-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Construction Engineering and Management

2012; 1(3): 33-41

doi: 10.5923/j.ijcem.20120103.04

Environmental Assessment of Concrete Structures

Julián García-Rey 1, Víctor Yepes 2

1School of Civil Engineering, Universitat Politècnica de València, Valencia, Spain

2Institute of Concrete Science and Technology (ICITECH), Universitat Politècnica de València, Valencia, Spain

Correspondence to: Víctor Yepes , Institute of Concrete Science and Technology (ICITECH), Universitat Politècnica de València, Valencia, Spain.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

In recent decades, with the objective of reaching a more sustainable development, worldwide society has increased its concern about environmental protection. Nevertheless, there are still economic sectors, such as the construction industry, which produce significant environmental impacts. Life Cycle Assessment (LCA) is a tool that enables identifying environmental issues related to both finished products and services, and allows focusing efforts to resolve them. The main objective of this paper is to asses LCA applicability on concrete structures so that construction’s environmental performance can be improved. For this purpose, an attempt is made to provide a decision-making tool for construction-sector stakeholders with reliable and accurate environmental data. The research methodologies used in this paper are based on a literature review and are applied to a case study. This review was performed to collect information on LCA methodologies currently in use and their practical application. The case study subsequently described in this paper involved identification of the most sustainable type of slab for a reinforced concrete structure in a residential building, using two different databases. It was observed that, depending on the database selected and inherent assumptions, results varied. Therefore it was concluded that in order to avoid producing incorrect results when applying LCA, it is highly recommended to develop a more constrained methodology and grant access to reliable construction-sector data.

Keywords: Applicability, Concrete, Construction, Life Cycle Assessment (LCA), Structure, Sustainability

Cite this paper: Julián García-Rey , Víctor Yepes , "Environmental Assessment of Concrete Structures", International Journal of Construction Engineering and Management , Vol. 1 No. 3, 2012, pp. 33-41. doi: 10.5923/j.ijcem.20120103.04.

Article Outline

1. Introduction

- In spite of the economic crisis that nowadays is being experienced world-wide, human population is expected to continue increasing. According to a report by United Nations Population Fund (UNFPA)[29], it is expected that world’s population will increase from the current 7 billion to more than 8 billion in 2025. Consequently, resource and supplies are expected to show a similar behaviour, as that of pollutants emission. Therefore, it can be stated that nowadays Earth’s scenario of growing population, high resources consumption and pollutants emission is driving the planet to a critical situation. Furthermore, according to a report from the World Wide Fund for Nature (WWF)[31] in 2007 humanity already overpassed Earth’s bio-capacity by 1.5 times. This means that the capacity of our planet to replace natural resources consumed and to absorb all CO2 emissions is currently exceeded. But it is most relevant to emphasize from this same source that by 2030 human requirements are expected to double Earth’s bio-capacity. Therefore, it seems crucial to incorporate design criteria to minimize these impacts[32-33].Since the early 1990’s, sustainability already was considered in the construction environment as an issue of great importance. Nevertheless, when in 1992 “The Earth Summit” was celebrated, a new environmental trend took form with the motto: “Sustainable Development”[25]. This is based in a triple-factorized development considering: economy, society and environment. Therefore, in order to accomplish economic growth or development, there is no need to jeopardize human society or environmental integrity. In response to this trend, both governments and private institutions have worked on implementing more sustainable measures and policies, as the European Union’s EPBD or CPD directives. The first measure, Energy Performance of Buildings Directive (2002/90/EC) is focused on reducing building’s energy consumption by the optimization and efficiency when supplying its energetic requirements[4]. On the other hand, the Construction Products Directive (89/106/ECC) is a set of regulations established for construction and building products requiring various aspects before product’s commercialization (in order to comply with sustainability concerns)[6]. But there are additional examples, such as Green Procurement (COM 2008-400)[8], product’s green labelling (COM 2008-241)[7] or waste reutilization (Directive 2008/9/EC)[5].Construction industry is considered to be one of the most important economic sectors worldwide but, at the same time, it is also one of the most pollutant emitting and resource demanding. It is held responsible for 25-40% of energy consumption in OECD countries[23] and according to other studies it is established that construction’s environmental impact in developed countries can be as high as 40%[16]. Concrete, with an estimated consumption of 6 billion tons per year (what is the same as 1 ton per person/per year)[20], is considered the most world-wide construction material used. Therefore, a better use of concrete is a relevant and challenging issue for construction industry, already pointed out in 1998 by the “Lofoten Declaration”[11].In this scenario, numerous attempts to reduceenvironmental, social and economic impacts due to construction activities have already been made to this date. Nevertheless it is a fact that, when considering the complete life cycle of a construction project, effectiveness of measures decrease as the project progresses. Therefore, if improving sustainability is a must of the construction industry, it is necessary to provide decision-makers with effective tools to be applied at the initial phases of project’s life cycle (e.g., pre-design or design phases). This objective can be achieved by incorporating tools such as Life Cycle Assessment in the design, construction, operational and demolition phases of concrete structures.

1.1. Life Cycle Assessment: Birth and Evolution

- At some point in the late 1960’s, two researchers at the Midwest Research Institute began working on a technique for quantifying energy and resources, as well as environmental emissions, related to the manufacturing process and use of products[28]. Initially named “Resource and Environmental Profile Analysis” (REPA), it was first applied in 1969 by America’s Midwest Research Institute (MRI) together with Coca-Cola’s Corporation for analysing and selecting the environmental-friendliest vessel material (glass or plastic) in terms of whether disposable or recycled vessels produced less impact[10].LCA development showed an accelerated growth during the energy oil-crises of the 1970’s. At the beginning LCA’s were used to study energy consumption of products packaging (glass bottles, plastic bottles, cardboard, etc.). Again, for a short period in the late 1980’s and early 1990’s, LCA achieved great significance for environmental marketing claims[24]. As this method became popular, and studies performed over same products gave great differing results, many initiatives to harmonize LCA methodologies were proposed. This tendency resulted in various methodological guidelines (known as the Dutch and Nordic Guidelines), which included different and often conflicting methodological recommendations. An effort to reach consensus on a broad international level was initiated in 1990 by the Society of Environmental Toxicology and Chemistry (SETAC). Later, in March 1993, the North American and European SETAC LCA advisory groups met in Sesimbra (Portugal) and produced the so-called “Code of Practice for Life Cycle Assessment”. In addition, many different initiatives to standardize LCA methodology were started (e.g., the Z-760-LCA guideline of the Canadian Standards Association), but the most recognized standardization process was begun in the late 90’s within the framework of the International Organization forStandardization[26].During the 1990s, first Japan and later Australia and Korea increased their LCA practice activity performing a wide number of environmental studies. In contrast, LCA activity in the rest of Asia, Latin America and Africa was scarce. This trend has begun to change, as activity in LCA is increasing in Latin America, South Asia and Africa. The Brazilian government, for example, recently launched a national project to develop life cycle inventory data. LCA practitioners are also developing data and impact assessment methods, and applying them in both public and private sectors, in various Latin American countries, such as Mexico, Argentina, Chile, Colombia and Peru. The African LCA Network recently hosted an LCA training workshop in which the participants began to develop a life cycle inventory data specifically applicable to each country[21].LCA practice on construction industry started in the last decade, but only for environmental assessment of building and construction materials selection. Therefore, LCA in the construction industry is less developed nowadays than in other industries, but appears to be developing quickly[27]. Furthermore, Life Cycle Assessment on buildings is nowadays a hot research theme in developed countries like, such as Japan, North America and the European Union[9].

1.2. Life Cycle Assessment Methodology

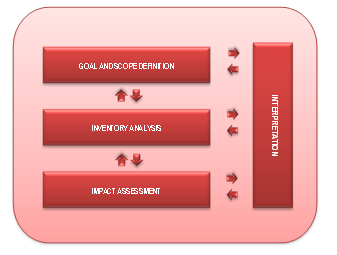

- The International Organization for Standardization (ISO) issued four relevant international standards in 1997 for LCA practice. According to the standards of the fourth series of ISO 14040 standard Life Cycle Assessment can be defined as "a method for summarizing and assessing the total investment of a product (or service) system in the whole life cycle, and the impact or potential influence on the environment"[15]. Therefore, LCA can be considered as a methodology for estimating the environmental burdens of production processes of goods and services during their life cycle (e.g., from cradle to grave).According to ISO 14.040, LCA is composed of four different phases, which are:• Goal and Scope definition. In this phase a discussion of motivations, altogether with the scope and depth of the assessment, is performed in order to establish all preliminary concerns relating the LCA study.• Inventory Analysis. In involves collecting data to quantify all materials, energy and emissions considered as inputs and outputs from the studied system during its life cycle.• Impact Assessment. This stage is related mostly to converting data recovered from the inventory into effects and impacts over the environment due to production of the system assessed.• Interpretation. The step presents the results obtained at the inventory and/or impact assessment steps, and includes conclusions and recommendations.Firstly, the environmental assessment’s goal and scope are established, subsequently followed by the inventory analysis. As pointed out by the ISO standard, the LCA can be finished at this step, providing a general perspective of the direct impacts generated by the assessed system; nevertheless, if the assessment is pursued further, then an impact assessment is performed. It is important to emphasize that, for both LCI and LCA studies; a sensitivity analysis of the assessment should be performed in order to identify mistakes or issues. Depending on the observations and results reached from this analysis, a revision of the previous steps can be required. Finally, all the impacts obtained from the LCI or LCA study, depending on the case, are summarised in the interpretation step, which provides a general view of the study results.

| Figure 1. Life Cycle Assessment’s procedure according to ISO 14040 |

2. Methodology

- Literature review was a fundamental part of this paper’s research, in order to summarise the state of the art for this subject. Papers recovered from the review were submitted to a thorough analysis, with particular emphasis on literature relating LCA studies on concrete structures. These studies were analysed in two different ways, in order to establish:• Current or trendy LCA methodological practice.• Existing issues and limitations on LCA practice.After all existing information was summarised from the literature review phase, a guide for LCA practice on the specific field of concrete structures was produced. Then, this same guide was tested with a case study located in Valencia (Spain). Data for the assessment was provided by two different databases, in order to demonstrate the applicability of the tool and to identify potential mistakes or weaknesses to be corrected.

2.1. Review of LCA Studies

- As previously indicated, literature review was performed in two stages. First a general review of literature relating ordinary practice of LCA was done, which allowed identifying: existing methodologies, software, databases, etc. Then, a deeper analysis was performed on LCA studies that specifically considered concrete structures as the assessed system. This more comprehensive analysis was done in two different ways. First, a general review was conducted in order to identify either ordinary or popular LCA practice. The aspects considered in this review are the following: year of publication, scope of the study, functional unit, LCA methodology used, type of Inventory Analysis or Impact Assessment performed, databases or software used, and sensitivity or data quality analysis performed. The second step involved identifying limitations and issues of LCA practice for concrete structures; this was done considering facts specifically mentioned/pointed out in the studies themselves.

2.2. Case Study Introduction

|

|

3. Results

3.1. Methodological Analysis

- Based on the review of published LCA studies, papers focusing on concrete structures range from 1998 to 2011. It is interesting to note that more than a half of these references (i.e., 59.26%) were published between 2005 and 2009, which indicated the current significance of the subject. When focusing on the methodology used for LCA practice, it was observed that the 67.34% of existing literature used process method and that the 51.85% completed the LCIA step. In 39.21% of all cases databases and software were used for the study’s calculations. Finally, it was also observed that only a few of them (i.e., 7.12%) performed a sensitivity analysis or data quality assessment, situation that causes assessments to be uncertain and are lacked of transparency. Furthermore, when a sensitivity analysis was claimed to be performed, it was actually a comparison of different scenarios and not a sensitivity analysis per se.An analysis of the deficiencies and limitations found while performing the case study, and in some of the analysed references, allowed establishing that LCA studies on concrete structures have the following weaknesses:• Incomplete or inaccurate definition of the functional unit, which causes great difficulties for subsequent comparison among different studies.• Limitations and assumptions of LCA study are not indicated. This significantly affects reviewing and reproducing the results obtained by others.• Incomplete life cycle, as the operational phase of concrete structures is excluded from the study’s scope.• No description of the inventory phase performed; in some cases sources of data are not mentioned at all.• Calculations of the impact assessment step are not included; therefore, many studies suffer from lack of transparency.• No graphical representation of the interpretation phase of the study is provided.Therefore, it can be concluded that LCA studies on concrete structures performed to the date show significant deficiencies. Among these, the most relevant are the following: lack of transparency, poor reliability and high uncertainty.

3.2. Case Study Assessment

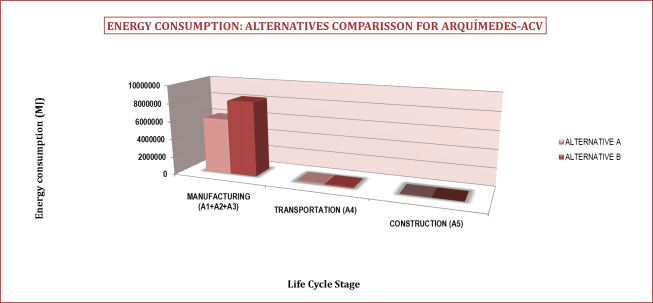

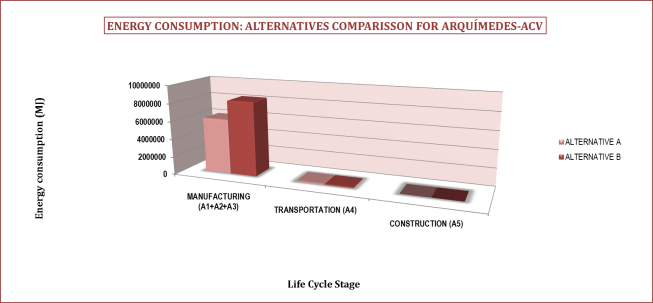

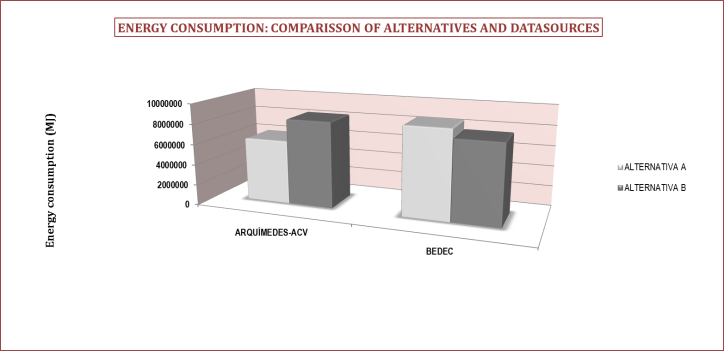

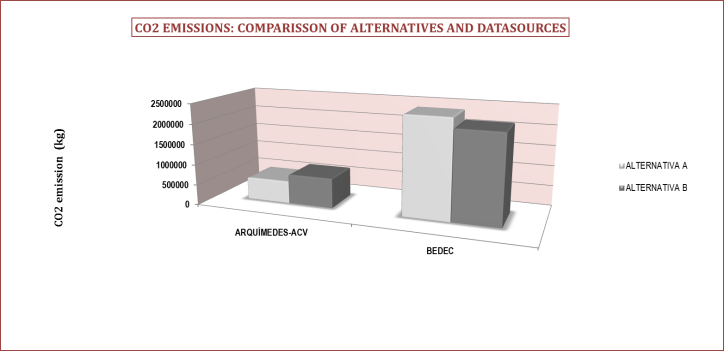

- The interpretation phase of the performed LCA study allowed identifying both construction units of each alternative and construction phases of the life cycle considered which had the worst environmental performance. It was also observed that, depending on the database selected, contradictory results for each alternative were obtained. E.g., according to ARQUÍMEDES-ACV, the best energy consumption and CO2 emissions performance corresponded to that of alternative A (one way slab), but BEDEC selected alternative B (one-way slab) as the best one.As pointed out before, concrete structure slabs are the construction units responsible for the most relevant part of impacts (energy consumption and CO2 emissions) to the environment. If results from the ARQUÍMEDES-ACV database are considered, it is observed that slabs generate 61-66% of the total impact, whereas the results obtained from BEDEC database vary between 65 and 80% (table 4).

| ||||||||||||||||||||||

| Figure 2. Distribution of energy consumption by each life cycle phase (ARQUÍMEDES-ACV database) |

| Figure 3. Distribution of energy consumption by each life cycle phase (BEDEC database) |

| ||||||||||||||||||||||

| Figure 4. Energy consumption comparison for each alternative and data source considered |

| Figure 5. CO2 emissions comparison for each alternative and data source considered |

4. Conclusions

- Sustainability concerns have reached the construction industry, and its environmental impacts are being gradually considered more seriously when designing, selecting materials or making operational decisions, among others. Therefore, it can be said that construction is getting greener and greener with time. Nevertheless, decision-makers have lacked reliable tools and managerial resources to evaluate construction impacts on the environment. With the introduction of LCA to this scheme, it is assumed this situation can be changed, as it is a tool capable of identifying items with the greatest environmental improvement (as it was observed in the results obtained from the case study).Although the methodology to practice LCA studies was standardized by the ISO standard 14040, it requires further improvement in order to prevent present limitations and uncertainties on its results[17]. Furthermore, limitations of LCA’s standardized methodology are not the only issue this tool is facing nowadays, but also subjectivity introduced by real practice[16,18,26]. Unfortunately, when conducting a LCA study, there are a wide number of tools and databases which in turn introduce more variation to each study. These elements cause LCA studies to produce significantly different results when assessing a system, depending on the practitioner’s criteria, inherent assumptions and choices made, even when the system assessed is exactly the same. This issues could be resolved by clearly establishing each assumption on the assessment’s goal and scope definition step[17].Moreover, as the impact inventory step is directly based on data, its transparency and reliability are essential. Therefore, previous evaluation of input data used in LCA studies is a must[1]. Some authors have even introduced the concept of statistical methods to minimize inaccuracy and improve reliability on data used for LCA studies[24]. But, contrary to this recommendation, only a few LCA studies published to the date have taken into account statistical analysis of data incorporated.As far as the specific practice of LCA on concrete structures, its main purpose has been to compare and identify the environmental friendliest frame materials. Concrete structures have been assessed and compared to wooden frames[10], steel frames[12] and bamboo frames[30]. LCA studies have mainly been focused on building structures, and very few studies have been applied on other types of constructions, although examples on concrete bridges[3,14] or concrete sidewalks[22] can also be found in the scientific literature reviewed.Regarding the methodology used by the authors to assess concrete structures, it was observed that process analysis (ISO 14040) was predominant. Notwithstanding, in the literature review it was found one EIO-LCA[14], and three Hybrid LCA[1,10,12]. In relation to the scope of these studies, it was seen that the predominant life cycle considered were cradle-to-gate and cradle-to-grave. As far as the LCA calculations, a few studies included materials reutilization or recycling at the structures’ end-of-life. This can be explained by the scarcity of data and limited information on construction’s end-of-life.Based on the results obtained from the case study described in this paper, and following the indications established in the LCA guide to concrete structures, steel offered a greater impact when compared to concrete, as it was also indicated by the study performed by Guggemos and Horvath[12]. Moreover, in relation to the embodied energy and emissions produced, it was also concluded that the frame materials manufacturing caused greater impacts than the construction process (also indicated at the study by Guggemos and Horvath[12]). Finally, when comparing the different construction units assessed at the case study, it was observed that the largest environmental impacts corresponded to the concrete slab, as it was already concluded in the study performed by Lopez-Mesa et al[19]. These results lead to concluding that, independently of the LCA methodology used, assumptions taken or databases used consulted for assessing a concrete structure, there are some common results that can be accepted as standards.As it was already indicated, when performing a LCA study on a concrete structure there is a lack of data for operational/maintenance and end-of-life activities. Moreover, there are significant constraints in access to software and database available in the market, as they required license purchase for their use. In our case study, these constraints limited our scope but, when performing LCA on a real scenario, available project data and assumptions from the designer allow overcoming these limitations.Finally, as pointed out by ISO 14040, the objective of LCA studies is the assessment of environmental performance of products and services. Nevertheless, actions in the direction of integrating economic and social issues to LCA assessments are in course. For example, integration of LCA with LCCA (Life Cycle Cost Analysis) has already been achieved in different papers[12], but the most difficult challenge comes when trying to integrate social concerns. If LCA developments achieve to utterly integrateenvironmental, economic and social issues; then LCA practitioners will be counting with a tool for decision-making that meets the triple-bottom objectives of Sustainable Development.So according to everything previously exposed, it is stated that Life Cycle Assessment counts with wide applicability and great number of opportunities for the construction environment. Nevertheless, it requires of great efforts for eliminating issues relating to results variability and unreliability. Moreover, if the integration of sustainable development concerns is achieved, LCA practitioners will count on a trustful and reliable tool that will provide scientific basis and objectiveness to decisions taken all along a construction life cycle.Back to the applicability of LCA on concrete structures, despite its great potential, nowadays it is not a common tool neither in the international construction environment nor much less in the Spanish context. Therefore, it is required to improve and develop specific databases considering the whole life cycle. Moreover, if this objective is reached, practice of LCA on other types of construction projects will be feasible too.

ACKNOWLEDGEMENTS

- The research and case study performed would not have been possible without the technical support offered by Alberto Criado, from CYPE INGENIEROS, S.A. Also special thanks for revision performed by Dr. Victor Torres Verdín. This work was supported by the Spanish Ministry of Science and Innovation (Research Project BIA2011-23602).

References

| [1] | Bilec, M. et al. “Example of a hybrid Life Cycle Assessment of construction processes”. Journal of Infrastructure Systems (2006, vol. 12, no. 4, pp. 207-215) ISSN 1076-0342. |

| [2] | Bjórklund, A. “Survey of approaches to improve reliability in LCA” The International Journal of Life Cycle Assessment (2002, vol. 7, no. 2, pp. 64-72). ISSN 0948-3349. |

| [3] | Bouhaya, L.; Le Roy, R. and Feraukke-Fresnet, A.D. “Simplified environmental study on innovative bridge structure”. Environmental Science & Technology (Mar. 2009, vol. 43, no. 6, pp. 2066-2071). ISSN 0013936X. |

| [4] | Council and Parliament of the European Communities. “Directive 2002/91/EC of the European Parliament of the Council of 16 December 2002 on the energy performance of buildings”. Official Journal of the European Communities (4.1.2003, L 1/65). |

| [5] | Council and Parliament of the European Communities. “Directive 2008/9/EEC of 12 February 2008 laying down detailed rules for the refund of value added tax, provided for in Directive 2006/112/EC, to taxable person not established in the Member State of refund but established in another Member State”. Official Journal of the European Communities (L 44, 20.2.2008, pp. 23-28). |

| [6] | Council and Parliament of the European Communities. “Directive 89/106/EEC of 21 December 1998 on the approximation of laws, regulations and administrative provisions of the Member States relating to constructions products”. Official Journal of the European Communities (L 40, 11.2.1989, pp. 12-26). |

| [7] | European Commission “Proposal for a Regulation of the European Parliament and of the Council on a Community Eco label scheme (COM 2008-241)” (June 2008). |

| [8] | European Commission “Public procurement for a better environment (COM 2008-400)” (July 2008). |

| [9] | Ge, J. “Chinese energy/CO2 intensities based on 2002 input-output table and Life Cycle Assessment of residential building by accumulative method”. Lowland Technology International (2010, vol. 12, no. 1, pp. 14-22). ISSN 1344-9656. |

| [10] | Gerilla, G.P.; Teknomo, K. and Hokao, K. “An environmental assessment of wood and steel reinforced concrete housing construction”. Building and Environment (Jul. 2007, vol. 42, no. 7, pp. 2778-2784). ISSN 0360-1323. |

| [11] | Gjorv, O. E. and Sakai, K. “Concrete Technology for a Sustainable Development in the 21st Century”. Proceedings of an international workshop in Lofoten, Norway, June, 1998, ed. by (E & FN Spon, London and New York, 2000) 386. |

| [12] | Gu, Y.; Chang, Y and Liu, Y. “Integrated Life-Cycle Costs Analysis and Life-Cycle Assessment model for decision making of construction project”. Beijing ed., 21 October 2009 through 23 October 2009. ISBN 978-1-42443-670-5. |

| [13] | Guggemos, A.A. and Horvath, A. “Comparison of environmental effects of steel and concrete-framed buildings”. Journal of Infrastructure Systems (2005, vol. 11, no. 2, pp. 93-101). ISSN 1076-0342. |

| [14] | Horvath, A. and Hendrickson, C. “Steel versus steel- reinforced concrete bridges: environmental assessment”. Journal of Infrastructure Systems (Sep. 1998, vol. 4, no. 3, pp. 111-117). ISSN 1076-0342. |

| [15] | ISO 14040:2006. “Environmental management. Life-cycle assessment: Principles and framework”. Geneva, Switzerland: International Organization for Standardization Office; 2006. |

| [16] | Junnila, S.; Horvath, A. and Guggemos, A.A. “Life-cycle environmental effects of an office building”. Journal of Infrastructure Systems (2003, vol. 9, no. 4, pp. 157-166). ISSN 1076-0342. |

| [17] | Khasreen, M.M.; Banfill, P.F.G. and Menzies, G.F. “Life Cycle Assessment and the environmental impact of buildings: a review”. Sustainability (2009, vol. 1, no. 3, pp. 674-701). ISSN 2071-1050. |

| [18] | Klöpffer, W. “The critical review process according to ISO 14040-43: an analysis of the standards and experiences gained in their application”. International Journal of Life Cycle Assessment (2005, vol. 10, no. 2, pp. 98-102). ISSN 0948-3349. |

| [19] | López-Mesa, B., et al. “Comparison of environmental impacts of building structures with in situ cast floors and with precast concrete floors”. Building and Environment (2009, vol. 44, no. 4, pp. 699-712). ISSN 0360-1323. |

| [20] | Marinkovic, S., et al. “Comparative environmental assessment of natural and recycled aggregate concrete”. Waste Management (2010, vol. 30, no. 11, pp. 2255-2264). ISSN 0956053X. |

| [21] | Norris, G.A. “LCA into the future: going global, getting social”. Building Design and Construction (Nov. 2005, pp. 56-60). ISSN 0007-3407. |

| [22] | Oliver-Solá, J., et al. “The GWP-chart: an environmental tool for guiding urban planning processes. Application to concrete sidewalks”. Cities (2011, vol. 28, no. 3, pp. 245-250). ISSN 0264-2751. |

| [23] | Organization for Economic Co-operation and Development (OECD). “Environmentally Sustainable Buildings: Challenges and Policies”, OECD (Apr. 2003, Paris). ISBN 978926403386. |

| [24] | Owens, J.W. “Life-Cycle Assessment in relation to risk assessment: an evolving perspective”. Risk Analysis (1997, vol. 17, no. 3, pp. 359-365). ISSN 1539-6924. |

| [25] | Reza, B.; Sadiq, R. and Hewage, K. “Sustainability assessment of flooring systems in the city of Tehran: an AHP-based life cycle analysis”. Construction and Building Materials (May 2011, vol. 25, no. 4, pp. 2053-2066). ISSN 0950-0618. |

| [26] | Russell, A.; Ekvall, T. and Baumann, H. “Life Cycle Assessment: introduction and overview”. Journal of Cleaner Production (2005, vol. 13, no. 13-14, pp. 1207-1210). ISSN 0959-6526. |

| [27] | Scheuer, C.; Keoleian, G.A. and Reppe, P. “Life cycle energy and environmental performance of a new university building: modeling challenges and design implications”. Energy and Buildings (Nov. 2003, vol. 35, no. 10, pp. 1049-1064). ISSN 0378-7788. |

| [28] | Trusty, W. and Dery, M. “The U.S. LCI database project and its role in Life Cycle Assessment”. Building Design and Construction (Nov. 2005, pp. 26-29). ISSN 0007-3407. |

| [29] | United Nations Population Fund (UNFPA). “The State of World Population 2011” (New York, U.S.A., on 28 October 2011). ISBN 978-0-89714-990-7. |

| [30] | Van der Lugt, P. and Van den Dobblesteen, A.A.J.F. and Janssen, J.J.A. “An environmental, economic and practical assessment of bamboo as a building material for supporting structures”. Construction and Building Materials (Nov. 2006, vol. 20, no. 9, pp. 648-656). ISSN 0950-0618. |

| [31] | World Wide Fund for Nature (WWF). “Living Planet Report 2010. Biodiversity, bio-capacity and development” (Gland, Switzerland, on 2010). |

| [32] | Yepes, V.; Alcalá, J.; Perea, C. and González-Vidosa, F. “A Parametric Study of Optimum Earth Retaining Walls by Simulated Annealing”, Engineering Structures (March 2008, vol. 30, no. 3, pp. 821-830). ISSN 0141-0296. |

| [33] | Yepes, V.; Gonzalez-Vidosa, F.; Alcalá, J. and Villalba, P. “CO2-Optimization Design of Reinforced Concrete Retaining Walls Based on a VNS-Threshold Acceptance Strategy”, Journal of Computing in Civil Engineering (May/June 2012, vol. 25, no. 3, pp. 378-386). ISSN 0887-3801. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML