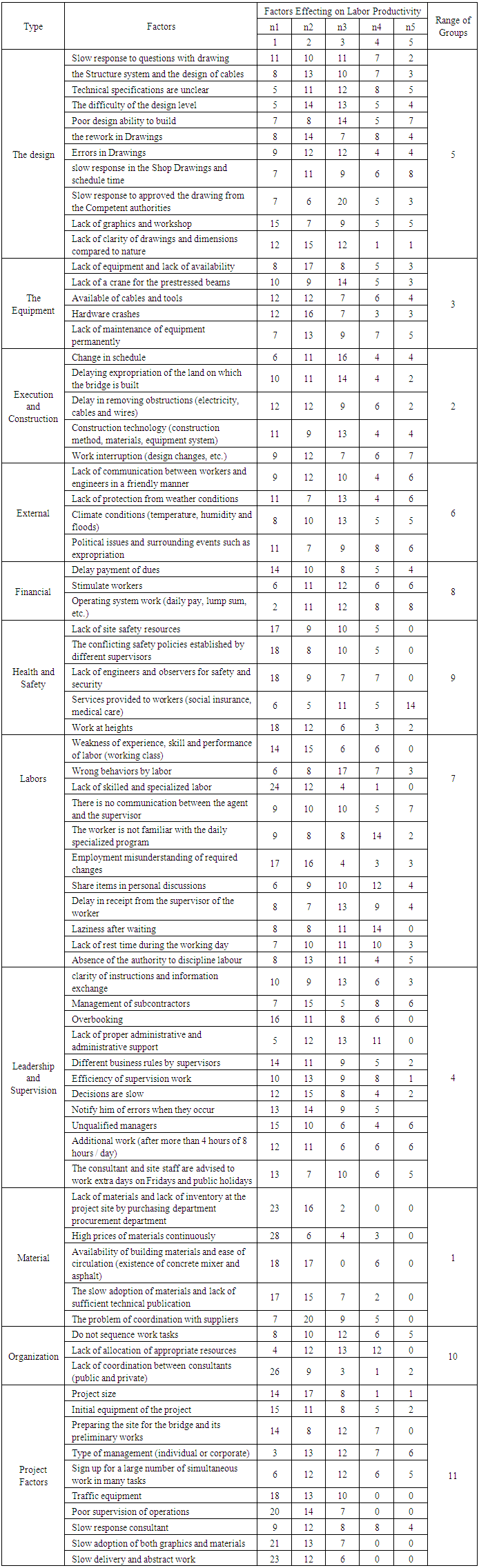

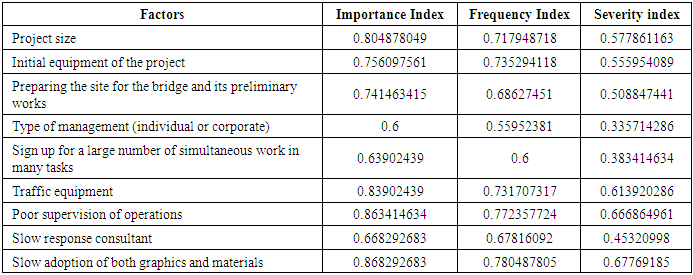

5. Results of the Arrangement the Sub Main Factors of Project Delay on Labour Productivity

- 1-Material Factors:

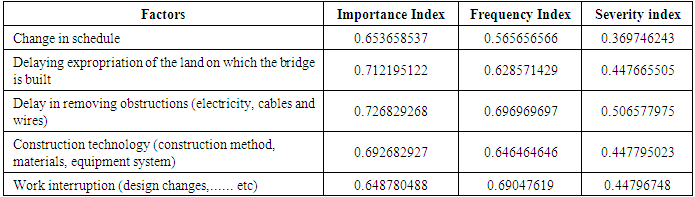

2-Execution and construction Factors:

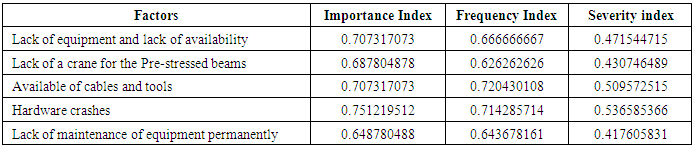

2-Execution and construction Factors: 3-Equipment Factors:

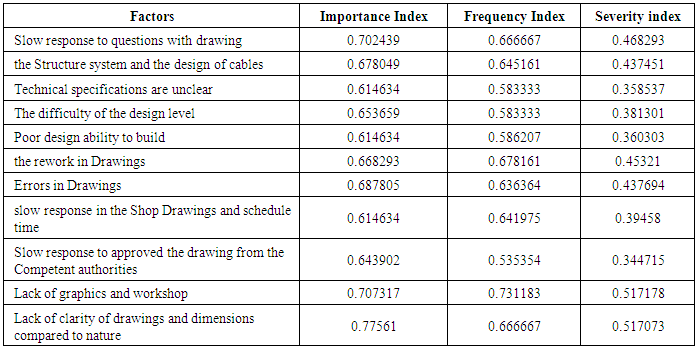

3-Equipment Factors: 4-Design Factors:

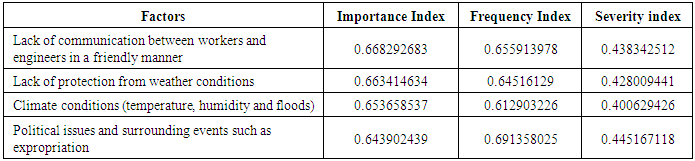

4-Design Factors: 5-External Factors:

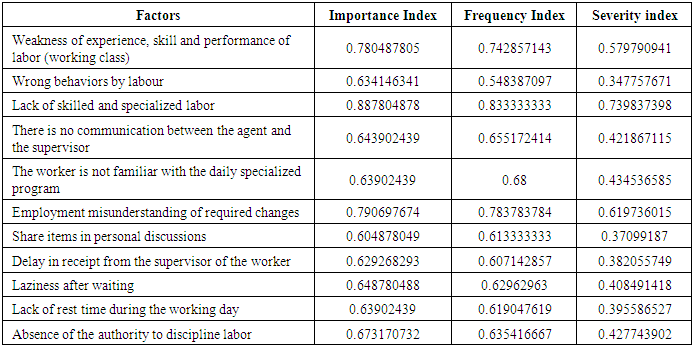

5-External Factors: 6-Labors Factors:

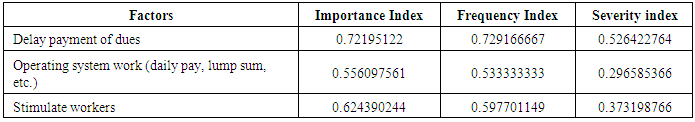

6-Labors Factors: 7-Financial Factors:

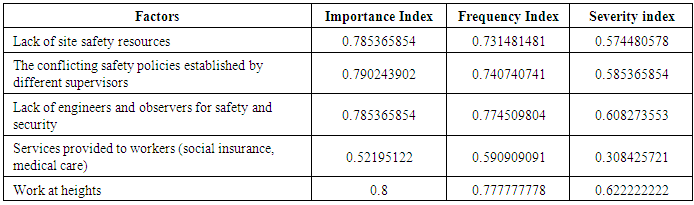

7-Financial Factors: 8-Health and Safety Factors:

8-Health and Safety Factors: 9-Organization Factors:

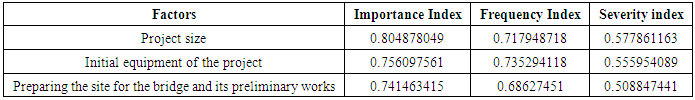

9-Organization Factors: 10-Project Factors:

10-Project Factors:

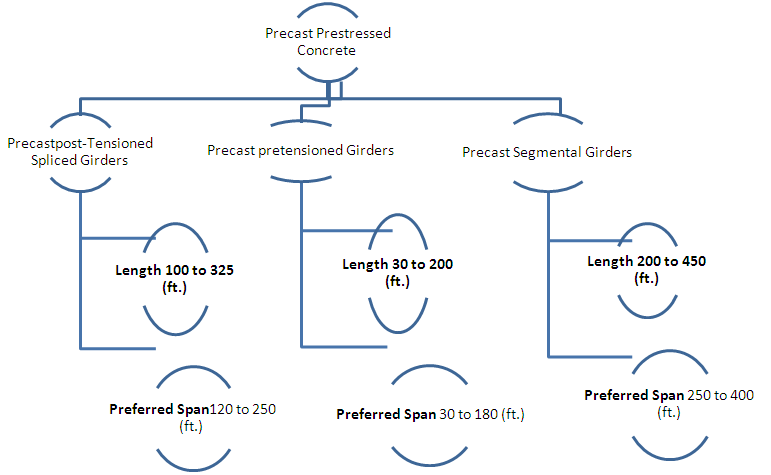

6. Typical Sections and Span Ranges

- Prestressing systems have developed over the years the prestressing members classified into for three types of prestressing systems. There are three main PC bridge types, Precast Bridge Types and Span Lengths (Caltrans, 2012) Bridge:

| Figure 1 |

7. The Relative Advantages of Post-tensioning as Compared to Pre-Tensioning are

- 1) Post-tensioning is suitable for heavy cast-in-place members.2) The waiting period in the casting bed is less.3) The transfer of prestressed is independent of transmission length.

8. Disadvantage of Post-tensioning as Compared to Pre-Tensioning is the Requirement of Anchorage Device and Grouting Equipment

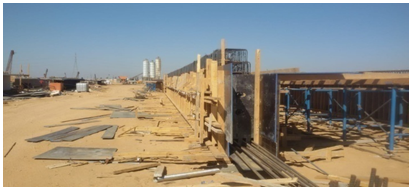

Casting bed & prepare the formwork beams (Reference: sample 30june bridges)

Casting bed & prepare the formwork beams (Reference: sample 30june bridges) Prepare the formwork beams (Reference: sample 30june bridges)

Prepare the formwork beams (Reference: sample 30june bridges) Prepare the steel works prestressed beams (sample 30june bridges & shoubra bnha)

Prepare the steel works prestressed beams (sample 30june bridges & shoubra bnha) Prepare the steel works prestressed beams (sample shoubra bnha 22+400 bridge)

Prepare the steel works prestressed beams (sample shoubra bnha 22+400 bridge) Grouting equipment:

Grouting equipment: -Transportation:

-Transportation: Erection beams:

Erection beams: The following photographs show some steps in the manufacturing of a post-tensioned & pre-tension I-girder for a bridge 30 June Bridge and shoubra Bnha Bridges.

The following photographs show some steps in the manufacturing of a post-tensioned & pre-tension I-girder for a bridge 30 June Bridge and shoubra Bnha Bridges.9. Factors Affecting Construction Labour Productivity in the Method of Statement for Construction of Pre-stressed Concrete Bridges

- - Design and Approve Shop Drawings Shop drawings are an essential part of the manufacturing process of prestressed beams. They should be submitted to the builder for checking and approval prior to casting any concrete. The builder may be required to or prefer to submit shop drawings to the designer for approval or review.The standard convention for precast shop drawings is that each element is drawn the way the production workers will view the mould. Nonstandard finishes and special lifting and handling procedures must be clearly noted on the drawings.Shop drawings may include an erection layout drawing and should note the requirements for special handling and propping where this is part of the precast concrete design, but will not necessarily detail the temporary propping and bracing.The builder must co-ordinate between the precast manufacturer and the erection subcontractor to determine the requirements for propping, bracing and special lifting procedures.- Propping and Support DetailsProps are required for a variety of reasons to:• Reduce the self-weight deflection of precast flooring systems while the cast-in-place topping concrete is placed and cured;• Provide temporary gravity load support during construction. For example, where seating lengths are less than the specified minimum, or where the connection requires cast-in-place concrete or welding to provide permanent support;• Resist wind loads and accidental side loads during erection;• Prevent torsional instability or rotation of beams loaded along one edge;• Provide fine adjustment of the precast element to the correct level while freeing the crane quickly for the next lift; and• Support temporary construction loads that exceed the design capacity of any part of the structure.Where the element requires propping, that requirement should be noted on the shop drawings.Support details for precast elements include temporary shims, rubber or plastic bearing pads, levelling bolts or mortar pads.Direct concrete to concrete, or concrete to steel bearing should be avoided unless some edge spalling and cracking is acceptable.Precast floors exposed to the sun (for example the top levels of caparking buildings) require special consideration as the long term effects of thermally induced movements can cause severe spalling at the support.Permanent grouting or mortar packing of precast concrete support points requires care and supervision to ensure that the requirements for strength and durability are met.- Lifting and Handling StressesAllowable lifting and handling stresses will be determined by the degree to which cracking can be tolerated. Units will either be designed to be handled with no visible cracks, or to be handled in a manner that restricts the crack widths to acceptable limits for the environment that the unit will be exposed to in service.Lifting and handling concrete flexural stress calculations may assume an impact allowance of 50% for transport and handling. For precast units that must be transported over rough terrain, an additional impact factor should be allowed.- Capacity of Lifting InsertsLifting inserts may often be required to carry more load than is apparent.Increased loads can result from:• The angle of lifting chains or slings;• Impact or inertia forces;• Unequal sling lengths, where there are more than two slings (even relatively minor variations in length can be significant);• Suction or mould friction• Mispositioning of anchors.Unless special means are taken to equalise loads it is safer to assume that only two lifting inserts will be carrying the load.- Location of Lifting Inserts and TolerancesThe position of lifting inserts are calculated to limit lifting stresses and to ensure that the precast element hangs in the correct orientation during lifting from the mould and while it is lifted into its final position.Tolerances on the location of lifting inserts for typical precast elements.- Stability and BucklingSome precast elements, such as long slender bridge beams and thin wall panels, may buckle if handled or transported incorrectly. Where the designer is aware of this possibility, it should be clearly noted on the contract drawings.The manufacturer should also check the potential for lateral instability taking into account tilting due to road camber, additional axial loads due to lifting sling angles, and wind forces on the element during erection.

10. Recommendations

- The results of the survey indicated the top important, frequent and severe factors in bridges that are adversely affecting construction labor productivity in prestressed beams bridges.This would affect the workers’ motivation and productivity in bridges. Mentioned below are the recommendations which were found to be important factors for improving the crew productivity for the Construction of prestressed beams in bridge project: This study is one of the few that has been done in the area of crew productivity for the Construction of beams in bridges projects. This study is conducted to achieve the following objectives. - To identify the factors affecting the variation of labour productivity in the construction and design PC in bridges & to assess the impact of influenced factors on the variation of labour productivity in bridges. - To suggest recommendations in order to reduce variation of labour productivity in the construction of prestressed breams bridges. It is hoped that future studies will improve on the techniques used in this study, while taking into consideration the difficulties encountered in this study.Finally, this research provides a basis for future work in for improving the crew productivity for the construction precast prestressed in bridges, given the numerous factors affecting crew productivity. It is hoped that future studies will improve on the techniques used in this study, while taking into consideration the difficulties encountered in this study.

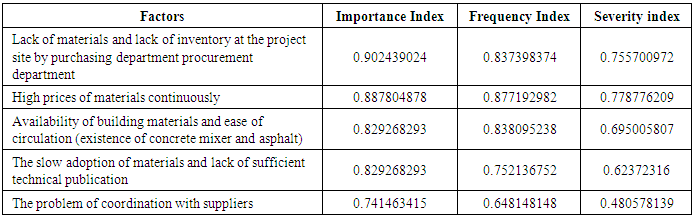

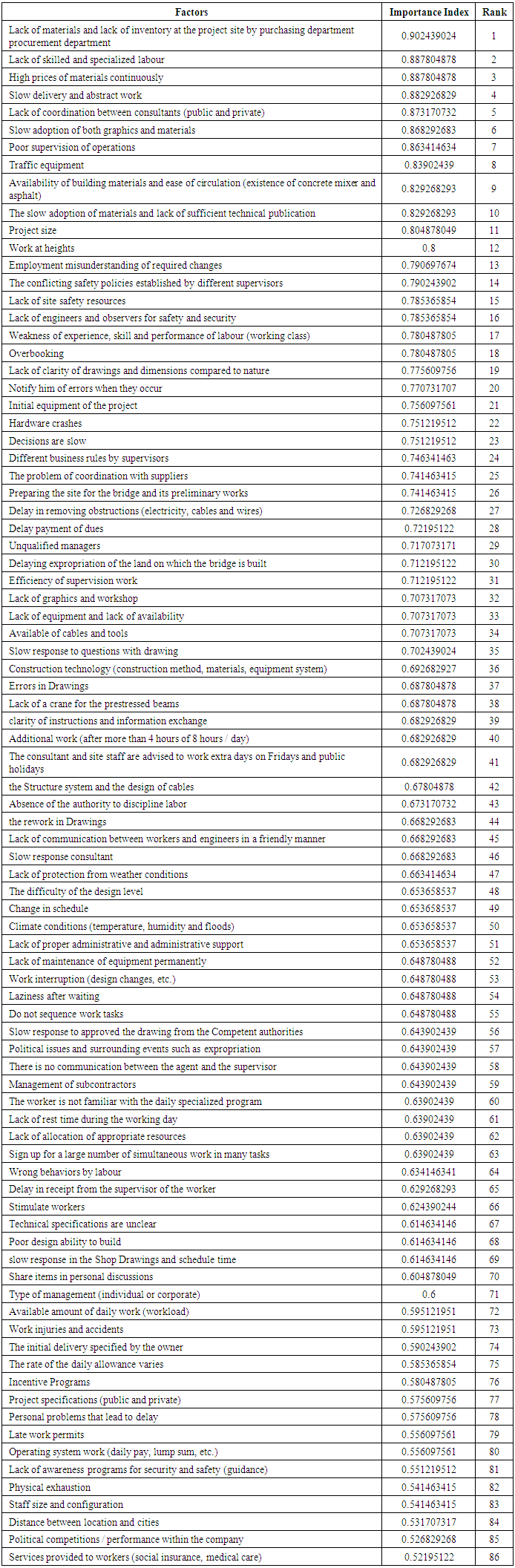

11. Conclusions

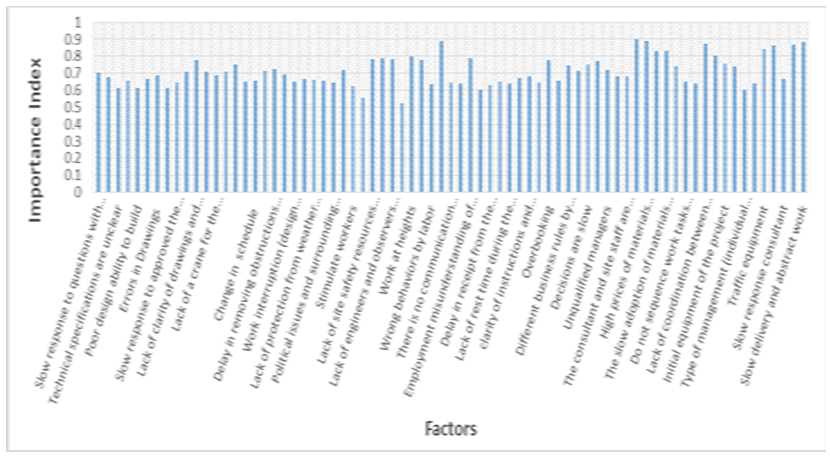

- The Egyptian construction bridges experiences time and cost overrun due to various project delay factors that affect construction labor productivity in the main and sub main factors. This paper has identified and ranked those factors that affect construction labor productivity. Results indicated that the eleven most important factors that affect labor in prestressed beams, they are as follows ranged by important to compare resultd with the proposed patterns geometrically such MATLAB:1. Material Factors 2. Execution and construction Factors 3. Equipment Factors 4. Leadership and supervision Factors 5. Design Factors6. External Factors 7. Labors Factors 8. Financial Factors 9. Health and Safety Factors 10. Organization Factors 11. Project Factors Finally, the most severe project delay factors are listed below ranged by the important index from all factors:

| Figure 2 |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML