-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Construction Engineering and Management

p-ISSN: 2326-1080 e-ISSN: 2326-1102

2017; 6(3): 103-109

doi:10.5923/j.ijcem.20170603.05

Experimental Study of the Thermal and Mechanical Properties of Compressed Earth Blocks Stabilized with Sawdust According to the Rates for the Thermal Insulation of a Building

Drissa Boro, P. Florent Kieno, Emmanuel Ouedraogo

Laboratoire d’Energies Thermiques et Renouvelables (L.E.T.RE), Université Ouaga 1 Pr Joseph KI-ZERBO, Unité de Formation et de Recherche en Sciences Exactes et Appliquées (UFR/SEA), Burkina Faso

Correspondence to: P. Florent Kieno, Laboratoire d’Energies Thermiques et Renouvelables (L.E.T.RE), Université Ouaga 1 Pr Joseph KI-ZERBO, Unité de Formation et de Recherche en Sciences Exactes et Appliquées (UFR/SEA), Burkina Faso.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

This paper presents an experimental study on the thermal and mechanical characterization of local materials used in building. These materials are blocks of compressed earth and stabilized with sawdust. Measurements of the thermophysical properties reveal that thermal conductivity decreases as the volume of sawdust in the mixture increases. It is 0.962 W.m-1.K-1 for simple compressed earth blocks, 0.907 W.m-1.K-1 for 1% sawdust and 0.512 W.m-1.K-1 for a dosage at 8%. These materials diffuse less heat and rapidly warm up significantly on the surface if the rate of sawdust increases. Dry compressive strength tests show an improvement of the mechanic strength when the dosage rate ranges between 0% and 1%. Lastly, we have also calculated the depth of diffusion of a room according to the various types of blocks used to build it.

Keywords: Thermophysical properties, Mechanical strength, Compressed earth blocks, Sawdust, Stabilization

Cite this paper: Drissa Boro, P. Florent Kieno, Emmanuel Ouedraogo, Experimental Study of the Thermal and Mechanical Properties of Compressed Earth Blocks Stabilized with Sawdust According to the Rates for the Thermal Insulation of a Building, International Journal of Construction Engineering and Management , Vol. 6 No. 3, 2017, pp. 103-109. doi: 10.5923/j.ijcem.20170603.05.

Article Outline

1. Introduction

- Housing issue in developing countries like Burkina Faso will not be handled with modern building materials. Production capacities are limited and, above all, their costs are high [1]. As a result, research is being conducted on local materials to improve their thermal behavior, strength and reliability to be used in buildings. However, it is obvious that the earthen-made habitat suffers from a lack of mechanical strength. To overcome these weaknesses, the physical stabilization by adding sawdust and the mechanical one with mechanical compression remain the appropriate solutions. P. Meukan et al. [2] in a thermal and mechanical study of earth stabilized with sawdust have shown that laterite blocks to which sawdust is added are better thermal insulators than simple laterite blocks.In this paper, we expound the study of the thermophysical and mechanical properties of the compressed earth blocks stabilized with sawdust at different dosage rates. The work by Imbga et al [3] presented the thermophysical parameters of various formulations with laterite and slaked lime. This investigation has shown that the thermal conductivity decreases when the rate of lime is lower than 4% and increases when the rate is higher than 4%. This study indicates also that the compressive strength increases but very slowly. J. Torkaman et al [4], in a parametric experimental study on the effects of partial replacement of Portland cement by wood fiber, rice husk ash and limestone powder waste for producing a lightweight concrete block as building materials, have founded that the optimum replacement level of these materials was 25% by weight; this replacement percentage resulted in good physic-mechanical properties. Amir Rahimi et al [5] studied the effects of using different percentages of organic waste ash instead of cement by weight on the mechanical properties and ductility of concrete specimens. Their results showed that 5% of these organic waste ashes instead of cement by weight lead to optimum performance. Influence of banana fibers on the mechanical properties of banana compressed block have been studied by Marwan M. et al [6]. They concluded that the blocks constructed by adding banana fibers throughout the mix performed better than the block with no fibers. We particularly study the impact of wood sawdust content on the thermal conductivity and the compressive strength of the stabilized materials and we will determine the optimum wood residue content for the best thermal and mechanical performances.The compressed earth block is raw clay molded into metal molds (iron, steel) or any other material offering the same qualities. It is a thermal mass which is a stock of heat or freshness, due to its high density and its quality as a hygrometric regulator [7].

2. Methods and Techniques used in Materials Production

- The experimental device used to make test tubes includes a manual press, a mold with its accessories. The BTC production process is subdivided into five (5) steps (choice of soil, riddling, mixing, production, drying). The production of BTC is done using the relevant manual presses for the various types of blocks produced. Concerning the production site, presses are designed to produce two or more bricks at a time. The press used to produce blocks is provided with a steel mold to reduce deformations due to the compression load. This mold includes two (02) blocks of the following dimensions: Length L = 14cm, Width l = 14cm Height H = 8cm. Bricks marked L0 are obtained after preparing the mixture without any stabilizer. The bricks marked L1 are made of lateritic earth plus 1% of the mass of sawdust used to prepare the mixture. The bricks market L2 are those made of lateritic earth plus 2% of the mass of sawdust used to prepare the mixture. This process was repeated by varying the rate of sawdust to 8% of the total mixture. Beyond this content of sawdust, the material no longer has the least mechanical strength.

3. Study of the Dry Compressive Strengths of Materials According to the Dosage Rate of the Sawdust

- Tests to determine the compressive strength of dry materials have been developed. These tests consist in applying to a dry block sample (dry BTC), using a crushing press, a simple compressive load until the complete breaking and determining the load value (read on the screen of the crushing press). The dry compressive strength of the bricks is given by the following formula:

With:• RC(MPa) compressive strength;• F(N) the maximal load born by the brick;• S(mm²) the strength pressure area.

With:• RC(MPa) compressive strength;• F(N) the maximal load born by the brick;• S(mm²) the strength pressure area.3.1. Measurements of the Compressive Strengths of Earth Blocks Stabilized with Sawdust

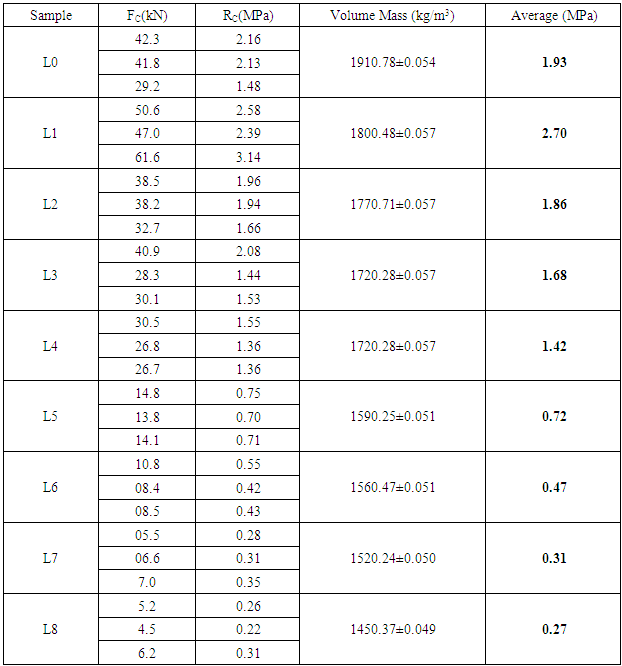

- Table 1 below gives the results of the compressive strength measurements.

|

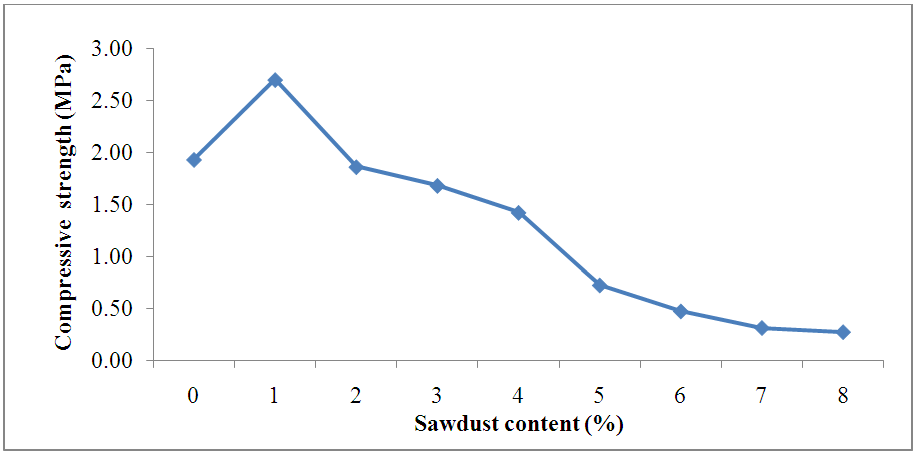

| Figure 1. Variation of the compressive strength according to the sawdust content |

3.2. Analysis and Interpretation of Results

- We find that the average value of the compressive strength of compressed laterite bricks without stabilizer is 1.93 MPa. This strength increases to reach the maximum average value of 2.70 MPa if we add 1% of sawdust, accounting for an increase of 0.77 MPa or 28.51%.The dry compressive strength is due to the molecular cohesion; the greater the cohesion, the higher the compressive strength. For a sawdust content of more than 1%, the strength value decreases due to poor adhesion of the laterite with the sawdust. Indeed, test tubes become thicker and thicker (larger dimensions than simple earth test tubes) just after the release from the mold when the sawdust content increases.The volume increase could be explained by the fact that water absorbed by wood alters these physical properties, including its elasticity modulus (mechanical stress that would lead to an extension of 100% of the initial length of the material). The increase in the volume of the test tube after the release from the mold may be explained by the fact that the elastic limit (value of the maximum stress which generates irreversible deformation) is not reached during compaction. The sawdust therefore tends to resume its initial dimensions as soon as the compressive strength stops. Thus, the reduction in density is accompanied by losses in mechanical compressive strength due to the decrease in the material compactness. For 1% stabilization, the compressive strength increases by 0.77 MPa, i.e. 28.51%.

4. Experimental Measurements of the Thermal Properties of Laterite Bricks

4.1. Principle to Measure Thermal Properties

- Thermophysical properties of materials are quantities that characterize the behavior of materials. They constitute the capacity of heat to spread in a body or to be stored in it. Thermophysical characteristics such as thermal conductivity, thermal diffusivity and volumetric specific heat were measured using KD2-pro, a dual-needle probe developed by Decagon [8]. This device uses the model proposed by CRASLAW and JAEGER [9] to solve the equation of heat transfer using the linear heat source propagation method in a transitory regimen in semi-infinite medium, an equation published in the IEEI [10]. The advantages of this type of method lie mainly in the simplicity of the equipment, the speed of measurements and the possibility to do it in situ under any hygrothermal conditions.

4.2. Results of the Measurements of Thermophysical Properties

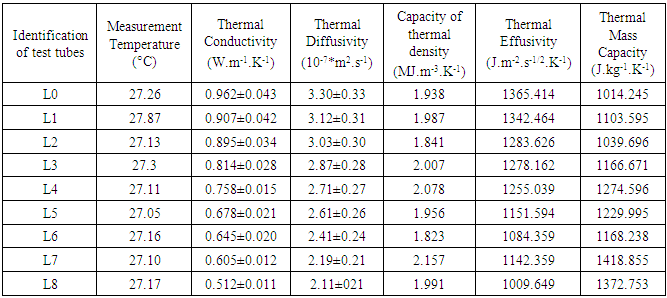

- The results of the measurements of the thermal properties are registered in the table 2 below.

|

4.3. Analysis and Interpretation of Experimental Results

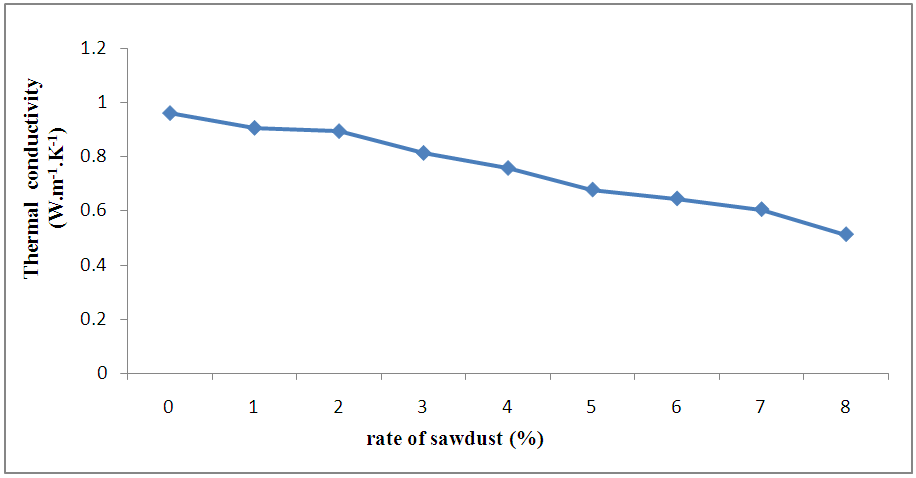

- a) Thermal ConductivityThermal conductivity values per rates of sawdust are represented in figure 2.

| Figure 2. Variation of the thermal conductivity with the rate of sawdust |

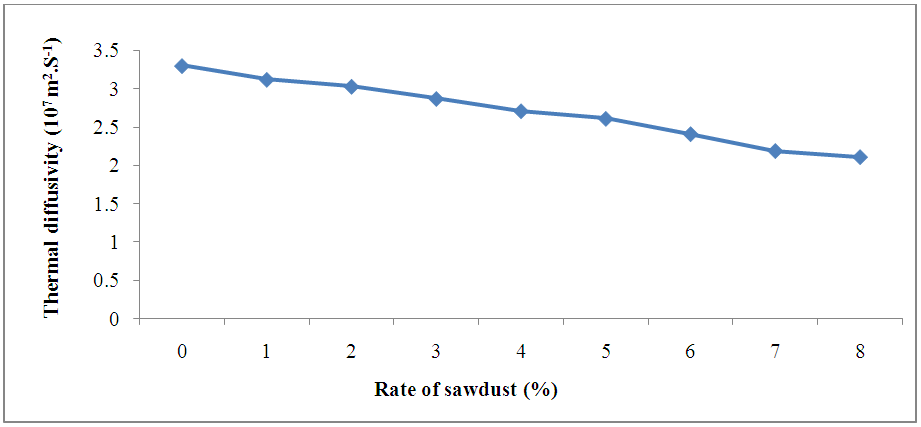

| Figure 3. Thermal diffusivity values with the rate of sawdust |

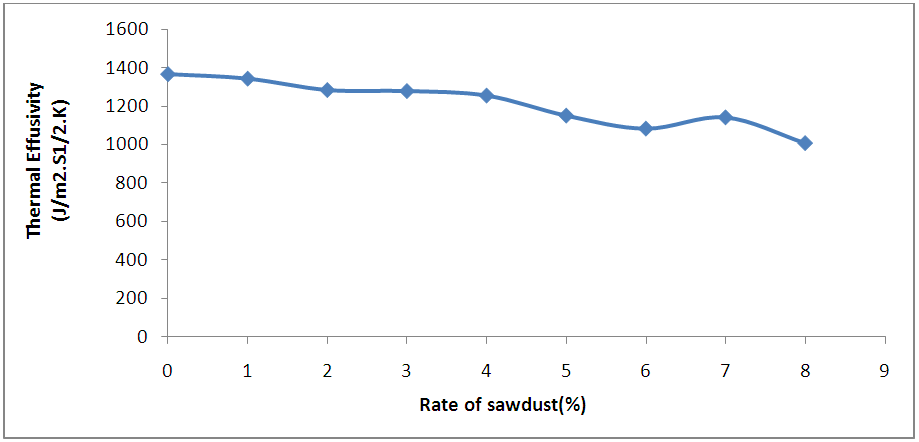

| Figure 4. Variation of the thermal effusivity with the fraction of sawdust |

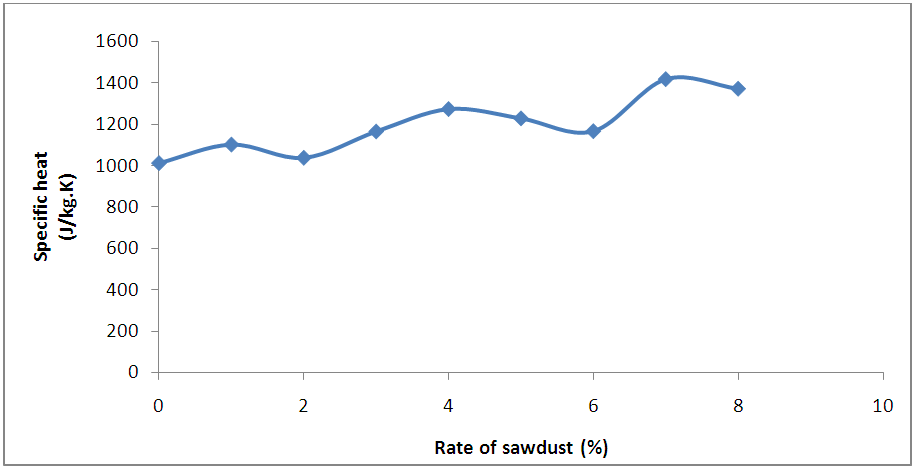

| Figure 5. Values of the specific heat according to the rate of sawdust |

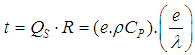

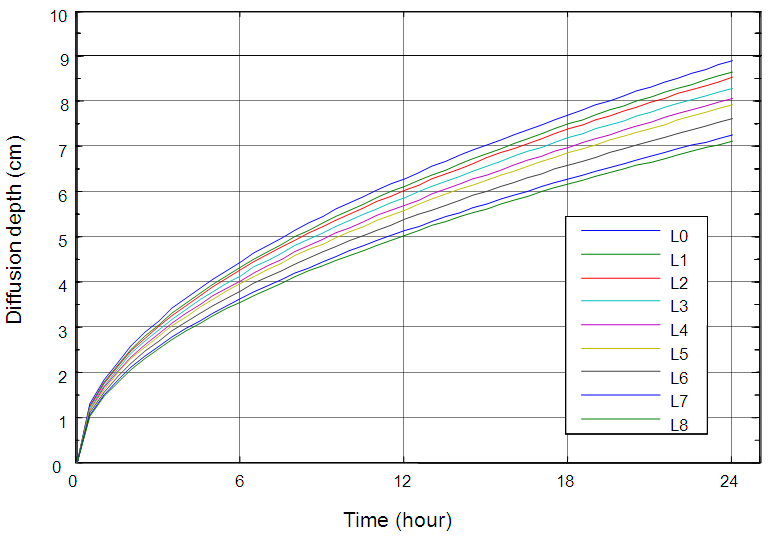

5. Depth of Heat Diffusion

- Heat diffusion in the material depends on its diffusivity (𝜶) which is the ratio of its thermal conductivity λ (W.m-1.K-1) by the volume specific heat. Thermal diffusivity α (m2.s-1) determines the rate at which heat spreads over in the material. More the material has high conductivity and small calorific capacity, more the diffusivity is high. The relationship between the thickness requested and the heat diffusion time within a homogeneous component of the building is established by calculating the product of the surface calorific capacity Qs (J.mol-1.K-1.m-2) by the thermal strength of this component R (m2.KW-1).The diffusion time t (s) is given by the equation (1) below.

| (1) |

| (2) |

| Figure 6. Diffusion depth of BTC formulated |

6. Conclusions

- At the end of our study, we were able to determine the thermophysical properties (thermal conductivity, diffusivity, effusivity, volumetric heat) and the compressive strength of the compressed earth bricks stabilized with sawdust.For a sawdust ratio ranging between 0% and 8%, the value of the thermal conductivity decreases from 0.962 to 0.512 W.m-1.K-1, i.e. a decrease of 46.77%.On the whole, the thermal conductivity decreases when the sawdust content in the making up of the mixture increases, which shows that these materials have good thermal insulation. We also find that the compressive strength of the compressed laterite brick without stabilizer has an average value of 1.93 MPa. This strength increases to reach the maximum average value of 2.70 MPa if we add 1% of sawdust and then decreases as from 2%. The mechanical strength (strength higher than 1 MPa) of the blocks is acceptable for a maximum stabilization rate of 4%. If we take the thermal and mechanical properties of the bricks into account, the best rate of sawdust to recommend is 1%. Concerning thermal performances, we see that the depth of diffusion is less than the thickness of the wall whatsoever the material used.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML