-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Construction Engineering and Management

p-ISSN: 2326-1080 e-ISSN: 2326-1102

2014; 3(4): 109-116

doi:10.5923/j.ijcem.20140304.02

Hot-Mix Asphalt Pavement Construction Practices in Ghana and Their Impact on Pavement Quality

Yaw A. Tuffour1, Kenneth A. Tutu2, Abena A. Obiri-Yeboah3

1Department of Civil Engineering, Kwame Nkrumah University of Science and Technology, Kumasi, Ghana

2Associated Consultants, Accra, Ghana

3Department of Civil Engineering, Kumasi Polytechnic, Kumasi, Ghana

Correspondence to: Yaw A. Tuffour, Department of Civil Engineering, Kwame Nkrumah University of Science and Technology, Kumasi, Ghana.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

Premature asphalt concrete pavement failures are prevalent in Ghana with the major blame often erroneously placed on axle loads. In this study, hot-mix asphalt pavement construction practices in Ghana were investigated. The aim was to establish the potential impact of the practices on pavement quality, performance, and durability. Data and information on asphalt pavement construction practices were collected through a questionnaire survey and supplemented with observation of practices at a number of sites where asphalt paving works were on-going. In addition, condition survey of selected asphalt pavements was carried out. The results indicated that hot-mix asphalt pavement construction practices in the country do not exemplify contemporary advancements within the asphalt paving industry and are partly to blame for the premature failures of asphalt concrete pavements. Sub-standard construction practices are prevalent due, in part, to the existence of significant gaps in the technical specifications used in the country for asphalt pavement construction and, in part, to lack of commitment by the contractors to pursue high construction quality because they do not suffer penalties for substandard works. The overall effect is a middling pavement performance characterized by early failures. To improve the quality and longevity of asphalt concrete pavements, a revamp of Ghana’s asphalt pavement construction practices, revisions to construction specifications used for road work, and adoption of innovative performance-based contracting arrangements are suggested.

Keywords: Construction practices, Hot-mix asphalt, Pavement quality, Premature failure, Technical specifications

Cite this paper: Yaw A. Tuffour, Kenneth A. Tutu, Abena A. Obiri-Yeboah, Hot-Mix Asphalt Pavement Construction Practices in Ghana and Their Impact on Pavement Quality, International Journal of Construction Engineering and Management , Vol. 3 No. 4, 2014, pp. 109-116. doi: 10.5923/j.ijcem.20140304.02.

Article Outline

1. Introduction

- The road transport sector in Ghana accounts for approximately 98% delivery of people and freight [1] and will continue to play a vital role in the socio-economic development of the country unless new policy initiatives are introduced to restructure the current transport modal mix. However, the sector is plagued by early pavement performance failures which need to be addressed. In particular, premature failure of hot-mix asphalt (HMA) pavements is prevalent with the major blame often placed erroneously on excessive axle loads. Premature asphalt pavement failures and poor performance have existed for a long time and are reflected by the increasing volume of early maintenance interventions required on asphalt concrete roads [2-5]. Annually, the road transport sector alone is allocated about 35% of Government of Ghana Investment Budget [6], a substantial proportion of which goes into maintenance and reconstruction of prematurely-failed roads. The asphalt paving industry in Ghana is characterized by high presence of foreign contractors, price-based contractor selection methods, use of end-result construction specifications, and the absence of penalties for work that does not fully meet specification and yet does not warrant removal and replacement. Construction within the road sector is guided by the Ministry of Roads and Highways (MRH) Specifications which essentially encourage end-result construction. Performance-based construction contracts motivate contractors to continuously pursue high construction quality on their own volition as extraordinary quality achievement is rewarded. It is not yet clear the extent to which these factors impact asphalt concrete pavement construction and, by extension, the quality of completed works. However, it is recognized that high construction quality minimizes the incidence of premature failures and ensures pavement durability and longevity.Studies [7, 8] have shown that low construction quality prevails in Ghana and does not appear to be a recent development. A little more than two decades ago, Ofori-Kuragu [3] and Attoh-Okine [9] had attributed the major cause of the poor performance of the country’s road network to unacceptable construction practices. Today, pavement performance is still poor and probably worsening. In 2010, the Ghana Highway Authority reported that only 44% of the asphalt concrete roads under its jurisdiction were in good condition [4]. In 2012, the Statistical and Analytical Report of the Ministry of Roads and Highways [5] indicated that paved roads in good condition in the country had decreased from 60% in 2005 to 56% in 2010. In Ghana, the travelling public has a low view of the quality of road works undertaken in the country because of its experiences with the poor performance of roads [10, 11]. During the construction of the N8 Highway, for example, public complaints about poor workmanship were rife in the media. Unsurprisingly, not long after the road had been opened to traffic, some sections failed [3]. Upsettingly, HMA is an expensive flexible pavement material and yet constructions involving the material do not seem to receive the deserved attention in the country. Based on World Bank data on road construction costs, it is estimated that, on average, it costs a little over one million United States dollars to construct one kilometer of a new two-lane HMA road in Africa [12]. Undoubtedly, the high construction cost accounts, in part, for the small size of HMA road network in many sub-Saharan countries, including Ghana. The HMA road network in Ghana is estimated to be only 6% of the country’s entire network size of about 68,000km. Regardless, no empirical studies have focused on hot-mix asphalt pavement construction practices to date to determine the state of practice and recommend improvements where necessary. This study explored hot-mix asphalt paving practices in Ghana and examined their impact on pavement quality and performance.

2. Methodology

2.1. Questionnaire Survey

- Questionnaires were administered to collate the knowledge of civil engineers, construction technicians and contractors in hot-mix asphalt concrete design and construction practices in Ghana. In all, 45 civil engineers and technicians were contacted; 60% of them responded. The respondents had an average of 10 years’ experience in hot-mix asphalt pavement construction. Thirteen contractors participated in the study with the geographical distribution of their origin being as follows: Asia – 46%; Ghana – 31%; Europe –15% and Middle East – 8%.

2.2. Observation of Asphalt Paving Works

- Eight asphalt concrete road construction projects that were under execution in five regions in Ghana were shadowed; three involved the construction of trunk roads and the remaining were urban roads. The shadowing of the paving process made it possible to collect data on certain asphalt concrete paving practices that could not have been obtained through the questionnaire survey.

2.3. Condition Survey of Selected Asphalt Pavements

- The condition of nine randomly selected asphalt concrete roads constructed between 2000 and 2013, and totaling 670km in length, was examined through windshield survey to identify major distresses and to explore their potential causes. The average age of the study roads was 6.5 years, with majority (87%) being within the 0-10 year bracket. The selected roads were divided into18 sections based on the year in which (re)construction was completed. The average daily traffic on the roads in 2011 ranged from 5,000 to 24,000 with heavy vehicles constituting between 0.4% and 25%.

3. Results and Discussion

3.1. HMA Mix Design

- The Marshall mix design procedure was noted to be popular in the country. Eighty-five percent of the respondents indicated that the 102mm diameter mould is utilized in the preparation of test specimens for mixes containing maximum particle size greater than 25mm. This practice violates the empirical criterion to maintain a minimum mould diameter-to-maximum particle size ratio of four [13, 14]. By definition, the maximum particle size is the smallest sieve through which 100 percent of the aggregate sample particles pass while the nominal maximum size is the largest sieve that retains not more than 10% of the aggregate particles [15]. For mixes with maximum aggregate size exceeding 25mm, the 152mm mould is required to be used for the preparation of test samples [14].With respect to material used as filler in mix design, 75% of the respondents indicated that both hydrated lime and Portland cement are commonly used. While the use of lime is specified, the use of cement is subject to stipulation in project-specific specifications. The lack of precise guideline on when to use each material fosters subjectivity and arbitrariness and the tendency is for contractors to use cement as this material is less expensive than lime. But concerns have been expressed over the propensity of cement-treated asphalt concrete pavements to crack.

3.2. Material Handling and Storage

- Significant breaches existed in the handling and storage practices of asphalt cement and mixtures. Nearly one-third of the contractor respondents said that quality test on samples of asphalt cement delivered to site is not a routine procedure; acceptance of the product is based solely on quality certificates provided by the supplier. Regrettably, quality certificate may not guarantee product quality as contamination may occur during the loading operation or from oil leakage from heating coils in asphalt storage tanks. Only 22% of the respondents said that asphalt cement is sampled from both the storage tank and transporting vehicles for quality testing. With regard to stockpiling aggregate blends, 93% of the responses indicated a procedure whereby aggregates are heaped in a conical shape as opposed to storing in horizontal layers which is recognized as an effective technique for minimizing segregation.

3.3. Mix Production and Handling

- On the course of action taken when the source of HMA aggregates changes, a substantial percentage (33%) of the respondents said that sieve analysis and quality tests are conducted on the new aggregates, and if the results meet specifications, mix production resumes with the existing job mix formula. The implication of this action on mix quality can be serious as aggregates from different quarries may possess different mineralogical and geological properties with varying asphalt binder requirement for optimum mix properties.The survey also revealed that diesel is widely used in aggregate drying operations in hot-mix production and tests are rarely conducted to ascertain the completeness of the combustion process during aggregate drying. Regardless, 73% of the respondents said that no test is conducted to determine partial fuel combustion although according to the Asphalt Institute [16], insufficient air and/or excess fuel flow results in partial combustion with the unburnt fuel leaving an oily coating on the aggregates which reduces binder-aggregate bonding. Regarding the use of storage silos and surge bins, nearly 80% of the respondents stated that the installation of such facilities is rare. The installation of a surge bin is a standard specification requirement. The foremost technique, according to the survey, for reducing excessive heat loss during HMA transport is to cover the mix with tarpaulin. The survey found tarpaulin use to be dependent on the proximity of the asphalt plant to the paving site and weather conditions; tarpaulin use is rare when the distance from the production source to the construction front is short. When the mix is not covered, cooling causes crust to form on the surface of the paving mix, which to some extent, may be beneficial in insulating the rest of the mix from further heat loss. However, the crust must be decomposed before the mix is discharged into the paver to avoid ‘tears and pulls’ appearing on the surface of the finished mat [16]; this was not found in practice. To prevent HMA from sticking to the inside of truck buckets, the release agent found to be most preferred was diesel fuel. This material is considered unacceptable due to the possibility of contamination of the HMA.

3.4. Surface Preparation

- The survey established that priming and tack-coating are major surface preparatory activities that precede HMA lay down in the country. But according to the Asphalt Institute [17], over the past two decades, there has been no evidence that asphalt pavements with overall thickness of at least 100mm constructed without priming have failed because of non-application of prime coat. It is argued that the main purpose of priming is to protect the granular layers from wet weather, so if the mix can be placed prior to rainfall, then a prime coat is not required. It was noticed at the paving sites of the constructions shadowed that laydown commenced only when the prime coat had cured. In the literature, there is no unanimity on the influence of curing on the performance of emulsified asphalt prime or tack coat. Some [15, 18, 19] claim that curing is necessary to improve bond strength but others [20-22] advance that it is unnecessary because when the mix is placed “breaking” occurs as the water in the emulsified asphalt steams off. Responses to the length of time required for the curing of prime and tack coats differed. Majority of the respondents indicated between 12 hours and 24 hours curing time for prime coats and 30 minutes to one hour for tack coats. Others said they rely on colour change from brown to black and not a specific duration. Invariably, application of tack coat is done on the day of paving, ostensibly to prevent accumulation of dirt, but construction truck tyres tended to pick up binder from the surface (Fig. 1). As observed, no preventive action was taken to deal with removal of tack coat by truck tyres. At locations where tack coat is non-uniformly applied or removed by the tyres of construction trucks, slippage failures and de-bonding may occur [23]. The survey established that it is not a general practice in the country to apply tack coat between asphalt layers placed on the same day; 85% of the engineers/ technicians and 70% of the contractors confirmed this. In the literature, opinions differ on the necessity to apply tack coat between asphalt pavement layers placed on the same day. Hachiya and Sato [18] have indicated that tack coat between HMA layers placed on the same day is needless provided the underlying course is hot.

| Figure 1. Binder pick-up by construction truck tyres |

3.5. Mix Placement

- When there is a continuous supply of paving mix, material transfer vehicles (MTVs) serve as surge bins to ensure uninterrupted laydown operation, which is important for reducing non-uniformity of HMA and also obtaining a smooth-riding pavement. Also, MTVs solve the problem of trucks bumping the paver and causing depressions on the pavement mat. Surprisingly, 93% of the respondents indicated that MTVs are never utilized on their projects. The method for establishing the truck–paver contact was the same on all the projects visited: trucks reversed and bumped the paver. Preferably, the paver should move forward into a stationary truck. Manual placement of HMA as observed on site (Fig. 2) did not conform to best practice.

| Figure 2. Improper manual placement of HMA |

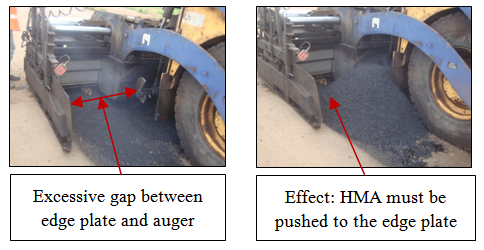

| Figure 3. Wide gap between edge plate and auger (left) and its effect (right) |

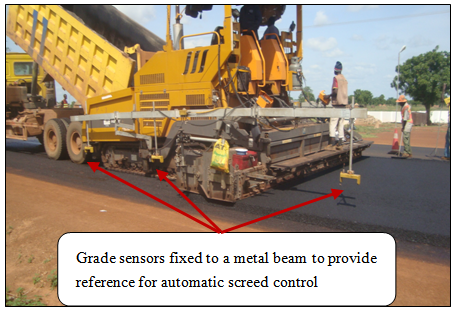

| Figure 4. Use of grade sensors to provide reference for screed control |

3.6. Joint Construction

- The survey results and site observations established that the straight butt joint is the longitudinal joint technique utilised in Ghana. Although this technique lends itself to easy construction, studies [25, 26] show that it does not provide satisfactory performance compared with the notched-wedge tapered joint. In terms of joint compaction, 77% of the contractors indicated that the technique commonly adopted is to begin rolling from the cold side (see Fig. 5). With this method, the first roller pass occurs in a static mode with a major part of its wheels on the cold lane and only about 150mm overlapped onto the hot lane.

| Figure 5. Compaction of longitudinal joint from cold side |

3.7. Quality Control

- Regarding quality control during paving operations, the survey responses revealed that the statistical quality control scheme outlined in the standard construction specification is rarely utilized. Apart from the initial acceptance testing, quality testing of aggregates is rarely carried out unless the quarry source changes. The usual sampling rate of HMA from the asphalt plant for quality testing is once per day as against the required sampling rate of four per day or part thereof. Cores extracted from field-compacted layers are not subjected to gradation analysis in spite of the fact that it is the gradation which would confirm that the mix placed was specification-compliant.Half of the respondents said that mix segregation is prevalent, the major causes being attributed to paver and asphalt plant operations. As a remedy, 82% said fresh mix is broadcast on the defective area, followed by raking to allow fines to fill the pores (see Fig. 6). Broadcasting as a remedy is only cosmetic as the lower depth of the mat would still remain segregated. Stroup-Gardiner and Brown [31] found that segregation could increase agency cost by 10% to 50% of the original cost of the HMA depending on its severity.

| Figure 6. Correcting segregation by broadcasting HMA on defective areas |

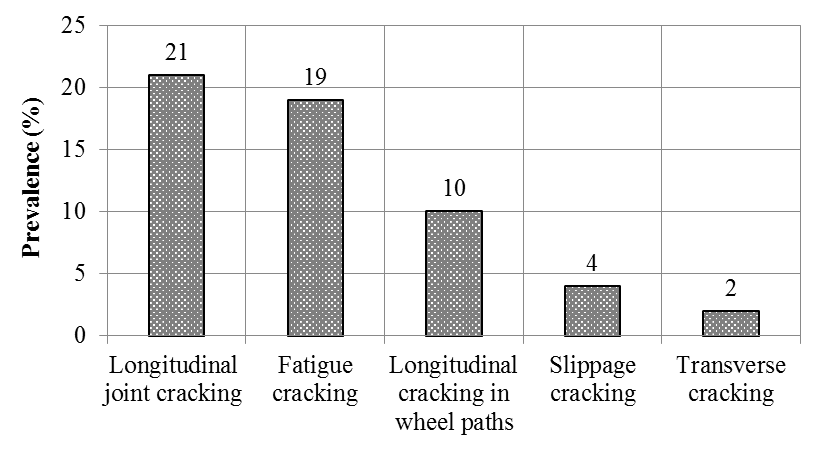

3.8. Pavement Distresses Identified in Condition Survey

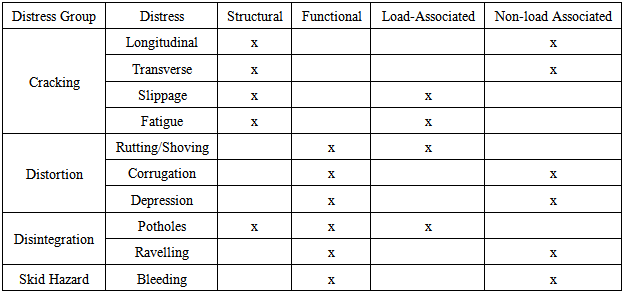

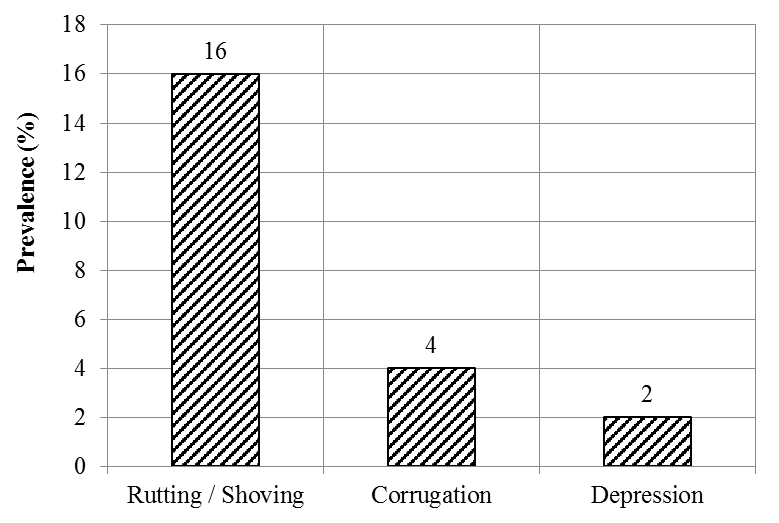

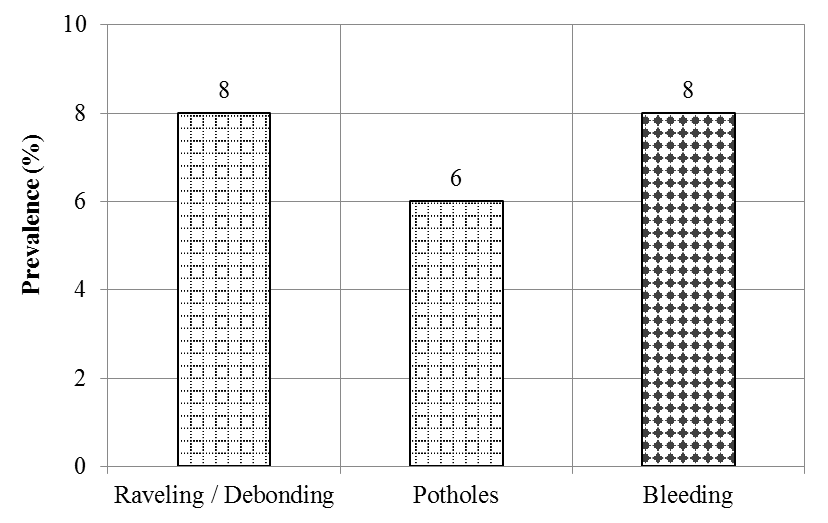

- The pavement distresses identified in the condition survey were categorized into cracking, distortion, disintegration, and skid hazard distress groups and qualified as structural and/or functional. Structural distresses affect the ability of the pavement to carry traffic load whereas functional distresses are associated with ride quality and safety [30]. Furthermore, the distresses were characterized as either load-associated or non-load associated using the guide in Table 1 [30, 31]. Non-load associated distresses are caused mainly by climatic factors, poor quality construction materials and construction deficiencies [30].

|

| Figure 7. Prevalence of cracking distresses |

| Figure 8. Prevalence of distortion distresses |

| Figure 9. Prevalence of disintegration and skid hazard distresses |

4. Conclusions

- It has become clear from the study that hot-mix asphalt pavement construction practices in Ghana do not exemplify contemporary advancements within the asphalt paving industry and are partly to blame for the premature failures of asphalt concrete pavements. Several benefits of current advances in the HMA industry such as the use of storage silos and material transfer vehicles, joint construction devices, stringent quality control and proper material handling and storage at all stages are not appropriated. More importantly, the Technical Specifications for road works of the Ministry of Roads and Highways were found inadequate in several respects which included inappropriate specification for joint construction, lack of specification to check partial combustion of aggregate drying liquid fuels, lack of definitive specification on tack coating, and the absence of a criterion for rejecting segregated and sub-standard pavement sections. In principle, the specifications allow sub-standard construction practices to prevail and provide no motivation for contractors to pursue high construction quality because contractors do not suffer penalties for substandard works. The overall effect is a middling pavement performance characterized by early failures. Most of the distresses identified on selected asphalt pavements in a condition survey were non-load associated. This suggests that the prevalence of such types of distresses could generally be minimized through high quality construction practices. Therefore, to improve the quality and longevity of asphalt concrete pavements, a revamp of Ghana’s asphalt pavement construction practices, revisions to the technical specifications used for road works, and adoption of innovative performance-based contracting arrangements are necessary.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML