-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Agriculture and Forestry

p-ISSN: 2165-882X e-ISSN: 2165-8846

2017; 7(3): 76-79

doi:10.5923/j.ijaf.20170703.03

Analysis of Solid Waste Generation in a Wood Processing Machine

Diego Henrique de Almeida1, Tiago Hendrigo de Almeida2, Fabiane Salles Ferro2, Eduardo Chahud3, Luiz Antonio Melgaço Nunes Branco4, André Luís Christoforo1, Francisco Antonio Rocco Lahr5

1Department of Civil Engineering (DECIv), Federal University of São Carlos (UFSCar), São Carlos, Brazil

2Department of Materials Engineering (SMM), Engineering School of São Carlos (EESC), São Paulo University (USP), São Carlos, Brazil

3Department of Civil Engineering, Federal University of Minas Gerais (UFMG), Belo Horizonte, Brazil

4Faculty of Engineering and Architecture, FUMEC University, Belo Horizonte, Brazil

5Department of Structures Engineering (SET), Engineering School of São Carlos (EESC), São Paulo University (USP), São Carlos, Brazil

Correspondence to: Diego Henrique de Almeida, Department of Civil Engineering (DECIv), Federal University of São Carlos (UFSCar), São Carlos, Brazil.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The processing of the wood generates a significant amount of waste, presenting itself as a problem to the environment. The volume of waste generated from processing depends, in addition to other factors, on the type of processing machine. This work aimed to present a case study regarding the volume of waste generated in the processing of the logs of Eucalyptus sp.genus specie using processing machine Pica-Pau type. Pica-Pau type machine was located in Itapeva (state of São Paulo, Brazil). A total of 38 logs were used, with na average diameter of 34cm (excluding the bark and measured at base and top of the log), average length of 3 m and conicity of 1%. The average volume of 38 logs was equal to 10.35m³ and the volume of residues generated during log processing was 2.17m³, implying a transformation coefficient (Ct) of 79%. Processing machine Pica-Pau type was classifies a good machine to be used in the processing of logs, however, the processing time is higher than the time used by the most used band saws, making it less attractive in the processing of wood by large companies. From the qualitative point, the waste generated in the production of the plank is mostly the sawdust.

Keywords: Eucalyptus sp., Log, Sawdust, Waste, Wood

Cite this paper: Diego Henrique de Almeida, Tiago Hendrigo de Almeida, Fabiane Salles Ferro, Eduardo Chahud, Luiz Antonio Melgaço Nunes Branco, André Luís Christoforo, Francisco Antonio Rocco Lahr, Analysis of Solid Waste Generation in a Wood Processing Machine, International Journal of Agriculture and Forestry, Vol. 7 No. 3, 2017, pp. 76-79. doi: 10.5923/j.ijaf.20170703.03.

1. Introduction

- Wood can be used of several ways, for examples, in civil construction as structural members or materials to buildings and as raw material to panels and furniture industries [1-4]. In Brazil, woods of the genus Pinus and Eucalyptus from planted forests are used by this companies [5, 6].One of the most important phases of the transformation of the wood into the most diversified products is its first processing, which must be carried out in a rational way taking full advantage of the log with the least possible residue production [7].However, timber industries, particularly sawmills, generate a large amount of residue, with low yields of timber production, since the necessary uses of these wastes are not always given, which are dispersed and can lead to serious environmental and social problems [8].It is estimated that the loss of wood in the first processing is around 50% of the original volume of the wood log used, that is, not only the problems of pollution, but also the economic problem with the waste of the raw material [9-13].The company was chosen to carry out this research because it presents a different method of first processing than is usually used in the other sawmills of the region, using an alternative saw, wood processing machine, called Pica-Pau type. Company still uses this machine because, according to its directors, its main focus is the treatment of roundwood, that is, whole wood, and sometimes some customers order for sawed pieces of the genus Eucalyptus sp.The aim of this paper was investigate the solid waste generation (qualitatively and quantitatively) during first processing of log in an alternative saw, wood processing machine, Pica-Pau type.

2. Material and Methods

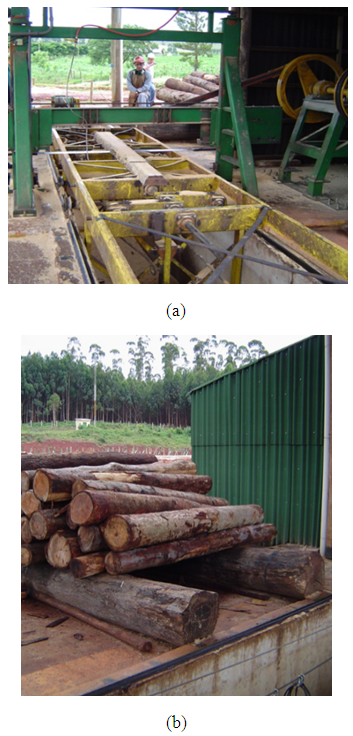

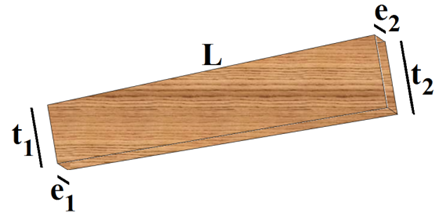

- The wood processing machine Pica-Pau type (Fig. 1.a) studied in this research was installed in a company located in the Itapeva city, state of São Paulo, Brazil. For study of waste volume were considered 38 logs of Eucalyptus sp. wood genus (Fig. 1.b) with average diameter (disregarding of bark and measured at the base and top of the log), length and conicity equal to 34 cm, 3 m and 1%, respectevely, with the average extraction of 10 planks per log.

| Figure 1. (a) Wood processing machine Pica-Pau type; (b) Eucalyptus sp. wood genus logs |

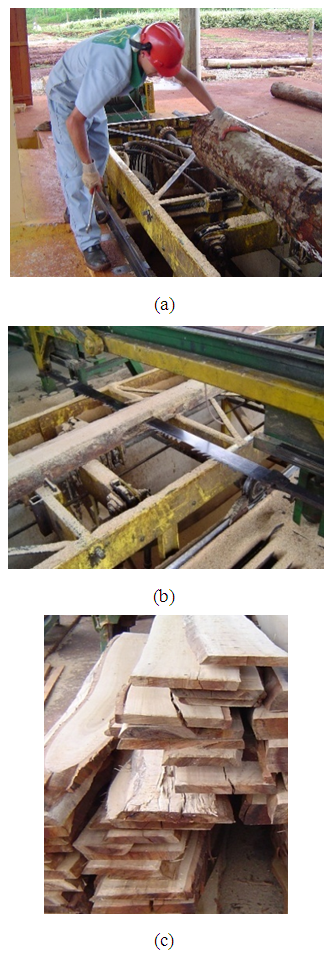

| Figure 2. (a) Machine adjustments; (b) First processing of Eucalyptus sp. log; (c) Produced planks by machine Pica-Pau type |

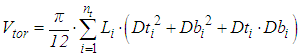

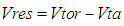

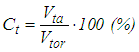

| (1) |

| Figure 3. Geometry considered to total volume of logs |

| (2) |

| (3) |

| Figure 4. Geometry considered to volume of planks |

| (4) |

3. Results and Discussions

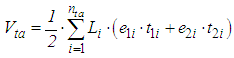

- Using Eq. 3, the volume of residues generated during processing of the 38 Eucalyptus wood genus logs was 2.17 m3. This volume of waste is equivalent to 20.97% of the total volume of the logs, implying a transformation coefficient of 79%, which classifies the Pica-Pau type as a good machine to be used in the processing of logs.However, a negative point for its use is the processing time, which is higher than the time used by other machines used by the industry [9-18], which makes it impossible to use it in the processing of roundwood by large companies, due to increased competitiveness and technological advances aimed at minimizing waste production with the shortest time of machine operations [16].It can be observed that, even with this machine that has a high conversion value (Ct = 79%), there is a considerable waste production, being the use of techniques that minimize the formation of residues a systemic practice during the processes of logs in sawmills, always aiming at improving production lines to reduce waste generations.Qualitative analysis of resídueFrom the qualitative analysis, the residues generated in the processing machine Pica-Pau type are mostly saw dust. The sawdust was deposited in a special compartment for collecting the residue (Fig. 5) or on the different points of machine elements (Fig. 6).

| Figure 5. Sawdust generated by process with Pica-Pau type machine on the compartment for collecting |

| Figure 6. Sawdust generated on the different points of machine elements |

4. Conclusions

- Researches on waste production in the wood process industries is important for improvements in this sector. This study of, processing machine Pica-Pau type, proved to be eficient in agreement with the low production of waste versus the quantity of planks produced, however, the required processing time is higher than the time used by other machines with the same purpose, making it less attractive in large sawmills.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML