-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Construction Engineering and Management

p-ISSN: 2326-1080 e-ISSN: 2326-1102

2018; 7(1): 1-21

doi:10.5923/j.ijcem.20180701.01

An Investigation into Cost Overrun in Construction Projects in United Arab Emirates

Muralidaran Ramabhadran

Head of Estimation, Shapoorji Pallonji Mideast LLC, Dubai, United Arab Emirates

Correspondence to: Muralidaran Ramabhadran, Head of Estimation, Shapoorji Pallonji Mideast LLC, Dubai, United Arab Emirates.

| Email: |  |

Copyright © 2018 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The construction industry contributes to the overall economy of United Arab Emirates (UAE) significantly, but it is plagued by cost overrun due to various factors. This paper looks at the, various factors influencing cost overrun in UAE construction industry and the mitigation measures. The most important causes of cost overrun are poor productivity, insufficient early planning, delayed completion, and lack of skilled resources and motivation. The most effective mitigation measures for cost overrun are detailed estimation, conducting brain storming sessions for cost control, procurement planning, mobilizing resources at the right time and training of workers. The paper recommends that higher management should focus and provide more support to Human resource related issues for controlling cost overrun, as they are the predominant causes of cost overrun. In addition, improving productivity, efficient estimation process, value management, change management and procurement management are also crucial to minimize cost overrun in construction industry in the United Arab Emirates.

Keywords: Project management, Cost Overrun, Delays, Causes, Mitigation measures, United Arab Emirates

Cite this paper: Muralidaran Ramabhadran, An Investigation into Cost Overrun in Construction Projects in United Arab Emirates, International Journal of Construction Engineering and Management , Vol. 7 No. 1, 2018, pp. 1-21. doi: 10.5923/j.ijcem.20180701.01.

Article Outline

1. Introduction

1.1. Background

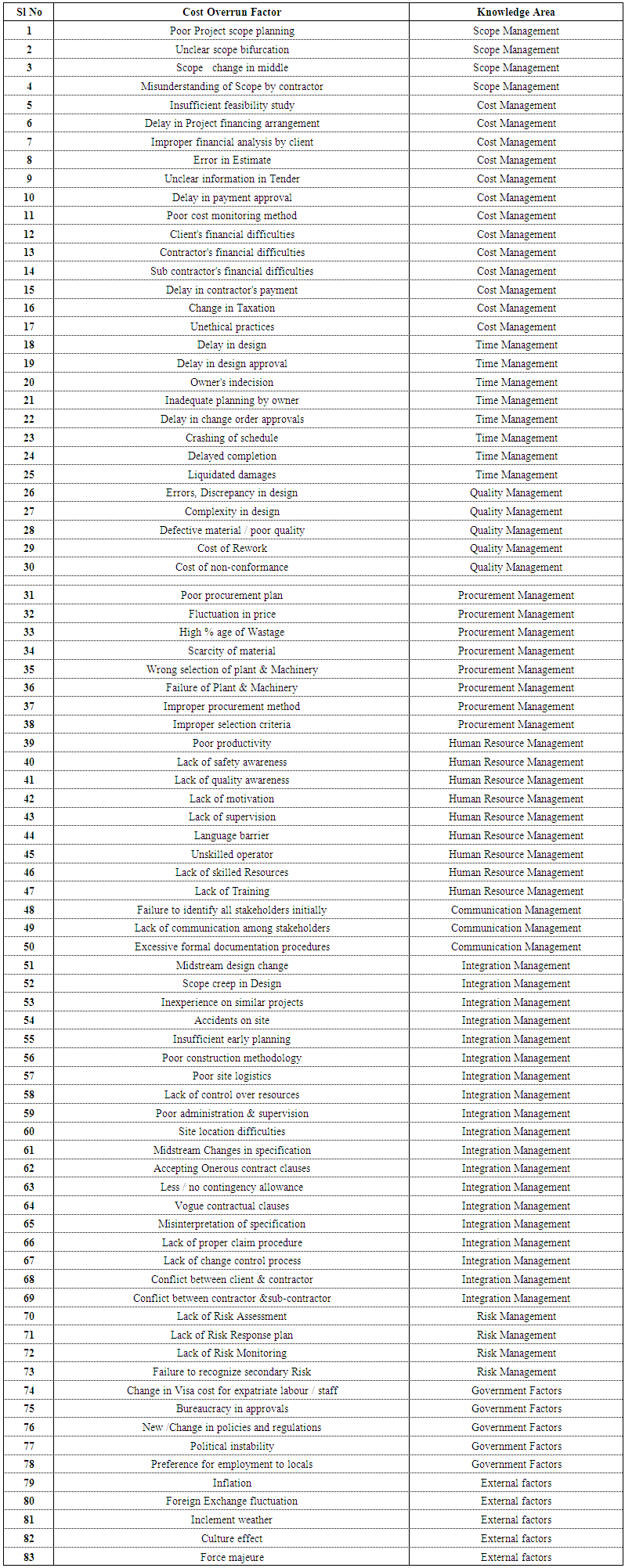

- One of the important criteria for project success is project completion within budget, time and the satisfaction of the client’s requirement. In the construction industry, completing a project within budget is even more critical, as companies work on narrow margins. Completing a project within budget is a complex task. Even with various cost control software and techniques, cost overruns in construction projects are not uncommon all over the world (Olawale & Sun, 2010). Cost overruns, whether they are due to delay or estimation errors or any other factors, do not just happen; they are caused (Maieli, 2001). The construction industry significantly impacts the economy of all countries (Leibing, 2001). The cost of construction project is affected by a large number of factors (Chan and Park, 2005). Eden, Ackermann & Williams (2005) illustrated that the growth in project cost is “amoebic” in nature. According to them, it is not easy to track down what drives total cost overrun. They suggested it tends to spread in an amoebic manner. They also stated that project costs escalate in an exponential manner and not linearly.There has been extensive research on the causes of cost overrun in construction projects in various countries like Vietnam (Hoai, Lee & Lee, 2008) Nigeria (Mansfield, Ugwu and Doran, 1994), Ghana (Frimpong, Oluwoye, and Crawford, 2003), Kuwait (Koushki, Al-Rashid & Kartam, 2007) Turkey (Arditi, Akan & Gurdamar, 1985), Malaysia (Abdul kadir et al., 2005), Libya (Al Gathafi, 2005), Pakistan (Azhar, Farooqui & Ahmed, 2008) and Indonesia (Kaming et al., 1997). These studies concluded that cost overrun is a common phenomenon on construction projects all over the world.Factors causing cost overrun differ from country to country and depend on the political, economic and cultural factors. United Arab Emirates (UAE) looks different from that in most other countries in many ways. Its GDP annual growth during 2001-2008 was 7.2%. The construction industry contributed about 8% of GDP in the last years which is high compared to western countries. UAE construction industry had witnessed an unprecedented boom and doom in recent years. The 2007 recession affected UAE only in 2009 and house prices declined by 35%. The above factors warrant an exclusive study on cost overrun & mitigation measures in UAE industry.

1.2. Research aim and Objectives

- This paper, therefore, aims to answer the following research question: What are the causes of cost overruns in construction projects in UAE and how can they be mitigated? The following research objectives address this research question:Ø To determine the factors which, influence cost overruns in construction projects, in UAE,Ø To explore the interrelationships between the factors.Ø To rank the factors in terms of frequency and impact.Ø To identify measures that could be taken to mitigate against the factors causing the cost overrunsØ To propose a model on best practice to avoid cost overruns in construction projects

2. Litreature Review

2.1. Causes of Cost Overrun

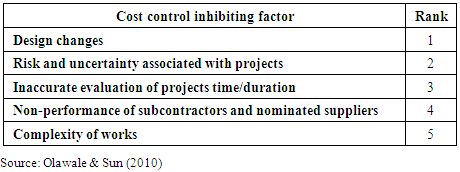

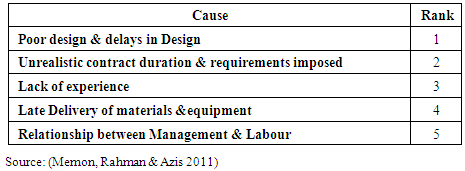

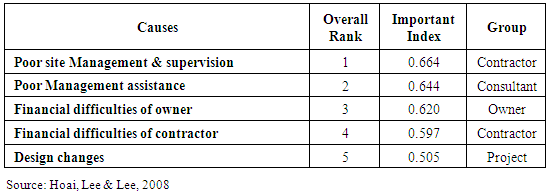

- A literature review was carried out to list out the various factors causing cost overrun and their importance in various countries.The top five ranked causes of cost overrun in the survey conducted by Olawale & Sun (2010) in the U.K are tabulated in Table 2.1.

|

|

|

| Table 2.4. Common causes of Cost overrun in various countries |

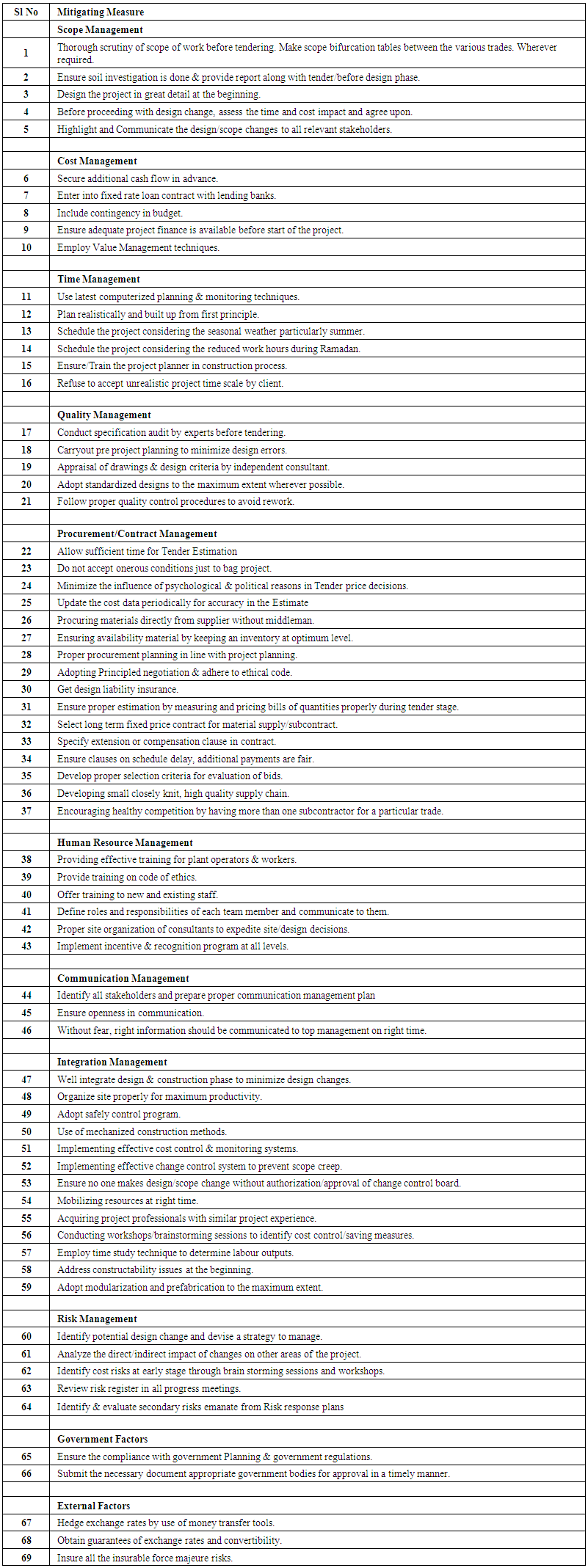

2.2. Mitigation Measures for Cost Overrun

- Roachanakanan (2005) suggested the need for project owners and architects to work together to complete the design drawings before project estimates are prepared or contracts are awarded in order to prevent inaccurate project estimates and cost overruns subsequently. Oberlender & Pevrifoy (2002) suggested that risk analysis of uncertainties needs to be performed in order to arrive at a proper contingency cost, and this should be added to the budget estimate. In cost planning process, both design economists and the architect should participate (Brandon & Ferry (1984).Halpin (1985) states that management should detect the actual cost overrun in field construction at the start of the project and plan remedial measures at the beginning itself to reduce the impact of cost overrun. Hoai, Lee and Lee (2008), concluded that most causes of delay and cost overrun of construction project relate to human and management problems and hence improving the ability of managers and engineers may mitigate cost overrun. Frimpong, Olvwoye, & Crawford (2003) recommended measures such as determination of appropriate funding at the planning stage, continuous work-training programs with project management techniques and processes, effective and efficient procurement system and adequate contingency allowance for mitigating cost overrun and delays. To minimize time delays and cost overruns Koushki, Al Rashid & Kartam (2007) recommended the following:ü Ensure adequate finance, ü Perform proper preconstruction planning on tasks & resourcesü Allocate sufficient time & money for the design phaseü Hire an independent, supervising engineerü Select a competent consultant & reliable contractor.Mansfield, Ugwu & Doran (1994) recommended that the client should perform the following to minimize time delays and cost overruns.ü Allow sufficient time to prepare project briefs and feasibility studiesü Ensure that adequate funds are available before projects are startedü Ensure that contractors establish an efficient material Management systemü Carry out institutional strengthening and manpower development in the areas of project management, information and data base management.Chan & Kumaraswamy (1997) recommended continuous professional development schemes, thorough site investigation, clearly defined roles and responsibility matrix, client brief, value management techniques, bridging the gaps in perception between the different groups as some of the measures to mitigate project delay, which in turn, will mitigate cost overrun, as well. According to them, effective site management is the key for productivity.Olawale & Sun (2010) identified 90 measures to mitigate the effect of the top five leading project cost and time control inhibitors and classified them under preventive measures, predictive measures, corrective measures and organizational measures. They concluded that although external factors are generally difficult to control or even beyond the control of project managers, the frequency of their occurrence is generally low. On the other hand, internal factors are persistent and require constant control. Bubshait's (2001) research in petrochemical plant on incentive/disincentive (I /D) contracting supports the use of incentive/disincentive provision to improve labor productivity and reduce cost overrun. Jergeas (2009) recommended the following for the development of efficient and effective best practices to improve construction productivity:ü Incentive and recognition program.ü Proper transport system for people to reach remote sites.ü Improving labour management & relationship.ü Overtime & work schedule.ü Proper management of tools, equipment, scaffolding.ü 80% engineering completion& 100% IFC drawings before construction.Kaming et al. (1997) recommended the following to eliminate delays and cost overruns based on the interviews carried out with project managers, in Indonesia:ü To avoid price hikes, select the long term contracts with construction material suppliers, sub-contractors, labor suppliers.ü Avoid substructure work during the rainy season.ü Maintain & update cost data base of materials, equipments at a unit price.ü Establish the site/logistics properly to maximize productivity.ü Provide accommodation & arrange welfare facilities to workmen to minimize absenteeism and maximize productivity.Based on the above literature review, 83 significant variables that cause cost overrun and 69 best practices which can mitigate the cost overrun were identified in the literature review.

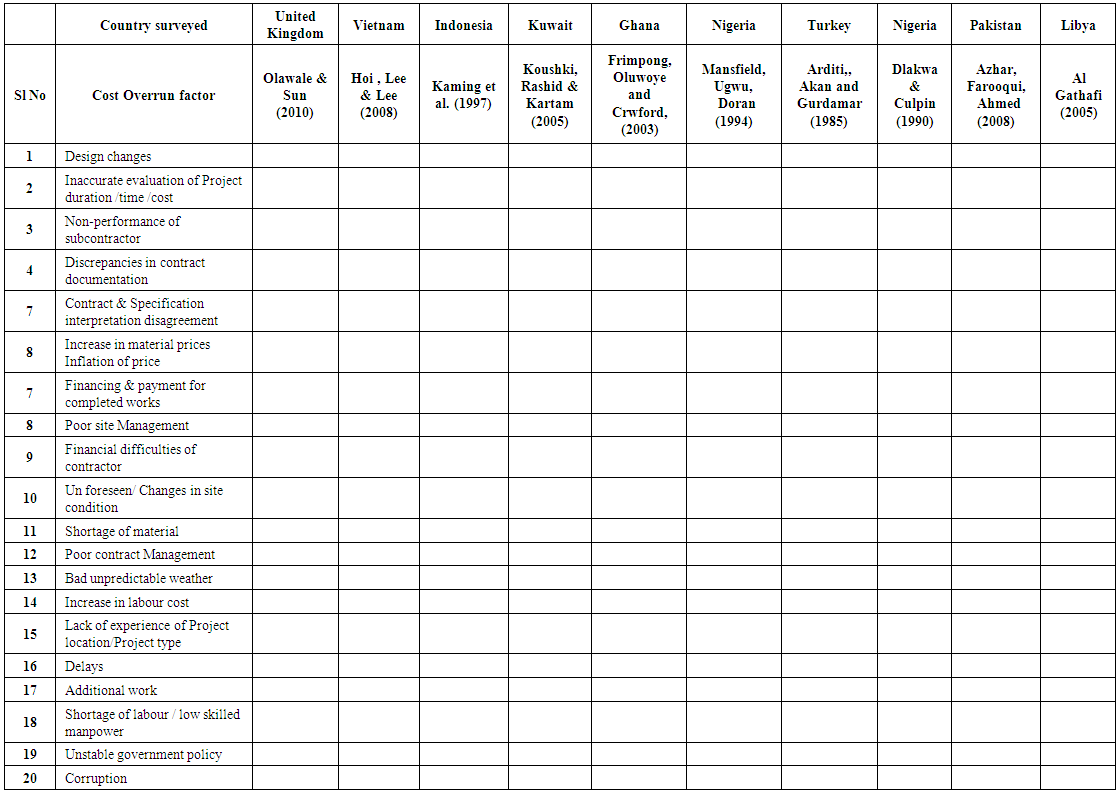

3. Methodology

3.1. Research Strategy & Design

| Figure 3.1. Flow Chart of Proposed Research Process |

3.2. Sample Criteria and Selection

3.2.1. Quantitative Sample

- To determine the sample size for the large population of respondents, the following Cochran formula was used.no = Z2pq / e2Where no = Sample sizeZ2 =Abscissa of the normal curve that cuts off an area at the tailsE = Desired level of precisionP = Estimated proportion of an attribute that is present in the populationQ = 1-p (Cochran, 1963)Assuming maximum variability i.e., p = 0.5, 93% confidence level, +/- 7% precision and Z2=1.96 (Unit normal distribution table, Vassar stats), size required = 1.962 x 0.5 x 0.5 / (0.07)2 = 196 respondents.Hence the proposed total sample size for the questionnaire survey was 200.Furthermore, stratified random sampling method was employed. In this method, the population was divided into homogeneous sub groups such as Contractors, Sub contractors, Cost Consultants, Developers & Project Managers. Further a simple random sampling was done for each sub group. This ensures representation of not only the overall population, but also key subgroups of the population; especially small minority groups. It gives higher statistical efficiency than simple random sampling (Krishnaswami and Sathyaprasad, 2010, p.62). Accordingly responses were solicited from 127 Main Contractors, 68 Sub-Contractors, 20 Cost Consultants, 23 Architects, 22 Developers and 35 Project Management firms. The questionnaire was addressed to chief estimators, cost consultants, cost controllers, Project Managers, Planning Engineers etc, in order to obtain appropriate answers to the questionnaire.

3.2.2. Qualitative Sample

- For the qualitative method, the sampling approach was based on purposive sampling since the objective was to select participants who have knowledge or experience of the issues being investigated. Purposive sampling is particularly useful for this situation as it helps to reach a targeted sample quickly, and sampling for proportionality is not the primary concern here. Purposive sampling is more convenient and guarantees inclusion of relevant elements in the sample (Krishnaswami and Sathyaprasad, 2010, p.77).

3.2.3. Qualitative Data Collection

- The qualitative method via semi structured interviews was used after the questionnaire survey. Semi structured interviews were used because they provide a wide deal of freedom to probe various areas and to raise specific queries (Naoum, 1998, p.58). They also provide the flexibility and detailed information to support exploratory research and also the opportunity to compare responses (Bryman, 2004:320-324). In addition, they can also provide insights and in-depth explanations (Saunders, Lewis, and Thornhill, 2009, p.323). Thus, the semi structured interviews were invaluable as a tool to investigate further. The interviews were conducted with a selected number of participants who were determined based on the outcome of the questionnaire survey. However, in view of the time limitation of this dissertation the total number of interviewees was restricted to three.

3.3. Data Collection

3.3.1. Quantitative Data Collection

- The data collection was conducted in three stages, with the first two stages involving the quantitative method. In the first stage, a preliminary questionnaire based on the literature reviews was pre tested on a small sample population. This was mainly to check to ensure that the wording of the question is not ambiguous (Royer and Zarlowski, 2001).

3.4. Data Analysis

3.4.1. Index Analysis

- The primary data collected from the questionnaire survey was quantitatively analyzed using the following four types of indices (Hoai, Lee & Lee, 2008).§ Severity index expresses the severity of the factors that cause overrun, and it is calculated as follows:Severity Index (S.I) = ∑Ws / (H x N)Ws= Total of severity weight given to each factorH= Highest Ranking Available which is 5 in this caseN= Total Number of Respondents who have answered the question.§ Frequency index expresses the frequent occurrence of the factors that cause cost overruns, and it is calculated as follows:Frequency Index (F.I) = ∑Wf / (H x N)Wf= Total of severity weight given to each factorH= Highest Ranking Available which is 5 in this caseN= Total Number of Respondents who have answered the question.§ Importance Index is the overall importance based on the severity and frequency, and it is calculated as follows:Important Index (IMP.I) = F.I x S.I§ Effectiveness index expresses the effectiveness of the mitigation measure to control the cost overrun and it is calculated as follows:Effectiveness Index (E.I) = ∑ We / (H x N)We = Total of Effectiveness weight given to each factorH = Highest Ranking Available which is 5 in this caseN = Total Number of Respondents who have answered the question.

3.4.2. Spearman’s Rank Order Correlation

- Spearman’s coefficient of rank order correlation was used to analyze the agreement or disagreement among each pair of parties. (I.e. Owners & Contractors, Contractors & Consultants, etc.), and it was calculated using Statistical Package for Social Sciences (SPSS). This was crucial to measure and compare the association between the rankings of two parties (Wakijara, 2011).

3.4.3. Factor Analysis

- Principal component factor analysis (PCFA) technique was used to summarize a large number of original variables into a smaller number of factors in order to determine the relationship among sets of variables (Krishnaswamy, Sivakumar and Mathirajan, 2006). Correlation matrix table, KMO & Barlett’s test of sampling adequacy, Communalities, and Rotated factor matrix table were done with the aid of SPSS. Rotated factor matrix table was calculated by principal axis factoring extraction method and varimax rotation method. This was used to group the top 20 ranked variables in to the small number of groups. (Leech, Barrett, Morgan, 2005, pop. 78-90).

4. Research Findings and Discussion

4.1. Respondent’s General Information

- The questionnaire was sent to a total of 295 construction professionals and 194 professionals responded to the questionnaire. The overall response rate was 66%, which is good. The total of 194 respondents consisted of 5 designated groups namely Project Managers, Cost controllers, Planners, Chief Estimators, and General Managers. Project Managers and estimators formed the largest group. 46% of the respondents had more than 20 years’ experience, and 93% of respondents had more than 10 years’ experience. The overall average experience of the respondents was 17 years, reflecting response to the survey by sufficiently experienced professionals, a factor that enhanced the reliability of the study's results.

4.1.1. Level of Project Cost Overrun

- 7% of the respondents stated that cost overrun occurred in all their projects while 34% of the respondents stated that cost overrun occurred in 50% of their projects. 46% of the respondents confirmed that cost overrun occurred in about 25% to 50% of their projects and only 16% of the respondents stated that cost overrun occurred in less than 25% of their projects. This confirmed Olawale & Sun’s view that cost overruns in construction projects are not uncommon all over the world (Olawale & Sun, 2010) and it is indeed a serious problem in the UAE construction industry.

4.2. Index Analysis

4.2.1. Frequency Index & Ranking

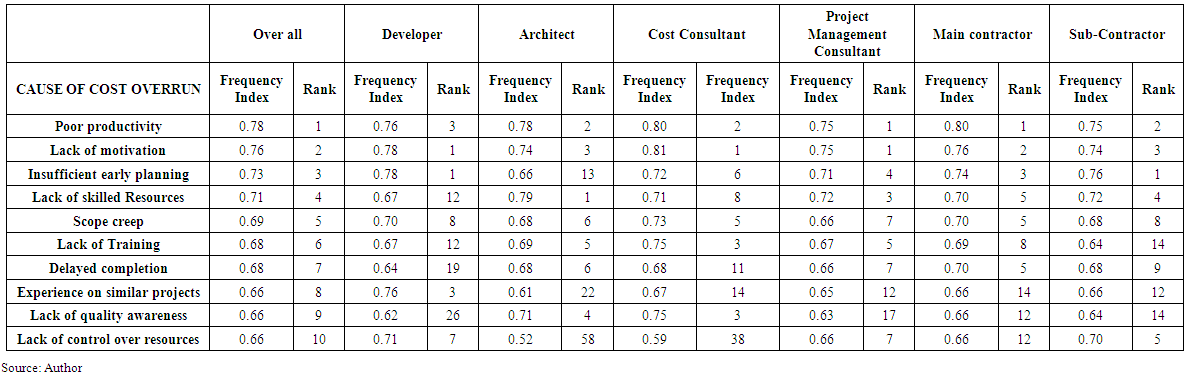

- Based on the rating on the factors causing cost overrun given by the 194 respondents, frequency index was calculated and ranked. The top ten ranking of extremely highly likely causes of cost overrun is tabulated in Table 4.1.Work force in UAE is predominantly made up of expatriates from south Asian countries. There is no proper mechanism to check the skill level of the workforce before deploying them on the job. This leads to poor productivity. The welfare of the workforce is generally ignored by the construction companies, and this result in lack of motivation towards work. Short and demanding project schedules cause insufficient preconstruction planning. There is no skilled construction resource readily available locally and, therefore, this needs to be recruited overseas, based on the specific requirement of the project. Mobilization of human resources from South Asian countries takes time, and until they are available, the contractors tend to hire at higher rates from other contractors locally (if available). This incurs additional cost. Short tender period and hasty evaluation of techno commercial offers results in improper / unclear scope definition. These results in scope creep and ends in cost and time overrun. A review of the above causes shows that problems in human resource management alone contribute 5 causes: integration management contributes 4 causes and time management contributes 1 cause.However, surprisingly lack of quality awareness and delayed completion were ranked 26 and 19 respectively by the developers compared with their overall rankings of 7 and 9. Change in policies, wrong procurement method, inclement weather, force majeure and political instability are ranked at the bottom. All groups of respondents stated that, external as well as government related factors rarely caused cost overrun. This is understandable because of the dynamic leadership and business friendly policies of the UAE government.

4.2.2. Severity Index & Ranking

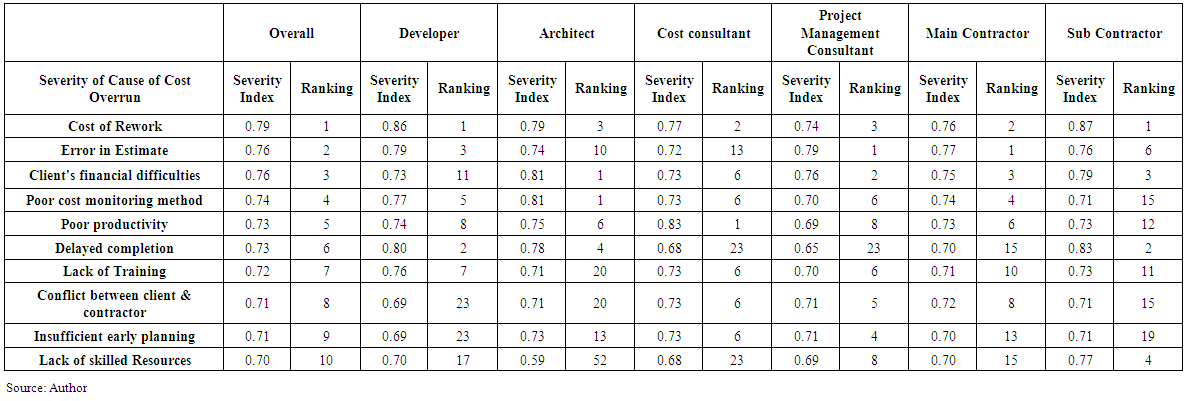

- Based on the rating of the factors causing cost overrun by the 194 respondents, severity index was calculated and ranked. The top ten ranking of very highly severe causes of cost overrun is tabulated in Table 4.2.

| Table 4.2. Top Ten Severity Index and ranking |

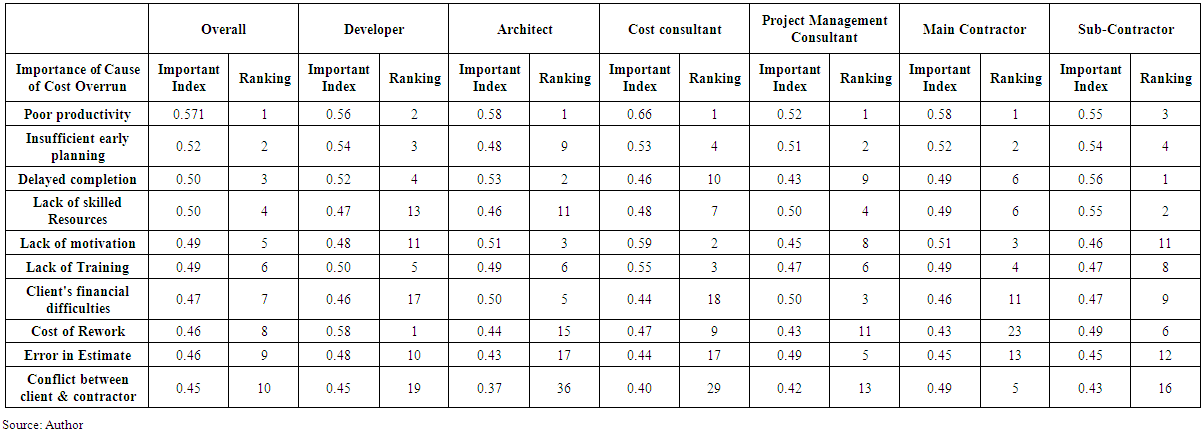

4.2.3. Important Index & Ranking of Causes of Cost Overrun

- Based on the frequency index and severity index, important index was calculated and ranked. The top ten ranking of the extremely important causes of cost overrun is tabulated in Table 4.3.

| Table 4.3. Top Ten Importance Index and ranking |

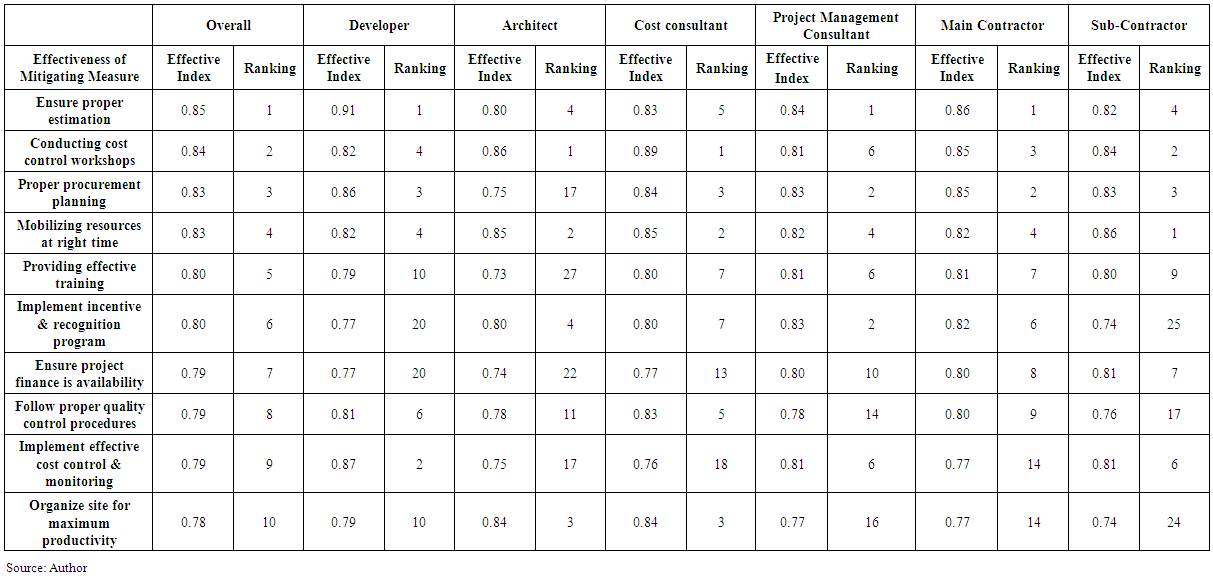

4.2.4. Effectiveness Index & Ranking of Mitigation Measures for Cost Overrun

- Based on the rating on the effectiveness of mitigation measures factors given by the 194 respondents, an effectiveness index was calculated and ranked. The top ten ranking of extremely effective mitigation measure for cost overrun is tabulated in Table 4.4.

| Table 4.4. Top Ten Effective Index and Ranking |

4.3. Spearman’s Rank Order Correlation

4.3.1. Frequency Index Correlation

- Spearman’s Correlation coefficient for frequency index was calculated and it shows an excellent correlation of the frequency of causes of cost overrun among the various stakeholders of the construction industry. In particular the correlation between the developer category and Main Contractor category is high with the coefficient of 0.837. This is followed by the correlation between PMC category and subcontractor category with the coefficient of 0.807. The correlation between Developer category and Architect category is the lowest with the coefficient of 0.566. As the correlation between the parties in ranking the frequency of causes of cost overruns is good, the data could be considered reliable for further analysis.

4.3.2. Severity Index Correlation

- Spearman’s Correlation coefficient for severity index was calculated and it shows an excellent correlation on the severity of causes of cost overrun among the various stakeholders of the construction industry. Particularly correlation between Main Contractor category and Sub Contractor category is high with the coefficient of 0.789. This is followed by the correlation between Cost Consultant category and Main Contractor category with the coefficient of 0.783. On the other hand, the correlation between Cost Consultant category and Sub Contractor category is the lowest with the coefficient of 0.59. As the correlation between the parties in ranking the severity of causes of cost overruns is good, the data could be considered reliable for further analysis.

4.3.3. Important Index Correlation

- Spearman’s Correlation coefficient for important index was calculated and it shows an excellent correlation on the importance of causes of cost overrun among various stakeholder of the construction industry. Particularly the correlation between Main Contractor category and Architect category is high with the coefficient of 0.859. This is followed by the correlation between the Main Contractor category and Sub Contractor category with the coefficient of 0.851. On the other hand, the agreement between Architect category and Developer category is the lowest with the coefficient of 0.714. As the correlation between the parties in ranking the importance of causes of cost overruns is good, data could be considered reliable for further analysis.

4.3.4. Effectiveness Index Correlation

- Spearman’s Correlation coefficient for effectiveness index was calculated and it shows an excellent correlation on the effectiveness of mitigation measures for cost overrun among various stakeholder of the construction industry. Particularly the correlation between Main Contractor category and Sub Contractor category is high with the coefficient of 0.919. This is followed by the correlation between the Main Contractor category and PMC category with the coefficient of 0.813. The correlation between Architect category and Developer category is the lowest with the coefficient of 0.616. As the agreement between the parties in ranking the effectiveness of mitigation measures is good, data could be considered reliable and used for further analysis.

4.4. Factor Analysis

- Factor analysis with principal component extraction technique was employed to extract a manageable subset of factors for the following.○ Top 20 ranked frequent causes of cost over runs○ Top 20 ranked severe causes of cost over runs ○ Top 20 ranked mitigation measures.

4.4.1. Factor Analysis on Frequency of Cost Overrun

- KMO and Bartlett’s test shows sampling adequacy of 0.646. The Kaiser – Meyer – Olkin measure of sampling adequacy was found to be 0.646 (>0.50) with a significant level of 0.000 level for Bartlett’s test of sphericity. These measures confirmed the suitability of the data for proceeding with factor analysis. Initial Eigen values and rotation sums of squared loading for the 20 variables were calculated and found that seven factors have Eigen values greater than 1.0, which is a common criterion for a factor to be useful.The rotated component matrix sorted out the 20 variables in to 7 overlapping groups of items, having loading of absolute value of 0.3 and above. The groups of variables identified are,ü Human resource Managementü Time Managementü Risk Managementü Planning & Controlü Safety & Quality ü Estimation & Scope controlü Inexperience

4.4.2. Factor Analysis on Top 20 Severe Causes of Cost Overrun

- KMO and Bartlett’s test shows sampling adequacy of 0.699. The Kaiser – Meyer – Olkin measure of sampling adequacy was found to be 0.699 (>0.50) and significant at 0.000 level for Bartlett’s test of sphericity. These measures confirmed the suitability of the data for proceeding with factor analysis. Initial Eigen Values and Rotation sum of squared loading were calculated for the 20 variables and found seven factors have Eigen values greater than 1.0, which is a common criterion for a factor to be useful.The rotated component matrix sorted out the 20 variables in to 7 overlapping groups of items, having loading of absolute value of 0.3 and above. The groups of variables identified are,ü Human resource Managementü Time Managementü Planning, Control & Monitoringü Procurement & Quality ü Estimation ü Change Managementü Project Finance

4.4.3. Factor Analysis on Top 20 ranked Mitigation Measures

- The Kaiser – Meyer – Olkin measure of sampling adequacy was found to be 0.64 (>0.50) and significant at 0.000 level for Bartlett’s test of sphericity. These measures confirmed the suitability of the data for proceeding with factor analysis. Initial Eigen Values and Rotation sums of squared loading were calculated for top 21 variables and found that seven factors have Eigen values greater than 1.0, which is a common criterion for a factor to be useful.The rotated component matrix sorted out the 21 variables in to 8 overlapping groups of items, having loading of absolute value of 0.3 and above. The groups of variables identified are,ü Human resource & communication Managementü Procurementü Value Managementü Estimationü Risk managementü Quality ü Experience

4.5. Interviews

- The outcome of the interviews with the three construction professionals was generally in agreement with the ranking of the factors causing cost overrun as well as the mitigation measures. Discussion with these professionals revealed many fascinating insights into how the factors are interlinked and how the mitigation measures could be implemented more effectively.

4.5.1. Productivity, Motivation & Training

- All interviewees agreed that poor productivity is indeed a critical problem in UAE. The Project Director said “Train to gain is the slogan in my project” He explained that productivity depends on the skill level and motivation of the work force. He suggested the importance of ensuring that critical materials are available on time to avoid idle labour. The Cost Control Manager suggested that detailed workshops should be conducted with the consultant, the Main contractor & subcontractors at regular intervals so that the workforce can be planned properly to enable discrepancies to be sorted out at the right time. The Project Management Consultant suggested that the need for management to invest in both offsite and onsite training of workmen. This will increase the productivity, quality of work, improve motivation and reduce rework and delays. He was certain that the benefits of training would be much higher than the cost of training and it is a Project Manager’s duty to convince higher management about the importance of training and also arrange suitable training for the project staff and workmen. “Project Manager is largely responsible for success or otherwise of the project. Unless he is proactive, project’s goal can’t be achieved” he summed it up.

4.5.2. Project Planning & Control

- All three interviewees agreed that poor project planning is extremely crucial to limiting delays and cost, and it is not generally carried out meticulously in UAE. The Project Director opined that lack of company data base on activity duration and productivity norms leads to poor planning. The Cost Control Manager opined that the lack of involvement of all parties in project planning leads to poor planning. He suggested that expertise in operating a planning tool like Primavera Project planner (P3) alone cannot ensure a proper project plan, because the involvement of the Project Manager, as well as specialist subcontractors, is paramount in developing a workable project plan. The Project Management consultant said “Fail to plan indeed is a plan to fail” He suggested that the project plan should be prepared, taking into consideration the specific characteristics of the project such as logistics, location, complexity, funding arrangement and should be modified based on changing market conditions. He insisted the Project Manager should envisage the changes in market condition and take proactive measures.The Project Management consultant added that Earned Value Management (EVM) is the best tool for monitoring & control, but unfortunately, only few companies were adopting this control system in UAE. He suggested activity based cost booking along with EVM will be helpful to identify the problem exactly, so that remedial measures can be implemented early. The Cost consultant quipped “you can’t reach goal post without knowing where you are now” He mentioned that on many projects, due to poor monitoring systems, the reasons of cost overrun are identified only after project completion.

4.5.3. Risk Management

- The Project Management consultant mentioned that risk assessment and monitoring are done on many projects in UAE, as a formality only and not as a critical process. He suggested that it is necessary for Project Managers to change their mindset about risk management and take it seriously. He insisted that risk management is even more crucial in a volatile market conditions as exists in the UAE. He pointed out the need for the risks to be identified, throughout the project life time and control measures implemented. The Cost consultant said “Never ignore your instincts. It smells the risks better” He mentioned that failure to envisage the impending risks resulted in the termination of many projects in 2009.

4.5.4. Procurement

- All interviewees agreed that proper procurement planning is critical for preventing not only time overrun, but also cost overrun. The Project director pointed out that, in many projects in UAE, the developer delays the appointment of nominated sub-contractors such as Mechanical, electrical & Plumbing (MEP) works, Interior decoration works. However, main contractors are forced to accept the delayed nomination without extension of time. For mitigating the delays, the Main contractor tries to fast track and crash the schedule. This results in rework and additional cost to the Main contractor. To avoid this, the main contractor's schedule should have milestones for the nomination of sub-contractors. The Main contractor should proactively work with the developer for the nomination of sub-contractors at the right time. The Project management consultant suggested that the actual construction progress should be coordinated with the suppliers properly, so that they are delivered just in time to avoid double handling, wastage and to reduce inventory cost. “Bid shopping is a curse to this market” said the Cost consultant. He insists that the developer should not go for bid shopping, as it will tarnish the image of the developer in the long run. He opined that specifying a single source in the tender document leads to unethical practice.

4.5.5. Experience

- The Project management consultant pointed out that appointing inexperienced contractors based on low bid was not a wise decision. Generally it leads to time overrun, disputes, low quality and ultimately cost overrun. The Project director mentioned that relevant experience is necessary for proper coordination between various trades, and lack of experience leads to rework and delays.

4.5.6. Estimation

- The Project director opined that, contractors were forced to estimate the project cost on lump sum basis with incomplete information and scope bifurcation. Pressure from the client to submit unqualified lump sum offer in a short time compounds the problem. He pointed out that queries raised by contractors are vaguely answered by consultants and results in improper estimation during tender stage and disputes / cost overrun in later stage. To overcome this, pre bid meeting should be conducted in the presence of the client’s representative. The Project management consultant pointed out that, the main contractor is ultimately responsible for the project cost in lump sum contracts. Based on his experience, he should allow contingency for such unclear items. The Cost consultant pointed out that on many projects, clients themselves evaluate the contractor’s bid based on lump sum prices, but they could not identify the contractor’s estimation errors. Early involvement of a cost consultant may reduce estimation errors. He suggested that every company should have their productivity norms and other cost data from their current projects and the same shall be used for the estimation of tenders.

4.5.7. Change Management

- “Claims & dispute settlement is a big business here, which is a loss loss situation to both client and contractor. Mutual trust is the key to avoid dispute” said the Project Director. He mentioned that approvals for change order costs are usually delayed by consultants and clients and settled only at the end of the project. This leads to dispute and cash flow problems to contractors. The Project Management Consultant pointed out that mistrust between the contractor & the client is the main reason for such disputes. He suggested that change management procedure should be agreed between all the main stakeholders at the beginning of the project and strictly adhered to. The Cost consultant admitted that “We are supposed to be unbiased but we couldn’t be so”. He insisted that impartiality of the consultant is paramount for settling the cost of change but many clients expects cost consultant to act in their favor. He suggested that partnership contract is ideal for projects where frequent changes are expected. However, the Project Director pointed out that partnership contract in UAE is rare and failed miserably on a beach development project he worked on. He expressed the view that the construction industry in UAE is not matured enough for partnership arrangement.

4.5.8. Value Management

- All the interviewees concurred that Value Management was an ignored concept in UAE until the economic downturn. They pointed out that it was ignored due to the urgency of the client for starting the project. They were of the view that Value Management is extremely effective only if it is carried out at the beginning of a project. The Project Management Consultant pointed out that, in some cases, value management will shorten the project time. He further explained that, after the economic downfall, most of the projects are going through Value Management and Value Engineering processes. The Project Director mentioned that client’s awareness and the involvement of the contractor at the design stage are paramount for effective Value Management. However he cautioned that dilution of specification and compromise on the design for short term benefits in the name of Value Engineering may back fire in the long term. “All for me attitude of client desist the contractor from value engineering” said the Cost Consultant. He suggested that Value Management can be implemented effectively only if the benefits are shared between the contractor and client.

4.5.9. Project Finance and Client’s Financial Difficulty

- The Interviewees felt the client’s financial difficulty is a serious problem causing cost overrun, but they pointed out that this has been a prevalent phenomenon only after 2009 and unexpected changes in the economy account for it. However, the project director pointed out that, underestimation of the cost of projects and overestimation of the financial returns from the projects are the other reasons for the client’s financial difficulty. The Cost Control Manager opined that change in scope & design without evaluating the cost and time impacts compounds the client’s financial difficulty. The Project Management Consultant explained that, the over estimation of demand, non-consideration of current projects results in oversupply. The projects become unviable due to over -supply of buildings and puts the client in financial woes. He noted that starting the project without sufficient financial arrangements does not only affect the contractor, but also the developer and the investors. This leads to dispute and loss of reputation. The Project director mentioned that there are some instances where the developer siphoned the investor’s money for purposes other than project purposes and thus jeopardizing the project, the contractor and the investor's interests. He suggested that government should regulate the project finance, so that investors and contractors interests are protected. Some of the salient concepts surfaced during the interview are the following:ü Project Managers are responsible to prevent cost overrun, and they should be proactive and not reactive.ü Higher management should support and take the initiative to implement training programs, recognition and reward programs to improve productivity and motivation.ü Updating the cost data from current projects is crucial for reducing estimation errors. Lessons learnt from previous projects are valuable to prevent cost overrun.ü Changes cause friction. Effective client management & Change management process are paramount to mitigate the same.ü Collaborative approach improves value management and benefits the Contractor as well as Client.

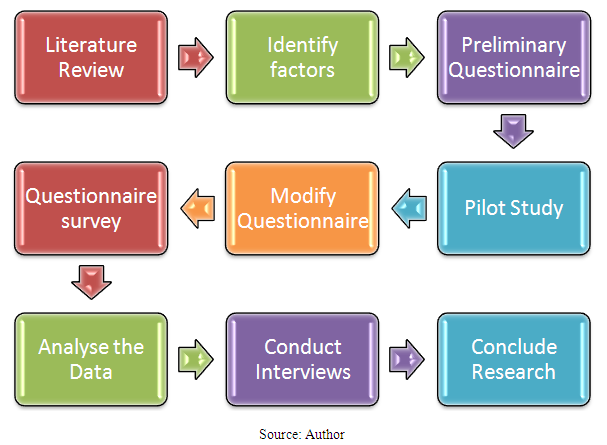

4.6. Model for Mitigating Cost Overrun

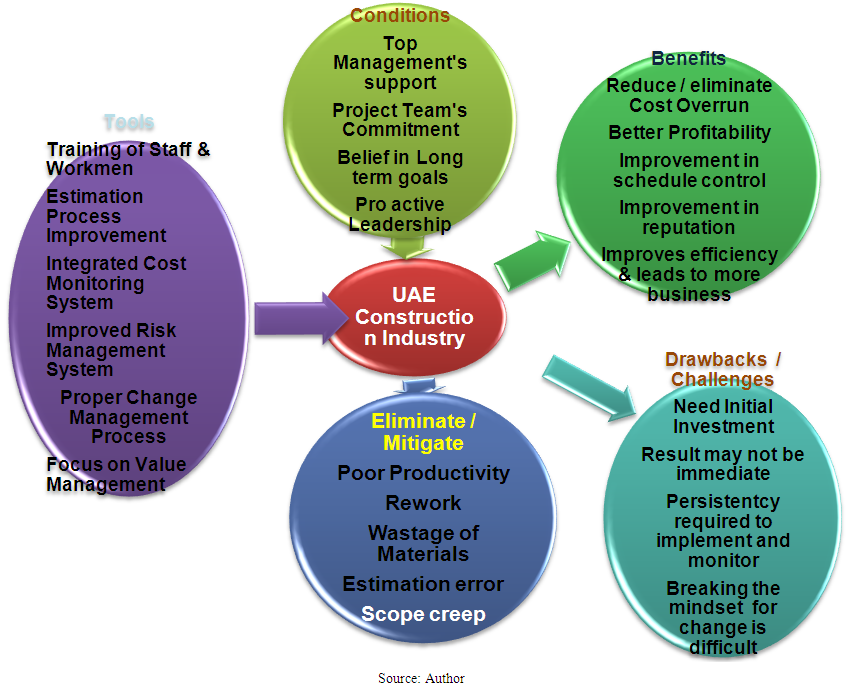

- Based on the literature review, questionnaire survey and interview outcomes a general model for mitigating cost overrun in UAE Construction industry is presented in Figure 4.4. This model proposes the need for training of staff & workmen, estimation process improvement, integrated cost monitoring system, risk management system improvement, proper change management process and focuses on value management. Conditions like top management's support, project team's commitment, belief in the long term goals and proactive leadership are necessary to reduce cost overrun, improve profitability and schedule control. This would also improve the reputation of the organization, efficiency and leads to more business. However, process improvements & training need investment and results may not be immediate. Persistency is crucial to implement and monitor the recommended process improvements. Breaking the mindset of the employees towards the changes may also be a challenging task. Nevertheless, since these drawbacks have been highlighted, efforts could be directed to mitigate them. Finally in the next section, a discussion on measures that could be taken to improve the following is presented based on the outcomes of the study: (i) Productivity, (ii) Estimation Process, (iii) Value Management, (iv) Change Control Process, and (v) Procurement Management.

| Figure 4.4. General Model for Mitigating Cost Overrun in UAE Construction Industry |

4.6.1. Improving Productivity

- Improving productivity requires strict recruitment procedure, training of staff & workmen, rewards & incentive scheme, improving welfare, better construction methodology, efficient & effective communication and sufficient material inventory at the site. As noted by Jergeas (2009), incentive and recognition program is pivotal in improving productivity. Conditions like top management support, project team's commitment, unbiased incentive scheme, and proper trainers are essential to reduce or eliminate cost overrun, improve profitability, improve relationship improve productivity & motivation, reduce employee turnover and improve efficiency. However, training requires investment and results may not be immediate. Persistency is crucial to implement and monitor the recommended process improvements. A caution is that incentive scheme may also trigger unethical practices.

4.6.2. Improving Estimation Process

- Improving estimation process proposes the need for a risk assessment for bid / no Bid decision, analyze impacts of techno commercial conditions, integrated software for estimation, cost & productivity data from organization's projects, regular update on cost data, clear understanding of scope and sufficient time to cross check the estimate. Hence as suggested by Olawale & Sun (2010), risk register shall be prepared from tender stage. Cost data base shall be updated regularly to avoid estimation error. Conditions like top management support, estimation team's commitment, avoiding impulsive decisions are crucial to improve estimation process, which improves accuracy of estimate, reduce / eliminate cost overrun, scope creep, reduce disputes, improve order booking and reduce risks. However, the drawbacks or challenges are that declining to quote may upset the client, and a refusal to accept an onerous clause could lead to loss of tender.

4.6.3. Improving Value Management

- Improving value management needs early involvement of the contractor, cost / benefit analysis of all major items, specification audit, and benefit sharing between the client & the contractor, and preferably a partnership contract. Value engineering exercise should not be disruptive to the progress of the project. Conditions like top management support, and trust between the client, the consultant & the contractor are paramount to ensure maximum value and better profitability. However, the drawbacks or challenges are that value management may lead to dilution of quality, if the purpose is misunderstood. Breaking the mindset for change is also difficult. Nevertheless, since these drawbacks have been highlighted, efforts could be directed to mitigate them.

4.6.4. Improving Change Control Process

- As recommended by Love & Li (2000), efforts shall be focused on proper understanding of the client requirements, coordinating and checking design documentation and conducting design analysis review to reduce design changes, errors and omissions. Improving the Change Control Process requires a change control board with a well-defined authority. Conditions like top management support, project team's commitment and strong leadership are necessary to support the change control board in its work to ensure the elimination or mitigation of scope creep and thereby help to reduce or eliminate cost overrun to improve profitability and lessen disputes. However, the drawbacks or challenges are that the process might affect the project progress if this process becomes rigid, bureaucratic and decisions are delayed.

4.6.5. Improving Procurement Management

- Lastly, improving procurement management requires, procurement planning, envisaging inflation / deflation & planning accordingly, written procedure & approval levels, risk transfer measures, integrated software, just in time, inventory control and principled negotiation. Conditions like top management support, strict adherence to procedure, avoiding impulsive decisions, no political & psychological influence and ensuring transparency are critical to improve procurement management in its bid to reduce / eliminate cost & time overrun, reduce disputes, reduce idling time, and reduce risks. However, the drawbacks or challenges are that adherence to procedure may upset some stakeholders / political class. Also, foreseeing inflation / deflation is also difficult. Furthermore, supply chain must be efficient for the implementation of just in time process.

5. Conclusions

5.1. Key Research Findings

- The cost overrun mitigation strategy was developed to deal with the common challenges in UAE Project Management system. In general, the findings indicated that the external & government factors were rarely influencing the cost and only internal factors and more particularly Human Resource related factors were highly influencing the cost overrun. As the principal causes are internal, it is possible to minimize the cost overrun by adopting proper project management methodology and the mitigation measures discussed in this study. Since the crux of the cost overrun is found to be issues related to human resource and estimation, higher management could give due importance to training at all levels. They could also focus on establishing a proper estimation procedure, as estimation will make or mar the future of the company. Estimation should also be adjusted continually, based on the feedback from the current projects.

5.1.1. Research Objective 1

- This first objective was to determine the factors that influence cost overrun in construction projects, in UAE. A total of 83 factors were identified through various literature reviews and listed in appendix 1. It was classified under eleven categories.

5.1.2. Research Objective 2

- The second objective was to explore the inter relationship between the cost overrun factors. The correlations between the top twenty ranked cost overrun factors were identified using SPSS software and grouped in to seven categories. Correlation matrix for Top 20 ranked frequent causes of cost overrun is identified. Some of the highly correlated frequent causes of cost overrun are:ü Between, delays in project financing arrangement and delayed completion.ü Between, poor productivity and lack of skilled resources.Correlation matrix for Top 20 ranked severe causes of cost overrun in displayed in table 4.13. Some of the highly correlated severe causes of cost overrun are:ü Between, defective material / poor quality and cost of rework.ü Between, delayed completion and liquidated damages.

5.1.3. Research Objective 3

- The third objective was to rank cost overrun factors in terms of frequency and severity. 83 causes of cost overrun identified in appendix 1 were ranked based on the rating of respondents in the questionnaire survey.

5.1.4. Research Objective 4

- The fourth objective was to identify the measures that could be taken to mitigate cost overrun. A total of 69 mitigation measures were identified and tabulated in appendix 2. Based on the questionnaire survey ratings, these 69 measures were ranked. In addition, with the help of SPSS software, the top 20 effective mitigation measures were sorted out to 7 groups.

5.1.5. Research Objective 5

- The fifth objective was to propose a model on best practices to avoid cost overrun in construction projects. Based on the literature review, the questionnaire survey and further interviews with experienced professionals, a general model with supporting models were prepared and presented in figures 5.1.

5.2. Contributions to the Knowledge

- The main contributions of this research study are as follows.a. The factors influencing the cost overrun of construction projects in UAE are identified. Their likelihood as well as severity is rated, ranked and grouped. This can be used as a checklist at the project initiation stage to ward off cost overrun.b. The mitigation measures for cost overrun factors are identified. Their effectiveness is rated and ranked. The conclusion of the research emphasizes the need for training and motivation for the human resources for preventing cost overrun. This author believes this research conclusion could change or influence the mindset of higher management regarding human resource management.c. The study presents a model that could be employed to mitigate the cost overrun in UAE was developed. This could help the construction professionals to minimize cost overrun.

5.3. Research Limitations

- This research is limited to construction projects in UAE and also public infrastructure projects are not included. Thus, the respondents of this research were mostly from the private sector. Hence the results and the recommendations of this research would appear to be more suitable for private sector construction projects in UAE. Therefore, caution is required, when using this data and recommendations for infrastructure /government projects, as the causes of cost overrun and their mitigation measures for government & infrastructure projects could be different.This research was carried out at a time when the construction industry was facing severe recession. Hence some cost overrun factors like non availability of materials, inflation which is rated as less important in this study could become extremely important when boom time comes.

5.4. Suggestions for Further Research

- While this study focused only on the cost overrun factors and their mitigation measures, further research could include time overrun factors, their correlation with cost overrun factors and also mitigation measures for time overrun. Another area for future research could be to measure the cost of training against the cost benefits of training since a key finding of this research was that providing training is one of the most effective mitigation measures for cost overrun. This will enable the higher management to make an informed decision on investing on the training of human resources.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML