Jabbar-Ali Zakeri , Farshad Hashemi Rezvani

School of Railway Engineering, Iran University of Science & Technology, Tehran, Narmak, P. O. box 16846 – 13114, Iran

Correspondence to: Jabbar-Ali Zakeri , School of Railway Engineering, Iran University of Science & Technology, Tehran, Narmak, P. O. box 16846 – 13114, Iran.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Abstract

Sleeper, after rail, is the most important component of track superstructure in conventional track. Keeping track geometry, bearing loads acted from rail and transferring to the ballast is the main duty of sleeper. Their quality conditions have considerable influence on geometry quality. Moreover, track maintenance costs affected by this element due to their higher number. For this, in order to reduce operation & maintenance volume and, in the other hand, for more recognition of B70 sleepers used in Iranian Railways, some studies and field investigations carried out on concrete sleepers and its results expressed as categorization of concrete sleeper failures. This paper, evaluates effective factors and the reasons of their creation, while considering failures and conventional defects during sleeper service life (including production stage, transportation, construction and operation), and proposed some approaches for their reduction.

Keywords:

Concrete Sleepers Construction, Sleeper Defects, Sleeper Failure

1. Introduction

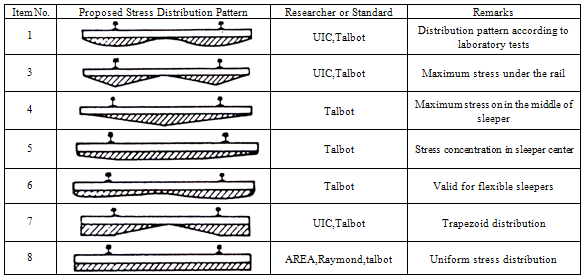

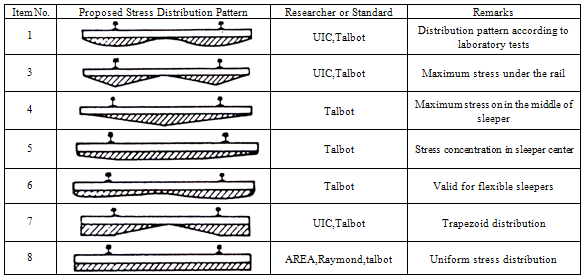

Railway sleepers are the main structural elements of railway track. As well as pressure distribution and load transfer to the underlying layers, railway sleepers are in duty to maintain track gauge, grantee lateral stability of the track and contribute in better geometrical conditions of the track[4,10]. Vertical, lateral and axial forces are applied to rail sleepers. These forces should be transferred to the underlying ballast layer within the admissible stress range with minimum disturbance of track quality and permanent deformation. In fact, no comprehensive approach is existed when dealing with sleeper pressure and load transfer mechanism of the track structure,[2, 12].Grassie[2] has studied the effect of unsupported sleepers in increasing imposed forces on adjacent sleepers and Kerr[5] has described the effects of support hardness changes with sleeper type change (wooden to concrete). Gustavson[8] has also studied static & dynamic behavior of the sleeper. In these studies increase of imposed forces on sleeper due to existing of defect in superstructure have been mostly dealt with. This paper took a glance look on concrete sleepers used in Iranian Railways and collected& categorized all defects, appeared in them, in different stages including production, coupling (track panel), transportation, installation and maintenance.In addition to categorization of concrete sleeper defects as well as deterioration, causes of the defects were also rooted and stated proportionate to their type. The first step to analyse a sleeper is to diagnose appropriate distribution of contact stress between sleeper and ballast and its changes to the time. In real conditions in railway superstructure it is very difficult to predict correct distribution of contact stress on a sleeper[6].There are various assumptions concerning contact stress distribution between sleeper and ballast[1] as well as bending moment diagrams of a sleeper which are show in figure (1).

2. Methodology of Research

B70 and B58 with Vossloh and Pandrol type fastenings are type of concrete sleepers used in Iranian Railways. B70 sleepers are used with rails UIC 60 and sleepers B58 with rails U33 (only with Vossloh clips) .To recognize main defects of concrete sleepers , life cycle defects of sleepers were primarily categorized as follow[3]:1. Deteriorations during manufacture and coupling (track panelling)2. Deterioration during transportation and installation3. Deteriorations during use.Data collection for deterioration during production and coupling (panelling) carried out by optical inspection from plants producing concrete sleepers in Karaj and Andimeshk and analysing quality control reports, asking opinion of production experts. In this survey 1000 unusable defected sleepers in producing plant studied and their defects detected.Recognizing deteriorations during transportation and installation were also carried out through defected sleepers study in track laying workshops and analysing QC reports.Deteriorations in operation time could be detected and categorized due to existing of monthly reports of supervising on track maintenance by supervising experts.5years report study and using engineers' opinions with maintenance experience and especially in different mountainous, plains and dry lands and etc. can give effective help to detect and diagnose these defects .In other sections detected deteriorations will be explained.

3. Detected Defects

3.1. Deteriorations during Production and Coupling (Panel)

Among causes of deteriorations during production and coupling, faults & defects related to primary material, concrete , processing, and unloading (evacuation) from the form, structural faults & defects like roll-plaque inclination, excess roll-plague cover, penetration of concrete sap, and/or other excessive material inside roll-plaque, penetration of water inside roll-plaque and its freezing in cold winter and/or existing of external material inside roll plaque can be mentioned. In spite of production process monitoring, unfortunately, happening of some of such a fault or defect may be assumed. The conventional deteriorations diagnosed in this stage are longitudinal crack, muscle crack, head zone crack, concrete decayed, concrete tear, and filling of roll plaque. Deterioration and its causes explained in table No.1

3.2. Defects during Transportation & Installation

Installation of sleeper or panel (coupling) carried out through different methods. Using Plattow crane and installing by panel laying method is conventional In Iranian Railways. In this method proper distribution of ballast first layer is one of the factors prevent appearing of concrete sleepers defects.Moreover, from other causes of defects ,plug cap fall down, improper depot, inaccuracy in loading & unloading the panel as well as improper pack, un-layering first ballast layer panel laying with ballast accumulation in sleeper center, sleeper broken due to incorrect primary loading, unloading and improper track laying can be mentioned. Defects &deteriorations observed in this stage include: chipped sleepers, bending cracks, cutting cracks, sleeper instable in fastening points. Introduction of these defects illustrated in table (2) with their causes. | Figure 1. Stress Distribution Patterns |

| Figure 2. Longitudinal crack in concrete sleeper |

| Table 1. Deteriorations during production and coupling |

| | Longitudinal crack | Introduction: This crack happened along sleeper longitudinal axle and in a distance between roll-plaques. (fig(2))Causes: un-greasing (un-lubrication)of sleeper muscle part, incorrect performance of screw driving machine, and incorrect vibration of the concrete inside the form, human faults such as incorrect positioning of roll-plaque ,incorrect mixing of concrete constituent material &components, the way of taking concrete inside the form ,fault in roll-plaque diameter size, unsuitable tamping ,entering of concrete sap ,rate of moment exerted on bolts during coupling, asymmetric displacement of coupling | | Muscle crack | Introduction: Emerge in concrete sleeper muscles area toward the main &horizontal axis. This crack appears at the time of exertion of prefabricate force and also when offloading sleeper from its form.Causes: The manner of exerting prefabricate force, the manner of bolts unscrew, no valvalin used inside forms. | | Crack in head zone | Introduction: This kind of track is diagonal and begins from prefabricate bolt holes point and terminate to (rail) seat.Causes: lack of concrete cover behind plaques, asymmetric infrastructure &tamping, improper processing, inaccuracy in exerting prefabricate force, inaccuracy in unloading (evacuate) sleeper, manner of bolts unscrew, wear of prefabricate rods. | | Decayed concrete sleeper | Introduction: These kinds of defect happen around concrete sleeper and are not detected before evacuation of sleeper from its steel mould.Causes: Improper concrete mixing plan, throwing concrete inside the form ,manner of vibrating concrete ,non-observance of steaming time, non-observance of steaming temperature, concrete solidity, inaccuracy in form typical oil rate. | | Concrete sleeper tear | Introduction: due to damaging the concrete sleeper prefabricate system, torn sleepersAre out of use completely and they are not repairable yet. | | Filled plug | Introduction: Due to plug breakage or cracking, usually this component filled by concrete sap or other material and defects emerge as a result of this phenomenon.Causes: nonstandard plug material ,plug crack, plug break, open-bottom plug(if plug not to be through),uncovering holes of plug, entering external material in panel site, concrete sleeper depot in free air and of snow & rain enter inside plug hole, manner of rail fastening unscrew for welding. |

|

|

| Table 2. Defects during transportation & installation |

| | Chipped sleepers | Introduction: as from structure point of view it does not damage sleeper structure, chipped sleeper which (their chippness) has not exceed permissible limit, being accepted.Causes: Un-lubricated form bottom with special oil, inaccuracy in processing time and temperature, vibration rate, manner of unloading concrete sleepers from forms, transporting of sleepers with lifters to depot site, lifting of sleepers with catenaries cranes. | | Bending cracks | Introduction: bending cracks in concrete sleepers appeared in sleeper center transversal &diagonal.Causes: Strikes touched to unload sleeper from the form ,concrete sleeper depot excessive altogether, sleeper transportation by lifters &cranes ,asymmetric panel transportation in site, ballast pollution and reduced track elasticity ,un-permitted load passing and increased loading cycle, deficiency in drainage system and track solidity increase, improper infrastructure and insufficient compression ,asymmetric tamping ,jet- mud phenomena, inlaying ballast first layer. | | Cutting cracks | Introduction: cutting cracks usually appear in rail seat area and in a distance between plug holes transversally along rail longitudinal axis.Causes:, concrete sleeper depot excessive altogether, ballast pollution and reduced track elasticity ,un-permitted load passing and increased loading cycle as well as fatigue phenomena, deficiency in drainage system and track solidity increase, improper infrastructure and insufficient compression ,asymmetric tamping ,reduced ballast layer thickness . | | Sleeper instability in fastening point | Introduction: This kind of defect appears due to improper screwing &unscrewing fastenings for welding, and result in un-monotonous stress distribution and due to load passing and weak sleeper conjunction with ballast under, concrete sleeper damaged.Causes: Inaccuracy in fastening screwing in panel site, plug diameter rate ,inaccuracy in correct fastening of rail clips after rail welding , bolts diameter rate ,external material falling down inside plugs, broken or cracked plugs ,manner of unloading panels, wheel defects and overwhelming strike effect, axle load value, climate(weather) changes and expansion &contraction cycles. |

|

|

| Table 3. Defects during operation and maintenance |

| | Bending cracks | Introduction: bending cracks in concrete sleepers happen in centre of sleeper transversal and diagonal.Causes: shocks or strikes imposed on to take out sleeper from the form, excessive concrete sleepers depot (store) over each other, sleeper carried by lifter and crane, asymmetric transportation of panels in site, ballast pollution and reduced track elasticity, no permitted load cross over and loading cycle increase, deficiency in drainage system and track solidity increase ,improper infrastructure and insufficient compression | | Asymmetric tamping, jet-mud phenomena, un-layering first ballast layer | | Sleeper breakage dueto derailments | Introduction: concrete sleepers break due to derailment considered as un-returnable defects and damages of concrete sleepers due to which these sleepers are not able to do their task in track any more.Causes: manpower fault, existing impermissible defects in track or rolling stocks and/or for ant reason fig 3. | | Cutting cracks | Introduction: cutting cracks usually appear in rail seat area and in a distance between plug holes transversally along rail longitudinal axis.Causes:, concrete sleeper depot excessive altogether, ballast pollution and reduced track elasticity ,un-permitted load passing and increased loading cycle as well as fatigue phenomena, deficiency in drainage system and track solidity increase, improper infrastructure and insufficient compression ,asymmetric tamping ,reduced ballast layer thickness |

|

|

| Figure 3. Sleeper breakage due to derailment |

3.3. Deterioration or Defects during Operation

State of track maintenance has significant role in deterioration of track and its components. For this, track maintenance management, determining inspection cycles, cyclic inspections, defect detection, on time repairmen' has significant effect in track life increase as well as track life cycle costs reduction. Climate conditions including dry lands with flowing sand problems, is, of course effective in superstructure components destruction and deterioration.Pick or bade of regulator hit the sleeper and damage it, improper screwing &unscrewing the rail clips (fastenings) when welding, wastes fall inside sleeper plug and screwing the bolt without its cleaning, inaccuracy during ballasting and ballast deficiency during maintenance , improper tamping ,derailments and their effects of sleeper structure, sand keeping climate,(dry land and sand effects on track components specially on sleepers) , freezing during operation(melt & freeze cycle) ,sleeper twisting around their longitudinal axe , improper sleeper spacing and nonalignment of sleepers in track can be mentioned among the causes of such defects.The main defects of this stage are: bending cracks, sleeper break due to derailment, cutting cracks, and sleeper instability in fastening area and sleeper damage in dry land.[13]These defects with their causes introduced in table (3).

4. Sleeper Defects Reduction Methods

According to the studies done in this research and identifying the reasons of the defects, the effective methods for reducing these effects in manufacturing, installation and operation stage are also studied. These methods are recommended for Iranian Railways and, it is expected that by implementation of an appropriate quality control system and controlling the items described in this chapter, there would be a significant decrease in life cycle costs, specifically concrete sleepers.Statistical analysis of sleeper defects in Iranian Railway shows that the major quantities of defects occur in operation stage. Some of these defects can be prevented by works in manufacturing stage. After manufacturing stage, the most defects are manufacturing defects.Among the studied statistical society, 1.2 % of manufactured sleepers had defects, which 0.3 % of them are used in secondary lines and the remaining (0.9 %) are discarded. In the case of operation stage defects, it is necessary to provide the statistical information of existing sleepers in Iranian Railways.Three kind of sleepers, concrete, wooden and steel sleepers are used in Iranian Railway. The information about these sleepers is summarized in the Table 4.Statistical analysis of concrete sleeper defects shows that near 0.5 % of concrete sleepers are replaced by track maintenance contractor companies (private companies) because of the defects each year.Of course, it includes sleeper breakages due to derailments.| Table 4. Types of sleepers in Iranian railways |

| | Parameter | Concrete Sleeper | Wooden Sleeper | Steel sleeper | D-Block Sleeper | Total | | Length (km) | 4829 | 1903 | 1406 | 128 | 8266 | | Percentage | 58.4 | 23 | 17 | 1.6 | 100 |

|

|

Because of the concrete sleeper vulnerability to derailment, near 0.15 % of concrete sleepers are replaced each year, which comparing to 0.35 % maintenance is a significant amount.In order to decrease the defect through manufacturing and operation stage, controlling steps are summarized in Table 5. A planning anticipation to decrease the concrete sleeper defects from 0.9-0.6 % in a 2 year period has been done.According to establishment of track laying instructions, and identification of sleeper defects in this study, it is expected to reduce the shipping and installation defects, in the 4th five year plan of Iran economical-social development.| Table 5. Control steps in manufacturing and operation stage |

| | Control Item | Control Steps | | Bar Control | 1 Bar length , smoothness2 Corrosion amount3 Bar depot location | | Mould condition | 1 Mould appearance2 Inside mould appearance3 Inside mould defects | | Mould lubrication | 1 Mould lubrication quality2 oil concentration in mould bottom3 Greasing | | Fastening (clip) andScrew bolt control | Mould top conditionScrew bolt condition on the clipScrew bolt depot condition | | Plate and Clinch condition | Plate appearanceSymmetry of dimensions and clinchClinch crack | | Bolt condition | Appearance and diameter of tensional boltsAppearance and diameter of stationary boltsBolts length | | Bar condition | Amount of tensionBar arrangementConcrete cover over plate | | Condition of materials in batching mix | Time of materials mixCement amount of the batchProportion of stone materials mixConcrete slumpConcrete distribution in mould | | Condition of materials behind batching | Waste in materialsDust in materialsWarming the materials in cold weather | | Vibration performance | Quality of concrete distribution in mouldBottom vibration period (2min)Trowel vibration period (30s) | | Product Tracking | 1 Production date on the sleeper | | Bolt opening condition | 1. Order of bolt opening from top to bottom |

|

|

5. Conclusions

According to the importance of sleeper and its role in railway superstructure, identification of the sleeper defects is the first step in increasing the efficiency of track and decreasing the maintenance costs. After identification of defects, surveying in order to find the reasons of that defect is the second major step. In this study, according to the kind of sleepers used in Iranian Railway (Concrete B70 sleeper), the major defects of the life cycle of these sleepers are categorized in three groups :1. Defects during manufacture.2. Defects during shipping and installation.3. Defects during operation or maintenance.Statistical analysis shows that most defects occur in operation stage. After operation stage, most defects occur during manufacture and maintenance. Among the studied statistical society, 1.2 % of manufactured sleepers had defects, which 0.3 % of them are used in secondary lines and the remaining 0.9 % are discarded. In case of operation defects 0.35 % sleepers are replaced in current maintenance each year. According to identification of concrete sleeper defects reason and using appropriate solutions to control them, it is expected to reduce the manufacturing defects, from 0.9 to 0.6 %.

References

| [1] | AREMA, (2006), Manual Recommendations, Special committee on concrete ties, AREAM Manual Vol. 2 |

| [2] | Grassie S L, Cox S. J. (1985) "The dynamic Response of Railway Track with Unsupported sleepers " Proceedings of Institution of Mechanical Engineers (part D), 199(2): 123~135 |

| [3] | Hashemi R. (2006) “Effective factors on failures of concrete sleepers" BS.c. Thesis, Iran University of Science & Technology |

| [4] | Kerr, A. D., (2003), Fundamentals of Railway Track Engineering, Simmons-Boardman Books, Inc |

| [5] | Kerr, A. D., (1976), "On the stress analysis of rail and ties," AREA proceeding, vol. 78 |

| [6] | Kumaran G., Devdas M. and Krishnan N. (2002) "Evaluation of dynamic load on rail track sleepers based on vehicles track modeling and analysis", International Journal of Structural Stability and Dynamics, Vol. 2, No. 3 |

| [7] | ORE, (1968), Stresses in concrete sleepers; Stress in the rails, Report D71/RP9/E, Utrecht |

| [8] | RIKARD GUSTAVSON, (2002), "Static and Dynamic Finite Element Analyses of Concrete Sleepers", MS. C. Thesis, Chalmers University of Technology |

| [9] | Zakeri, J. A., Xia H., Fan J., (2000), Effect of Unsupported sleeper on Dynamic Responses of Railway Track, Journal of Northern Jiaotong University Vol. 24 No. 1 |

| [10] | Zakeri J. A., Xia H. and Fan J. J. (2000) “Dynamic Behavior of High-Speed Railway Tracks”, Proceedings of the Second International Conference on Traffic and Transportation Studies, Northern Jiaotong University |

| [11] | Zakeri J. A. (2007) "Effective Factors on Failures of Concrete Sleepers", CD- Proceedings of 8th International conference on Railway Engineering, London |

| [12] | Zakeri J. A and Sadeghi J. (2007) “Field Investigation on Load Distribution and Deflections of Railway Track Sleepers" Journal of Mechanical Science and Technology, V 21 No. 12, pp. 1948-1956 |

| [13] | Zakeri J. A., Abbasi R. (2011) "Field investigation on distribution of contact pressure between sleeper and saturated ballast with flowing sand" 11th International conference on Railway Engineering, London, Uk |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML