-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Agriculture and Forestry

p-ISSN: 2165-882X e-ISSN: 2165-8846

2016; 6(3): 109-114

doi:10.5923/j.ijaf.20160603.02

Composition and Physical Properties of Hingot (Balanites Roxburghii) - An Non-Edible Oil

Priyanka Khanvilkar1, Grishma Patel1, P. S. Nagar2, Shailesh N. Shah1

1Bio-Energy Research Group, Chemistry Department, Faculty of Science, The M. S. University of Baroda, Vadodara, Gujarat, India

2Botany Department, Faculty of Science, The M. S. University of Baroda, Vadodara, Gujarat, India

Correspondence to: Shailesh N. Shah, Bio-Energy Research Group, Chemistry Department, Faculty of Science, The M. S. University of Baroda, Vadodara, Gujarat, India.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Since the last few years lots of research and works have been conducted to identify non-edible seeds as a potential feedstock. The non-edible seeds are useful for extraction of oils. The plant oils from Ratanjyot (Jatropha curcas), Karanj (Pongamia pinnata), Neem (Azadirachta indica), and Mahua (Madhuca longifolia var. latifolia) have been extracted and exploited as the non-edible feedstocks for “Environmental Friendly Fluids”. The current study highlights that the extraction of oil from one of the non-edible feedstocks Balanites roxburghii is located at semi-aride perennial zone of Gujarat, India. The fatty acid composition and physico-chemical properties of (Balanites roxburghii) oil BRO were evaluated by the American Oil Chemist’ Society (AOSC) methods and the obtained results were compared with other Balanites roxburghii oils BRO-a and BRO-b. These results were collected from different regions of India, Nigeria, Arava rift valley which has been reported earlier and also been compared with the standard Soybean oil (SBO). The Balanites roxburghii belongs to theZygophyllaceae family. The seed had yielded to 2.5 tons/acres in the third year. While in the 7th year, in non-irrigated conditions it had yielded 8.5 tons/ acres. In the present paper BRO was extracted from BR kernels using petroleum ether (50°C) via a Soxhlet extraction process (SEP). The oil yield was 45 wt%. The Gas Chromatography (GC) analysis of fatty acid methyl ester showed the presence of major fatty acids such as Palmitic (16.07 wt%), Oleic (39.79 wt%), Linolieic (34.95 wt%). The extracted BRO was then characterized using the spectroscopic techniques like FT-IR, NMR (1H/13C). The BRO exhibited good physio-chemical properties which could be used in the production of biodiesel. The properties such as Density (ρ), Kinematic viscosity (KV), Acid Value (AV), Saponification value (SV), Iodine value (IV), Cloud point (CP), Pour point (PP) and Bromine number (BN) had been studied in the experiment.

Keywords: Non-Edible, Balanites roxburghii plant oil, Soxhlet extraction process, Fatty acid

Cite this paper: Priyanka Khanvilkar, Grishma Patel, P. S. Nagar, Shailesh N. Shah, Composition and Physical Properties of Hingot (Balanites Roxburghii) - An Non-Edible Oil, International Journal of Agriculture and Forestry, Vol. 6 No. 3, 2016, pp. 109-114. doi: 10.5923/j.ijaf.20160603.02.

Article Outline

1. Introduction

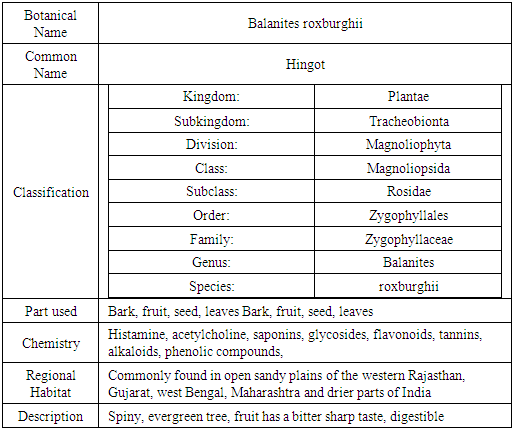

- Plant oils from Ratanjyot (Jatropha curcas), Karanj (Pongamia pinnata), Neem (Azadirachta indica), and Mahua (Madhuca longifolia var. latifolia) etc., have been extracted and exploited as non-edible feedstock [1] for Environmental Friendly Fluids [2]. Our continuous efforts have been focused to find area specific to non-edible feedstocks. With this in mind, Hingot (Balanites roxburghii) plant oils belonging to the Zygophyllaceae family [3] was chosen as a non-edible feedstock and further studies had been carried out. The Zygophyllaceae family encompasses over 285 species of flowering herbaceous plants belonging to more than 22 genera [4] Among these, Balanites is a genus of flowering plants in the caltrop, family Zygophyllaceae, comprising of 9 species and 11 intraspecific taxa of which Egyptian balsam and Zachum oil tree are widely grown desert trees. These trees have potential of uses [3]. The Balanites roxburghii trees are dispersed in dry parts of India, Africa, Syria and Arabia, these trees are small to large evergreen scraggy shrub or small thorny trees deciduous with erect, short body and ascending branches, approximately 8-10 meters tall, the leaves have a tendency to alternate, coriaceous, flowers are regular, bisexual, drupe fly shy, ovoid and one seeded [5]. The abbreviated description of Balanites roxburghii (BR) plant is shown in Table 1 [3].

|

2. Materials and Methods

2.1. Materials

- The Balanites roxburghii trees were located at Kissannagar, near Dabhoi village, Vadodara district, Gujarat state, India. The healthy fruits of Balanites roxburghii were collected from fully grown trees, during the months of March and April. Approximately 5 Kg fruits were collected. They were soaked in large containers of clean water and were boiled for 3 hours, then were allowed to cool down at room temperature. The epicarp and glycoside pulp of the fruits were taken out and the nuts were washed with fresh water and air dried for 4-5 days in summer. The nuts were then cut using the mechanical cutter and the kernels were removed. Using this BR kernels further oil extraction process was carried out. The solvent petroleum ether has been purchased from SRL (Sisco Research Laboratories Pvt. Ltd. Mumbai, India).

2.2. Balanites Roxburgh Oil (BRO) Extraction

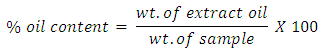

- 200 grams BR kernels were macerated to a fine powder using a mechanical grinder. The grinded material was quantitatively filled in a soxhlet apparatus, packed with cotton at two ends. The whole apparatus was placed on mental heater and water condenser was attached to a pinnacle of the apparatus. Petroleum ether was used as solvent for the extraction process. The assembly was heated around 45°C for 7 hours. The solvent was evaporated using a rotary evaporator under reduced pressure. The extracted BRO were weighed and the portion of oil content was estimated using Equation shown below:

The above mention process is called Hot Soxhlet extraction (HSEP). Sufficient amount of oil was obtained by repeating the extraction process. 40 wt% BRO was extracted using Hot Soxhlet extraction process. The Cold Soxhlet Extraction Process (CSEP) was borne out at room temperature for 3 days, 23 wt% BRO was yielded.

The above mention process is called Hot Soxhlet extraction (HSEP). Sufficient amount of oil was obtained by repeating the extraction process. 40 wt% BRO was extracted using Hot Soxhlet extraction process. The Cold Soxhlet Extraction Process (CSEP) was borne out at room temperature for 3 days, 23 wt% BRO was yielded.3. Equipment and Methods

3.1. Fatty Acid Profile by GC

- BRO was converted to the respective methyl esters (BRME) according to the literature method [7]. The fatty acid composition of BRME was determined using Electron Impact Ionization (EI) method on Auto system XL Gas chromatograph (Perkin Elmer instrument, Germany) and the capillary column [30m (column length) × 0.25μm (film thickness) × 0.25μm (internal diameter)] was used. The detector temperature was programmed at 270°C with the flow rate of 0.8 ml/min. The injector temperature was set at 270°C. Helium was used as carrier gas. The identification of peaks was achieved by retention times of known reference standards. BRME determination was run in triplicate and average values are accounted (Sophisticated and Instrumentation Centre for Applied Research and Testing, SICART laboratory, Vallabh Vidyanagar, Gujarat, India).

3.2. Nuclear Magnetic Resonance (NMR)

- 1H NMR and 13 C spectra were recorded on a Bruker AR X 400 Spectrometer at 400 MHz using CDCl3 as solvent.

3.3. Fourier Transform- Infrared (FT-IR) Spectrums

- The FT-IR spectrum was performed on a Shimadu-8400S Spectrophotometer by neat method. The spectra were obtained over the frequency range 4000-400 cm-1 at a resolution of 4 cm-1.

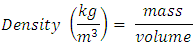

3.4. Density

- The density (ρ) normally expressed as specific gravity, which defines that, the ratio of the mass of a volume of the fuel to the mass of the same volume of water [4]. The density was determined by general method. 10 ml BRO was carried in a measuring cylinder and was estimated by equation as demonstrated under:

3.5. Kinematic Viscosity

- The viscosity that measures the fluid resistance to flow is called Kinematic viscosity [4]. (Ʋ, mm2/s) which was measured at 40°C using Stabinger Viscometer SVM 3000 as per ASTM D7042. The experiment was run in triplicate and mean values are reported [8].

3.6. Acid Value

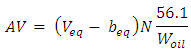

- Acid value (AV, mg KOH/g) titration was performed by a method using 2 gram of sample and 0.02 M KOH. The titration end point was defined by the colour change to pink and visually verified using a phenolphthalein indicator. Twice the titration was carried out and means values are accounted.

Where Veq is volume of titrant (ml) consumed by BRO and 1 ml of spiking solution at the equivalent point, beq is the volume of titrant (ml) consumed by 1ml of spiking solution at the equivalent point, 56.1 is the molecular weight of KOH, Woil is the mass of the BRO sample in gram, N is the molar concentration of titrant calculated using the following equation,

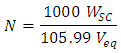

Where Veq is volume of titrant (ml) consumed by BRO and 1 ml of spiking solution at the equivalent point, beq is the volume of titrant (ml) consumed by 1ml of spiking solution at the equivalent point, 56.1 is the molecular weight of KOH, Woil is the mass of the BRO sample in gram, N is the molar concentration of titrant calculated using the following equation, Where Wsc is mass (g) of SC (sodium carbonate) in 20 ml of SC standard solution, Veq is the volume of titrant (ml) consumed by 20ml standard solution at the equivalent point and 105.99 g/mol is the molecular weight of sodium carbonate.

Where Wsc is mass (g) of SC (sodium carbonate) in 20 ml of SC standard solution, Veq is the volume of titrant (ml) consumed by 20ml standard solution at the equivalent point and 105.99 g/mol is the molecular weight of sodium carbonate.3.7. Iodine Value

- Iodine value (gI2 / 100g), that measures the number of double bonds present in fatty acid, was estimated from the fatty acid (FA) profile according to AOCS official method Cd Ic-85 [10].

3.8. Saponification Value

- Saponification value is the number of mg of KOH required for complete hydrolysis of 1 gram oil into potassium salt of fatty acid (soap) [11]. Reagents required were 1N HCL, 1M KOH. 1 gram of the sample, volumetric Titrations was performed using phenolphthalein as indicator. Endpoint note by color change.

3.9. Cloud Point

- Cloud point (CP, C) determination was determined using ASTM D5773 method, by the model PSA-705 Phase Technology analyser Cloud point was rounded to the nearest whole degree (°C) [12].

3.10. Pour Point

- Pour point (PP) determination using Lin Tech as per ASTM D97, respectively. All runs were carried out in duplicate. Sample temperature was measured in 3°C increments at the height of the sample until it stopped pouring [13].

3.11. Bromine Number

- Bromine number determination using ASTM-D1159 method. Bromine number is the amount of bromine in grams absorbed by 100 grams (3.5 oz.) of a sample. The number indicates the degree of unsaturation [14].

3.12. Average Molecular Weight of Vegetable Oils

- The average calculated molecular weight (MWcal, g/mole) was determined by a weighted average method by utilizing the FA profiles depicted in (table 3). The molecular weight of FA found in the vegetable oil was multiplied by its corresponding weight percentage as found out by GC (section 3.1). The total of these values (minus the acidic proton) was multiplied by 3 and the glycerol fragment (minus the oxygen atoms, as they were accounted for in the FA fragments) was tallied, resulting in an average calculated MW of vegetable oil. For the sake of providing calculated MW values that were not artificially low [15].

4. Results and Discussion

4.1. The Morphological Parameter of Balanites Roxburghii Fruit (BRF)

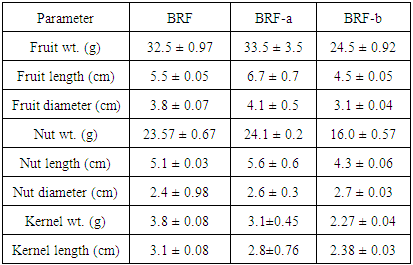

- The structural parameters of BR fruits collected from Gujarat were compared with BR fruits, gathered up from different sections of the globe. As shown in Table 2, the morphological parameter of BRF was almost similar with BRF-a [5] and slightly different with BRF-b [4]. That show the oil content in BRF kernel is similar (40 wt. %) to BRF-a (40-42 wt. %) (See Table 4), but the oil content in BRF-b may be less than BRF on the bases of morphological study.

|

4.2. FTIR Data Analysis

- The BRO was analysed by using FT-IR method and relevant peaks were obtained, such as: 721.39 (-CH2 rocking), 914.26 (-OH loop), 964.44 (-CH2 wagging), 1236.37 (C-C-O-O), 1159.25 (-O-CH2-C-), 1457, 1743 (C=O ester), 2851.75 (-CH2) n, 3009.02 (-CH) n.

4.3. 13C and 1H NMR Data Analysis

- The BRO extracted here were also analysed by NMR. The following peaks were observed in 1H-NMR, agreeing with the 1H-NMR spectra of other plant oil esters having almost similar fatty acid compositions: δ5. 37 (-CH=CH-), 2.79 (-CH=CH-CH2-CH=CH-; t), 2.07 (-CH2-CH2-CH=CH-; m), 1.65 (CH3-O-CO-CH2-CH2-; m), 1.30 (-CH2-) x; m), 0.94 (-CH=CH-(CH2) -CH3; m). In 13C NMR, characteristic peaks were observed at 174.30 and 174.25 (-O CO-), 130-126.93 (-CH=CH-), 35.12, 34.08, (O-CO-CH2-), 29.78-27.07 (O-CO-CH2-CH2-), 22.68 and 22.56 (-CH2-CH2-CH3), 14.9, 14.02 (-CH2-CH3).

4.4. Fatty Acid Composition and Free Fatty Content

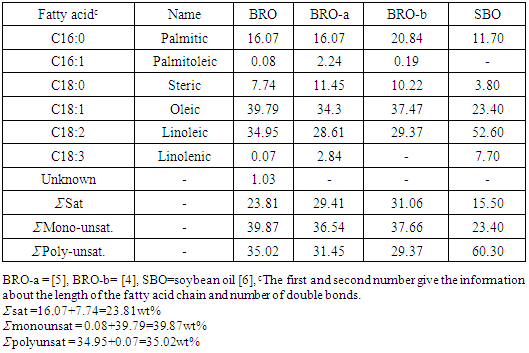

- The primary FA identified in BRO was oleic (C18:1; 39.79 wt.%) acid and linolenic (C18:3; 0.07 wt.%) acid with palmitic (C16:0; 16.07 wt.%) acid, palmitoleic (C:16:1; 0.08 wt.%) and linoleic (C18:2; 34.95 wt.%) acid also steric (C18:0; 7.74 wt.%) acid were detected in significant quantities along with trace amount (<1.0 wt.%) of other constituents (Table 3). This result was compared with previous studies BRO-a and BRO-b. The FA reported in BRO-a, as oleic (C18:1; 34.3 wt.%) acid and linolenic (C18:3; 28.61 wt.%) acid with palmitic (C16:0; 17.96 wt.%) and linoleic (C18:2; 28.61 wt.%) also steric (C18:0; 11.45 wt.%) and the FA profile reported in BRO-b was as oleic (C18:1; 37.47 wt.%) acid and palmitic (C16:0; 20.84 wt.%) and linoleic (C18:2; 29.37 wt.%) also steric (C18:0; 10.22 wt.%). As seen when all those results were compared (FA composition of BRO and BRO-a/ BRO-b) it can be stated that BRO sample content considerably lower saturated FA than BRO-a / BRO-b (23.81 wt.% versus 29.41 wt.% /31.06 wt.% Table 3) with greater abundance of mono-unsaturated and poly-unsaturation than that in BRO-a / BRO-b (39.87 wt.% versus 36.54 wt.% / 37.66 wt.%) and polyunsaturated (35.02 wt.% versus 31.45 wt.% / 29.37 wt.%). So, from the above study of the FA profile we can state that the FA composition of Balanites roxburghii plant oil varies with ecological condition. Equally it can be drawn from the (Table 3) that palmitoleic acid was present in the sample collected from Jodhpur, Rajasthan BRO-a and from Israel BRO-b, whereas it was nearly negligible in samples collected from Gujarat BRO. Similarly the composition was variable in other saturated FA and unsaturated FA of the various samples. Specially linolenic acid which was 0.07 wt.% in present study and 2.84 wt.% in BRO-a and while totally absent in BRO-b. The BR oils samples FA were then compared to FA of SBO. That stated, saturated and mono-unsaturated FA contents in all the three samples of BR oil were relatively. high (Table 3) compared to SBO (15.5 wt.%, 23.4 wt.%, respectively). Correspondingly, the poly-unsaturated FA content of BRO was considerably more depressed than that of SBO (60.3 wt.%). It can be understood that the primary fatty acid in the SBO is linoleic acid (52.6 wt.%) followed by oleic acid (23.4 wt.%) and the principal fatty acid in all the three samples of BR oil is oleic acid followed by linoleic acid (see Table 3).

|

4.5. Molecular Weight

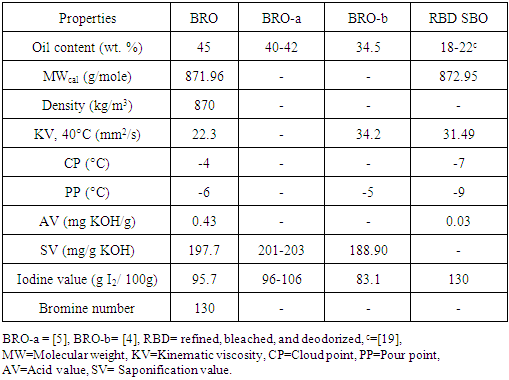

- The molecular weight of BRO was calculated using fatty acid profile, which totals out to be 871.96 g/mole, when compare to SBO was about 872.95 g/mole (Table 4). The overall saturation and unsaturation present in BRO was around 98.7 wt.% and that in SBO was 99.2 wt.% (Table 3). As the FA composition in SBO is somewhat higher than compare to the FA composition of BRO so indicating slightly higher molecular weight.

4.6. Kinematic Viscosity

- The kinematic viscosity of SBO (31.49 mm2/s) was higher than that of BRO (22.3 mm2/s) at 40˚C temperature (Table 4), As the degree of unsaturation is higher in SBO so more the unsaturation it will move towards liquid and that increase the viscosity of oil. The degree of unsaturation is less in BRO (see Table 3) so viscosity is also less than comparable to SBO.

|

4.7. Low Temperature Properties

- The low temperature operability of BRO was characterized by a PP of -6°C, which was more depressed than that obtained for RBD SBO -9°C. The CP of BRO was -4°C and the CP of SBO was -7°C (Table 4). The comparatively high level of saturated FA contained in BRO (23.81 wt.%) versus SBO (15.5 wt.%; Table 3) is attributed to its enhanced low temperature operability. A previous study elucidated reasonable relationship between saturated FA content and low temperature properties [6].

4.8. Acid Value

- The percentage of free fatty acid (FFA) in BRO was relatively high, as evidenced by an AV of 0.43 mg KOH/g (FFA content = 2.1 wt.%) (Table 4). Refined, bleached, and deodorized (RBD) soybean oil was essentially free of FFA (AV 0.03 mg KOH/g), which was expected due to additional purification of commercially available commodity oil [6]. The FFA content is very important for that chemical modification which is taken in the mien of a catalyst, showing more sensitivity towards carboxylic acids [15], The feedstock in which FFA content is greater than 0.5 wt.% would take down the product yields [16]. Therefore, the acid-catalyser pre-treatment is necessary in order to lower the higher FFA content in BRO [17].

4.9. Iodine Value

- The Iodine value (IV) is calculated based on the fatty acid profile obtained. IV determines the level of unsaturation present in the oil. The IV among all three BR oils samples were compared comes out to be that the IV of BRO and BRO-a were almost similar (95.7g I2/ 100g, 96-106 g I2/ 100g; Table 4) but higher than BRO-b sample (83.1 g I2/ 100g; Table 4). The degree of unsaturated FA content is almost similar in BRO/ BRO-a (Table 3) but the unsaturated FA content in BRO-b is lower than BRO/ BRO-a (Table 3). This evidence is supported by IV as studied above. When the IV of all the three samples was compared with SBO, the SBO IV (130 g I2/ 100g; Table 4) is higher than the entire three BRO sample, as expected it is showing the highest degree of unsaturated FA content (Table 3).

4.10. Saponification Value

- The saponification value (SV) of BRO-a was around 201-203 mg/g KOH and that of BRO (197.7 mg/g KOH; Table 4) and BRO-b (188.90 mg/g KOH; Table 4). Due to higher SV in BRO-a, contains significantly lower content of un-saponifiable matter such as saponins [4] than that content in BRO/ BRO-b samples.

5. Conclusions

- Our study has demonstrated a new class of non-edible feedstock Balanitis roxburghii as a potentially “Environmental Friendly Fluid”. The Balanites roxburghii oil BRO was extracted using the Hot Soxhlet extraction process (HSEP) rather than the Cold Soxhlet extraction process (CSEP), as it’s a cold process it takes more time. The krenel weight and length of BRF was 3.8 ± 0.08 and 3.1 ± 0.08 which was quite higher than BRF-a and BRF-b that proved to have a higher yield of BRO 45%. In addition the BRO was characterized by the spectroscopic techniques like FT-IR, NMR (1H/13C) and GC. The relevant peaks were observed which elucidated the structure of BRO. The major fatty acids found in BRO were Palmitic, Oleic and Linolieic. The degree of saturation in BRO (23.81 wt%) is lower than the degree of unsaturation (74.89 wt%). It was also compared with the previously reported BRO-a and BRO-b belonging to same Zygophyllaceae family. The level of unsaturated FA content was higher in the BRO (74.89 wt%) than in BRO-a (67.99 wt%)/ BRO-b (67.03 wt%). As we discussed above, the FA composition of BR oils (which had been extracted from BR kernel) was collected from different parts of the world. They had varying results even though they belonged to the same Zygophyllacea family. This was expected because it comes from different parts of the globe which has many factors effecting the FA composition. The physio-chemical properties of BRO such as low temperature operability, kinematic viscosity, acid value, iodine value were determined and were again compared with previously reported BRO-a, BRO-b and relevant standard SBO. The BRO exhibited a reasonably low temperature fluidity CP and PP -4°C and -6°C respectively. The acid value 0.43 mgKOH/g was higher compared to the SBO 0.03 mgKOH/g. Hence, it was necessary to give the acid-catalyser pre-treatment. This would lower the acid value for the production of biodiesel. The kinematic viscosity of BRO 22.3 mm2/s was lower than BRO-b 34.2 mm2/s and SBO 31.49 mm2/s. The Balanites roxburghii seeds were non-edible seeds for which the current work tested the hypothesis as to whether non-edible seeds can produce biodiesel as a new energy source. The BR oil has a promising future for the local farmers, business proponents and automobile industries. An ecological parameter could be studied in co-relation with the oil composition and its application as biofuels.

ACKNOWLEDGEMENTS

- The authors thank to UGC, New Delhi, India, for providing financial support pursuing this project further. Dr. Bharat Newalkar (Bharat Petroleum Corporation Limited, central Noida, Uttar Pradesh.) And his research group for offering us an excellent support for analysis of Physical properties.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML