-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Construction Engineering and Management

p-ISSN: 2326-1080 e-ISSN: 2326-1102

2013; 2(1): 8-14

doi:10.5923/j.ijcem.20130201.02

An Integrated Approach for Project Management of the Wooden Constructions Using the CNC Production

Marek Krajňák 1, Renáta Bašková 1, Ľubomír Vojtáš 2

1Institute of Civil Engineering Technology and Management, Faculty of Civil Engineering, Technical University of Kosice, Košice, 042 00, Slovakia

2Tauber, Ltd., Spišská Nová Ves, 052 01, Slovakia

Correspondence to: Marek Krajňák , Institute of Civil Engineering Technology and Management, Faculty of Civil Engineering, Technical University of Kosice, Košice, 042 00, Slovakia.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Contribution deals with options of innovation the production process of wooden structures from design to production itself, including the establishment of preconditions for seamless installation on site. An essential step is the introduction of CNC (Computer Numerical Control) production which paves the way for more effective management of the resources which enter into the production, as well as the opportunity to qualitatively higher level of the process controls of manufacturing of the wooden houses. This paper presents the proposed measures, at the same time their anticipated impact on the production of wooden houses. These measures have a major impact on the return an investment throughout the implementation of CNC manufacturing.

Keywords: CNC Production, Wooden Constructions, CAD/CAM Software, Woodworking Machines, CNC Communication, Prediction and Simulation of Processes

Cite this paper: Marek Krajňák , Renáta Bašková , Ľubomír Vojtáš , An Integrated Approach for Project Management of the Wooden Constructions Using the CNC Production, International Journal of Construction Engineering and Management, Vol. 2 No. 1, 2013, pp. 8-14. doi: 10.5923/j.ijcem.20130201.02.

Article Outline

1. Introduction

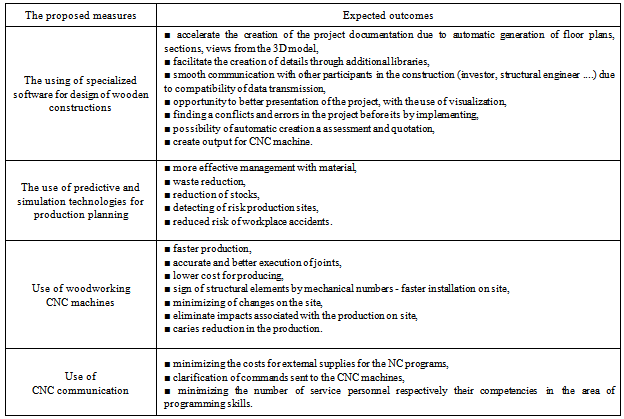

- Currently, wooden constructions are implemented largely by the traditional way directly on the site from timber of the various cross-sections. Carpenters, on basis of project documentation, divide the given timber to necessary length, consequently they produce on the individual components a carpentry joints and thereby adapted segments are assembled into the structure. The carpenter on construction site has to respond to possible differences of the actual situation on the construction site against a project documentation with that the wooden structure is adapted to the actual situation. This method is demanding in terms of time. The speed of implementation is directly dependent on weather conditions. In case of bad weather conditions, for example by reason of the rain, is occurring to interruption of works. Manufacture of the carpentry joints in place requires amount of time, expertise and skill of carpenters.During several generations in our country has created a negative view of the wooden constructions, so today is a wooden house in the majority of Slovak citizens associated with something that is not durable enough and it is a cheap and uncomfortably alternative of housing only[1]. Nevertheless numbers of the new wooden houses in Slovakia is growing. Year on year the share of wooden houses increases from the total number of houses by about 0.8%.

| Figure 1. Percentage share of wooden constructions from the total number of houses built in 2009 in different countries[2-4] |

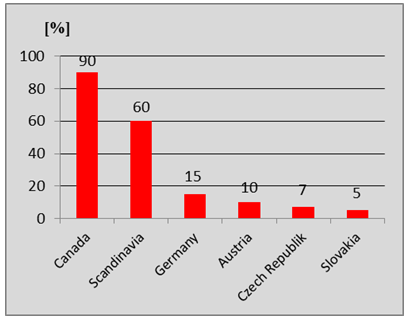

| Figure 2. Comparison of shares for wages costs and for building materials in the masonry constructions and wooden constructions (construction of raw structure)[6] |

2. Literature Preview

- At the beginning it is necessary to mention a level of elaboration of the subject in the papers. The issue of data transfer and sharing in an integrated approach for planning and management of construction projects dealing with multiple contributions. Xu et al.[7] described the integration of CAD and CAM stage and exchange data between them, including a description of the problem NC (Numerical Control) programming of the CNC machines in different countries. Overview of available CNC technology[8] indicating a potential of creating CNC machine tools more open, interoperable and intelligent. Lazaro et al.[9] focused in knowledge-based approach for improvement of CNC part programs as well attempts to illustrate the structure for coordinating sensing data and expert knowledge to tune the CNC program. This approach would involve project management of production on a qualitatively higher level.Contribution follows the above-mentioned approaches in an effort to integrate CNC production within the implementation of construction projects and integrate it while preserving the special conditions in which the production of construction is performed.

3. Design and Project Management of the Wooden Constructions

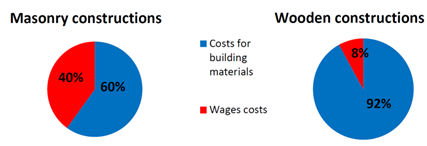

- With the increasing interest of consumers in wooden constructions, arose the question of how the process of production of wooden constructions to innovate and optimize in order to shorten the construction time, improve the quality and reduce production costs. The answer is a qualitatively higher level of management, from design concept to installation on site. In Fig. 3 are described different parts of the production process of wooden constructions, each of which creates space for optimization.Production begins on the first stage of CAD-Computer- aided design. The purpose of this stage is to create a design that meets the requirements from the investor and would take into account the possibility of production of the construction company. Consequently, it is necessary the proposal design to analyze to meet the strength, thermal, and fire safety requirements. This stage dimensioning of structural elements is known as CAE-Computer-Aided Engineering. This is a complex engineering work in support of development-stage design and set computing, modeling and simulation tools. Thus verified the structural design is then divided into structural elements.Itself production should precede production planning with regard to speed, quality production and efficiency of managing with the basic production material - wood. These activities dealing with CAP (Computer-aided production planning), it is a computer aided planning, preparation of data for sub-activities and instructions for installation. CAP is from this point of view is very important optimization tool, which has four basic functions: construction work plans, choosing the means of production, making installation instructions, NC (Numerical Control) programming. By this step provides an opportunity for production itself on the CNC machines. The course of the production is supervised and controlled simultaneously using CAM (Computer Aided Manufacturing). A special part is the labeling and classification of elements before exporting, which creates conditions for a successful and trouble-free installation on site. Completion of the production cycle is CAQ (Computer Aided Quality), thus computer controlled machine test of quality of the finished product while desired parameters are compared with the actual parameters of the final design element.

| Figure 3. Integrated approach to project management of the wooden constructions |

3.1. Specialized Software for Design of the Wooden Constructions

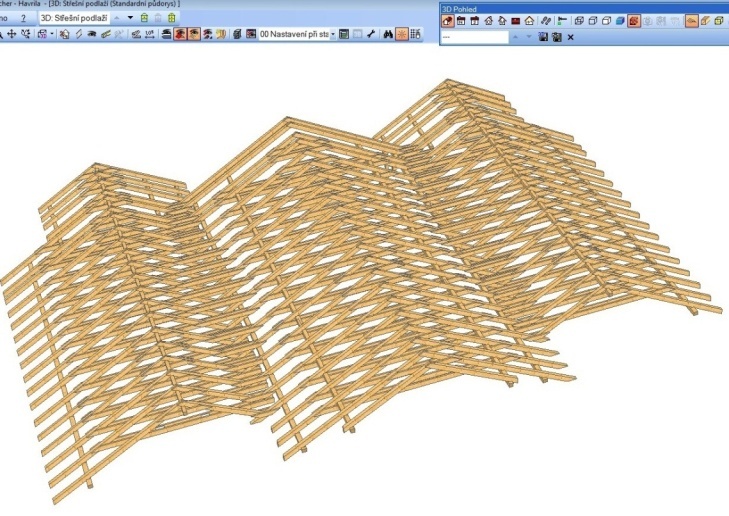

- By the gradual development and improvement of we have programs on the market today that perfectly connect knowledge of wooden structures with computer technology. In Europe there are programs: SEMA, DIETRICH'S, WETO-VisCon, WETO-Designer Vista (Germany),Cadwork (Switzerland) and FINE (Czech Republic). The advantage of these programs is that they consist of an individual modules (truss frame construction, log cabin construction, stairs, etc.) while at procurement customer can compile program from the modules needed and then other complementary modules can complete.A big benefit of these programs is a high quality 3D visualization, which helps to eliminate errors in design and detail design of wooden constructions. The programs provide a rich library of the carpentry joints, which can easily be applied to create a structure. We must not forget the possibility of 2D and 3D outputs of axis and node modules that are compatible with static programs. This allows us to consider the elements of static structures and all structures in the real conditions.

| Figure 4. Creation of roof structure in the software SEMA |

3.2. Predictive and Simulation Technology for Production Optimization

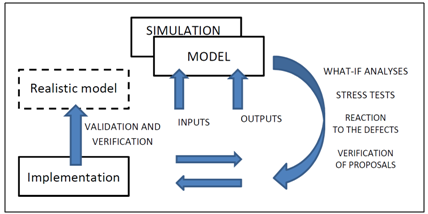

- Simulation (statistical modeling) is a mathematical method, which consists in simulating the production, economic and other processes on digital computers by reproduction of elementary phenomena and processes in the context reflecting real bonds and interdependencies. It is a synthetic imitation of process so that random variables implement process for each value obtained randomly, but with a probability distribution with a mean value, which corresponds to a real process. On the basis of a sufficient number of realizations allows simulation performed to appreciate the likelihood of the phenomenon or process[10].

| Figure 5. The dynamic presentation of the real system by computer model[11] |

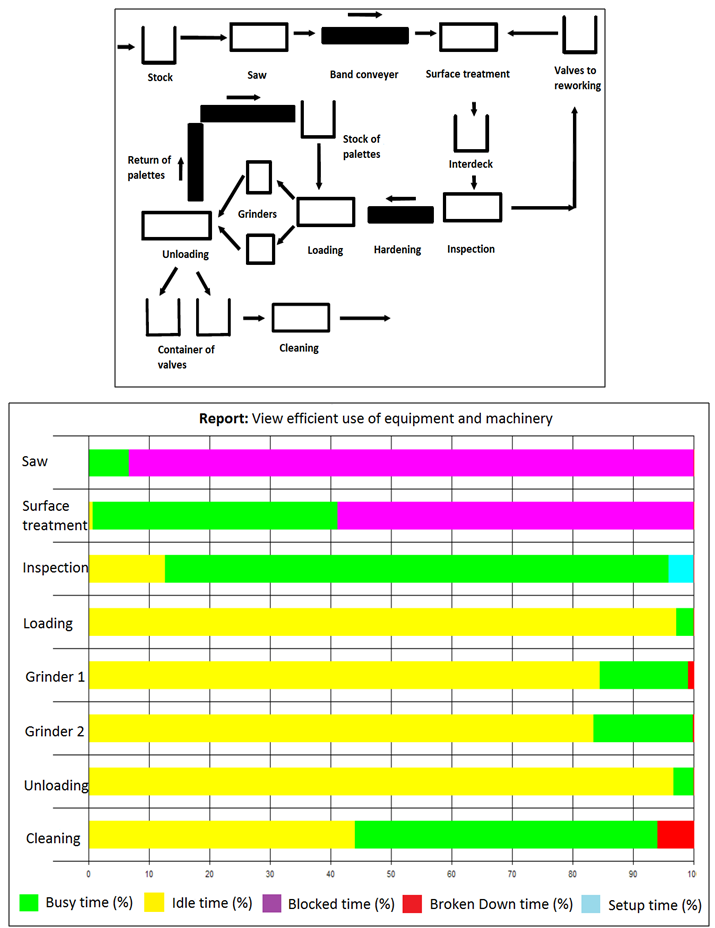

| Figure 6. Top: Distribution of the production process in Witness, Bottom: View efficient use of equipment and machinery in Witness[11] |

3.3. CNC Woodworking Machines

- In conjunction with the machine tools you can use the equivalent of computer-controlled machine tool, thus using CNC machine tool control system to ensure that the product could be farmed by prearranged technological NC programs.NC programs contain so. G- and M-codes. G-codes are defined as the coordinates of working positions in order to working tool can smoothly move by the shortest possible route. Additional information is feed rate. M-codes describe the auxiliary functions, which relate to specific operations and control of CNC machines. The next step is to determine the coordinates of the start of the workpiece against the machine zero point. This is very important because for this point will be subject to all working operations while entering coordinates may be absolute or incremental units[13].Writing a NC program can be in any text editor, which is then transferred to the CNC control system, or is possible to enter the commands directly at the machine. CNC Machines can be connected into a computer network and directory of the CNC control system share within the computer network. Advantage of some of the NC editors is option of simulation consultation of the working operations, including the exchange of the instruments and turning logs all operations in real-time or accelerated time, thus we have a fair idea of the duration of the construction element production[13].

| Figure 7. The woodworking machine Hundegger[14] |

| Figure 8. The control unit of the woodworking machine Hundegger[15] |

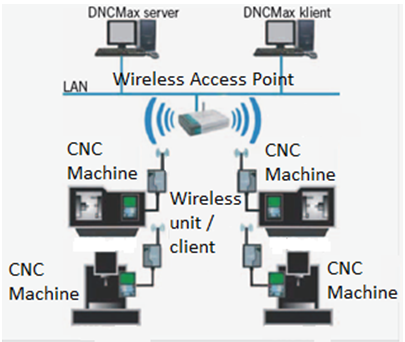

3.4. Communication for CNC Woodworking Machines

- Control programs NC (Numerical Control) of machining of parts were inserted at first in the NC control system on punched tape. Later, these programs were saved in computer control DNC (Direct / Distributed Numerical Control) and into control systems in NC machine tools are so transferred so. bypass of reader (BTR way - Behind The Reader). The development of personal computers between 1980 and 1990 marked the end of the use of special computer terminals and occurred a period of the application of modern DNC systems for communication with CNC control systems of woodworking machines. Currently, exercises already wireless communication of DNC (Wireless DNC)[16].

| Figure 9. Wireless DNC communication[16] |

4. Procedural Steps for Implementation CNC Production of the Wooden Constructions

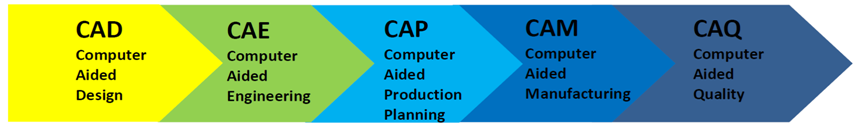

- In the text above has been specified a number of proposals and tools which are linked together and complement the "empty spots" in an integrated approach for managing projects of wooden constructions. An additional benefit is the synergy effect, which in this case far exceeds the sum of potentials of individual actions. These measures are divided into four groups: use of the specialized software for design, use of the predictive simulation technology in the production planning, use of CNC woodworking machines and the use of CNC communication. The proposed measures and their expected effect are shown in the following table.

|

5. Conclusions

- The proposed measures create a space for improving the efficiency of the production process of wooden constructions and compared to the traditional method of production wooden construction bring time savings, material savings, higher quality of the joints execution and conditions for seamless installation on site. All proposed measures that are related to the implementation of CNC production mean for construction companies large financial burden, but with the ever increasing interest for wooden constructions from the side of customers, it can be seen as an investment in the future.

ACKNOWLEDGEMENTS

- Contribution was created within the project VEGA 1/0840/11 Multi-dimensional approaches to support integrated design and management of construction projects.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML