-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Agriculture and Forestry

p-ISSN: 2165-882X e-ISSN: 2165-8846

2017; 7(5): 111-114

doi:10.5923/j.ijaf.20170705.02

Effect of Temperature and Time Torrefaction on the Energetic Properties of Bracatinga Wood

Iasmin Panzarini Silva1, Matheus Moraes e Silva1, Gilmara de Oliveira Machado1, Victor Almeida de Araujo2, Diogo Aparecido Lopes Silva3, André Luis Christoforo4, Francisco Antonio Rocco Lahr5

1Department of Forestry, State University of Midwest (UNICENTRO), Irati, Brazil

2Research Group LIGNO of UNESP-Itapeva, Department of Forest Sciences, School of Agriculture Luiz de Queiroz of University of São Paulo (ESALQ/USP), Piracicaba, Brazil

3Department of Production Engineering, Federal University of São Carlos (UFSCar), São Carlos, Brazil

4Centre for Innovation and Technology in Composites (CITeC), Department of Civil Engineering (DECiv), Federal University of São Carlos (UFSCar), São Carlos, Brazil

5Department of Structures Engineering (SET), Engineering School of São Carlos of University of São Paulo (EESC/USP), São Carlos, Brazil

Correspondence to: André Luis Christoforo, Centre for Innovation and Technology in Composites (CITeC), Department of Civil Engineering (DECiv), Federal University of São Carlos (UFSCar), São Carlos, Brazil.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

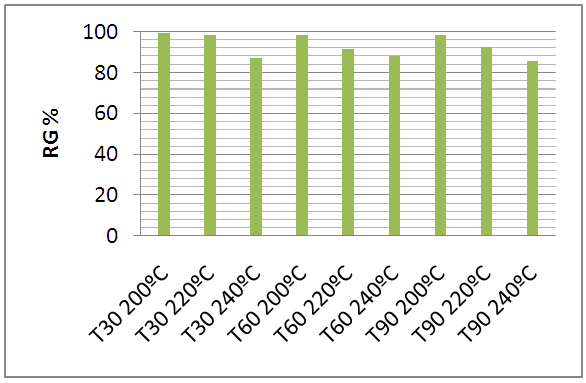

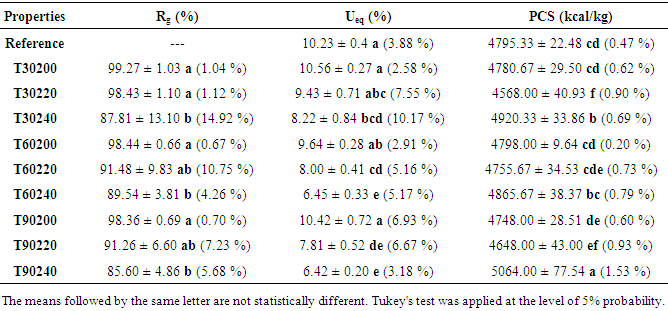

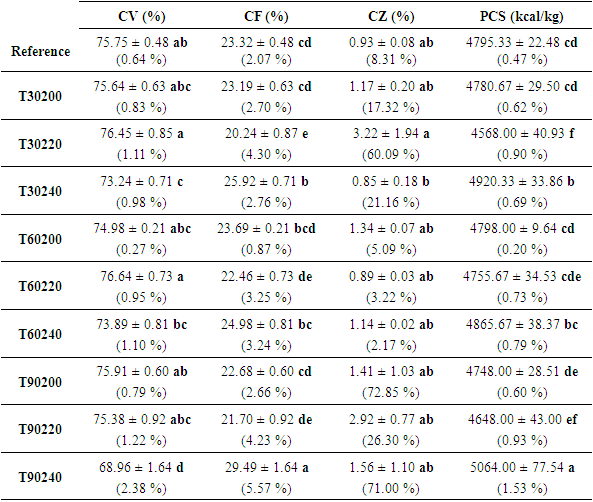

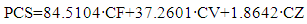

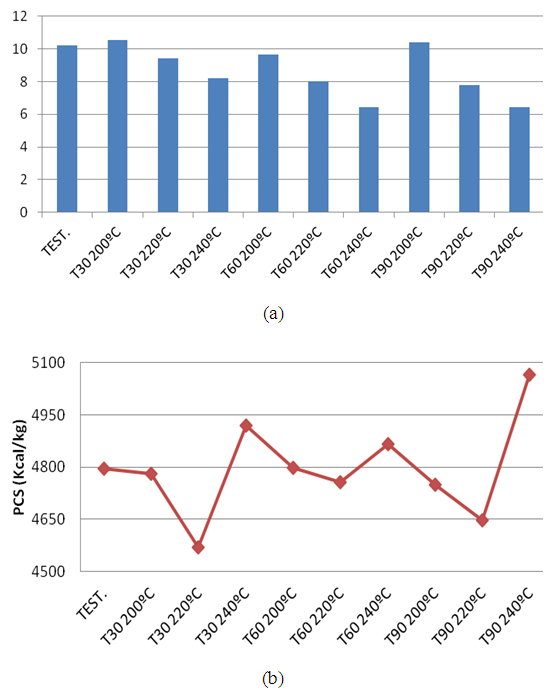

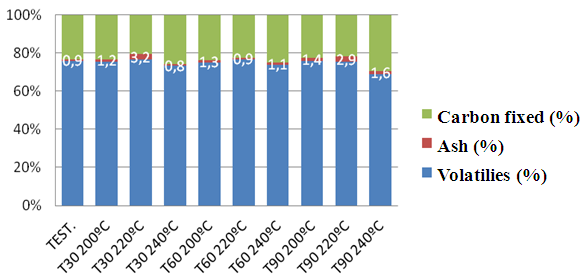

Torrefaction of Bracatinga wood was realized to determine the effect of temperature (200°C, 220°C and 240°C) and time (30 min, 60 min and 90 min) on its energetic properties. We found that the gravimetric yield of torrefied wood decreased from 99.27% to 85.60%. The heat treatment at 240°C for 60 min produced the less hygroscopic sample as evidenced by an equilibrium moisture content of 37% lower than fresh wood (control sample). In addition, torrefaction produced samples of higher fixed carbon and lower levels of volatile content, reaching a maximum increase of 21% and decrease of 9%, respectively. As the most important, the gross calorific value of terrified wood is about 5% higher than control. The increase of fixed carbon together with the reduction of both moisture and volatiles content show that this thermal treatment improve the energy content of torrefied wood that becomes a promising option for biofuels.

Keywords: Heat treated wood, Biomass combustion, Exotic wood species

Cite this paper: Iasmin Panzarini Silva, Matheus Moraes e Silva, Gilmara de Oliveira Machado, Victor Almeida de Araujo, Diogo Aparecido Lopes Silva, André Luis Christoforo, Francisco Antonio Rocco Lahr, Effect of Temperature and Time Torrefaction on the Energetic Properties of Bracatinga Wood, International Journal of Agriculture and Forestry, Vol. 7 No. 5, 2017, pp. 111-114. doi: 10.5923/j.ijaf.20170705.02.

1. Introduction

- In Brazil Bracatinga (Mimosa scabrella Benth.) has a natural occurrence in the Southeastern and South regions. It is a fast growing species and can be harvested to use directly as fuel or transformed in charcoal. Bracatinga is mainly used as firewood for domestic cooking stoves in rural areas and heating boilers in small industries [1-3].The potential energetic of bracatinga’s wood can be increased by applying heat. Torrefaction is a mild pyrolysis that promotes a controlled thermal degradation of wood, and happing at lower temperature (from 200 to 280°C) than carbonization (from 300 to 700°C) [4].Torrefaction produces a solid biofuel that has its properties between wood and charcoal and retaining approximately 70% of the initial mass. The torrefied wood has hydrophobic properties and a higher calorific value than the fresh wood. Fresh wood has about 50% and 10% lower energy content than charcoal and torrified wood, respectively. Thus, submit wood to heat is a method that modifies its chemical and physical properties to obtain a biomass fuel with a higher energetic density.The torrefaction causes chemical changes in the constituents of cell wall (cellulose, hemicelluloses and lignin) and extractives. The extractives, which are compound by a wide range of organic substances of low molecular mass, evaporate rapidly when exposed to heat. Additionally, among the macromolecules and having a relative lower thermal stabilities, the high hydrophilic hemicelluloses are the most affected by heat than other constituents of wood, as cellulose and lignin. As lignin is the highest thermal stable macromolecule, it is the less affected by heat, and therefore contributes to increase the energy content because the lignin is the most energetic macromolecule of the wood [5].Furthermore, the thermal treatment promotes the desacetylation of hemicelluloses that produces acetic acid, which act as a depolymerization catalyst of polysaccharides. The hemicelluloses degradation can lead to darkness of the wood fuel. During heat process, the dehydrating of hemicelluloses induces the formation of furfural and hidroximetifurfural, the latter compound contribute to the darkness of the wood [1, 6].Under heat effect, crystalline cellulose increases because of the degradation of amorphous cellulose and additionally the hemicelluloses decomposed almost completelly; as a result, the accessibility of the hydroxyl groups to the water molecules decrease and the moisture content of heat treated wood is lower. The lower moisture content produce a better fuel by decreasing the transport cost and turning the torrified wood more resistant to attack by rot fungi [7].For energetic purposes, the main goals of this research is to investigate and compare the changes in chemical and physical properties of heat treated wood of Bracatinga at temperatures of 200, 220 and 240°C; and time of 30, 60 and 90 min. For better understanding how the heat treatment affects the Calorific value of bracatingas’s wood, we are using the results of the Approximate Analyses (fix carbon, volatile compounds and ash content), gravimetric yield, and equilibrium moisture content.

2. Material and Methods

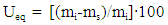

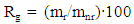

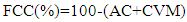

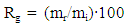

- The specie selected for the present investigation was Bracatinga (Mimosa scabrella). The trees were obtained from a farm plantation belong to the Forest College in Irati city, São Paulo state, Brazil. To have representative samples, the wood was collected by cutting boards from a trunk and the boards were then cut into test-pieces. The heat treatment was carried out in a laboratorial Ética electric furnace, model 400.4. Eleven pieces of wood, with dimensions of 2 cm length, 3 cm width and 5 cm thick, were used by each treatment in the temperature at 200, 220 and 240°C and in the times at 30, 60 and 90 min. The time of each treatment was recorded after reaching the required temperature.Determination of the equilibrium moisture content: the test pieces were heated in the oven at 100±3°C until the mass constant. The measure was done in three times by each treatment, using the following equation:

| (1) |

| (2) |

| (3) |

| (4) |

| (5) |

3. Results and Discussions

- Wood is composed of polysaccharides (cellulose and hemicellulose) and lignin, which are responsible for their physical and chemical properties. The torrefaction promotes changes in these variables. Figure 1 illustrates the results of gravimetric yield referring to the nine treatments.

|

| Figure 2. Equilibrium moisture content (a), calorific power higher of terrified samples including the reference condition (control) (b) |

| Figure 3. Immediate composition of terrified and non-torrified samples |

|

4. Conclusions

- These results indicated that torrefaction increases the energy content of Bracatinga wood making it more suitable for applications such as fuel in heating plants whose power supply comes from biomass burning.The samples treated for longer times and temperatures showed lower hygroscopicity, as evidenced by a lower equilibrium moisture content: reduction of 37% compared to control, at the temperature of 240°C and time of 30 min; as well as the higher carbon content fixed (21% increase) and lower volatile content (decreased 9%).As the most important factor, it was found that the gross calorific value increased in 5% with increasing temperature and roasting time.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML