-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Biological Engineering

p-ISSN: 2163-1875 e-ISSN: 2163-1883

2012; 2(3): 23-26

doi: 10.5923/j.ijbe.20120203.01

Possibility on Agriculture Mechanization for Tropical Yam (Dioscorea Hispida)

Hudzari R. M. 1, Ssomad M. A. H. A. 1, Syazili R. 1, Musa W. M. W. 1, Asimi M. N. N. 2

1Department of Agriculture and Biotechnology Universiti Sultan Zainal Abidin (UniSZA), 20400 Kuala Terengganu, Terengganu, Malaysia

2Department of Innovative Design and Technology, Universiti Sultan Zainal Abidin (UniSZA), 20400 KualaTerengganu, Terengganu, Malaysia

Correspondence to: Hudzari R. M. , Department of Agriculture and Biotechnology Universiti Sultan Zainal Abidin (UniSZA), 20400 Kuala Terengganu, Terengganu, Malaysia.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Ubi Gadong (Dioscorea hispida) is a toxic plant which contains toxic poison. It can only be consumed after the poison of dioscorin is removed. It is normally found in wildlife forest and planted in clay soil condition in Asia region. The advancement of technology should introduce in most important area; agriculture, as for benefit of mankind. The solid modeling software may use for design, model and simulate the workability of the designed equipment in CAD environment system. The simulation analysis will make the designer choose the best decision for fabrication stage of agriculture mechanization tool. The farm mechanization for ubi gadong is help to produce the good quality and output in this new exploration of wildlife food for commercialization.

Keywords: Agriculture, Mechanization, Discorea Hispida, Innovative Tool, Harvester, Parametric Software

Article Outline

1. Introduction

- Dioscoreae hispida is one of the Discorea spp (Yam) species and characterize as a climbing plants with glaborous leaves and twining stems, which helix readily around take. Asiatic Bitter Yam (Dioscoreae hispida) is one of the most economically important yam species, which serves as a fasten food for a millions of people in tropical and subtropical countries (Hahn, 1995; Udensi. 2008) and was classified as a wild creeping and climbing plant which can grow up to 20 meters in height. D. Hispida is commonly found in secondary forest and grow under shaded areas or near streams which is known by the local or vernacular names such as Ubi Gadong (Nashriyah et al., 2010). Figure 1 show the Tuber of ubi gadung.

2. Mechanization Notational

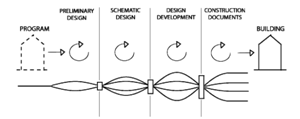

- Mechanization is a concept and cannot be measured drectly. Appropriate indicators must be selected to determine levels of mechanization like variable that allow describing and monitoring the processes (Wan Ishak, 2010). States and tendencies of system at the farm, regional, national and worldwide level (Morteza et al., 2010). As stated in righteous book, Al-Quran in sura Yassin verse 82, Allah SWT when intends something, He just ask without ant help from others. It is different, we as a mankind. The flow for construction of the design, it is need for a design, model before start on fabrication stage. (Sarah, 2008) stated that before construct final product including the preliminary design, schematic design and son on. Figure 2 show the flow of construction design. It shown that the numbers of document was significantly growth and was reassessed on at every stage of process.

| Figure 1. The tuber and roots of ubi gadong |

| Figure 2. Flow chart process for designing and fabrication level |

3. Product Simulation

- Simulation program is very useful in designing stage before final fabrication of product (Sapuan et al., 2007 and Razali et al., 2008). For the concept of mechanization in agriculture of ubi gadung, the solid modeling software like CATIA or SOLIDWORKS can be use in the designing and simulation stage. This parametric software was available at Faculty of Innovative Design and Technology, UniSZA, Malaysia. The parametric software is necessary to simulate the practicality and workability of the conceptual design (Erlinda et al., 2010). The concurrent engineering environment is used which a conceptual arena is created by any or all technologies enabling collaborative efforts in the building process. The reverse engineering concept will applied which is at first is extraction of the design layout of the machine, then schematic and wireframe of the model, modification in computer aided design (CAD) environment, simulation and last is the complete drawing for fabrication purpose (Darius and Azmi, 2003).

4. Conceptual Design for Innovative Hand Tool Harvester

- In Malaysia, normally the farmer will collect the ubi gadong by using chisel or ’cangkul’. The farmer needs to plow on around of the stem with the size of fruit. Sometime the farmer needs to cut the root of the fruit and also from outside tree the farmer will used the cangkul to push it up and sometimes need repetitive work. It is conceptually designed to replace the old method of manual harvesting of ubi gadung using chisel or namely cangkul. It consists of a designed bar with a foot press ladder. Figure 3 show the conceptual design on three dimensional orientations using surface modeling software. The circular rod with penetrate the bar and will stick at the bottom. The penetrate bar is designed which will easily penetrate the soil while at the back surface is designed flat which will not damage the “ubi gadong” during manual harvesting process. The handheld rod is designed bend 45 degree to enable the user easily pull up the tuber without or less in moving the body. Figure 4 show the designed innovative tool during harvesting ubi gadong. The user needs to press down by body weight for penetration process and pull it up the tuber. The user needs to cut the tuber roots using sharp edge or knife before harvest the ubi gadoung fruit. The field site was at Kg. Kudat, Agil Kuala Terengganu, and Malaysia. Similar designed was fabricated by Mohd Solah et al., (2009); the loose fruit picker with bend hand holder make reduced the back pain of the worker during collection oil palm fruits. The worm and worm gear also can apply which then later; the user will just need to rotate the drive gear for penetrating the rod bar deeply into soil while other side gear will grab the ubi gadong tuber of.

| Figure 3. Conceptual design for manual harvester |

| Figure 4. The designed innovative tool for harvesting ubi gadong |

| Figure 5. Innovative hand tool designed for cassava |

5. Conceptual Design of Semi Automated Machine

- The mechanism produced in handheld harvester design will later be use for integration in development of semi-automated machine. This machine will operate on both side of planting and harvesting stage. The kubota tractor available at Universiti Sultan Zainal Abidin UniSZA will be used for this. The implement will buy from outside country which already success in harvesting etc. potato harvesting machine. The modification on the front side of the machine is required for adoption to the physiological of the ubi gadong. Figure 6 shows the image for modification purpose start at intake web part (adaption from Pringle et al., (2009), Potatoes Postharvest, CABI Publishing).

| Figure 6. Modification purpose will start at intake web part |

| Figure 7. Semi automated machine also was developed for harvesting the ubi kayu |

6. Conceptual Design for the Laboratory Equipment of Ubi Gadung

- The determination on the fine chemical of ubi gadong was need to peel it skin surface (Mohd et al., 2011b). Using manual peel by small knife, the dirt from debris may stick on the fruit and affect the experiment result (Sharifah, 2011). The mechanization on peeling process of ubi gadong skin was challenging due it surface was not at symmetrical manner. One good example on the concept of peeling machine is potato (Potato peel machine, 2011). Figure 8 show the peel machine consists of rotating bar which hold the fruit at fix position. The knife attached at end of arm rod which retained the force spring. The force was designed enough on which only the force to penetrate the knife for peeling the potato surface.

| Figure 8. Designed peeling machine for potato |

7. Conclusions

- Mechanized on agriculture research for ubi gadong can be divided into three parts. The innovative hand tool harvester is important for replacement the traditional method using chisel during harvesting the tubers on the jungle. The equipment for assisting for chemical experiment on laboratory for ubi gadung research like peel machine also important to develop since well known peeling type machine was available in the market. The semi automated machine for ubi gadong also conceptually reviewed in this paper. The operation for planting, weeding and harvesting should cover for full operation of ubi gadong. The solid modeling software will used to design, model and simulate the workability of the designed equipment in CAD environment system.

ACKNOWLEDGMENTS

- Thanks a lot for En Mohd Rokhli and En. Amir from UniSZA for assisting and information given.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML