-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Construction Engineering and Management

p-ISSN: 2326-1080 e-ISSN: 2326-1102

2013; 2(2): 33-37

doi:10.5923/j.ijcem.20130202.01

Testing Water Vapour Permeability of Sawdust and Banana Peels Ply Board as Non-Veneer Panel

Tomas U. Ganiron Jr.

Department of Physics, University of the East, Manila, 1001, Philippines

Correspondence to: Tomas U. Ganiron Jr., Department of Physics, University of the East, Manila, 1001, Philippines.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

This experimental study aimed to measure the moisture performance of sawdust and banana peels ply board as non-veneer panel for construction projects. The goal was to measure the vapour permeability values of sawdust and banana peels ply board, compare the results with those done for oriented strand board and to investigate the efficiency of structures through these panel products. Structures made of different materials have different drying efficiencies under high relative humidity conditions that are representative of their application as non-veneer panel in cold climates

Keywords: Banana Peels, Sawdust, Construction Materials, Ply Board

Cite this paper: Tomas U. Ganiron Jr., Testing Water Vapour Permeability of Sawdust and Banana Peels Ply Board as Non-Veneer Panel, International Journal of Construction Engineering and Management, Vol. 2 No. 2, 2013, pp. 33-37. doi: 10.5923/j.ijcem.20130202.01.

Article Outline

1. Introduction

- Today, onlyone-fourth of the land surface is forested[1]. Nonetheless, with the right planning andconservation of the environment, forests, and wood, a never-ending supply of wood couldbe available in the future. The historical records available all over the globe shows that the basic materials used in construction were either derived from the earth made from wood. Wood is one of the construction materials were being used of the civil engineer to build a house, building and bridge[2][23]. For the most part of the native origin and satisfied environmentally compatibility as well as financial constraint.Wood has been used throughout human history. However the variety of uses ofwood today would amaze our ancestors. These developments in wood technology havebeen made possible by scientific research[3],[6]. Three growths have been improved. Plywoodand its manufacture have been made better .The plywood or ply board is a panelproduct composed of 3 or more thin layers of wood that are glued and united underhigh temperature and pressure. The grain of each layer runs at right angles to the grain ofthe layer it faces. Plywood is light, strong, stable, waterproof and very versatile[5]. Theseproperties make it the product of choice for many construction applications. It is easilycut to size and nailed. The large sheet size is convenient for roofing or flooring jobs.Structural plywood is used extensively in residential and commercial construction and inindustry. Construction uses include light-frame structures, roof and wall sheathing, subfloors, underlayment and siding. Industrial uses include plywood for van liners, furniture,cabinetry, signs, pallets, crates and concrete forms[7],[10]. Plywood is also used in the manufactureof engineered building components such as I-beams. Decorative plywood uses hardwoodveneers to face the panels[8]. This type of plywood can be used in wall panelling andfor furniture manufacturing. The fiber by-products from sawmills and low grade logs canbe used to manufacture a range of particle-based panels and lumber products such as particleboard,wafer board, oriented-strand board and composite lumber[9].[12]. Particleboard isproduced using glue and compression to form small particles of wood into a panel. Byvarying the wood particle size, the amount of resin is used. The lamination of timbers havebeen made possible by new glues and adhesives[13]. Thermosetting resins are used in adhesives, finishes, and moldedobjects[14],[17]. Urea-formaldehyde resin'sattribute includes high tensile strength, flexural modulus and heat distortion temperature,low water absorption, mold, high surface hardness, elongation at break, and volumeresistance[15]. Urea-formaldehyde foam insulation started being used in the 1950s. In the1980s, concerns began to develop about the toxic formaldehyde vapour emitted in thecup process, as well as from the breakdown of old foam[18],[20]. Consequently, its use wasdiscontinued. Science will continue to make wood ever more useful in the future.The manufacturer of the lumber is the oldest industry. Thus, wood technology is highly developed. Waste in forestry and wood processing is now being made into useful products[19]. The increasing demand for wood materials will probably strengthen this trend. The use of wood and wood products continues to increase even in this age of spacecraft, computers, and unusual alloys. About two million housing units are built every year. The average one-family wood home has about 11,595 board feet (23m3) of lumber and 7510 square feet of plywood and other wood products[21].[24]. The lumber and wood products industries continue to develop and expand, partly because of more efficient forestry practices. In recent years, there has been a great increase in the use by products of lumber production. Among the wood products that are rapidly expanding in use are particleboard and hard board[22]. These are used more and more in the production of furniture, cabinets, houses, mobile homes and interior panelling in both residential and commercial buildings.The never ending demand of wood is inevitable and unstoppable as one of the major commodities, as long as there is an enough trees to be cut out from the forest, but this well also leads to the rapid destruction if we become so much dependable into our forest, and as well know, our forest takes a major role in the balance of our ecosystem.In the Philippines, deforestation is so rampant and abusive compared to the forestation.The results due to the program of the government that is not well implemented and most often violated by corrupt public bribery just to approve the operation of illegal loggers[4],[23]. That’s why there is a need to protect it, and one way of protecting is to conserve the use of wood, and preserve the forest by making use of waste materials coming from wood processing.Sawdust is made available from sawmills and to thelarge-scale manufacturers of wood product. As a waste it has many uses, it can use forsoaking up oil spills. It can beused in pottery making, as firewood for cooking[26].The researcher attempts to use sawdust and banana peels as onecomponent of a non-veneered panel for interior wall in response to the problem of thegrowing high cost of different wall materials.

2. Literature Review

- “Kaatoan Bangkal” was made into a three-layer type particle board bonded with banana peel extract[4],[6].[22]. Three board densities (200, 300, and 400 kg/m3) were produced varying their pressing conditions depending on the densities. The highest board density gave the largest values for all the mechanical properties. Dimensional stability determined particularly water absorption was also lowest compared with the lower board densities. At 400 kg/m3 board density, the following values were obtained: modulus of rupture= 6.65 MPa, modulus of elasticity =1.48 x 103MPa, internal bond strength= 0.34 MPa, screw withdrawal = 16.4 kg, thickness swelling = 11.8% and water absorption = 68.8%[5].[27]. Analysis of variance and Duncan multiple range test showed that all the data were highly significant [22]. The use of “isocyanate” resin adhesive as a new binder in the production of particle board lowered down the compaction ratio of the board produced without sacrificing its properties and qualities[24].Stylex Research Institute states that the particle board such as veneers which are constructed from high quality sawdust and banana peel extract is being selected for their suitability in all commercial situations[22]. All panels are made from 33mm Highly Moisture Resistant (HMR) particle board, laminated both sides with a decorative hard wearing melamine surface. The HMR core is manufactured from Australian Plantation Pine to Australian Standards 1859 for HMR grade particle board/veneers and meets the specification of the international V313 test[18],[22]. The HMR core board is sandwiched between layers of decor paper which provides the colored finish. The board is being impregnated with banana peel extract resin and dried[18]. The sandwich is then brought together in a press where the treated mixture are thermoset and polymerized under high pressure (28kg/cm2) and at high temperature (180c) creating a hardened surface and an extremely powerful bond[19].[23].

3. Experimental Investigation

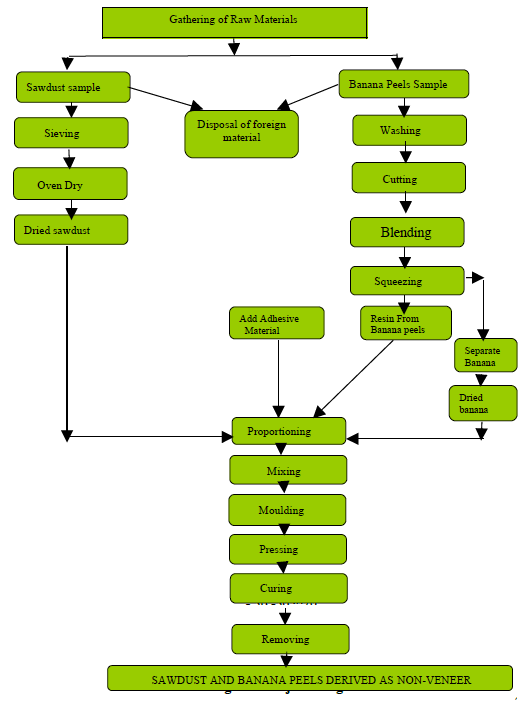

3.1. Project Design

| Figure 1. Project design |

3.2. Products Used in the Experiment

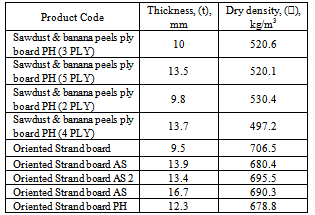

- Table 1 presents the sawdust and banana peels ply board products used in the experiments. Nine different products were studied: Four sawdust and banana peels ply board products and five oriented strand board products. One of both products were Philippines (code PH), the other products were Asia (code AS). All the products were meant to be used also as panel board. The dry densities of sawdust and banana peels plywood products were 497- 897 kg/m3 and that of oriented Strand board 680.4 kg/m3. The measured average product thickness was in the range of 9.5 mm – 16.7 mm.

|

3.2.1. Water Vapour Diffusivity Measurements

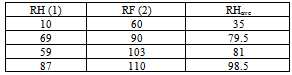

- Water vapour transmission properties were determined by a cup method based on standard EN 12086, All nine materials were tested in four different humidity conditions at constant temperature T = 22 °C (Table 2) using five parallel samples and one 'blind cup' without salt solution in the cup.Table 2 shows that dry and wet cup tests, one very wet (110/87% RH) and one moisture safe set of relative humidity conditions (90/69 % RH) were used. The conditions 90/69 % RH represent high, but still safe level of humidity because a humidity level of 90 % RH is considered to be the pivot value for the starting risks of fungal growth. When the temperature is lower than 15 ºC, this critical level of relative humidity starts to increase[25],[26]. Typically the temperature of the ply board panel is close to outdoor air temperature, and thus the relative humidity conditions that are less than or equal to 90 % RH can be considered safe in cold and moderate climate conditions. This level can be exceeded for some periods without causing moisture risks to structures. Higher humidity levels mean also higher vapour permeability level of the panel board and better drying efficiency for the structure.

|

3.2.2. Cup Test Results

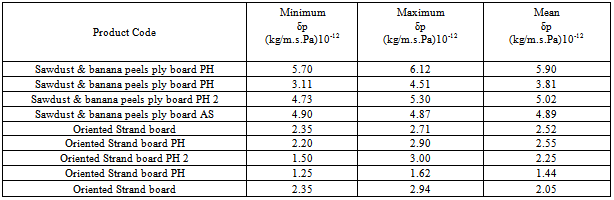

- The dry cup conditions correspond to those near the inside surface of a structure during the heating period in cold and moderate climates. Under these conditions, the vapour permeability of sawdust & banana peels plyboard was about half of that of the oriented strand board products. Under high but safe humidity conditions (90/69% RH), however, the vapour permeability of the plywood products is 3 to 4 times higher than that of the oriented strand board products. In these representative drying conditions, the vapour permeability of sawdust & banana peels ply board was in the range 3.8 – 6.0 ⋅10-12 kg/(m.s Pa) while that of oriented strand board products was 1.4 - 2.6 ⋅10-12 kg/(m.s Pa) shown in table 3. The vapour resistances from wet cup tests were in same level as those measured under the so called safe conditions.

|

3.3. Experimental Method in Drying Efficiency

- A simplified test method has been developed to study the drying efficiency of structures exposed to atemperature gradient[24],[27]. In this test, the 1-dimensionalintersection of the building envelope structure is sealed in a chamber, open from above to the cold side air.The warm side of the structure section is closed with a water vessel. This watervessel is bounded to the warm side air. The drying of the structure is based only on diffusive moisturetransport through the outer material layers and it is monitored by periodical weighing of the wholeinstallation frame of each structure section together with the initially set additional water.

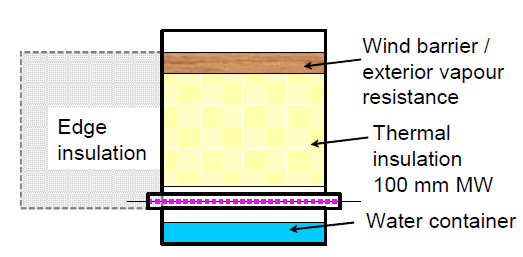

3.3.1. Drying Set up

- The test device consisted of 20 frames in which the different structure sections were installed. Due to the sealing of the sides and the edge insulation, the temperature and moisture flow fields were as 1-dimensional as possible. The top surface of each test structure was in contact with the controlled cold side air. The warm side temperature below the test frames was maintained constant with controlled heating of the air space shown in figure 2.As shown in table 1, drying efficiency of all the products was studied using two parallel structure components for each product.

| Figure 2. Test device for drying efficiency experiments |

3.3.2. Test Conditions

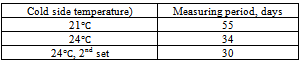

- In the experiments the warm side air temperature was maintained at +25 °C with less than 19 °C range of variation. The tests consisted of two measuring periods having different cold side air temperatures shown in table 4. The cold side temperature had about 20 °C variation from the set value. After the first period one of each parallel structure was removed to determine their moisture distribution.

|

4. Conclusions

- The results show clearly the differences between oriented strandboards and,sawdust and banana peels ply board products. The products are not interchangeable and the climate conditions and moisture loads have to be studied to evaluate their suitability and moisture safety aspects in different applications. In additions to drying efficiency, there are other performance properties that have to be considered when applying exterior sheathing products.The vapour permeability values and vapour resistances determined in 90/69% RH conditions represent the safe level that can be used when analyzing the performance of the ply board products under continuous conditions. These results were in the same range as those derived from wet cup tests and thus the wet cup results give a good approximation for the possible continuous vapour resistance of the exterior ply boards during drying conditions in a cold climate.The drying experiments confirmed what was found in the vapour permeability measurements. When the exterior sheathing board is under freezing conditions, the drying efficiency was quite low both with sawdust and banana peels ply board and oriented strand board. In above freezing conditions the amount of moisture dried from the structures with ply board sheathing were about 10 times higher than that dried from the structures with oriented strand board.

ACKNOWLEDGEMENTS

- The writer wish to express his sincere gratitude and deep appreciation to his former colleagues in University of Makati and Emilio Aguinaldo College for their untiring guidance, inspiring encouragement and sincere concern for the completion of the research and Prof. Lucina Galera for her intellectual comments and suggestions towards the improvement of the manuscript.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML