-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Construction Engineering and Management

p-ISSN: 2326-1080 e-ISSN: 2326-1102

2015; 4(5): 191-200

doi:10.5923/j.ijcem.20150405.04

A Comparative Life Cycle Assessment Modeling of External Wall Construction Systems: Case Study Residential Complex in Al-Ain, United Arab Emirates

Abdulaziz Banawi, Ghulam Qadir

United Arab Emirates University, Alain, UAE

Correspondence to: Abdulaziz Banawi, United Arab Emirates University, Alain, UAE.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

The construction industry is a major contributor to most countries’ Gross Domestic Product (GDP), yet every year it consumes anabundance of natural resources and produces significant atmospheric environmental impacts. Countries such as the United Arab Emirates have started to develop improved efforts toward this global issue such as Estidama; a green building rating system. In this paper a Life Cycle Assessment (LCA) was performed to measure the environmental impacts of two types of exterior wall structural systems, a Light Steel Frame (LSF) and Insulating Concrete Forms (ICF). The study was performed to help an owner choose a sustainable alternative which would earn points under the materials selection category in Estidama. A two-bed room villa of 260 squaremeter was chosen for the study. Later, the four steps of the LCA: goal and scope definitions, life cycle inventory (LCI) analysis, life cycle impact assessment (LCIA) and interpretation were applied following the guidelines set by the International Standardization Organization (ISO). The results showed that ICF) has a great environmental impact during the construction phase in eight categories of the Tools for Reduction and Assessment of Chemical and Environmental Impacts (TRACI), while LSF showed higher impacts for one category, which is Ozone depletion. Although ICF has great benefits during the use phase, for this study it generated high emissions during the construction phase. Furthermore, the use of LCA shown that ICF might have contributed more toward the environmental benefits. However, applying such a green building technology like ICF in a city like Al-Ain would not enhance local industry due to the dependence on expertise and resources brought from overseas. Most of the green buildings in the UAE were constructed by specialists who were recruited from outside the UAE, due to the shortage of resources within the country.

Keywords: United Arab Emirates, Construction Industry, Green Construction Materials, Life Cycle Assessment

Cite this paper: Abdulaziz Banawi, Ghulam Qadir, A Comparative Life Cycle Assessment Modeling of External Wall Construction Systems: Case Study Residential Complex in Al-Ain, United Arab Emirates, International Journal of Construction Engineering and Management , Vol. 4 No. 5, 2015, pp. 191-200. doi: 10.5923/j.ijcem.20150405.04.

Article Outline

1. Introduction

- The construction industry is a major contributor to countries’ Gross Domestic Products (GDP). In the United States of America, the construction industry accounts for 9% of the total national GDP. [1] While in the United Kingdom, according to the construction industry policy and statistics annual report, 6.1% of the country’s total GDP represents the contribution of the construction industry [2]. The United Arab Emirates is no different either, where construction over the last ten years has contributed a lot to GDP. Different projects including residential, public, educational, and commercial were completed, more are in progress, and more are to come in the near future, as the construction industry is expected to contribute 11.8% to the country’s GDP by 2021 compared with 10.5% in 2009 [3]. On the other hand, the construction industry is also a major consumer of natural resources, and is responsible for releasing abundant amounts of Greenhouse Gase (GHG) emissions every year. The U.S. Environmental Protection Agency (USEPA) in a report released in 2009, states that constructed buildings consume about 36% of the nation’s total energy, and emit around 30% of the country’s GHG emissions. Also, in the United States, buildings consume every year 12% of the total nation potable water, 65% of electricity, and produce about 136 million tons of construction and demolition waste. [4]The buildings are responsible for more than 40% of global energy used, and as much as one third of global greenhouse gas emissions, both in developed and developing countries. At the same time; however, the building sector has the largest potential for significantly reducing greenhouse gas emissions compared to other major emitting sectors [5] Therefore, it becomes essential that building professionals consider alternatives including building materials, construction methods, and construction processes designed for lower environmental impacts and higher efficiency.Most of the time in the construction industry, decisions are made based on factors including allocated budget and allocated time, yet applying quality to construction work could be considered. It is not common that the generated environmental impacts are taken into account unless this is forced by law [6]. In this paper, the authors evaluate the environmental impacts of two different exterior wall construction systems; Light Steel Frame Structure (LSFS) and Insulating Concrete Forms (ICFs) for a residential complex in Al-Ain, UAE. The project was designed to meet the requirements of the US Green Building Council (USGBC) and to be Leadership in Environment and Environmental Design (LEED) Silver certified. Analyzing the potential environmental impacts of the two exterior wall construction systems will secure some points if the proper option with less environmental impacts is selected. This step will count towards reducing the carbon footprint of construction materials under the ‘selecting materials’ category within the USGBC rating systems. For such a purpose, a Life Cycle Assessment (LCA) methodology was used to evaluate the environmental performance of both structural systems including materials, equipment, and transportation to and from the construction site. Also, LCA is expected to highlight strengths and weakness of both systems within their life cycles.

2. Literature Review

- The paper is focused on evaluating two construction systems (LSFS and ICF) using LCA. Both the systems are known for their respective benefits. Similar studies have been carried out in the past in different countries and climates (e.g.) The Environmental impacts of steel and concrete framed buildings were compared using LCA by Guggemos in 2005 [7]. Two five-storey buildings with floor areas of 4400 m2 located in the Midwestern US were considered. Both were expected to be used for 50 years. Process based LCA was used to evaluate the life-cycle environmental effects of each building through its different phases: material manufacturing, construction, use, maintenance and demolition phases. It was found that concrete structural-frame had more associate use and emissions due to its longer installation process. Similarly in another case study [8] using LCA method in Canada for a typical five-storey commercial building with five variations of exterior wall system and two variations of climate. It was found that over the full life cycle, buildings with precast concrete walls have less environmental impact than those with masonry brick veneer walls and those with glass and aluminium curtain walls. All other factors were equal. The factors considered were environmental impacts from all life cycle stages: manufacturing, construction, occupancy, maintenance, and end-of-life (including, demolition, recycling, reuse, and land filling). Guardiglia et al [10] appliedan LCA to perform a comparison between a newly designed building, an innovative wood construction and a reinforced concrete construction in Italy. It was found that the estimated environmental impact of a wood building on human health, resources and ecosystem quality is generally smaller than a typical concrete structure.For a non-residential building like a school, Alshamrani et al [11] used an LCA method for sustainability assessment of structure and envelope types of school buildings. Various options were studied by considering concrete, steel, masonry and wood structures incorporated with envelope systems such as precast panels, steel stud, wood stud and cavity wall. The result was that concrete and masonry buildings have high energy consumption and global warming potential during their manufacturing, construction and demolition stages. However, they have lower energy consumption and environmental impact during the operating stage, as well as for the overall life cycle span. Xing et al [12] compared two general buildings made of concrete and steel in China using an LCA as well and found that lower energy consumption and environmental emissions are achieved by the concrete-framed building compared with the steel-framed building over the whole life-cycle of the building.This paper considers-several things in the comparison between the two systems. In addition to evaluating the environmental impacts, it further discusses the applicability of implementing green construction systems like ICFs in country like UAE.

2.1. Comparison between Light Steel Frame Structure (LSFS) and Insulated Concrete Form (ICF)

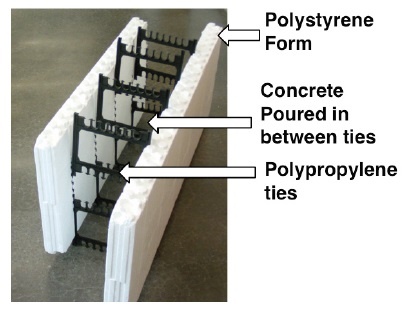

- LSFS constructions are composed of studs and beams made from thin C, U or Z shaped cold formed sections. The thickness of the section sheet can range between 0.6 mm to 2.5 mm for a maximum mass per unit of length of 0.075 kN/m. [13]. Whereas, .atypical ICF wall section consists of Expanded Polystyrene (EPS) and poured concrete with polymer ties connecting the EPS form as shown in figure 2. [14].The two systems are briefly explained under the headings of construction, benefits and costs.

2.1.1. Construction

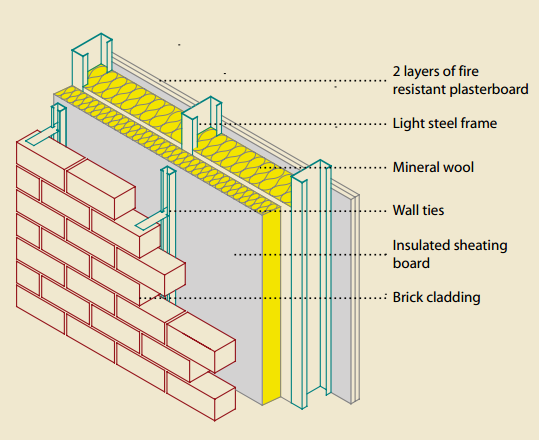

- LSFS walls are generally used as partition walls in structural systems [15]. They are typically 75 mm to 150 mm in depth & 1 mm to 3.2 mm thick, having a typical span of 2.4m to 5m between floors. LSFS walls have a high level of thermal insulation provided by insulation boards, as shown in Figure 1 and can be used to support a wide range of cladding systems. Their construction process is dry so shrinkage & other drying problems are eliminated. Large window parapets and other architectural features can be incorporated into them by using multiple layers of fire resistant plaster board. Because of their rapid installation, other activities within the building can proceed at the same time which is not possible with block-work infill walls [16]. On the other hand in ICF, the polystyrene that is used in it remains in place after the concrete has been cured and that is a difference between ICF & conventional construction. Further reinforcement, such as rebar, can be added according to the structural design using internal strapping made of polypropylene, as shown in figure 2.

| Figure 1. External wall with brick cladding attached to light steel framing |

| Figure 2. Insulating concrete forms |

2.1.2. Benefits

- Both LSFS and ICF have a lot of key sustainable benefits which satisfy the requirements of both Leadership in Energy and Environmental Design (LEED) and Building Research Establishment Environmental Assessment Methodology (BREEAM). [17] [18].LSFS have a foundation size reduced by 70 % compared to concrete & block work construction. Speed of construction is increased by 30%, which reduces site impacts. Transportation costs are reduced as a single delivery of LSFS is typically enough for three houses. Site waste is also eliminated. This is significant as the industry has an average waste of 10% in construction materials. Embodied carbon is reduced by 20% in the building fabric. Renewable Energy Technology (RET) can be attached and built in. Walls can also be modified and extended easily and can also be used in building extensions and renovations [18]. ICF is durable & resistant to hazards and natural disasters. Its performance has been evaluated by many organizations like the National Association of Home Builders (NAHB) in several locations throughout the United States [19]. Energy savings of 25% can be achieved during the use phase of an ICF structure, as the forms provide additional insulation & improve energy efficiency in buildings [20] The HVAC energy consumption can be reduced by 25 to 50% [21]. Themain factors which contribute to the energy efficiency of ICFs are R value, air infiltration reduction & thermal mass. If doors, windows & roof are made of traditional construction materials & wall sections of the house are made of ICFs, then air flow rates will be 10 to 30% lower than with typical frame construction [20].To examine the relative energy performance and air tightness of residential homes constructed from ICFs, experiments are being conducted at Oak Ridge National Laboratory (ORNL) [22]. The US department of defense (DoD) conducted its force protection equipment demonstration (FPED) using ICF boxes blasted with trinitrotoluene (TNT) resulting in no structural damage with minimum cracking [23].From a home owner’s point of view, ICF has less air leakage which results in greater thermal comfort & less temperature variations. Homes made from ICFs have high structural strength, less acoustical transmission, (hence reduced undesirable noise), fire resistance, durability and require less maintenance [19].

2.1.3. Cost

- A typical LSFS wall costs $1.69 per square foot [24], whereas ICF exterior wall homes cost $1 to $4 per square foot more than the cost of building a house with a conventional wood frame [21] but its initial construction cost is high compared to conventional construction. Light structure weight reduces the costs of transportation and cranes. It also reduces foundation costs accordingly. The building self-weight is only ¼ of brick-concrete structure. There is enough space between the light gauge steel wall and floor to lay all kinds of pipelines (wires, Telecommunication lines, drains, Air Conditioning) so nopipe is exposed, therefore making construction and maintenance very easy & cost saving. [25]. A high percentage of the steel used is recyclable, according to the American Iron and Steel Institute (AISI), Steel is the most recycled material on the planet, more than all other materials combined, 88% steel was recycled in 2012. [26]Efficient HVAC systems with decreased operating costs of ICF homes during the building use phase can achieve savings because of ICF thermal wall efficiency. The contractors can arrange the HVAC capacity by as much as 50% compared to wood frame houses. Improved designs with more efficient assembling procedures that reduce installation labor have resulted in a decrease of ICF construction prices. Insurance companies provide a premium reduction for high fire or wind resistant homes which ICFs provide, and the savings for an average home are in the range of $40 to $ 100/ year. [21] Construction materials like brick & vinyl siding can be applied to ICFs at a similar cost. ICFs give the designers an opportunity to make something new compared to traditional shapes of structures. [20]

3. Overview to Life Cycle Assessment (LCA)

- Life Cycle Assessment (LCA) quantifies the environmental impacts of a product, process or service through its entire life cycle, starting from the extraction of material and energy used in the production process to acquisition, product use and finally disposal. The International Standardization Organization (ISO) and the American National Standards Institute (ANSI) have worked together to standardize LCA. The LCA is a four-step approval including goal and scope definitions, life cycle inventory (LCI) analysis, life cycle impact assessment (LCIA) and interpretation [27]; [28] It is a valuable approach that helps in decision making and creating opportunities for improvements within processes, such as construction for better environmental performance [29-32].

4. Method

- A comparative LCA was performed to evaluate the environmental performance of both LSFS and ICFs systems to choose an option with less environmental impacts to build around 350 different residential units in Al-Ain, UAE. In this paper LCA was applied following the ISO and four ANSI steps including; 1) Goal and scope definition, 2) Life Cycle Inventories (LCI), 3) Life Cycle Impact Assessment, and 4) Interpretation. Each one of these steps will be later explained in further detail.

5. Case Study

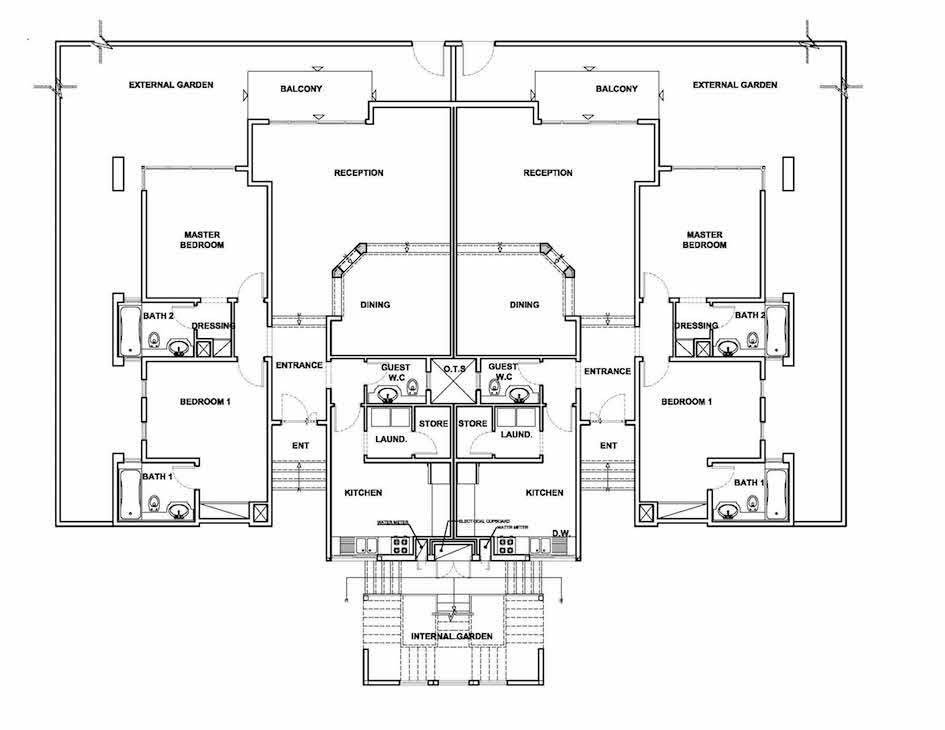

- The emirate of Abu Dhabi, UAE, has established a long term plan to be accomplished in the coming fifteen years (by 2030). Sustainability plays a major part in that plan, as the government will not allow new construction that does not meet Estidama requirements. Estidama is a building rating system similar to Leadership Environmental Energy and Design (LEED) that has been created by USGBC. Therefore, constructing new buildings that are environmental friendly is not an option anymore in the emirate of Abu Dhabi, it is a must. Residential projects constitute the majority of those taking place, due to thecontinuous growing population& expat intake in the UAE. For this case study, LCA was applied to evaluate the environmental impact of two exterior wall systems. The test case is designed to find out which would be the best environmental performance type of wall to use in the construction of the 350 townhouse units of two, three and four bedroom sizes. For this study, the two of the two-bedroom type were chosen for analysis. The total area of both two bedrooms units is 260 m2.Each one consists of two bedrooms, two bathrooms, kitchen, store with laundry, and reception/dining area as shown in figure 3. The residential project will also have a central area that has public facilities including; market, park, mosque, and school. The project location is in Al-Ain city which is a part of the emirate of Abu Dhabi. Al-Ain city is located 150 km south east from Abu Dhabi, the capital and 120 km south west from Dubai.

| Figure 3. Floor plan of Two bedroom units |

6. Goal and Scope Definition

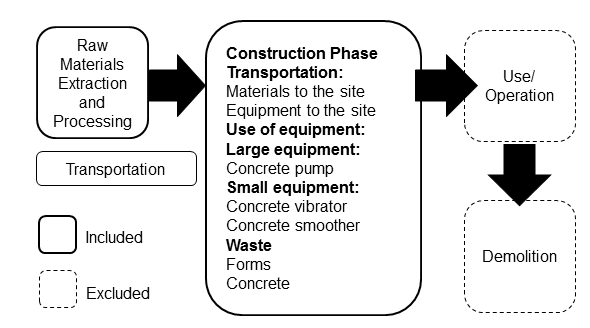

- This study has developed a comparative LCA to measure the environmental impact of constructing a two residential unit with an area of 260 m2 applying two different exterior wall structural systems; LSFS and ICFs The study took in account the energy usage and the generated environmental impacts of the following phases; raw materials extraction and manufacturing, transportation of equipment and materials to the site and equipment usage on the site see figure 4.

| Figure 4. LCA boundary system included for the exterior wall case study |

7. Life Cycle Inventory (LCI)

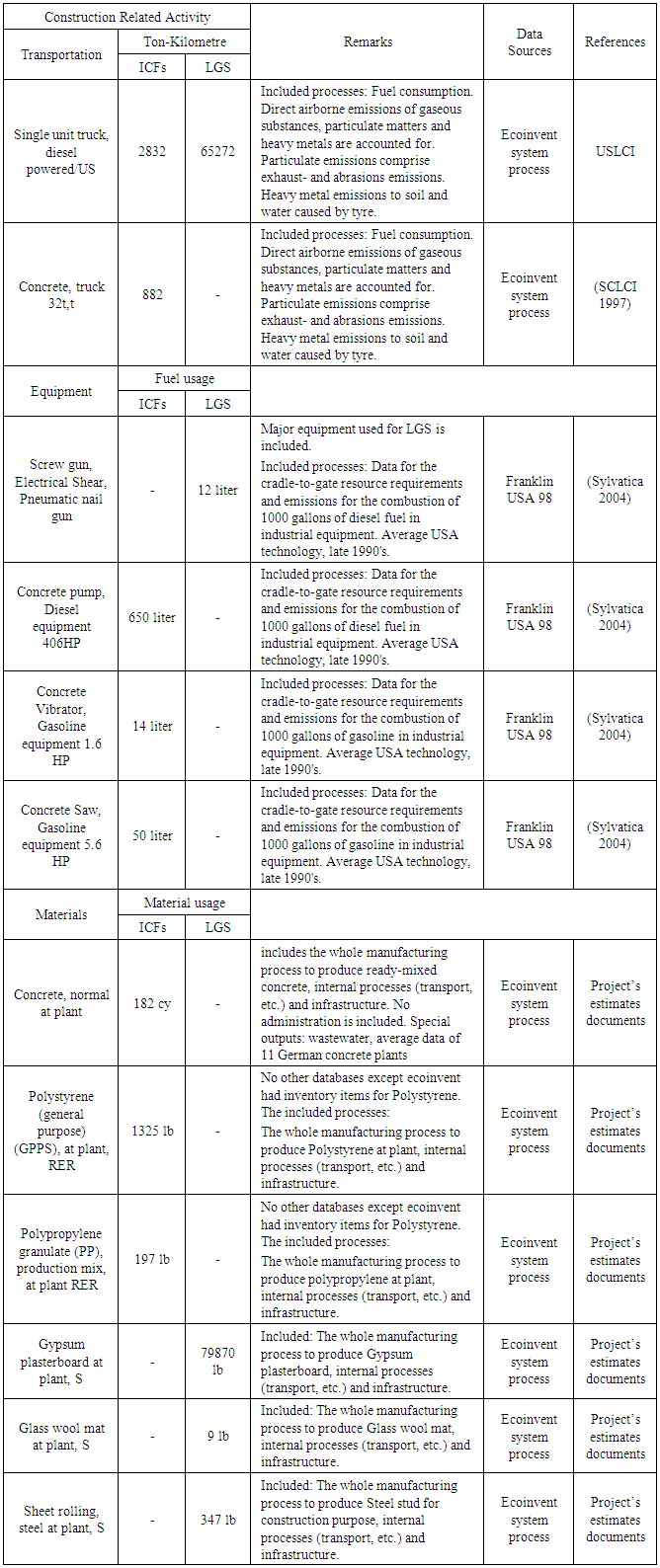

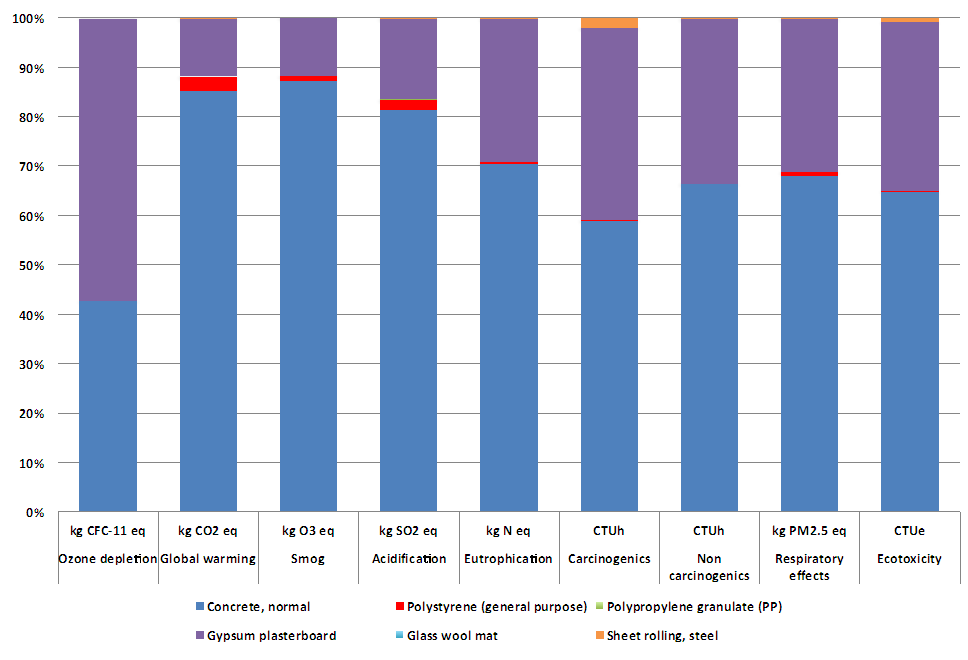

- In this step, a related data inventory was collected from different sources such as literature and relevant databases. This is an important step in an LCA as the final results rely on how well and accurately the LCI was implemented in the study. Extensive research was conducted to complete this stage included manufacturing visits and long hours of meetings with the main contractor, sub-contractors, professionals, and field engineers. Feedback received from those different channels regarding the LGSF and ICF systems was reviewed and compared with many databases and unit processes. This was to achieve a close match for both systems to be applied in this study to obtain results as accurate as possible. Database tools such as US LCI, Ecoinvent and other European databases were investigated to conduct the LCI for this study. Since several unit processes were available within the targeted database, the inventories were chosen according to a close examination of the construction materials industry and an extensive literature review. Some of the unit processes were modified to match the actual products [14] For example; the unit processes for materials for the ICFs system were included; concrete normal at plant, polystyrene, and polypropylene while the database was taken from ecoinvent. Ecoinvent was the one that has data relevant to this study. On the other hand, the LSFS unit processes materials were included; gypsum plasterboard, glass wool mat, and light steel for the frame structure. The ecoinvent database was used due to its close match with the matrials used for the analysis for the case study. Common materials for both the ICFs and LSFS systems are exterior finishes like stucco cement and paint. These were neglected. For transportation, both systems required a single unit truck, diesel powered to transport materials and equipment to and from the construction site in Al-Ain city. Materials for ICFs were acquired from a manufacturer located in the Kingdom of Bahrain, which was the nearest supplier. Only ready mix concrete used for ICFs was brought from Al-Ain industrial city, 20 km away from the location. To deliver the concrete, a concrete truck was used. Materials for LSFS were delivered from Al-Musafah, an industrial area that is located in Abu Dhabi, about 180 km away from Al-Ain city and the project location. For equipment, ICFs systems required a concrete vibrator and concrete pump, while LSFS didn’t require any major equipment except nail guns, saws and other minor tools. More details of the life cycle inventory data used to determine aggregate construction emissions for both systems is shown in Table 1.

|

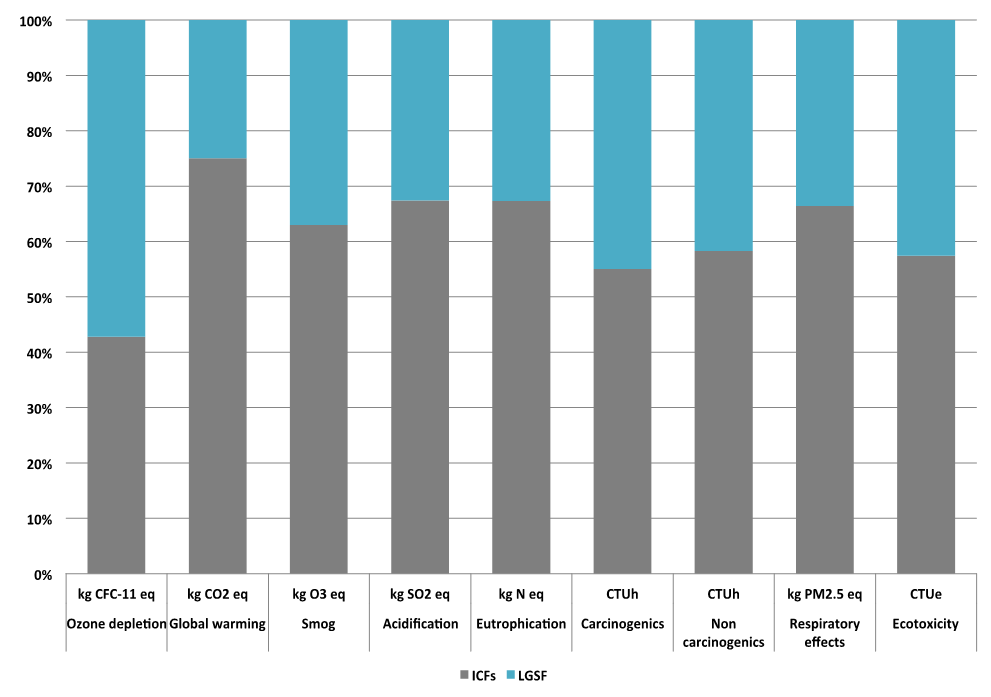

8. Life Cycle Impact Assessment (LCIA)

- LCIA converts LCI data into a understandable and quantifiable environmental impact, for example, Global Warming (GW). The LCIA tool used in this research is Tool for Reduction and Assessment of Chemical and other environmental Impacts (TRACI) that has been developed by the U.S. Environmental Protection Agency. TRACI translates the environmental loads identified by the LCI into different nine categories. These categories include ozone depletion, global warming, acidification, eutrophication, tropospheric ozone (smog) formation, eco toxicity, human health criteria-related effects, human health cancer effects, human health non-cancer effects, fossil fuel depletion, and land use effects. Each impact is calculated on a midpoint basis and is presented in kg Eq of a reference substance [33]. For this study, TRACI 2 V3.01 was used to perform the life cycle impact assessment.According to the LCIA results of this study, during the construction phase the ICF structural system showed great environmental impacts in all TRACI categories except for Ozone depletion, where the LSF structural system was the highest with 57% shown in figure 5.The materials usage for the ICFs was responsible for 86% of the total environmental impact. Transportation came second with 12% and finally came equipment manufacturing & combustion with only 2% (see figure 5). major contributor to such an increase in the generated environmental impacts for the ICFs was the used of concrete, a construction material that is been known for its associated high environmental impacts. According to the EPA, the production of cement, which is a major ingredient of concrete, releases a considerable amount of carbon dioxide to the atmosphere. [33]

| Figure 5. LCIA of the ICF and LSF exterior wall structural systems |

| Figure 6. LCIA of the materials components of both ICF and LSF exterior wall structural systems |

9. Results and Discussion

- Although the ICFs in previous studies [34] showed great benefits in saving energy during the use phase of buildings, yet in this study ICFs showed significant environmental impact during the construction phase. LCA methodology showed that ICFs are not necessarily a sustainable construction method or system for a project located in Al-Ain, UAE, for several reasons. In order to be considered sustainable, any building material or construction system has to provide benefits for end users under three categories including, environmental, economic and social. For this case study, having ICFs as the exterior wall structural system might have environmental benefits during the building use phase, yet it would not enhance the economic and social categories. To elaborate on this point, most of the certified green buildings in the Middle East (mainly in GCC) were completed by international contractors hired from overseas. Moreover, materials, specialized workers and other building resources were also shipped from aboard due either to the contractor’s recommendations or to the limited options available within the area. These reasons have led to an increase in the total initial cost of green buildings in the GCC area and in UAE in particular. This has caused people to lose interest in green buildings and to stick with conventional ones. It is not a sustainable approach from an economic and social point of view to bring an overseas contractor to do a job that could be done by a local contractor with some training in the field of green building. Another reason is that the construction industry is considered to be a major source for job opportunities in the UAE. Yet many local contractors, construction workers, subcontractors, and suppliers might lose their jobs due to the lack of knowledge of green buildings. As a result, this might decrease the quality of the social aspect of the local community and that’s not what sustainability is calling for. In 2012, Qatar’s first green building, called the ‘Passivhaus, was inaugurated. This was a collaborative project between Qatar Green Building Council (QGBC), Barwa Real Estate Group (BRE) and Kahramaa titled ‘Baytna’. The project had both a green villa and a conventional villa. The conventional villa was built to a one-star rating of the Qatari Global Sustainability Assessment System (GSAS) and has an area of 225m2. The Passivhaus villa delivered good results where It consumed at least 50% less energy and water. It produced less operational carbon dioxide, with a significantly reduced environmental footprint for the construction cost over the lifecycle of the project. However, the project was completed by contractors whom were from outside Qatar, used materials that were imported from overseas, and was staffed by professional workers who were mainly recruited for this purpose. As a result, there was a significant increase in the total building construction cost. A total of 20 different parties including subcontractors, suppliers and workforce providers were involved in this project the majority of whom were from international companies and firms assigned for this project . [35]; [36]In the UAE, at the same time as green building construction is increasing, the construction industry has to deal with a number of problems while working on these sorts of projects. For example, a Five Star Luxury beach resort in Dubai proposed to be a LEED accredited building was analysed against evaluated LEED principles and compared against a list of green elements compiled from the study. As the building was designed to be LEED rated, various design credit elements had been incorporated. It was found that a large number of design and execution points learnt in the planning techniques have been implemented to the design process of this resort building design in practice in Dubai. Due to the lack of experience in sustainable building practices within the region, there were no suppliers able to provide specific green products. Local materials were very few and those available were not cost-effective. To ensure efficient co-ordination between all team members, an integrated design approach was employed and LEED design workshops were held frequently. A LEED coordinator was essential in facilitating the progress of the design. The most difficult aspect was to reach an environmentally friendly design while making sure that the commercial benefits were not impacted. On the whole the project was a good example of sustainable design in the region. [37].Green buildings and green building materials along with related technology are still not fully embraced and adopted in the Middle East despite the great benefits green buildings have brought so far in the region. LCA methodology helped enlighten the owner in this study to recognize challenges, advantages and disadvantages of implementing both exterior wall systems toward the project. Not only from an environmental point view, yet it explained the potential impacts and benefits from an economic and social point of view for a green construction systems might introduced to the industry. Although the United Arab Emirates is a major supporter of sustainability and green buildings, still stakeholders are not fully committed to such an improvement. As a future work, the authors are proposing a further investigation to examine the barriers and the challenges to having green buildings widely in UAE. A survey will be developed and administrated to people involved with the building industry in the country including both governmental, and the private sector as well.

10. Conclusions

- In this paper an LCA comparative analysis was performed on two structural exterior wall systems: ICFs and LSFS, to examine the environmental impacts and to highlight the potential benefits by the two systems during the construction phase. The study was performed on a two of two-bedroom townhouse unit in Al-Ain, UAE. The LCI explained the materials usage and the associate quantities, the transportations required to deliver materials and equipment to and from the construction site for both wall systems, and the required equipment to execute this task. TRACI 2 V3.01 method was used to perform the life cycle impact assessment. The LCIA results showed that ICFs have a greater environmental impact in eight TRACI categories, while LSFS came the highest in the category of Ozone depletion. The materials usage, especially of concrete for the ICFs system, was the primary cause of the increase in environmental impact of ICFs. Although the ICFs have a high potential in saving energy during the use phase, it might be not a sustainable alternative for a project that is located in a city like Al-Ain, UAE, due to the minimum benefits of the ICFs system from an economic and social perspective. Resources, such as green certified contractors, green building materials and trained workers, all have to be brought from outside the country to finish the job. This caused less job opportunities for locals and generates less revenue for the local buildings industry as well.

ACKNOWLEDGMENTS

- The authors want to extend their thanks to the United Arab Emirates University for their generous funding and support to help the authors finish this work.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML