-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Biological Engineering

p-ISSN: 2163-1875 e-ISSN: 2163-1883

2015; 5(1): 11-15

doi:10.5923/j.ijbe.20150501.02

BioClean and Liquid Biofertilizers to Big Cleaning Day 2014

Sittisak Uparivong

Department of Biotechnology, Faculty of Technology, Khon Kaen University, Khon Kaen, Thailand

Correspondence to: Sittisak Uparivong, Department of Biotechnology, Faculty of Technology, Khon Kaen University, Khon Kaen, Thailand.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

BioClean and Liquid biofertilizers are green fermented liquid bioproducts. BioClean was produced by fermenting various flowers (such as lotus, marigold, orchid, etc.) while liquid biofertilizers were produced by using available biomaterials (such as vegetables, fruits, some herbaceous, etc.). These biomaterials had been fermented by mixing with molasses and adding 18 zymogenic synthetic microorganisms (18 ZSMs). The products of bioclean and liquid biofertilizers (v.2014) were aimed to produce and utilize for environmental and agricultural sectors to the two factories of Khon Kaen Fishing Net (Head office and Boworn branch) at Khon Kaen Province, Thailand. The properties of products were analysed and investigated by the steps of crops field test and water quality treatment for fishes living before servicing to target factories. The results of satisfactory rating of project service to the two target factories of Khon Kaen Fishing Net (Head office and Boworn branch) for encouraging along the way to “Big cleaning day and Green area 2014” were obtained 80.7% and 78.7% during services respectively, evaluated by the groups of general officers of two factories.

Keywords: BioClean, Liquid biofertilizers, 18 zymogenic synthetic microorganisms, Green area, Big cleaning day

Cite this paper: Sittisak Uparivong, BioClean and Liquid Biofertilizers to Big Cleaning Day 2014, International Journal of Biological Engineering, Vol. 5 No. 1, 2015, pp. 11-15. doi: 10.5923/j.ijbe.20150501.02.

Article Outline

1. Introduction

- BioClean and Liquid Biofertilizers are friendly green environmental liquid bioproducts to keep the faith an important role to along the way to environmental and agricultural sectors. BioClean was produced by using variously odoriferous flowers in order to service for environmental treatment. Liquid Biofertilizers were produced by using available materials in order to service for agricultural biofertilizers. These generated products of bioclean and liquid biofertilizers (version 2014) were aimed to service for the two factories of “Khon Kaen Fishing Net (Head office and Boworn branch)” on the event of “Khon Kaen Fishing Net Big Cleaning Day 2014” at Khon Kaen Province, Thailand. Thus, liquid biofertilizers products could applied for agricultural and environmental sections as similar as bioclean products. Furthermore, liquid biofertilizers were especially encouraged to green areas and small plant trees along all the main roads. The board of 18 microorganism species of zymogenic synthetic microorganisms [18 ZSMs] had been selected by Prof. Dr. Chaitat Pairintra, former professor at Khon Kaen University, and invented to our previously researched project of “Improvement of the theparuge’s liquid biofertilizer product” since 2002, which the group of 18 ZSMs were consisted of 9 bacteria, 6 fungi and 3 yeast species [1, 2].

2. Materials and Methods

2.1. Materials

- The diversity of flowers species such as lotus, rose, marigold, orchid, chrysanthemum, etc. were collected to produce bioclean (v.2014) by purchased from a flowery shop within Khon Kaen University and received donation from several Buddhist temples at the regions of Khon Kaen Province. Meanwhile, liquid biofertilizers were produced by using the previously researched stocks of bioextracts of original microorganism seeding as bioextract Biotech-1 and bioextract Biotech-2. These original bioextracts had been produced by using available biomaterials such as vegetables, fruits, some herbaceous crops, etc. since 2003-2004. Molasses as substrate were purchased from a local sugar cane factory at Khon Kaen Province.

2.2. Equipments

- The bioreactors of biofermenters and/or liquid biofermenters had been supported by using previous research bioreactors as a). A 300-L Liquid Biofermenter (Model KKU-1) equipped with a motor 1 hp, b). A 500-L Liquid Biofermenter (Model BT-1) equipped with a motor 1 hp and/or a compressor air supply, c-d). A pair of 500-L Liquid Biofermenter (Model BT-2) equipped with a stirrer motor 1 hp and/or an air pump supply and e). A 500-L Liquid Biofermenter (Model BT-3) equipped with a stirrer motor 1 hp and/or an air pump supply, as shown in Fig. 1(a, b, c-d, e) [2-15].

| Figure 1. Bioreactors Model KKU-1, BT-1, BT-2 and BT-3 |

2.3. Methods

- The methods to produce bioclean are the three steps of classified processes as similar as to produce liquid biofertilizers except only differential raw materials use, as the following [3-15].The 1st Step of Fermentation, available raw materials were cleaned and cut into small pieces for fermenting by mixing with molasses and adding 18 zymogenic synthetic microorganisms (18 ZSMs) as the ratio as “Materials : Molasses : 18 ZSMs of original microorganisms seeding of bioextract of liquid biofertilizer Biotech-1 = 3:1:1 or 3:1:2 [w/w/w]” to produce the bioextracts of microorganisms seeding (BMS) by using biofermenters during the retention time more than 2 weeks (≥14 days).The 2nd Step of Inoculation, the bioextracts of microorganisms seeding (BMS) from the first step were inoculated as the ratio as “Molasses : Clean Water : BMS = 1:40:1 or 1:40:2 [v/v/v]” to produce the liquid bioproducts of microorganisms (LPM) by using liquid biofermenters during the retention time of 1-2 week (≥7-14 days).The 3rd Step of Filtration, the liquid bioproducts of microorganisms (LPM) from the second step were filtrated by using filters such as clothing layer filters, etc. to obtain the final products as so called “BioClean” or “Liquid Biofertilizers” depend on the types of raw materials used.

2.4. Products Utilization

- The products utilization of bioclean and liquid biofertilizers (BC&LB) were mainly utilized for environmental and agricultural sections.For Agricultural Utilization, the products of liquid biofertilizers Biotech-1, 2 were utilized by using the concentration ratio of 1:2000 (0.05%) by spraying or pouring to growth crops every 5-7 days, and using the concentration ratio of 1:500 (0.2%) to plant trees and green areas for living places.For Environmental Utilization, the product of bioclean was utilized by using the dilution ratio of 0.05% (1:2000) for floor cleaning/ wastewater treatment/ water quality treatment/ flood treatment/ etc., and using the concentration ratio of 70-100% for reducing odour treatment to bathroom/ lavatory/ toilet/ wc./ sewerage/ etc.

2.5. Products Quality Test

- The quality tests of products were investigated by using the procedures of agricultural and environmental tests before servicing to target places and/or distributing to general humankinds.For Agricultural Tests, the products of bioclean and liquid biofertilizers Biotech-1, 2 were tested by cultivating for various crops to determine the growth rate of crops by pots test and/or fields test such as water convolvulus, flowers, etc.For Environmental and Healthy Tests, the products of bioclean and liquid biofertilizers Biotech-1, 2 were tested by reducing odour treatment for sanitary systems such as bathroom/ toilet/ sewerage/ etc., and especially water quality treatment for long live the fishes living.

2.6. Analysis Methods

- The analysis methods were determined microorganism’s populations and the properties products of bioclean and liquid biofertilizers Biotech-1, 2 by using standard methods as similar as previous researches. [2-15]For Microbial Populations, The samples of products were investigated by a method of standard plate count at “A Laboratory of Department of Microbiology, Faculty of Science, Khon Kaen University”.For Properties Products, The samples of products were investigated by standard methods as parameters; pH, EC [Electrical Conductivity, ds/m], OM [Organic Matter, %], Total N, P, K, Na, Ca, Mg, S, and Cl [% or ppm] at “A Laboratory of Department of Land Resource and Environment, Faculty of Agriculture, Khon Kaen University”.

2.7. Satisfactory Services Rating

- The satisfactory services rating of project services to two serviced factories were evaluated by surveying with using the questionnaire’s satisfaction of the applied satisfactory form of “Academic Service Centre of Khon Kaen University” by the three classified groups, as the following;The 1st group of general officers of factories at two serviced factories.The 2nd group of participated officers of factories for services projects.The 3rd group of students services project to two serviced factories.

3. Results and Discussion

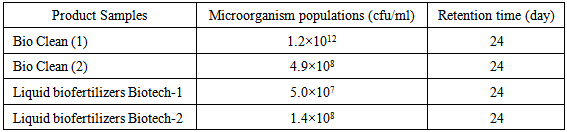

3.1. Properties Products

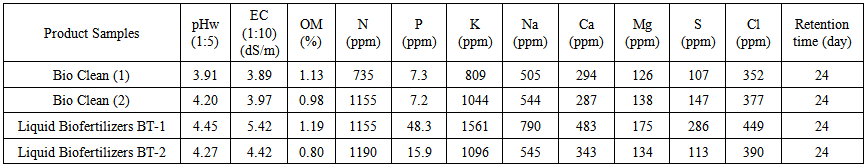

- The 5th generation products of bioclean and liquid biofertilizer Biotech-1, 2 (v.2014) were produced by containing in bottom and tank containers such as 780 cc., 1, 10, 20 liters, etc., as shown in Fig. 2(a, b). The results of properties products of bioclean and liquid biofertilizers (v.2014) were obtained that microorganism’s populations were 4.9x108-1.2x1012 cfu/ml for bioclean, 5.0x107 cfu/ml for biofertilizer liquid Biotech-1 and 1.4x108 cfu/ml for biofertilizer liquid Biotech-2 at the retention time of 24 days as shown in Table 1. The optimum microbial populations of products were obtained as nearly as limited standard products [107-108 cfu/ml]. The properties products were pH=3.91; EC=3.89 ds/m; OM=1.13%; Total N=735 ppm; P=7.3 ppm; K=809 ppm; Na=505 ppm; Ca=294 ppm; Mg=126 ppm; S=107 ppm; Cl=352 ppm for a sample product of bioclean (1) at the retention time of 24 days, and the other results of sample products of bioclean (2), liquid biofertilizers Biotech-1 and liquid biofertilizers Biotech-2 were shown in Table 2. These results were obtained as nearly similar as the results of properties products of previous researches [2-15].

|

| Table 2. The properties of bioclean and liquid biofertilizers (v.2014) |

3.2. Quality Products Tests

- The quality products tests of bioclean and liquid biofertilizers Biotech-1, 2 (v.2014) were proved by the procedures of qualitative tests for being standard products before servicing to target factories and distributing to general humankinds. [2-15]For Agricultural Quality Tests, the products of bioclean and liquid biofertilizers Biotech-1, 2 (v.2014) were satisfied by the growth rate of water convolvulus (Commercial sp.) (purchased at Khon Kaen province) in the 5rd year repeated soils of pots test as shown in Fig. 2(c). The results of total weight of water convolvulus in 9 pots/set were 42-70 g/pot for liquid biofertilizers Biotech-1 and 37-63 g/pot for bioclean, compared with 23-56 g/pot and 32-73 g/pot for two control sets at the ratio of 1:2000, 1:500, 1:50. The results of the average per 5 trees of weight of water convolvulus were 7-14 g/corps for liquid biofertilizers Biotech-1 and 7-16 g/crops for bioclean, compared with 8-16 g/crops and 7-19 g/crops for two control sets (due to add new soil 2-3 pots in previous a few year ago), respectively during 45 days. (Table not shown)For Environmental and Healthy Quality Tests, the products of bioclean and liquid biofertilizers Biotech-1, 2 (v.2014) were satisfied by testing for sanitary systems at home project such as reducing odour treatment in bathroom, toilet, sewerage, and including water quality treatment for long live the fishes living such as angelfish and goldfish fish living, as shown in Fig. 2(d).

| Figure 2. The quality tests of BioClean and Liquid biofertilizer Biotech-1 (v.2014) |

3.3. Satisfactory Services Rating Evaluations

- The project services (2014) were encouraged to two serviceable factories on the event of “Khon Kaen Fishing Net Big Cleaning Day 2014” as shown in Fig.3 and Fig.4. The results of satisfactory services rating of the two target factories of “Khon Kaen Fishing Net (Head office and Boworn branch)” were average score value 3.97 (79.31%) and 3.81 (76.13%) responded by the 1st group of 118 and 93 general officers of two factories, average score value 4.06 (81.20%) and 4.70 (94.0%) by the 2nd group of 20 and 20 participated officers of two factories, and average score value 4.35 (86.92%) and 4.61 (92.20%) by the 3st group of 13 and 10 students service project at two factories, respectively by surveying with using the total factors of questionnaires of satisfaction. By the way, the satisfactory services rating were average score value 4.025 (80.51%) and 3.76 (75.27%) before servicing, 4.033 (80.68%) and 3.94 (78.71%) during servicing, 4.127 (82.54%) and 4.10 (81.94%) after servicing, respectively, evaluated by the 1rd group of general officers of two factories (Khon Kaen Fishing Net) of Head office and Boworn branch, respectively.

| Figure 3. Project services to Khon Kaen Fishing Net (Head Office) in 2014 |

| Figure 4. Project services to Khon Kaen Fishing Net (Boworn Branch) in 2014 |

3.4. Project Services to Green Areas

- The project services to green area were satisfied by collaborating with the Sanitary and Environmental Division of Khon Kaen University, using a water truck for spraying liquid biofertilizer Biotech-1 at the ratio of 1:500 (0.2%) for encouraging plant trees such as “Kallapaphruek Trees” along all the main roads such as “Kaenkallapaphruek Road”, “Mordindaeng Road”, etc., at the regions of Khon Kaen University, and to evergreen areas for living places. [8-15]

4. Conclusions

- 1) Products of BioClean (v.2014) were satisfied to encourage by servicing project to the target factories of Khon Kaen Fishing Net (Head office and Boworn branch) on the event of “Khon Kaen Fishing Net Big Cleaning Day 2014” to reduce odour treatment for sanitary systems, friendly green environmental and healthy living places.2) Products of Liquid Biofertilizers Biotech-1, 2 (v.2014) were satisfied to encourage for being green project services to the two factories of Khon Kaen Fishing Net (Head office and Boworn branch), including were satisfied to encourage for small plant trees along all the way and green areas in order to ambient air and natural green environment for living places at the campus regions of Khon Kaen University, and related to climate change.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML