-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Construction Engineering and Management

p-ISSN: 2326-1080 e-ISSN: 2326-1102

2016; 5(4): 102-107

doi:10.5923/j.ijcem.20160504.02

A Systematic-Innovation Design Approach for Green Product

Yao-Tsung Ko, Ming-Shih Chen, Chia-Chen Lu

Department of Industrial Design, Tunghai University, Taiwan

Correspondence to: Yao-Tsung Ko, Department of Industrial Design, Tunghai University, Taiwan.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Without creativity in design there is no potential for innovation. However, both Quality Function Deployment (QFD) and Theory of Solving Inventive Problems (TRIZ) techniques have their own advantages and drawbacks. This paper presents a systematic-innovation design method for green product based on the QFD approach and TRIZ tools. Despite the recognized importance of conceptual design, there is a lack of a systematic and effective innovation creating process for green product. To address this gap, a useful and powerful design method of systematic innovation is created for green product, depending on the capability of QFD detailed problem analysis and the prowess of TRIZ innovative idea generation. The proposed design method was developed with QFD-I and an eco-contradiction matrix identifying the contradiction between customer needs and eco-efficiency elements for deriving TRIZ invention principles. The eco-innovative product could be created depended on these specific solutions. A case study of a innovative camping light design was demonstrated for the applicability of this method and the results validated the feasibility and effectiveness.

Keywords: Systematic-innovation, Green product, QFD, TRIZ, Eco-contradiction matrix

Cite this paper: Yao-Tsung Ko, Ming-Shih Chen, Chia-Chen Lu, A Systematic-Innovation Design Approach for Green Product, International Journal of Construction Engineering and Management , Vol. 5 No. 4, 2016, pp. 102-107. doi: 10.5923/j.ijcem.20160504.02.

Article Outline

1. Introduction

- Technological advance often conflicts with environment. It usually emphasizes the advantage and novelty of an innovation product but ignores its environmental impact. Corporate has the responsibility to make its activities be more environmentally friendly. Systematic-innovation for environmentally conscious design is particularly important in manufacturing industry. To implement systematic -innovation concept, it is critical to take environmental aspects into account in the early phases of design, such as the planning and the conceptual design phases Many systematic- innovation methods [1, 2] have been developed to assist the design engineers for reducing the environmental impact of the product throughout its life cycle. Nevertheless, those methods are focused on the redesign or optimization of existing products. Design engineers always attempt to reduce the harmful impact from products or processes; however, it is not easily achieved. It seems to be an irreconcilable problem for design engineers.Therefore, it is necessary to develop a pratical systematic-innovation approach for eco-product design. The purpose of this study is to develop a systematic-innovation methodology for green product based on Quality Function Deployment (QFD) approach and the Theory of Inventive Problem Solving (TRIZ) tools.

2. Related Works

- Many design methods and tools have been developed to support systematic-innovation. Cascini et al. [3] aimed to bridge systematic invention practice with product life cycle management systems by integrating TRIZ principles within a computer aided design system. Concerning eco-invention, Fresner et al. [4] applied TRIZ in cleaner production to have a more rational use of materials and energy to reduce waste and emissions in industrial activities. Sakao [5] proposed another extension, coupling TRIZ and quality function deployment by integrating life cycle analysis. In another research Grote et al. [6] used TRIZ evolution patterns to explain the relationship between product function and service. Chen [7] developed an eco innovative design method by incorporating green evolution rules and ideality laws to create products and processes that are innovative, useful, and environmentally friendly. Justel et al. [8] utilized TRIZ evolution patterns to get the evolution of joint parameter for disassembly. Although life cycle assessment (LCA) is an essential evaluation method for systematic- innovation based on the life cycle approach, in LCA the environmental burden is not evaluated until the detail design phase. Also, there are few quantitative methods for improving a product using LCA data. Karsak et al. [9] presented a QFD systematic decision procedure in product planning, which has been traditionally based on expert opinions and consider the interdependence between the customer needs and product technical requirements. Tsai et al. [10] used fuzzy QFD approach with an optimistic index in the priority ranking procedures. However QFD [11] is easy to use for clarifying key components from both the quality and environmental aspects in the initial design phases, but it does not support the generation of solution ideas. At the product level, it is important to detect local conflicts in products and to resolve those conflicts. TRIZ [12, 13] which is useful for resolving conflicts of parameters in the product is an inventive problem-solving method. Because of the capability of solving conflict problems, the ideas of implementing TRIZ for eco-innovative design have been proposed. There is still a disadvantage of finding hardly the contradiction parameters for invention principles. Although some above researches have successfully integrated QFD and TRIZ for NPD, these approaches and models are still very difficult to use in practice. Most of them just provide a procedure or guidelines instead of an operational model. However, this paper provides a more enhanced and robust method. The proposed systematic-innovation approach utilises TRIZ more effectively for eco-product. This will bring more efficiency and feasibility to the problem-solving processes. Meanwhile, this paper also proposes a operational model of eco-contradiction matrix to help designers generate more conveniently and effectively creative outcomes in NPD. The rest of this paper is organized as follows: Section 2 introduces the related works of systematic-innovation method. Section 3 describes the proposed methodology in detail. In section 4, a case study is illustrated to verify the feasibility and effectiveness of the proposed method, and finally, Section 5 provides some concluding remarks.

3. Methodology

- The proposed method is an systematic- innovation design method based on the eco-efficiency elements concept, QFD-I approach and TRIZ tools.

3.1. Integration of QFD and TRIZ

- QFD can be used to define systematically and decompose the leading design problem and to analyse the feasibility and validity of the design solution by the House of Quality (HoQ). TRIZ is a systematic method for creating innovative resolutions. However, both techniques have their own advantages. Here, these two techniques are applied to construct a framework of new design method. This method is achieved by integrating QFD and TRIZ with specific functions. This framework is called the systematic-innovation design approach. By combining QFD with TRIZ, we attempt to capitalise on the merits of both techniques. Firstly, QFD is adopted to analyze the customer needs and transfer the main problems into product design requirements with different functional problems. Then, based on TRIZ an eco-contradiction matrix can be used to identify the conflicts between customer needs and eco-efficiency elements for deriving TRIZ invention principles. The related specific solutions are conducted from these invention principles. The eco-innovative product could be created depended on these specific solutions. Hence, this framework tries to collaboratively utilize the capability of QFD essential problem analysis and the prowess of TRIZ innovative idea generation.

3.2. Systematic-innovation Design Process

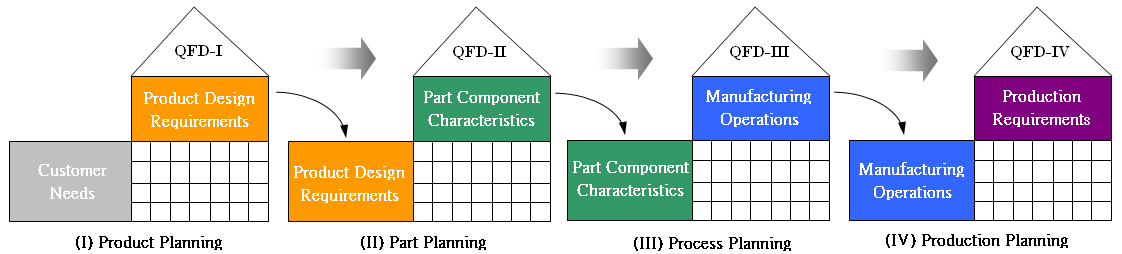

- Technology developing always impacts environment. Product designers must consider the balance between technical innovation and environmental protection when creating an innovative product. From the ecological and environmental perspective, the development of technology is important for a national economic growth but it also impacts the ecological environment. Air pollution, energy and material consumption, noise, and toxic waste water constantly influence the ecosystem directly or indirectly. They have made the greenhouse effect stronger, unknown diseases spread, and many species vanish. Therefore, the World Business Council of Sustainable Development (WBCSD) has identified seven major eco-efficiency elements for companies which develop eco-friendly products or processes in order to reduce environmental impacts. (A) Reduce the material intensity of its goods and services (material reduction).(B) Reduce the energy intensity of its goods and services (energy reduction).(C) Reduce the dispersion of any toxic materials (toxicity reduction).(D) Enhance the recyclability of its materials (material retrieval).(E) Maximize the sustainable use of renewable resources (resource sustainable).(F) Extend the durability of its products (product durability).(G) Increase the service intensity of its goods and services (product service).As each element improves or more elements improve simultaneously, it produces high eco-efficiency products or services. The proposed systematic-innovation method was established based on the above seven eco-efficiency elements. This systematic-innovation method integrated QFD-I and TRIZ concept to create innovative product. A new eco-contradiction matrix was proposed to find the conflict features. It can help a design engineer find the eco-conflict features easier than the traditional TRIZ contradiction matrix. The important point in the utilization of the eco-contradiction matrix is the identification of pairs of contradictory characteristics and their conversion into the standard terms in TRIZ. For this reason, a method to identify contradictory parameters using the QFD-I matrix and to find links to the eco-contradiction matrix has been proposed. In systematic-innovation, in addition to quality characteristics and environmental characteristics must also be considered at the same time. Therefore, the QFD-I approach and eco-efficiency elements were utilized to identify conflict features for use in eco-contradiction matrix in this paper.The procedure of the proposed systematic-innovation method is divided into 3 steps. First, define the seven eco-efficiency elements clearly for product design. Second, find the customer requirements and quality characteristics based on QFD-I approach. Then calculate the importance of the quality characteristics and set top priority of the quality characteristics for use in next phase. Third, put the quality characteristics and eco-efficiency elements into the eco-contradiction matrix and converse they to the standard technical features used in TRIZ. Review the matrix and find the conflict points. The proposed invention principles of TRIZ were derived based the contradiction parameters. A design engineer can generate a novel solution idea for green product based on the derived invention principles.

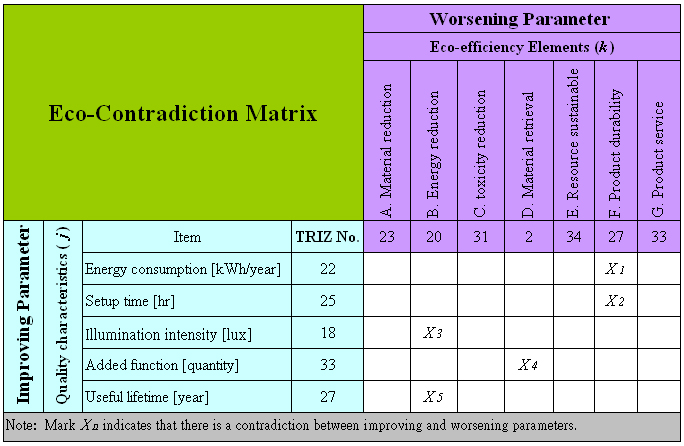

3.3. QFD-I Approach

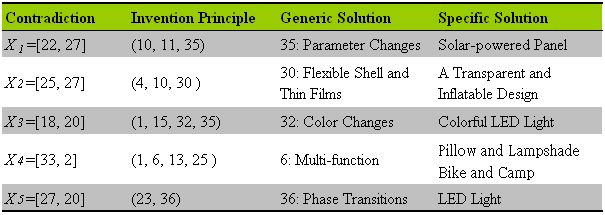

- The QFD is an implement to translate customer needs into product technical requirements of new products and services that have been developed from Japan in the late 1960s to early 1970s. The main concept of traditional QFD considered four relationship matrices that included product planning, parts planning, process planning, and production planning matrices, respectively. Each translation used a matrix, also called house of quality (HOQ), as shown in Figure 1. In the first place, the product planning matrix is established. The customer needs translated to the second QFD as inputs for the development of product design requirements. Secondly, in the part planning matrix, important design requirements are linked to part component characteristics deployment. Furthermore, the part component characteristics are similarly linked to manufacturing operations.

| Figure 1. The process of QFDs |

| Figure 2. Eco-contradiction matrix |

| Figure 3. QFD-I matrix |

are described in the QFD-I matrix (Figure 4). A design engineer can utilize QFD-I matrix to get the quality characteristics and its relative importance for further conflict analysis in eco-contradiction matrix.

are described in the QFD-I matrix (Figure 4). A design engineer can utilize QFD-I matrix to get the quality characteristics and its relative importance for further conflict analysis in eco-contradiction matrix. | Figure 4. The Eco-contradiction matrix of the camping light |

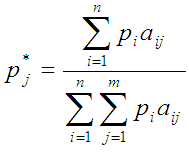

3.4. Eco-contradiction Matrix

- Note that the use of eco-contradiction matrix is not the same as the contradiction matrix of TRIZ. Figure 4. is for setting main conflicts in the target product and to identify them with the eco-contradiction matrix of TRIZ. In order to make it easy to set confliction points, the top priority quality characteristics that have the higher values of p*j are selected from QFD-I and the eco-efficiency elements are also considered in Figure 4. The selected quality characteristics would be regarded as the improving features and the eco-efficiency elements would be regarded as the worsening features in the proposed eco-contradiction matrix. The steps of eco-contradiction matrix is shown as follows: STEP 1: Put the quality characteristics into the improving column and the eco-efficiency elements into the worsening row.STEP 2: Replace quality characteristics and eco-efficiency elements with standard features in TRIZ intuitively.STEP 3: Sets contradiction marks (X) between the technical terms in TRIZ.STEP 4: Derive invention principles based on the TRIZ contradiction matrix.STEP 5: Develop eco-innovation product concept based on the invention principles.

4. A Case Study

- Company A, which is an international original brand manufacturing electronics company in Taiwan would like to cooperate with us to develop an all new camping light with green energy. The proposed systematic-innovation design method was employed to create an innovative outdoor camping light for Company A.

4.1. Customers Needs

- The target product is an outdoor portable camping light. The customer needs were carried out after discussing with the marketing members of Company A. The features of target product were listed as follows:(1) Easy to use; (2) Good form; (3) Eco-material; (4) Good brightness; (5) Easy to setup; (6) Small volume; (7) Light weight; (8) Long life cycle; (9) Multi-functional; (10) Green power.

4.2. Eco-Contradiction Matrix of the Camping Light

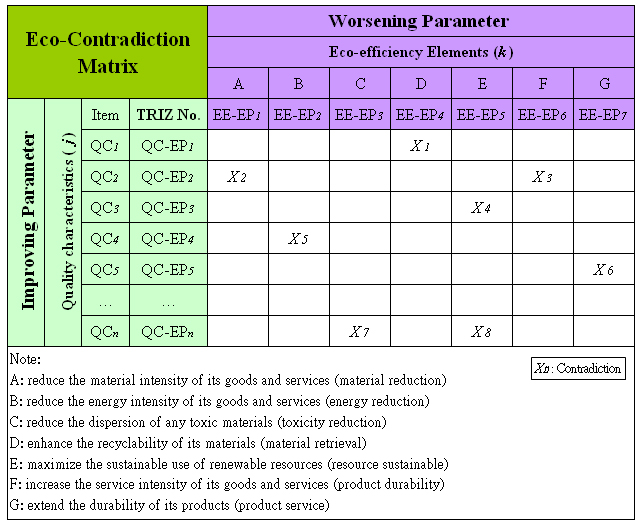

- In order to make it easy to identify conflict points, the top five quality characteristics that have the higher values of the relative importance p*j were selected from QFD-I. The five selected quality characteristics were considered as the improving parameters and the seven eco-efficiency elements were considered as the worsening parameters. These two different categories of parameters were put into the eco-contradiction matrix together to discuss the conflict for innovations in Figure 4. Meanwhile, the selected quality characteristics and eco-efficiency elements were transferred to the corresponding TRIZ engineering parameters shown as TRIZ No. on row and column in Figure 4. For example, “Energy consumption” can be transferred to “loss of energy (TRIZ No.22)”; “Illumination intensity” can be transferred to “Illumination intensity (TRIZ No.18)”. All of the quality characteristics and eco-efficiency elements were transferred to the standard features in TRIZ with the same manner. Finally, five contradictions were identified after reviewed the eco-contradiction matrix. They were X1, X2, X3, X4, and X5, respectively. X1 means if we want to improve the energy consumption, it will worsen the goal of product durability. X2 indicates if we want to improve the setup time, it will worsen the product durability and X3 means if we want to enhance the brightness of the light, it will impact the goal of energy reduction. X4 means if we want to add more functions on product, it will impact the goal of material retrieval. X5 means if we want to improve the useful lifetime of the product, it will worsen the goal of energy reduction.

4.3. Invention Principles

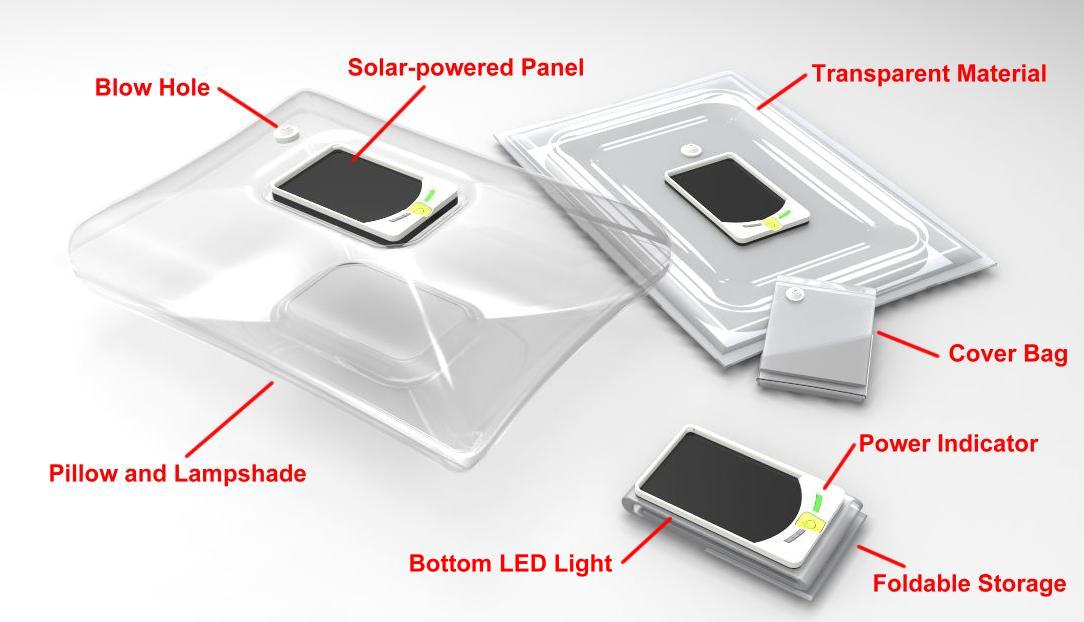

- In order to get the triggers of the innovative ideas, the TRIZ invention principles were derived based on the above-mentioned contradiction parameters. The specific solutions were proposed from the generic solutions with some creativity and imaginations. The design- thinking process is shown in Table 1. Finally, based on the above specific solutions the design concepts of the camping light are identified as follows:(1) Use solar-powered panel for green power.(2) Adopt a transparent and inflatable design for folded storage.(3) Adopt color-changeable LED light for dual usages of bike and camp. (4) Adopt a inflatable pillow design as lampshade for multi-functional usage.(5) Use LED (Light-Emitting Diode) light to reduce power consumption.

|

4.4. Visualization of Design Concept

- Considering the environment-friendly factor, the design concept of transparency was utilized to create the outlooking appearance. A inflatable pillow image was also adopted to present the portable camping light form. Finally, the camping light was created based on the above analysis results and the design concept of transparent pillow. The concept design of the camping light was visulized as following Figure 5.

| Figure 5. Design concept of innovative camping light |

5. Conclusions

- Creativity is an integral and essential part of the product design process. Without creativity in design there is no potential for innovation, which is where creative ideas are actually implemented and transformed into commercial value. Contradiction will be the largest block on the road for new generation of solution ideas. The design process integrating quality characteristics of QFD-I and WBCSD eco-efficiency elements into the proposed eco-contradiction matrix is established for solving eco-innovative design projects. The solution ideas of eco-innovation design will be effective approaches towards sustainable development. The proposed systematic-innovation method based on the above-mentioned ideas indeed can assist design engineers to create eco-innovative product. A case study example demonstrated the applicability and feasibility of the systematic-innovation method.

ACKNOWLEDGEMENTS

- The assistance of the R&D division of Everlight Company in developing the examples presented in this paper is acknowledged. This work is supported under grant: MOST 103-2622-E-029-003-CC3.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML