| [1] | Mwaniki, F., Muluvi, G., Gichuki, C., Oeba, V.O. and Kanyi, B. (2009). Development of non-mist vegetative propagation protocol for Eucalyptus Hybrid Clones. Journal of East African Natural Resources Management 3(1): 283–295. |

| [2] | Sprague, J. R., Talbert, J.T., Jett, J.B. and Bryant, R.L. (1983). Utility of the Pilodyn in selection for mature wood specific gravity in loblolly pine. Forest Science, 29, 696–701. |

| [3] | Zobel, B.J., and Van Buijtenen, J.P. (1989). Wood variation: Its causes and control. Springer–Verlag, New York. |

| [4] | FPL. (2010). Wood handbook -Wood as an engineering material. General Technical Report FPL-GTR-190. U.S. Department of Agriculture, Forest Service, Forest Products Laboratory. Madison. |

| [5] | Quilhó, T., Miranda, I. and Pereira, H. (2006). Within-tree variation in wood fibre biometry and Basic density of the Urograndis Eucalypt hybrid (eucalyptus grandis × E. urophylla). IAWA Journal 27 (3): 243 – 254. |

| [6] | Muga, M.O., Muchiri, M.N. and Kirongo, B.B. (2009). Variation in Wood Properties of Eucalyptus Hybrid Clones and Local Landraces Grown in Kenya. Journal of East African Natural Resources Management 3(1):215–227. |

| [7] | Turinawe, H., Mugabi, P. and Tweheyo, M. (2014). Density, calorific value and cleavage strength of selected hybrid Eucalypts grown in Uganda. Ciencia tecnología 16(1):13–24. |

| [8] | Bal, B.C., and Bektaş, I. (2014). Some mechanical properties of plywood produced from Eucalyptus, Beech, and Poplar Veneer. Maderas. Ciencia y tecnología 16(1): 99–108. |

| [9] | BS 373. (1957). Methods of testing small clear specimen of timber. British Standard Institution, 2 Park Street, London, United Kingdom. |

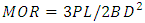

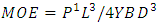

| [10] | ISO 3349. (1975). Wood-Determination of modulus of elasticity in static bending, International organization for standardization. Switzerland. |

| [11] | ISO 3133. (1975). Wood-Determination of ultimate strength in static bending, International organization for standardization. Switzerland. |

| [12] | Panshin, A.J. and De Zeeuw, C. (1980). Textbook of wood technology, 4th edition. McGraw-Hill, New York, USA. |

| [13] | ISO 3787. (1976). Wood-Test method - Determination of ultimate stress in compression parallel to grain, International organization for standardization. Switzerland. |

| [14] | ISO 3347. (1976). Wood-Determination of ultimate shearing stress parallel to grain, International organization for standardization. Switzerland. |

| [15] | Panshin, A.J., and De Zeeuw, C. (1970). Textbook of wood technology. Mc Graw Hill Book Co. Ltd., New York. |

| [16] | Carvalho, M.A. and Nahuz, M.A. (2001). The evaluation of the Eucalyptus grandis × urophylla hybrid wood through the production of small dimension sawnwood, pulpwood and fuelwood. Scientia Forestalis 59:61–76. |

| [17] | Santos, R.C.D., Carneiro, A.D.C.O. and Castro, A.F.M. (2011). “Correlation of quality parameters of wood and charcoal of clones of Eucalyptus,” Forest Sciences 90:221–230. |

| [18] | Zanuncio, A.J.V., Monteiro, T.C., Lima, J.T., Andrade, H.B. and Carvalho, A.G. (2013). Drying biomass for energy use of Eucalyptus urophylla and Corymbia citriodora logs. BioResources 8(4):5159–5168. |

| [19] | Ikemori, Y.K., Martins, F.C.G. and Zobel, B.J. (1986). The impact of accelerated breeding on wood properties. In 18th IUFRO World Conference Division 5: Forest Products. Ljubljana, Yugoslavia. 358–368p. |

| [20] | Miranda, I., Almeida, M.H. and Pereira, H. (2001). Provenance and site variation of wood density in Eucalyptus globulus Labill. at harvest age and its relation to a non-destructive early assessment. Forest Ecology and Management 149:235–240. |

| [21] | Kityo, P.W. and Plumptre, R.A. (1997). The Uganda Timber User’s Handbook. A guide to better timber use. Common Wealth Secretariat London. |

| [22] | Trugilho, P.F., Lima, J.T., Mori, F.A. and Lino, A.L. (2001). “Evaluation of Eucalyptus clones for charcoal production,” Cerne 7(2):104–114. |

| [23] | FAO (2010). Construction materials. Food and Agriculture Organization of Unites Nations. Chapter 5. Pp 45 – 91. Http://www.fao.org/decrep/015/i2433e/2433ec.pdf. |

| [24] | Carvalho, M. A., and Nahuz, M. A. (2001). The evaluation of the Eucalyptus grandis × urophylla hybrid wood through the production of small dimension sawnwood, pulpwood and fuelwood. Scientia Forestalis 59: 61–76. |

| [25] | Bhat, K.M., Bhat, K.V. and Dhamodaran, T.K. (1990). Wood density and fibre length of Eucalyptus grandis grown in Kerala, India. Wood Fibre Science 22:54–61. |

| [26] | Dutt, T. and Tyagi, C.H. (2011). Comparison of various Eucalyptus species for their morphological, chemical, pulp and paper making characteristics. Indian Journal of chemical technology 18:145–151. |

| [27] | El Moussaouit, M., Barcha, B., Alves, E.F. and Francis, R.C. (2012). Kraft pulping characteristics of three Moroccan Eucalypti. Part 1. Physical and chemical properties of woods and pulps. BioResources 7(2):1558–1568. |

| [28] | Jorge, F., Quilhó, T. and Pereira, H. (2000). Variability of fibre length in wood and bark in Eucalyptus globulus. IAWA Journal 21:41–48. |

| [29] | Olufemi, B., and Malami, A. (2011). Density and bending strength characteristics of North Western Nigerian grown Eucalyptus camaldulensis in relation to utilization as timber. Research Journal of Forestry 5(2):107–114. |

| [30] | Thelandersson, S., and Hansson, M. (1999). Reliability of Timber Structural Systems Effects of Variability and In Homogeneity. Lund University of Technology, Division of Structural Engineering, Sweden. |

| [31] | Wallis, N.K. (2010). Australian timber handbook, Halstead Press, Sydney, Australia. |

| [32] | Moya, R., and Muñoz, F. (2010). 'Physical and mechanical properties of eight fast growing plantation species in Costa Rica'. Tropical Forest Science 22(3):317–328. |

| [33] | Ismaili, G., Bakar, B.H.A., Duju, A., Rahim, K.K.A., Openg, I., Ismaili, Z. and Ismaili, S. (2013). Domination of Grain Bearing on the Strength Properties of Engkabang Jantong as Fast Growing Timber in Sarawak. Iranica Journal of Energy and Environment 4(3):311–315. |

| [34] | Acosta, M.S., Marco, M., Piter, J.C., Zitto, M.A.S., Villalba, D.I. and Carpineti, L. (2007). “Physical and mechanical properties of Eucalyptus grandis x E. tereticornis hybrid grown in Argentina”, IUFRO All Division 5 Conference, Taiwan. 35pp. |

| [35] | Lima, J.T., Breese, M.C. and Cahalan, C.M. (1999). Variation in compression strength parallel to the grain in Eucalyptus clones. Proceedings of the Fourth International Conference. 14-16 July 1999, Development of Wood Science, Wood Technology and Forestry, Missenden Abbey, UK. 28 – 36pp. |

| [36] | Malami, A.A. and Olufemi, B. (2013). Influence of Compression Stresses on Timber Potentials of Plantation Grown Eucalyptus camaldulensis Denhn in North-Western Nigeria. Nigerian Journal of Basic and Applied Science 21(2):131–136. |

| [37] | Madsen, B. (1992). Structural behaviour of timber. Timber Engineering Ltd., Canada. |

| [38] | Lima, I.L., and Garcia, J.N. (2011). Effect of fertilization on mechanical properties of Eucalyptus grandis. Ciência Florestal 21:601–60. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML